The intricacies of vehicle care and component upkeep are crucial for ensuring reliability and optimal performance. This guide provides an in-depth look at the steps, tools, and techniques needed to maintain and enhance the performance of the 4P motor model. With attention to detail and a clear structure, this resource is crafted for both enthusiasts and professionals.

Exploring key maintenance procedures is essential for extending the life and efficiency of the motor. Regular inspection, cleaning, and part adjustments are fundamental to maintaining functionality, especially in demanding conditions. This guide breaks down each process, offering practical advice and tips for smooth and effective upkeep.

Whether you’re tackling complex tune-ups or simply looking to understand the core systems better, this guide aims to empower users with valuable insights. Following the steps outlined here can significantly contribute to preserving the motor’s integrity and achieving consistent performance on the road.

Toyota 4P Engine Repair Guide

Understanding the key aspects of maintaining and restoring the 4P model’s core components can help ensure its optimal function over time. This guide outlines essential steps and best practices to address common issues that may arise with prolonged use.

- Initial Assessment: Begin by checking primary components for wear, residue buildup, or loose connections. Identifying minor issues early on can prevent more significant problems.

- Cleaning and Lubrication: Regularly cleaning parts like valves, pipes, and bearings enhances performance. Ensure all moving parts are properly lubricated to reduce friction and prevent early deterioration.

- Replacement Tips: For worn-out components, consider quality aftermarket options compatible with the 4P model, balancing cost and durability.

- Testing and Adjustments: After reassembling, test functionality and make adjustments if necessary. Ensure all connections are secure, and verify that the system runs smoothly without unusual noises or vibrations.

Following these guidelines will contribute to a longer service life for the 4P model, helping it run efficiently and reliably.

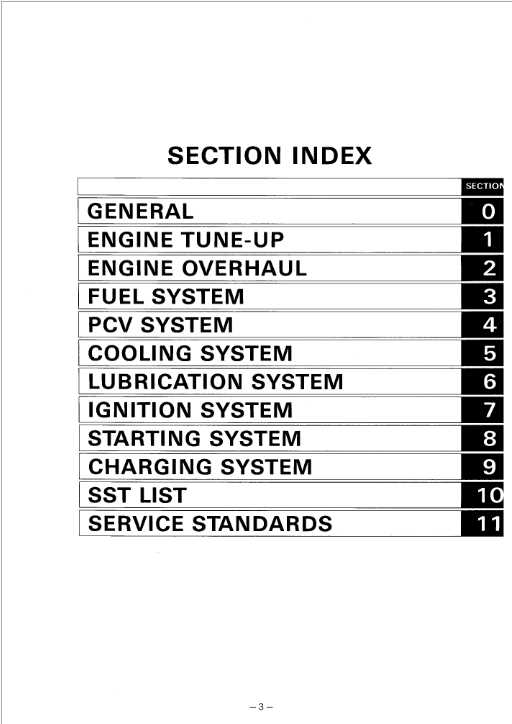

Understanding the Toyota 4P Engine Basics

The 4P series is known for its reliability and adaptability in a range of mechanical applications. This section covers the foundational elements of this model, focusing on its core components and how each part interacts to produce efficient functionality.

- Design Structure: Built with durability, this model incorporates robust materials, minimizing wear over time and allowing consistent performance.

- Fuel and Air Interaction: A balanced combination of fuel and air allows for efficient power output. This blend is carefully controlled to optimize both energy generation and economy.

- Cooling Mechanism: Effective cooling ensures that temperatures remain within optimal limits, extending the lifespan of various parts and improving overall functionality.

- Ignition System: The ignition is tuned to maximize energy transfer, resulting in a smooth

Essential Tools for 4P Engine Maintenance

When maintaining a 4P, having the right set of tools can make each step more efficient and help prevent unexpected issues. This section provides a list of essential tools to assist with regular upkeep and fine-tuning.

Hand Tools for General Maintenance

Standard hand tools are crucial for performing basic tasks, ensuring bolts and nuts are securely fastened, and components are accurately aligned. Some of the primary tools include:

- Socket Set: A comprehensive socket set enables working with various bolt sizes, making assembly and disassembly smooth.

- Torque Wrench: Ensures bolts and nuts are tightened to specific requirements, which is essential to avoid over-tightening or loosening.

- Feeler Gauge: Helps measure and adjust clearances accurately for optimal performance.

