In the realm of high-performance vehicles, certain powertrains have earned a legendary status among enthusiasts and mechanics alike. This guide serves as a vital resource for those looking to dive deep into the intricacies of one such revered unit. Whether you’re a seasoned technician or an ambitious hobbyist, understanding the nuances of this powerhouse is essential for maximizing its potential and ensuring longevity.

The focus here is on the critical aspects of maintenance and troubleshooting, providing detailed insights into each component’s functionality and common issues that may arise. With an emphasis on precision and clarity, this compilation is designed to equip you with the necessary knowledge to tackle challenges head-on.

From initial assessments to advanced tuning techniques, this resource aims to enhance your skill set, allowing you to navigate the complexities of performance enhancements and routine upkeep. Embark on this journey to unlock the secrets behind optimal performance and reliability, ensuring that your beloved machine remains a formidable contender on the road.

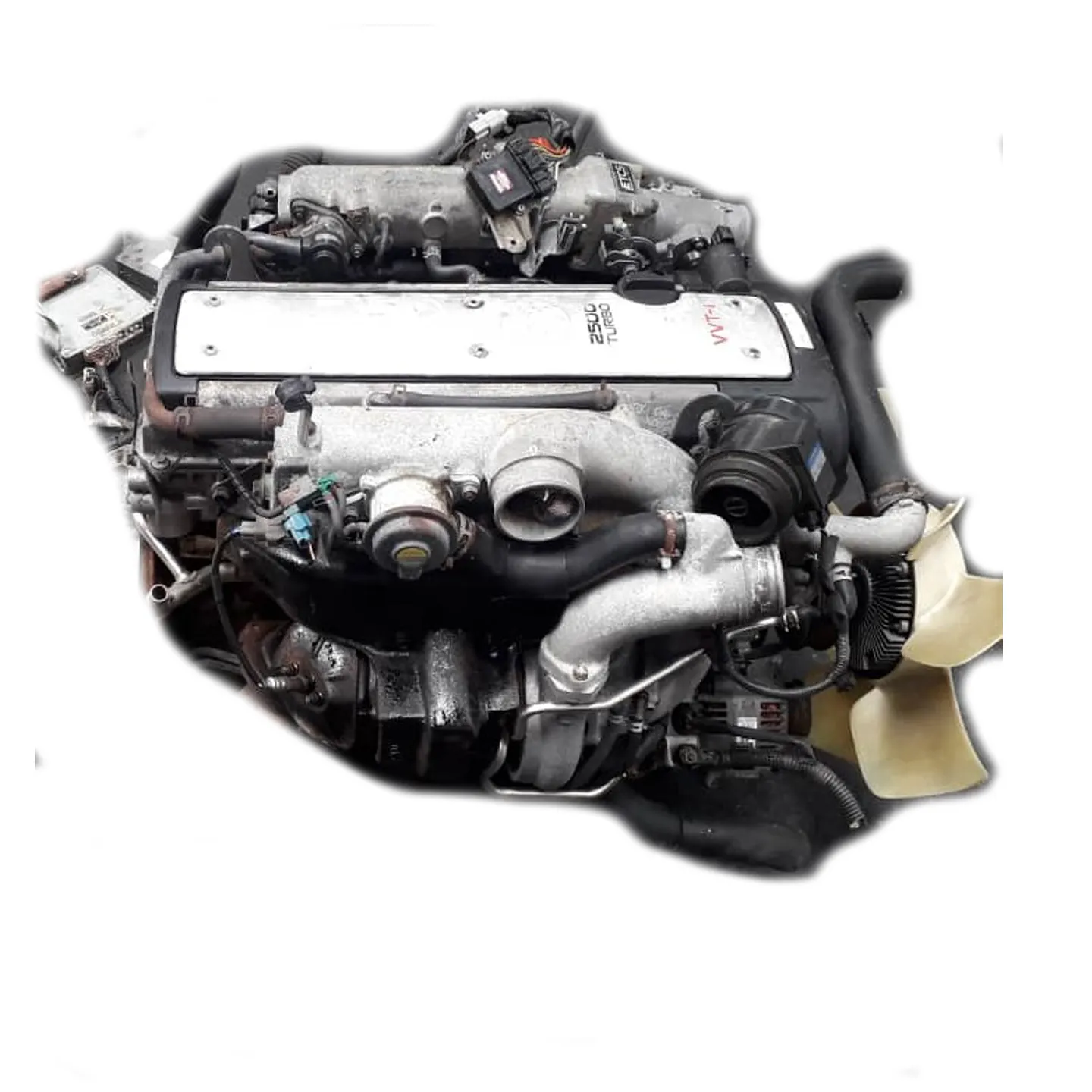

Toyota 1JZ-GTE Engine Overview

This section provides a comprehensive look at a renowned power unit known for its robust performance and engineering excellence. Celebrated for its balance of efficiency and power, it has gained a dedicated following among enthusiasts and professionals alike. Its design incorporates advanced features that enhance both reliability and driving experience.

Key Features

One of the standout characteristics of this unit is its inline configuration, which contributes to smooth operation and improved handling. The incorporation of a turbocharger allows for significant power output while maintaining relatively low displacement. Additionally, its lightweight construction aids in performance, making it an attractive choice for various applications.

Applications and Popularity

This powertrain has found its way into a diverse range of vehicles, from sports cars to sedans, establishing itself as a versatile option. Its tuning potential has made it a favorite in the automotive community, with many seeking to extract even greater performance through modifications. The combination of engineering sophistication and aftermarket support ensures its lasting appeal.

