Maintaining and restoring the performance of a specific power unit is essential for vehicle enthusiasts and mechanics alike. This section delves into the intricacies of servicing and enhancing a particular type of automotive machinery, providing invaluable insights and detailed processes. By understanding the inner workings and potential pitfalls, one can ensure longevity and optimal functionality.

Expertise in disassembly and reassembly is crucial for achieving satisfactory results. Knowledge of various components and their interactions allows for effective troubleshooting and modifications. This guide offers a systematic approach to tackling common issues, helping to navigate the complexities of mechanical repairs.

Furthermore, preventive maintenance plays a pivotal role in extending the lifespan of these units. Recognizing early signs of wear and understanding proper care techniques are fundamental to sustaining performance. This resource aims to empower readers with the tools and knowledge necessary for successful intervention and upkeep.

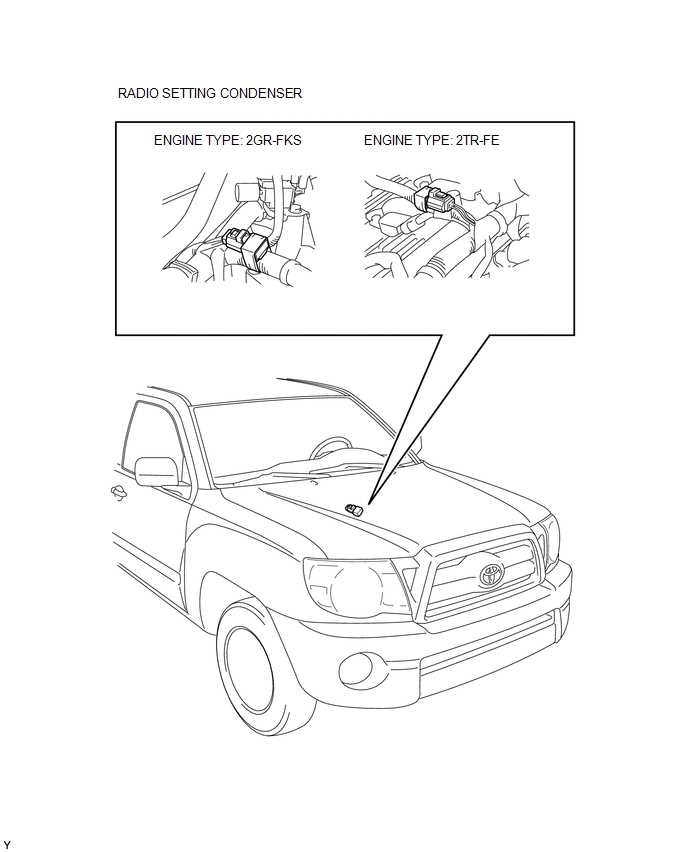

Toyota 2TR-FE Engine Overview

This section provides a comprehensive understanding of a widely recognized power unit designed for reliability and efficiency. It encompasses key features, specifications, and applications, catering to both enthusiasts and professionals.

- Configuration: Inline four-cylinder

- Displacement: Approximately 2.7 liters

- Fuel System: Multi-point fuel injection

- Power Output: Typically around 160 horsepower

- Torque: Approximately 180 lb-ft

Known for its durability, this unit is often found in various models, demonstrating versatility in different driving conditions. Understanding its mechanics can lead to improved performance and maintenance strategies.

Common Issues with the 2TR-FE

Understanding the frequent challenges associated with this powertrain can significantly enhance the maintenance and longevity of the vehicle. Awareness of these typical problems enables owners and mechanics to identify symptoms early, preventing more extensive damage and costly repairs.

Below are some prevalent issues often encountered:

- Oil Consumption: Excessive use of lubrication can indicate worn components, leading to leaks or reduced efficiency.

- Cooling System Failures: Overheating may result from a malfunctioning radiator or a failing thermostat, necessitating thorough inspection.

- Ignition System Problems: Misfiring and poor performance can stem from faulty spark plugs or ignition coils, affecting overall operation.

- Fuel Injector Issues: Clogged or malfunctioning injectors can lead to poor fuel economy and reduced power output.

- Vibration and Noise: Unusual sounds or vibrations may indicate problems with the mounting system or internal components.