Specialized Tools for Detailed Work

Some aspects of maintenance require specialized tools designed specifically for precision and efficiency. These tools help address more intricate parts and settings:

- Compression Tester: Useful for assessing internal pressure, which can indicate

Diagnosing Common 4P Engine Problems

Identifying typical issues within a 4P power unit involves a careful examination of various symptoms that can hinder performance. By recognizing certain indicators early, one can assess the root cause and address potential disruptions efficiently.

- Starting Difficulties: Problems in starting may point to issues within the ignition system or a weakened power supply. Check the fuel flow and connections to ensure all elements are functioning correctly.

- Unstable Idle: If the unit idles unevenly or fluctuates, consider inspecting the air intake or fuel delivery for blockages or inconsistencies.

- Overheating: Elevated operating temperatures often result from coolant flow issues or obstructions in airflow. Ensure proper fluid levels and clear paths for heat dissipation.

- Loss of Power: A noticeable decrease in output can indicate compression issues or worn components. A compression test may help pinpoint the exact area of concern.

- Excessive Smoke: Visible emissions, especially when persistent, might signal combustion issues or oil leaks. Examining exhaust color can reveal specific causes.

These common issues, when understood and identified, allow for timely action, helping to maintain optimal unit function and prevent more extensive mechanical failures.

Step-by-Step 4P Engine Disassembly

This guide provides a structured breakdown process, outlining each stage of disassembly with detailed instructions. By following these steps carefully, you can ensure a smooth and organized process, maintaining all components in good order for future reassembly.

1. Preparation and Safety

Before beginning, prepare your workspace and gather all necessary tools. Ensure that safety precautions are followed, including disconnecting power sources and wearing protective gear. Proper preparation minimizes risks and keeps components secure during the disassembly.

2. Removing the Main Assemblies

Start by detaching peripheral parts and key sections in a specific order. Begin with external attachments, followed by internal sections, while noting their position and condition. Label or store parts as they are removed to streamline the reassembly process later. This stage requires particular attention to avoid damage to delicate components.

Tip: Take photos or notes at each step to track the arrangement of pieces, especially smaller parts and fastenings. This documentation helps ensure accurate and efficient reassembly.

With methodical handling and attention to each step, the process becomes straightforward, and components can be stored or inspected as needed. Following this structured approach will aid in achieving an efficient and organized disassembly.

Replacing Worn 4P Engine Components

Over time, certain parts of the power unit may wear out, affecting overall performance and efficiency. Addressing these issues promptly is crucial for maintaining optimal functionality and prolonging the lifespan of the vehicle. This section focuses on identifying and substituting worn components, ensuring the power unit operates smoothly and reliably.

Identifying Worn Components

Before proceeding with any substitutions, it is essential to accurately diagnose the parts that require attention. Common indicators of wear include unusual noises, decreased power output, and increased fuel consumption. Regular inspections and maintenance checks can help pinpoint these issues early, allowing for timely interventions.

Steps for Component Replacement

Once the worn parts have been identified, the next step involves the careful removal and replacement of these components. Ensure you have the appropriate tools and replacement parts on hand. Follow the specified procedures for detaching the affected parts, taking care to avoid any damage to surrounding areas. After installation, verify that everything is securely in place and perform tests to confirm that the replacement has resolved the initial issues.

Cleaning and Restoring Engine Parts

Maintaining the functionality and longevity of mechanical components is essential for optimal performance. Proper cleaning and restoration processes can significantly enhance the efficiency of these vital elements. This section delves into effective techniques and tips for revitalizing various parts, ensuring they operate smoothly and reliably.

Preparation is a crucial step before diving into the cleaning process. Start by gathering necessary tools and materials, such as cleaning solvents, brushes, and protective gear. It is essential to work in a well-ventilated area to minimize exposure to harmful fumes.

Utilizing appropriate cleaning solutions is vital for removing grime, oil, and other contaminants. Soaking components in designated cleaners can help break down stubborn deposits. For intricate areas, soft brushes or cloths are ideal for gently scrubbing surfaces without causing damage.

After cleaning, thorough rinsing is necessary to eliminate any residual cleaning agents. Allowing parts to dry completely is equally important, as moisture can lead to corrosion and other issues. Once dried, applying protective coatings can further enhance durability and resistance to environmental factors.