Common Issues with 1JZ-GTE

This section highlights frequent challenges faced by enthusiasts and mechanics when dealing with a specific inline-six turbocharged power unit. Understanding these common problems can facilitate better maintenance and enhance performance longevity.

| Issue | Description | Symptoms |

|---|---|---|

| Oil Leaks | Wear and tear can lead to various gaskets deteriorating, causing oil to escape. | Visible oil spots under the vehicle, low oil levels. |

| Overheating | Cooling system failures, such as a faulty thermostat or radiator issues, can cause excessive heat. | Temperature gauge readings above normal, steam from the hood. |

| Boost Leaks | Hoses and connections can wear out, leading to pressure loss in the intake system. | Decreased power, hissing sounds under acceleration. |

| Fuel Delivery Problems | Clogged filters or failing pumps can disrupt fuel flow. | Stalling, poor acceleration, engine misfires. |

| Ignition System Failures | Worn spark plugs or coils can lead to inconsistent firing. | Rough idling, reduced power output. |

Essential Tools for Engine Repair

When tackling a complex mechanical project, having the right set of instruments is crucial for success. The appropriate tools not only facilitate the process but also ensure safety and efficiency. This section will highlight the key items necessary for any comprehensive restoration endeavor.

Basic Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket types, are essential for loosening and tightening fasteners.

- Screwdrivers: Both flathead and Phillips options are necessary for different screw types.

- Pliers: Needle-nose and slip-joint pliers help grip and manipulate various components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

Specialized Equipment

- Compression Tester: Measures the pressure in the combustion chambers, vital for diagnosing performance issues.

- Timing Light: Essential for checking the ignition timing to ensure optimal performance.

- Oil Pressure Gauge: Monitors the oil pressure within the system to prevent serious damage.

- Diagnostic Scanner: Connects to the system to retrieve error codes and performance data, aiding in troubleshooting.

Equipping yourself with these vital tools will set a solid foundation for any restoration task, enhancing both precision and confidence in your work.

