Ensuring the longevity and optimal performance of your vehicle requires a comprehensive understanding of its components and systems. This section offers valuable insights into the crucial aspects of upkeep, helping enthusiasts and owners alike navigate the intricacies of automotive care.

By familiarizing yourself with essential procedures, you can effectively address common issues and perform necessary adjustments. This knowledge not only enhances your driving experience but also empowers you to maintain the value and functionality of your cherished vehicle.

Whether you’re a seasoned mechanic or a novice looking to learn, this guide provides clear instructions and useful tips. With the right approach, anyone can gain the confidence to tackle maintenance tasks and ensure their vehicle remains in excellent condition.

Many individuals encounter similar challenges when managing their vehicles. Understanding these frequent problems can help in making informed decisions and ensuring proper maintenance.

Frequent Mechanical Challenges

- Engine performance issues such as misfiring or stalling.

- Transmission difficulties leading to shifting problems.

- Suspension wear resulting in a rough ride.

Electrical System Complications

- Batteries that frequently die or show signs of weakness.

- Lighting failures affecting visibility and safety.

- Malfunctions in the ignition system causing starting problems.

Essential Tools for Repairs

Having the right instruments is crucial for any maintenance task. A well-equipped toolkit can make the difference between a successful fix and a frustrating experience. Below are some fundamental tools that every enthusiast should consider having on hand.

Basic Hand Tools

- Wrenches: A variety of sizes ensures you can tackle different fasteners.

- Screwdrivers: Both flathead and Phillips types are necessary for various applications.

- Pliers: These are invaluable for gripping, bending, and cutting materials.

- Hammer: A reliable tool for driving nails and fitting parts together.

Specialty Equipment

- Torque Wrench: Essential for applying the correct tightness to fasteners.

- Jack and Stands: Necessary for lifting vehicles safely during inspections.

- Multimeter: Useful for electrical diagnostics and troubleshooting issues.

- Oil Filter Wrench: Simplifies the process of changing oil filters.

Understanding the Engine Specifications

Engines are the heart of any vehicle, playing a crucial role in its performance and efficiency. Understanding their specifications is essential for optimal functioning and maintenance. This section delves into the fundamental aspects that define engine capabilities, including power output, displacement, and design features.

The specifications typically highlight the engine’s displacement, which indicates the total volume of all the cylinders combined. This measurement is key to understanding the engine’s ability to generate power and torque. A larger displacement generally correlates with greater power production, although it can also influence fuel consumption.

Another important aspect is the power output, usually expressed in horsepower or kilowatts. This figure reveals how much work the engine can perform over time. It’s vital for assessing the vehicle’s acceleration and overall driving experience. In addition, torque specifications are equally important as they determine the engine’s pulling power, influencing how the vehicle performs during acceleration and towing.

Lastly, engine design features such as the number of cylinders, configuration, and fuel type contribute significantly to its characteristics. Each of these elements interacts to deliver a unique driving experience, impacting everything from fuel efficiency to performance under various conditions.

Maintenance Schedule for Longevity

Regular upkeep is essential for extending the lifespan of any vehicle. Following a systematic approach to maintenance can significantly enhance performance and reliability. This section outlines key practices to ensure the long-term health of your automobile.

Essential Maintenance Tasks

- Engine Oil Change: Perform every 3,000 to 5,000 miles to ensure proper lubrication.

- Air Filter Replacement: Check and replace every 15,000 miles to maintain airflow and efficiency.

- Tire Rotation: Rotate every 6,000 to 8,000 miles to promote even wear and extend tire life.

- Brake Inspection: Examine pads and discs every 10,000 miles for optimal stopping power.

Seasonal Checks

- Battery Inspection: Test during seasonal transitions to avoid unexpected failures.

- Coolant Flush: Change at least every two years to prevent overheating and corrosion.

- Wiper Blade Replacement: Check regularly, especially before rainy seasons, for clear visibility.

- Belts and Hoses: Inspect for wear and tear every 30,000 miles to prevent breakdowns.