Addressing these challenges promptly can prevent further complications and ensure reliable performance.

Essential Tools for Engine Repair

When delving into the intricate world of mechanical overhauls, having the right equipment is crucial for success. The tools you choose can significantly impact the efficiency and effectiveness of your work. This section will outline the fundamental implements needed to tackle various tasks associated with maintaining and restoring performance in automotive systems.

1. Wrenches and Sockets: A versatile set of wrenches, including both standard and metric sizes, is vital for loosening and tightening bolts. Ratchet and socket sets enhance speed and accessibility, allowing for easier manipulation of fasteners in tight spaces.

2. Screwdrivers: A variety of screwdrivers, including flathead and Phillips types, are essential for removing screws and components. Magnetic tips can simplify the process by keeping screws in place during assembly.

3. Pliers: These are invaluable for gripping, twisting, and cutting wires or hoses. Needle-nose pliers can reach into confined areas, while locking pliers provide extra leverage.

4. Torque Wrench: Precision is key in any mechanical project. A torque wrench ensures that bolts are tightened to the manufacturer’s specifications, preventing over-tightening that could lead to damage.

5. Oil Filter Wrench: This specialized tool is designed to remove stubborn oil filters with ease, making oil changes a smoother process and helping to maintain engine health.

6. Compression Tester: For assessing the health of the internal components, a compression tester provides valuable insights into cylinder pressure and overall performance.

7. Diagnostic Scanner: Modern vehicles often come equipped with complex electronic systems. A diagnostic scanner can interface with these systems to identify issues, providing crucial data for troubleshooting.

Having these essential tools on hand will enable any enthusiast or professional to effectively manage a variety of tasks, ensuring that each job is completed with precision and care.

Step-by-Step Disassembly Process

The disassembly of a complex mechanical assembly requires careful planning and methodical execution. This section provides a comprehensive guide to dismantling the unit efficiently and safely, ensuring that all components are handled with precision. Following these steps will help maintain the integrity of the parts for future reassembly or servicing.

Preparation

- Gather necessary tools, including wrenches, sockets, and screwdrivers.

- Ensure a clean and organized workspace to prevent loss of small components.

