In the realm of automotive enthusiasts, the charm of vintage models holds a special place. These vehicles not only symbolize a bygone era but also require a unique approach to upkeep and restoration. Understanding the intricacies of their mechanics is essential for anyone looking to preserve the essence of these classic rides.

Within this exploration, we delve into the essential knowledge and techniques necessary for the care and enhancement of a beloved vehicle. From troubleshooting common issues to performing routine service tasks, having access to detailed instructions can make all the difference. This resource aims to equip owners with the skills needed to keep their cherished machines running smoothly.

Whether you are an experienced hobbyist or a novice eager to learn, the information presented here serves as a valuable asset. Emphasizing practical advice and step-by-step guidance, this guide is designed to empower individuals to take charge of their automotive projects with confidence. The satisfaction of reviving a classic model is unparalleled, and with the right tools and knowledge, anyone can embark on this rewarding journey.

Understanding the 1980 Toyota Pickup

This section delves into the characteristics and features of a classic utility vehicle, providing insights into its design, functionality, and appeal. Exploring its components and operational mechanisms enhances the appreciation for this iconic model, which has garnered a loyal following over the years.

Key Features

- Durable construction for rugged use

- Efficient engine options with good fuel economy

- Compact size, ideal for urban and rural environments

- Versatile cargo space suitable for various applications

Common Specifications

- Engine Types: Inline-4 and V6 options

- Transmission Choices: Manual and automatic available

- Drivetrain Configurations: Rear-wheel and four-wheel drive

- Payload Capacity: Robust enough for everyday hauling needs

Understanding these aspects can significantly enhance one’s ability to maintain and enjoy this vehicle for years to come.

Common Issues in Older Models

As vehicles age, they often exhibit a variety of challenges that can affect performance and reliability. Understanding these typical problems is crucial for maintaining optimal function and ensuring safety. Drivers of vintage models may encounter specific wear-and-tear issues that can arise from prolonged use and environmental factors.

Engine Performance Problems

One prevalent concern involves engine performance, where older units may struggle with power delivery or efficiency. Factors such as degraded fuel injectors, worn-out spark plugs, and compromised air filters can lead to reduced acceleration and increased fuel consumption. Regular maintenance and timely replacement of these components can help mitigate these issues.

Electrical System Failures

Another common area of concern is the electrical system. Aging wiring and corroded connections can result in intermittent failures of lights, gauges, and other essential components. Ensuring that all electrical connections are clean and securely fastened is vital to prevent frustrating breakdowns and ensure the vehicle operates smoothly.

Essential Tools for DIY Repairs

Engaging in hands-on maintenance and troubleshooting can be both rewarding and cost-effective. Having the right set of instruments at your disposal is crucial for achieving success in any project. This section highlights the key tools that every enthusiast should consider for effective home-based servicing.

Basic Hand Tools

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are essential for loosening and tightening screws.

- Wrenches: Both adjustable and fixed, these are important for handling nuts and bolts.

- Pliers: Useful for gripping, twisting, and cutting materials.

- Hammers: A rubber or claw hammer can assist in various tasks, from aligning parts to removing stubborn components.

Power Tools

- Drill: A versatile tool for creating holes and driving screws, essential for many applications.

- Impact Wrench: This tool provides high torque output, making it easier to remove tight fasteners.

- Saw: A circular or reciprocating saw can help cut through different materials with precision.

Investing in these essential instruments will empower you to tackle a variety of maintenance tasks confidently and efficiently.

Engine Maintenance and Troubleshooting

Proper care and diagnosis of the power unit are essential for ensuring optimal performance and longevity of any vehicle. Regular maintenance not only enhances efficiency but also helps identify potential issues before they escalate into significant problems. This section focuses on best practices for upkeep and common troubleshooting techniques that can be employed to maintain engine health.

Routine Maintenance

Consistent attention to key components is vital. Start with frequent oil changes to keep the engine lubricated and free from debris. Checking the coolant levels and replacing the filter regularly also plays a crucial role in preventing overheating and maintaining proper temperature. Additionally, inspecting the belts and hoses for signs of wear can avert unexpected breakdowns.

Troubleshooting Common Issues

When performance issues arise, systematic diagnosis is crucial. If the engine exhibits rough idling or stalling, it may indicate fuel delivery problems or ignition system faults. Inspecting spark plugs for wear and ensuring the fuel filter is not clogged can often resolve these issues. Additionally, unusual noises such as knocking or ticking may signal more serious internal problems that require immediate attention.

Diagnostic Tools

Utilizing diagnostic tools can significantly streamline the troubleshooting process. An OBD-II scanner can provide valuable insights into error codes, helping to pinpoint specific faults within the engine management system. Regular use of such equipment aids in maintaining the vehicle’s performance and reducing the risk of costly repairs down the line.

By adhering to a proactive maintenance routine and employing effective troubleshooting techniques, vehicle owners can ensure their power unit operates smoothly and reliably for years to come.

Transmission Problems and Solutions

Issues related to the gear shifting system can manifest in various ways, affecting vehicle performance and drivability. Identifying the root cause of these complications is crucial for ensuring smooth operation. This section will explore common challenges encountered with the transmission system and provide effective strategies for resolution.