Finally, regularly inspecting and maintaining parts will help sustain their condition. By following these practices, mechanical elements can be restored to their optimal state, contributing to overall performance and longevity.

Proper Techniques for Reassembly

Reassembling complex mechanical components requires attention to detail and systematic methods. Ensuring that each part is correctly positioned and securely fastened is crucial for optimal performance and longevity. This section outlines essential practices that facilitate effective reassembly, minimizing the risk of future issues.

Here are key techniques to consider during the reassembly process:

- Organize Components: Arrange all parts in a logical order, making it easier to track what has been completed and what remains.

- Consult Documentation: Use reference materials to verify specifications and torque settings, ensuring everything aligns with manufacturer guidelines.

- Use Clean Tools: Employ clean, appropriate tools to avoid damaging surfaces and to maintain a safe working environment.

- Follow Sequence: Adhere to the specified sequence for reassembly to prevent complications or misalignment.

- Inspect Gaskets and Seals: Check all gaskets and seals for wear or damage before installation to avoid leaks and ensure a proper fit.

- Double-Check Connections: Verify that all connections, including electrical and fluid lines, are secure and free of obstruction.

By implementing these techniques, individuals can significantly improve the efficiency and accuracy of the reassembly process, leading to better overall outcomes.

Inspection Tips for Optimal Engine Health

Maintaining the health of your vehicle’s power unit is crucial for its longevity and performance. Regular assessments can help identify potential issues before they escalate, ensuring smooth operation and efficiency.

Begin by checking fluid levels, including oil, coolant, and transmission fluids. Proper lubrication is essential to minimize wear and tear, while sufficient coolant prevents overheating. Additionally, inspect for any leaks beneath the vehicle, which can indicate underlying problems.

Monitor the condition of belts and hoses, as these components are vital for overall functionality. Look for signs of wear, such as cracks or fraying, and replace them as necessary. Pay attention to the battery’s terminals and connections; corrosion can hinder performance and lead to starting issues.

Conduct visual inspections of filters, ensuring they are clean and free from obstructions. A blocked air filter can restrict airflow, impacting efficiency. Likewise, ensure that spark plugs are in good condition, as they play a critical role in the combustion process.

Lastly, listen for unusual noises during operation. Sounds such as knocking or hissing can signal serious issues requiring immediate attention. By following these tips, you can help maintain optimal functionality and extend the lifespan of your vehicle.

Preventive Maintenance for Long-Term Performance

Regular upkeep is crucial for ensuring the longevity and reliability of any vehicle. By implementing a consistent maintenance routine, owners can prevent potential issues before they escalate, thereby enhancing overall performance and safety. This proactive approach not only extends the lifespan of the vehicle but also optimizes fuel efficiency and driving experience.

One key aspect of preventive upkeep is regular inspections. Checking fluid levels, brakes, and tire conditions should be part of routine care. Additionally, keeping the air filters clean and replacing them as needed will contribute to optimal airflow and engine function. It is also beneficial to adhere to the manufacturer’s guidelines regarding service intervals.

Furthermore, addressing minor concerns promptly can prevent more significant problems in the future. Paying attention to unusual noises or changes in performance can help catch issues early. Regularly scheduled check-ups with a qualified technician provide an opportunity to identify and resolve these matters, ensuring that the vehicle remains in peak condition.

Lastly, maintaining a detailed record of all maintenance activities will assist in tracking performance trends and identifying areas needing attention. This organized approach not only fosters accountability but also serves as a valuable reference for future maintenance decisions.

Troubleshooting After Repairs

After completing maintenance tasks, it is essential to ensure that everything is functioning correctly. This section will guide you through common issues that may arise post-service and provide helpful tips for resolving them effectively. Identifying problems early can prevent further complications and ensure optimal performance.

Common Issues and Solutions

There are several typical concerns that might surface after conducting maintenance. Below are some frequent problems along with potential solutions:

Issue Possible Cause Recommended Action Strange noises Loose components Inspect and tighten all fasteners Decreased performance Improper installation Re-check the assembly and adjustments Unusual vibrations Imbalance in parts Examine for alignment and balance Warning lights on dashboard Faulty sensors or connections Check wiring and sensor integrity Final Checks

Once any issues have been addressed, it’s vital to perform final checks. Look for leaks, listen for abnormal sounds, and monitor the overall behavior of the vehicle during a test drive. Regular maintenance and prompt troubleshooting are key to maintaining longevity and reliability.