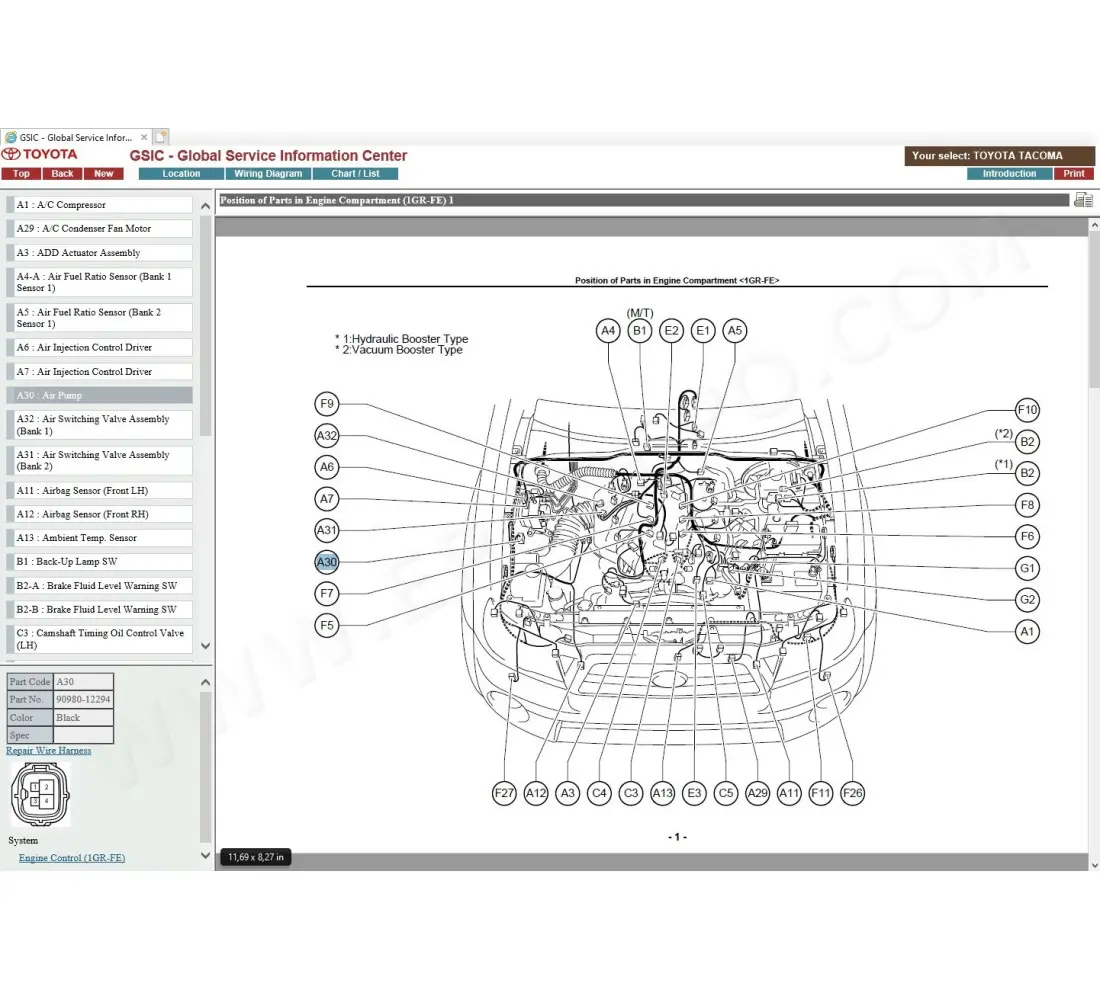

- Review the assembly layout or schematic to understand the configuration.

- Wear appropriate safety gear, such as gloves and goggles, to protect yourself during the process.