Step-by-Step Disassembly Process

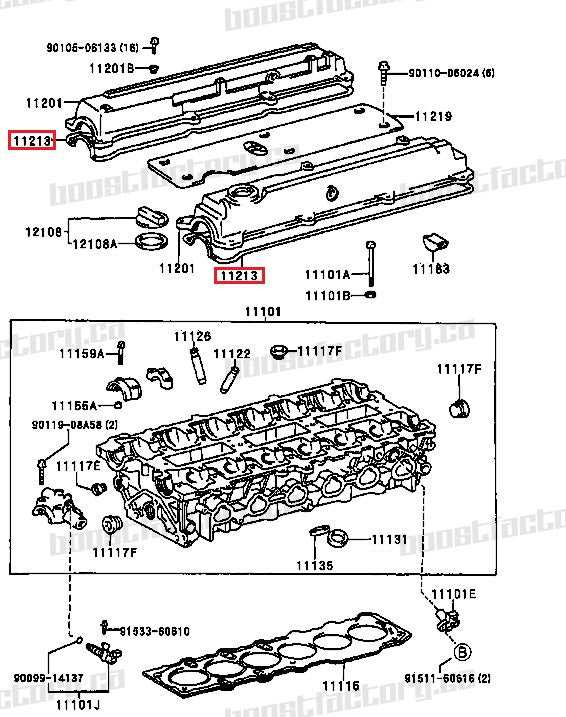

This section provides a comprehensive guide for breaking down a complex mechanical assembly into its individual components. Following a systematic approach ensures that each part is removed carefully, minimizing the risk of damage and facilitating easier reassembly.

Preparation

Before beginning the disassembly, ensure you have the following tools and materials ready:

- Socket set

- Wrenches

- Screwdrivers

- Pliers

- Container for small parts

- Clean workspace

Additionally, consult the specific guidelines relevant to your assembly type to understand the necessary steps and precautions.

Disassembly Steps

- Disconnect all electrical connections and hoses, labeling each for easy reattachment.

- Remove the outer casing or cover, ensuring not to lose any screws or fasteners.

- Take out ancillary components such as pumps and sensors, placing them in a designated container.

- Detach the main assembly sections, using appropriate tools to avoid stripping screws or damaging parts.

- Carefully extract internal components, taking note of their arrangement for future reference.

- Inspect each part for wear and damage, documenting any issues for later analysis.

Following this structured approach will lead to a successful breakdown, setting the stage for effective servicing or upgrades.

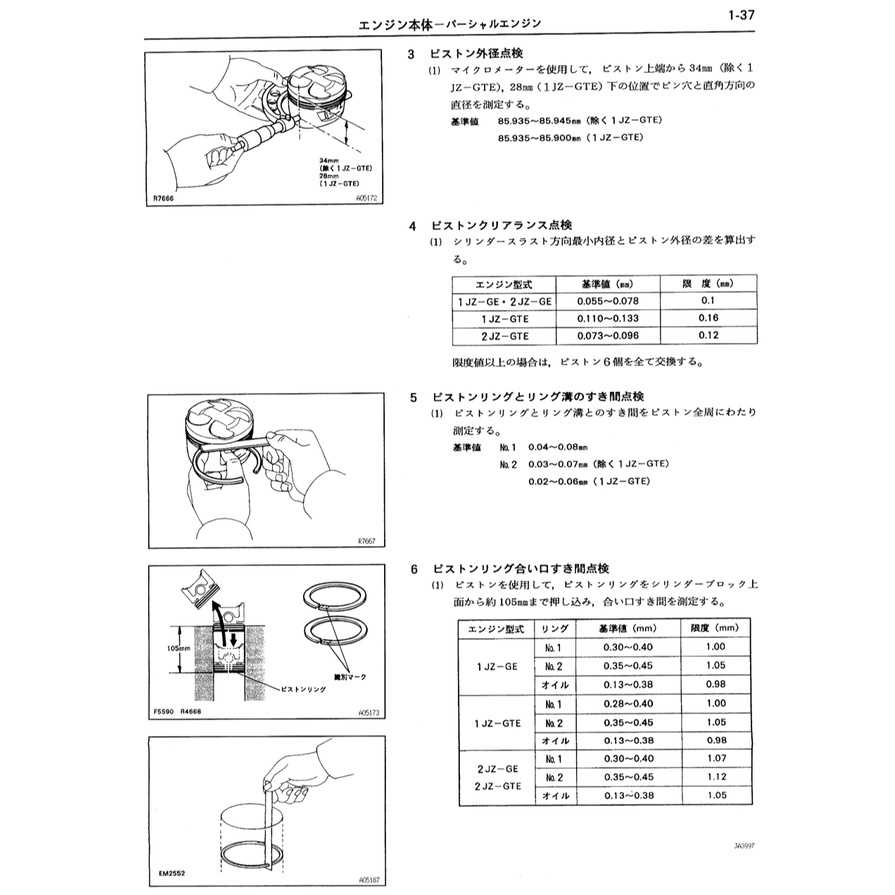

Inspecting Engine Components Thoroughly

Thorough examination of critical parts is essential for ensuring optimal performance and longevity of the power unit. This process not only helps in identifying wear and tear but also aids in preventing potential failures. A meticulous inspection routine is vital for maintaining the overall health of the machinery.