Common Issues

Among the frequent problems are slipping gears, difficulty in shifting, and unusual noises during operation. Slipping often indicates low fluid levels or worn components. Difficulty in shifting can result from linkage issues or internal wear. Meanwhile, unusual noises may signal serious mechanical problems that require immediate attention.

Solutions and Preventive Measures

To address these challenges, regular maintenance is essential. Checking fluid levels and replacing worn components can prevent many issues. For slipping gears, a thorough inspection of the fluid condition and a flush may restore function. Adjusting the linkage can resolve shifting difficulties, while unusual sounds may necessitate a complete assessment by a professional technician. Adopting a proactive approach to maintenance will significantly enhance the longevity and reliability of the transmission system.

Electrical System Diagnostics Explained

Understanding the intricacies of an automotive electrical system is crucial for effective troubleshooting. This section delves into methods and practices that facilitate the identification of faults within the electrical framework of vehicles. Proper diagnostics not only streamline repairs but also enhance the overall performance and reliability of the vehicle.

Common Issues and Symptoms

Various components can contribute to electrical malfunctions. Symptoms may range from dimming lights to failure in starting the engine. Recognizing these signs is the first step toward addressing potential problems. Wiring issues, such as frayed or corroded connections, often lead to intermittent failures that can be frustrating to diagnose. Additionally, faulty sensors can produce erratic readings, complicating the troubleshooting process.

Diagnostic Tools and Techniques

Utilizing appropriate diagnostic tools is essential for accurate assessments. Multimeters and oscilloscopes are invaluable in measuring voltage, current, and resistance throughout the system. By systematically testing each component, technicians can isolate issues and implement effective solutions. Furthermore, understanding circuit diagrams can significantly aid in visualizing the electrical pathways, thereby enhancing the diagnostic process.

Suspension and Steering Repair Tips

Maintaining optimal handling and ride comfort is essential for any vehicle. Proper attention to the components that support steering and suspension can enhance both safety and performance. This section provides practical advice for diagnosing and addressing common issues.

Common Symptoms to Watch For

- Unusual noises while turning or going over bumps

- Excessive bouncing or swaying during driving

- Difficulty in steering or a wandering sensation

- Uneven tire wear

Maintenance Tips

- Regularly inspect bushings and joints for wear.

- Check and maintain proper alignment to ensure even tire contact.

- Lubricate all moving parts to reduce friction and wear.

- Replace worn shock absorbers to improve ride quality.

- Ensure steering fluid is at the appropriate level and free of contaminants.

By staying vigilant and addressing these areas, you can significantly prolong the life of your vehicle’s steering and suspension system.

Bodywork and Rust Prevention Techniques

Maintaining the exterior of a vehicle is crucial for its longevity and aesthetic appeal. Effective techniques for bodywork and rust prevention can significantly enhance the lifespan of metal surfaces and ensure a smooth appearance over time. Understanding these methods will empower owners to take proactive steps in caring for their automobiles.

Here are some essential techniques for bodywork and rust prevention:

- Regular Washing: Clean the exterior frequently to remove dirt, salt, and debris that can lead to corrosion.

- Waxing: Apply a high-quality wax periodically to create a protective barrier against moisture and pollutants.

- Inspection: Conduct routine checks for scratches, chips, and dents. Addressing these issues promptly can prevent rust from forming.

- Touch-Up Paint: Use touch-up paint to seal small scratches and nicks. This helps maintain the integrity of the protective layer.

- Undercoating: Consider applying an undercoating treatment to shield the undercarriage from road salts and moisture.

By following these practices, vehicle owners can significantly reduce the risk of rust and maintain the vehicle’s structural integrity. Regular care not only preserves the appearance but also enhances the value over time.