Disassembly Steps

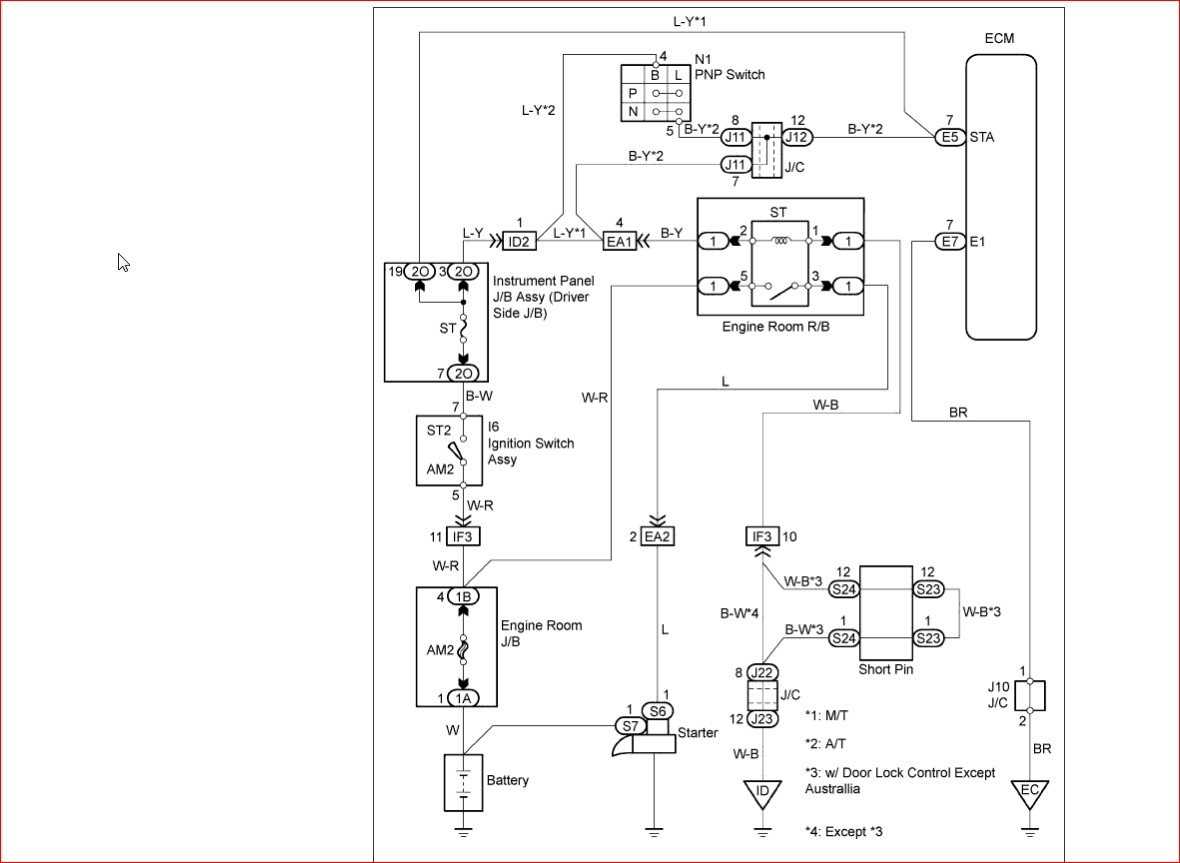

- Begin by disconnecting any electrical connections or sensors attached to the assembly.

- Remove any external covers or shields to gain access to internal components.

- Loosen and detach the mounting bolts securing the primary structure.

- Carefully take out the main components, noting their orientation and placement for reference.

- Continue to disassemble secondary parts, keeping similar components grouped together.

- Inspect each part for wear or damage, and document any findings for future reference.

- Once all components are removed, clean the workspace and organize the parts for reassembly.

By following these structured steps, you can ensure a systematic approach to disassembly that minimizes the risk of damage and maximizes efficiency.

Inspecting Engine Components for Damage

Thorough examination of vital machinery parts is crucial for ensuring optimal performance and longevity. Identifying wear, cracks, or other forms of deterioration can prevent catastrophic failures and enhance efficiency. This section outlines key aspects to focus on during the inspection process.

Visual Inspection: Begin with a careful visual assessment. Look for signs of corrosion, rust, or oil leaks that may indicate underlying issues. Pay close attention to surfaces for any irregularities that could affect functionality.

Physical Examination: Conduct a tactile inspection by feeling for any unusual textures or vibrations. Components should fit together snugly without excessive play. Check for signs of overheating, such as discoloration or warping.

Measuring Specifications: Utilize precision instruments to measure critical dimensions and tolerances. Compare findings with manufacturer specifications to determine if any parts are out of acceptable limits. This step is essential for maintaining operational integrity.

Testing: Implement diagnostic tools to assess performance under various conditions. Compression tests and leak-down tests can reveal internal issues that may not be visible externally. Document all results for future reference.

Documentation: Keep a detailed log of all inspections, including photographs and measurements. This record will aid in tracking wear patterns over time and guide decision-making regarding maintenance or replacement.

By systematically inspecting components, you can ensure that all parts are functioning optimally, ultimately prolonging the life of your machinery.