Step-by-Step Brake System Repair

Ensuring the functionality of your vehicle’s stopping mechanism is crucial for safety. This section provides a clear guide to assist you in addressing issues related to the braking components effectively. By following these detailed steps, you can maintain or restore optimal performance to the braking system.

Preparation and Tools Required

Before beginning the process, gather essential tools such as a socket set, wrenches, brake fluid, and a jack. Having the correct equipment at hand will streamline the procedure and minimize complications. Make sure the vehicle is parked on a flat surface and the parking brake is engaged for safety.

Executing the Repair

Start by lifting the vehicle with a jack and removing the wheels to access the braking assembly. Inspect the components for wear or damage, focusing on pads, rotors, and hoses. If any parts show signs of deterioration, replace them with new components. After installation, bleed the brake lines to remove air and ensure a firm pedal feel. Finally, test the braking system to confirm everything is functioning properly.

Transmission Troubleshooting Tips

Addressing issues related to gear systems can be challenging but essential for optimal vehicle performance. Identifying the signs of malfunction early can prevent more significant problems down the road. This section provides practical advice for diagnosing and resolving common issues associated with these components.

Start by observing the behavior of the gear shift. If it feels stiff or unresponsive, check the fluid levels and quality. Low or contaminated fluid can lead to shifting difficulties. Additionally, listen for unusual sounds when changing gears; grinding or whining noises may indicate wear or misalignment.

Another crucial aspect is to monitor the transmission temperature. Overheating can cause substantial damage. Ensure that the cooling system is functioning correctly and that there are no leaks. If you notice a burning smell, it may be time to seek professional assistance.

Lastly, consider any dashboard warning lights. A lit check engine light could signal underlying issues that need attention. Regular maintenance checks can help avoid these problems, ensuring a smoother driving experience.

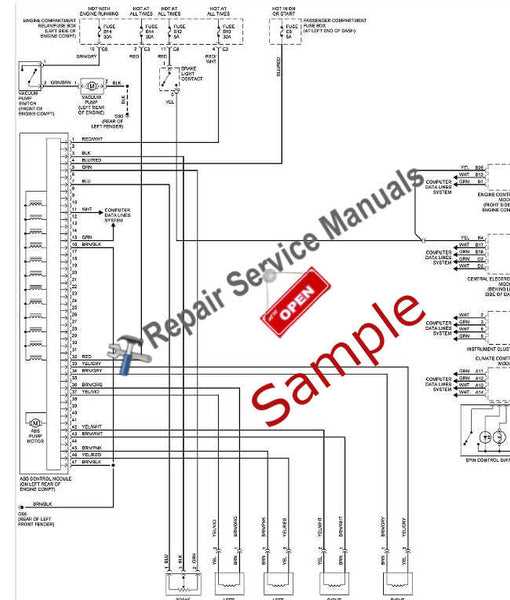

Electrical System Diagnostics Guide

This section focuses on assessing and troubleshooting the electrical components of your vehicle. Understanding the basics of the electrical system is crucial for effective maintenance and repair.

Identifying Issues: Begin by recognizing common symptoms of electrical malfunctions. These may include flickering lights, inconsistent power supply, or failure of electrical accessories. Pinpointing these signs can help narrow down the problem areas.

Testing Components: Utilize appropriate tools such as multimeters and circuit testers to evaluate various parts of the system. Measure voltage levels and check for continuity to ensure proper functionality. Regular testing can prevent minor issues from escalating into major repairs.

Consulting Schematics: Refer to detailed diagrams that illustrate the electrical layout of the vehicle. These resources can provide insight into wire connections and component locations, facilitating more efficient diagnostics.

Body and Frame Repair Techniques

This section focuses on essential methods for maintaining and restoring the structural integrity of a vehicle. Proper techniques ensure durability and enhance performance, ultimately prolonging the life of the automobile.

Understanding the fundamental approaches can significantly improve outcomes. Here are some common strategies:

- Visual Inspection: Regular checks for damage or wear help identify issues early.

- Aligning Framework: Proper alignment is crucial for handling and tire wear.