Visual Inspection

Begin with a detailed visual assessment of all accessible sections. Look for signs of damage, such as cracks, corrosion, or abnormal wear patterns. Pay close attention to gaskets and seals, as these components are crucial for maintaining integrity and preventing leaks.

Physical Measurements

Utilize appropriate tools to take measurements of critical dimensions. This includes checking tolerances on moving parts to ensure they meet specified standards. Deviation from these parameters can indicate the need for further action or replacement.

Fluid Analysis

Analyzing fluids is another key aspect of the inspection process. Examine the quality of lubricants and coolant for contamination or degradation. This can provide valuable insights into the internal condition and potential issues that may arise.

Functional Testing

Conduct functional tests to assess performance under various conditions. This involves running the unit and monitoring operational parameters, such as temperature and pressure. Any irregularities during these tests can signal underlying problems that warrant further investigation.

By following a comprehensive inspection protocol, potential issues can be identified early, ensuring reliable operation and extending the lifespan of the system. Regular scrutiny not only enhances performance but also contributes to a safer and more efficient overall setup.

Reassembly Tips for Optimal Performance

Reassembling a high-performance unit requires careful attention to detail and a systematic approach. Proper techniques not only ensure longevity but also enhance overall functionality. Here are some essential strategies to consider during the reassembly process.

- Cleanliness is Key: Maintain a clean workspace to prevent contaminants from entering critical components.

- Organize Parts: Sort and label components as you disassemble to simplify the reassembly process.

- Use New Seals and Gaskets: Always replace old seals and gaskets to avoid leaks and ensure a tight fit.

- Follow Torque Specifications: Adhere to the manufacturer’s torque settings to prevent damage and ensure proper clamping force.

Additionally, pay attention to the following:

- Apply assembly lube on moving parts to reduce friction during initial startup.

- Double-check alignment of components to avoid misfires or mechanical failures.

- Inspect all fasteners for wear and replace any that show signs of damage.

Finally, conduct a thorough inspection after reassembly to verify that everything is in order before the first test run. This diligence will lead to optimal performance and reliability in the long run.

Upgrades for Enhanced Engine Power

Improving performance can significantly elevate the driving experience and enhance overall vehicle dynamics. By focusing on specific components and modifications, enthusiasts can unlock additional horsepower and torque, leading to a more exhilarating ride.

Here are some effective upgrades to consider:

- Turbocharger Upgrade: Replacing the stock turbo with a larger, more efficient model can dramatically increase air intake and boost levels.

- Intercooler Enhancement: A larger intercooler helps reduce intake temperatures, allowing for denser air and improved combustion efficiency.

- Exhaust System Optimization: Upgrading to a high-flow exhaust system reduces back pressure, promoting better airflow and enhancing power output.

- Fuel System Improvements: Installing larger injectors and a higher-capacity fuel pump ensures adequate fuel supply for increased power levels.

- ECU Tuning: Custom tuning of the engine control unit can optimize fuel mapping and ignition timing for improved performance.

Additionally, consider enhancing the intake system to maximize airflow and incorporating lightweight components to reduce overall weight. Each modification contributes to achieving a balanced and responsive performance, providing a thrilling driving experience.

Maintaining the 1JZ-GTE Longevity

Ensuring the extended lifespan of a high-performance power unit involves several crucial practices. By focusing on regular upkeep and monitoring, enthusiasts can preserve optimal functionality and enhance reliability over time.

Key maintenance practices include routine oil changes, monitoring coolant levels, and ensuring proper air intake. Implementing these strategies helps prevent wear and tear while maintaining peak performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 5,000 miles | Use high-quality synthetic oil |

| Coolant Check | Every 3 months | Top up as needed |

| Air Filter Replacement | Every 12,000 miles | Clean or replace as necessary |

| Fuel System Cleaning | Every 15,000 miles | Use additives or professional service |

By following these guidelines, owners can delve into a comprehensive maintenance routine that supports long-term reliability and performance, ultimately enhancing the driving experience.