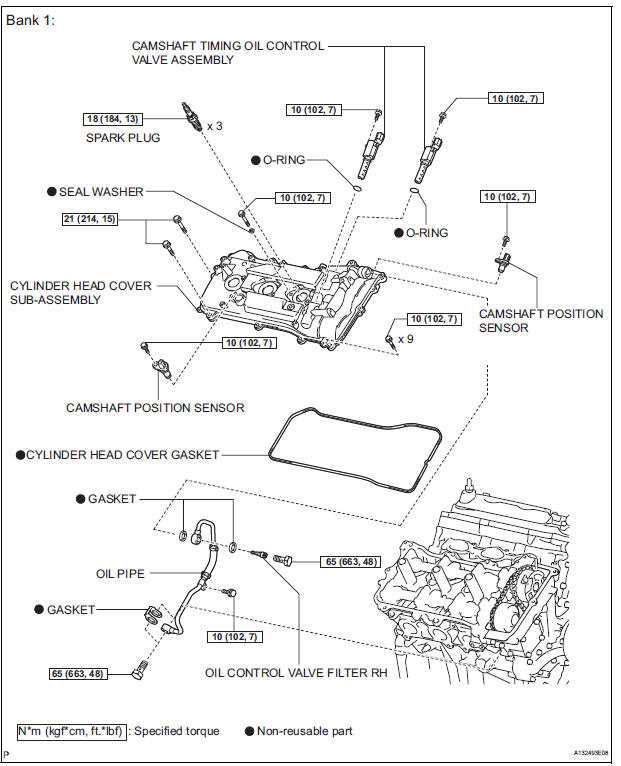

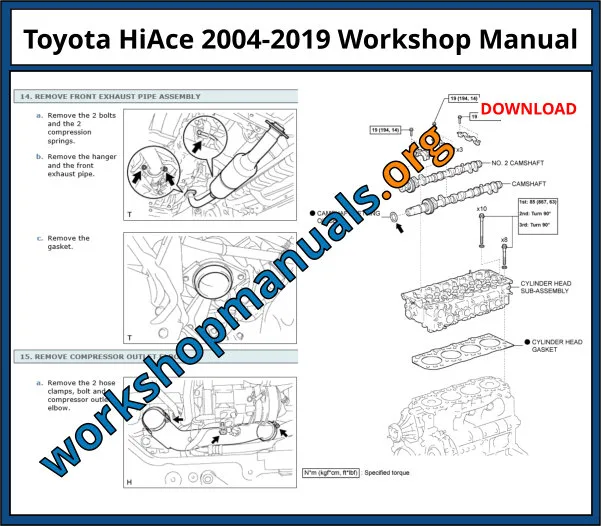

Rebuilding the Cylinder Head

Reconstructing the upper component of a combustion unit is a critical process that ensures optimal performance and longevity. This task involves meticulous attention to detail and an understanding of various techniques aimed at restoring functionality and enhancing efficiency.

The first step in this procedure is to carefully disassemble the unit, taking note of the arrangement of parts for accurate reassembly. Each component should be cleaned thoroughly to remove any deposits or contaminants that could affect performance. Utilizing specialized solvents and brushes can significantly improve the cleaning process.

Once cleaned, a thorough inspection is necessary to identify any cracks, warps, or other forms of damage. Utilizing precision measuring tools will help in assessing the condition of the surfaces. Any components that fail to meet specifications should be replaced to ensure reliability.

After identifying the necessary repairs, the next phase involves machining processes. This may include resurfacing the mating surfaces to ensure a proper seal. Attention to tolerances during this stage is essential to prevent future leaks or performance issues.

Once all repairs are completed, reassembly can commence. It is crucial to use new gaskets and seals to guarantee a tight fit. Following the manufacturer’s specifications for torque settings will help achieve the correct pressure on the components, ensuring their stability during operation.

Finally, a thorough testing phase is essential. This may involve running the unit under various conditions to verify that everything functions as intended. Properly executed, this comprehensive approach to rebuilding will contribute significantly to the overall efficiency and reliability of the system.

Replacing the Timing Chain

Changing the timing chain is a crucial task for ensuring optimal performance and longevity of your vehicle’s power unit. This procedure involves careful disassembly and reassembly to maintain the precise synchronization of various components. Proper execution is vital to prevent potential damage and ensure reliability.

Preparation and Tools Needed

Before starting, gather all necessary tools such as wrenches, a torque wrench, and a chain tensioner tool. It’s also essential to have a clean workspace and a suitable container for small parts to avoid loss. Familiarize yourself with the components involved to streamline the process.

Step-by-Step Process

Begin by disconnecting the battery and draining the coolant. Remove any obstructions, such as the valve cover and front timing cover, to gain access. Once exposed, carefully remove the old chain, paying attention to the alignment marks. Install the new chain, ensuring it aligns correctly with the sprockets. Reassemble all components in the reverse order, checking torque specifications to maintain integrity.

Finally, double-check all connections and refill fluids as necessary. A successful replacement will lead to smoother operation and enhanced efficiency.