- Welding Techniques: Utilizing effective welding methods strengthens joints and connections.

- Rust Prevention: Applying protective coatings reduces the risk of corrosion over time.

- Reinforcement: Adding support in key areas enhances stability and safety.

Each technique plays a vital role in the overall upkeep of the vehicle’s structure. Implementing these practices can lead to better performance and increased longevity.

Suspension System Adjustments Explained

The suspension system plays a vital role in maintaining a smooth and stable ride. Proper adjustments ensure that the vehicle handles well, absorbs shocks effectively, and provides comfort to passengers. Understanding how to fine-tune these components can greatly enhance performance and longevity.

There are several key areas to focus on when making adjustments to the suspension system. These include ride height, alignment, and shock absorber settings. Each of these factors contributes to the overall handling and stability of the vehicle.

| Adjustment Type | Description |

|---|---|

| Ride Height | Adjusting the distance between the vehicle’s body and the ground, which influences handling and comfort. |

| Alignment | Ensuring that the wheels are positioned correctly relative to the body and each other, affecting tire wear and steering response. |

| Shock Absorber Settings | Tuning the dampening characteristics to manage how quickly the suspension responds to bumps and dips. |

Regular maintenance and periodic adjustments can help maintain the ideal performance of the suspension system, leading to a more enjoyable driving experience.

Cooling System Maintenance Essentials

Proper upkeep of the cooling mechanism is vital for ensuring optimal engine performance and longevity. This system is responsible for regulating temperatures and preventing overheating, which can lead to severe damage. Regular checks and maintenance activities are essential to keep this vital component functioning efficiently.

One of the key aspects of maintenance involves inspecting coolant levels regularly. It is important to ensure that the fluid is at the appropriate level, as low coolant can lead to ineffective heat dissipation. Additionally, checking for leaks in hoses, connections, and the radiator can prevent unexpected failures. Keeping the system clean by flushing it periodically can also enhance performance, as contaminants can impede heat transfer.

Another critical task is to monitor the condition of the thermostat, which controls the flow of coolant. A malfunctioning thermostat can disrupt the cooling cycle, leading to overheating or insufficient heating in colder weather. Regular testing and replacement when necessary can help avoid these issues.

Finally, it is advisable to inspect the water pump, as it plays a crucial role in circulating coolant throughout the system. A failing pump can result in insufficient flow, leading to overheating. Ensuring that all components are in good working order contributes significantly to the overall efficiency of the cooling system.

Preparing for a Tune-Up Process

Before embarking on the maintenance procedure, it’s essential to gather the necessary tools and materials. This preparation will ensure a smooth and efficient process, allowing for optimal performance of the vehicle. Having the right equipment on hand can prevent delays and enhance the overall experience.

Begin by reviewing the specific tasks involved in the maintenance procedure. Understanding the steps will help identify what tools and supplies are required. Common items may include wrenches, screwdrivers, and replacement components. Additionally, it’s beneficial to have a clean workspace to facilitate easy access to your tools and the vehicle.

Next, ensure that the vehicle is parked in a safe and accessible area. This will not only allow for easy movement but also provide ample space to work. It’s advisable to wear appropriate safety gear, such as gloves and goggles, to protect yourself during the process.

Lastly, consider checking the condition of existing components before starting the procedure. This will help identify any parts that may need immediate attention, ensuring that all issues are addressed in a timely manner. Proper preparation sets the foundation for a successful maintenance session, leading to a well-performing vehicle.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is essential for both personal safety and the integrity of the vehicle. Adopting careful practices can significantly reduce risks associated with mechanical work.

Essential Safety Gear

Wearing appropriate protective equipment is crucial. Consider the following items:

- Safety goggles to protect eyes from debris

- Gloves to shield hands from sharp edges and chemicals

- Steel-toed boots to guard against heavy objects

- Hearing protection when working with loud tools

Work Area Management

A tidy workspace contributes to a safer experience. Follow these guidelines:

- Keep tools organized and within reach

- Ensure good lighting to avoid accidents

- Maintain proper ventilation when using solvents

- Clear the area of unnecessary clutter