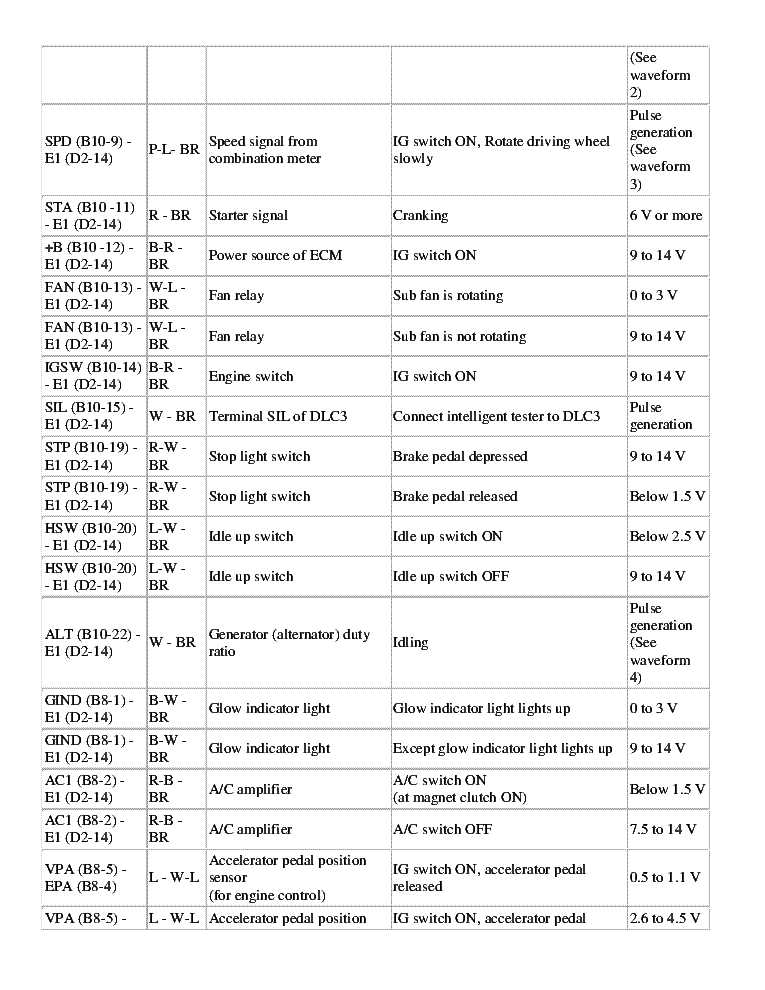

Diagnostic Procedures for Engine Problems

Identifying issues within a high-performance power unit requires a systematic approach. Accurate diagnostics not only save time but also prevent further complications. Understanding various symptoms and employing targeted techniques can lead to effective troubleshooting and resolution of problems.

Initial Assessment

Begin by gathering information about the symptoms exhibited. Pay attention to unusual noises, vibrations, or changes in performance. Conduct a visual inspection for any obvious signs of wear or damage, such as leaks or broken components. Documenting these findings will aid in forming a hypothesis about the underlying issue.

Testing and Analysis

Utilize specialized tools to measure vital parameters such as pressure and temperature. Conduct a compression test to assess the integrity of the combustion chamber. Analyzing the data collected can pinpoint potential malfunctions, allowing for a more focused intervention. Emphasizing a methodical approach will enhance the chances of a successful resolution.

Recommended Fluids and Lubricants

Proper maintenance of your vehicle requires careful selection of fluids and lubricants that enhance performance and longevity. Using high-quality products ensures optimal functioning of various components, reduces wear, and helps maintain efficiency. It’s essential to choose fluids that meet or exceed specified standards for best results.

Engine Oil

For optimal lubrication and protection, a high-performance motor oil with suitable viscosity is crucial. Look for products that offer excellent thermal stability and anti-wear properties. Synthetic oils are often recommended due to their superior performance in extreme conditions and extended drain intervals.

Coolant and Transmission Fluid

Choosing the right coolant is vital for temperature regulation and preventing corrosion within the cooling system. Ensure compatibility with your vehicle’s specifications. Similarly, the transmission fluid should provide smooth shifting and reliable operation, so select a formulation designed to meet the demands of your transmission type.