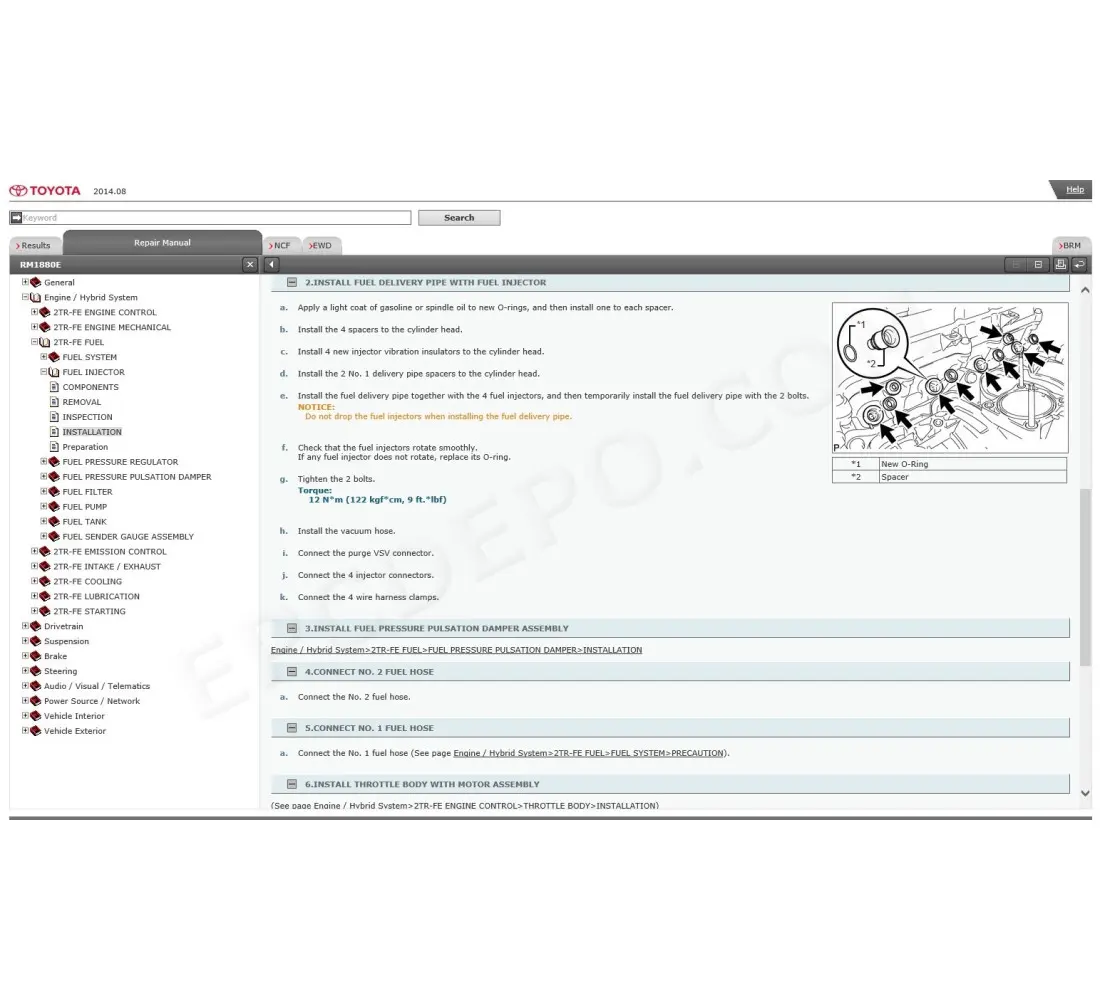

Fuel System Maintenance Tips

Regular upkeep of the fuel delivery components is crucial for optimal performance and longevity of your vehicle. Proper care ensures efficient combustion and minimizes potential issues that can arise from neglect.

Routine Inspections

Conducting frequent assessments of the fuel system can help identify leaks or blockages early on. Look for signs of wear or damage on hoses and connections.

Fuel Filter Replacement

Changing the fuel filter at recommended intervals is essential. A clean filter maintains proper flow and protects the injectors from contaminants.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect fuel lines | Every 6 months | Check for cracks or leaks |

| Replace fuel filter | Every 12,000 miles | Use quality replacement parts |

| Check fuel pressure | Annually | Ensure proper fuel delivery |

Understanding the Cooling System

The cooling mechanism is a crucial aspect of vehicle performance, designed to maintain optimal temperatures within the mechanical components. Effective temperature management prevents overheating, enhances efficiency, and prolongs the lifespan of vital parts. Understanding how this system operates is essential for troubleshooting and maintaining the overall health of the vehicle.

Components of the Cooling System

This system comprises several key elements, each playing a significant role in temperature regulation. The radiator serves as the primary heat exchanger, dissipating heat absorbed from the coolant. The water pump circulates the coolant throughout the system, ensuring consistent flow. Additionally, thermostats regulate the coolant temperature, allowing it to expand and contract as needed.

Common Issues and Maintenance

Torque Specifications for Reassembly

Proper fastening techniques are essential for ensuring the reliability and longevity of mechanical assemblies. Adhering to specific torque values during reassembly helps to prevent component failure and maintains optimal performance.

When reassembling parts, it’s crucial to follow a systematic approach. Below are the key torque specifications to consider:

- Fastener Size: Ensure you are using the correct size and type of fastener.

- Torque Value: Refer to the designated torque values for each fastener to avoid over-tightening or under-tightening.

- Tightening Sequence: Follow the prescribed sequence to distribute stress evenly across components.

- Lubrication: Use appropriate lubricants on fasteners when specified, as this can affect the torque readings.

To achieve the desired results, follow these general steps:

- Gather the necessary tools, including a reliable torque wrench.

- Consult the specifications for each component.

- Begin tightening fasteners gradually, starting from the center and moving outward.

- Double-check each fastener after initial tightening to ensure compliance with specifications.

By meticulously following these torque specifications, you can ensure the integrity and functionality of the assembled units, ultimately contributing to their operational efficiency.

Common Misdiagnoses to Avoid

When dealing with complex mechanical systems, it’s crucial to identify issues accurately to avoid unnecessary repairs and costs. Misinterpretations of symptoms can lead to incorrect conclusions, ultimately prolonging problems rather than resolving them. Understanding typical pitfalls in diagnosis can save time and resources.

1. Ignoring Symptoms

One of the most common errors is dismissing minor indicators of trouble. Symptoms like unusual noises, vibrations, or warning lights can provide vital clues. Neglecting these signs often results in more significant complications that could have been easily addressed if caught early.

2. Relying Solely on Error Codes

While modern diagnostic tools are invaluable, they can sometimes lead to oversimplified conclusions. Focusing exclusively on error codes without considering other factors–such as mechanical wear or environmental conditions–can lead to misdiagnosis. It’s essential to evaluate the entire system holistically.

Testing Engine Performance Post-Repair

Evaluating the functionality of a power unit after maintenance is crucial to ensure optimal performance and reliability. This assessment helps identify any lingering issues that could affect the overall driving experience. Conducting a series of tests can confirm that all components are working harmoniously, delivering the expected power and efficiency.

Key Performance Indicators

Before starting the evaluation, it’s essential to establish the key metrics that will indicate the success of the recent work. The following table outlines the primary factors to monitor during the testing phase:

| Metric | Description |

|---|---|

| Power Output | Measure the horsepower and torque to ensure they meet manufacturer specifications. |

| Fuel Efficiency | Assess miles per gallon (MPG) to verify improvements in consumption. |

| Emissions Levels | Test for pollutants to ensure compliance with environmental standards. |

| Temperature Stability | Monitor operating temperatures to prevent overheating during various conditions. |

| Noise and Vibration | Evaluate any abnormal sounds or vibrations that may indicate mechanical issues. |

Testing Procedures

To conduct a comprehensive evaluation, follow a systematic approach that includes both on-road and diagnostic tool assessments. Start with a visual inspection, followed by driving under varied conditions to gauge real-world performance. Utilize specialized equipment to gather data on the aforementioned metrics, allowing for precise analysis and adjustments if necessary.

Preventive Maintenance for Longevity

Ensuring the durability and efficient performance of your vehicle involves regular upkeep and attention to detail. Proactive measures can significantly extend the lifespan of vital components, reducing the risk of unexpected failures and costly repairs. Implementing a structured maintenance routine not only enhances reliability but also contributes to overall driving satisfaction.

Key areas of focus should include fluid checks, filter replacements, and timely inspections of essential systems. Following a systematic schedule allows for early detection of potential issues, ensuring they are addressed before escalating into major problems.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 5,000 miles | Reduces wear, improves performance |

| Air Filter Replacement | Every 15,000 miles | Enhances fuel efficiency, protects components |

| Coolant Check | Every 30,000 miles | Prevents overheating, maintains optimal temperature |

| Tire Rotation | Every 5,000-7,000 miles | Promotes even wear, extends tire life |

| Brake Inspection | Every 10,000 miles | Ensures safety, prevents costly repairs |

By adhering to these guidelines, you can enhance the performance and reliability of your vehicle, ensuring a smooth and enjoyable driving experience for years to come.