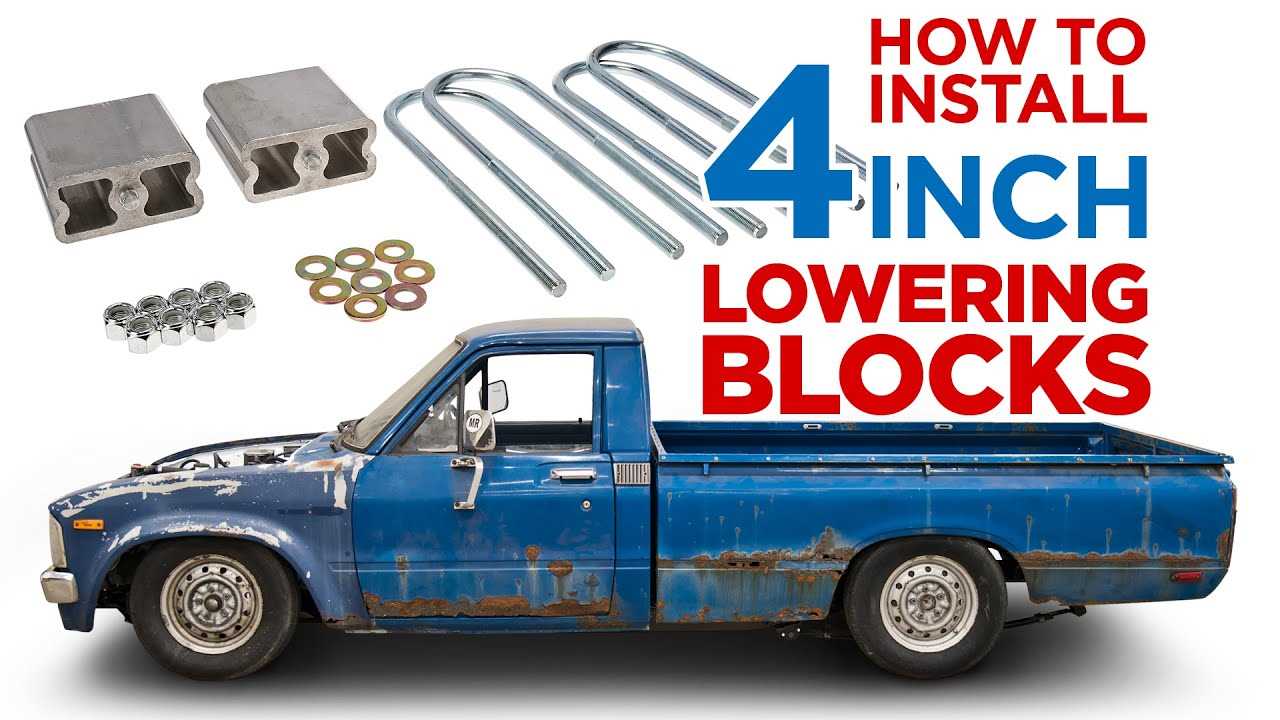

Upgrading Components for Better Performance

Enhancing the functionality of your vehicle involves a strategic approach to component improvements. By focusing on specific areas, you can achieve noticeable gains in efficiency, power, and overall driving experience. Upgrading various parts not only revitalizes your machine but also ensures it remains competitive and reliable on the road.

When considering enhancements, it’s essential to evaluate key components that can significantly impact performance. Below is a table outlining common upgrades and their potential benefits:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Engine | High-Performance Air Filter | Increased airflow, improved throttle response |

| Exhaust System | Performance Muffler | Enhanced sound, reduced back pressure |

| Suspension | Upgraded Shocks | Better handling, increased stability |

| Brakes | High-Performance Brake Pads | Improved stopping power, reduced fade |

| Wheels | Lightweight Alloy Rims | Reduced weight, improved acceleration |

Investing in these enhancements will not only improve performance metrics but also extend the lifespan of your vehicle. Careful consideration of each upgrade allows for a tailored approach that suits your driving style and requirements.

Finding Quality Replacement Parts

When it comes to maintaining a vehicle, sourcing reliable components is crucial for optimal performance and longevity. Ensuring that the parts you select meet high standards of quality can significantly affect the overall functionality and safety of your automobile.

Research and Verification should be your first step. Utilize reputable online platforms and forums where enthusiasts share their experiences and recommendations. Look for feedback on specific brands and components, as this information can guide you towards trustworthy options.

Compatibility is another vital consideration. Always cross-reference part numbers and specifications to ensure that the components you intend to purchase are suitable for your model. This helps avoid issues related to fit and function down the line.

OEM vs. Aftermarket parts present another choice. Original Equipment Manufacturer parts are designed specifically for your vehicle, while aftermarket alternatives may offer more competitive pricing. Weigh the pros and cons of each based on your budget and performance needs.

Finally, consider warranty and support. Opting for parts that come with a guarantee can provide peace of mind and protect your investment. Additionally, choosing suppliers known for excellent customer service can be beneficial if you encounter any issues with your purchase.

By following these guidelines, you can enhance your chances of finding durable and dependable replacement parts, ensuring your vehicle remains in top condition for years to come.

Safety Features and Upgrades

Enhancing safety in vehicles has become increasingly important, leading to various innovations and upgrades that improve driver and passenger protection. This section explores essential safety elements and possible enhancements that can significantly increase the overall security of your vehicle.

Key safety features to consider include:

- Seat Belts: Regular inspection and replacement of worn-out seat belts ensure optimal protection.

- Airbags: Upgrading to modern airbag systems can provide additional cushioning in the event of a collision.

- Braking Systems: Implementing anti-lock braking systems (ABS) enhances stopping control, especially in emergency situations.

- Lighting: Upgrading to brighter, more efficient headlights improves visibility during night driving.

Additionally, consider the following safety upgrades:

- Backup Cameras: Installing a rear-view camera helps prevent accidents while reversing.

- Blind Spot Monitors: These systems alert drivers to vehicles in adjacent lanes, reducing the risk of side collisions.

- Tire Pressure Monitoring Systems (TPMS): Regular monitoring of tire pressure enhances traction and reduces blowout risks.

- Stability Control: This feature helps maintain vehicle control during sudden maneuvers.

By focusing on these essential features and upgrades, vehicle owners can significantly enhance safety, ensuring a more secure driving experience for all occupants.

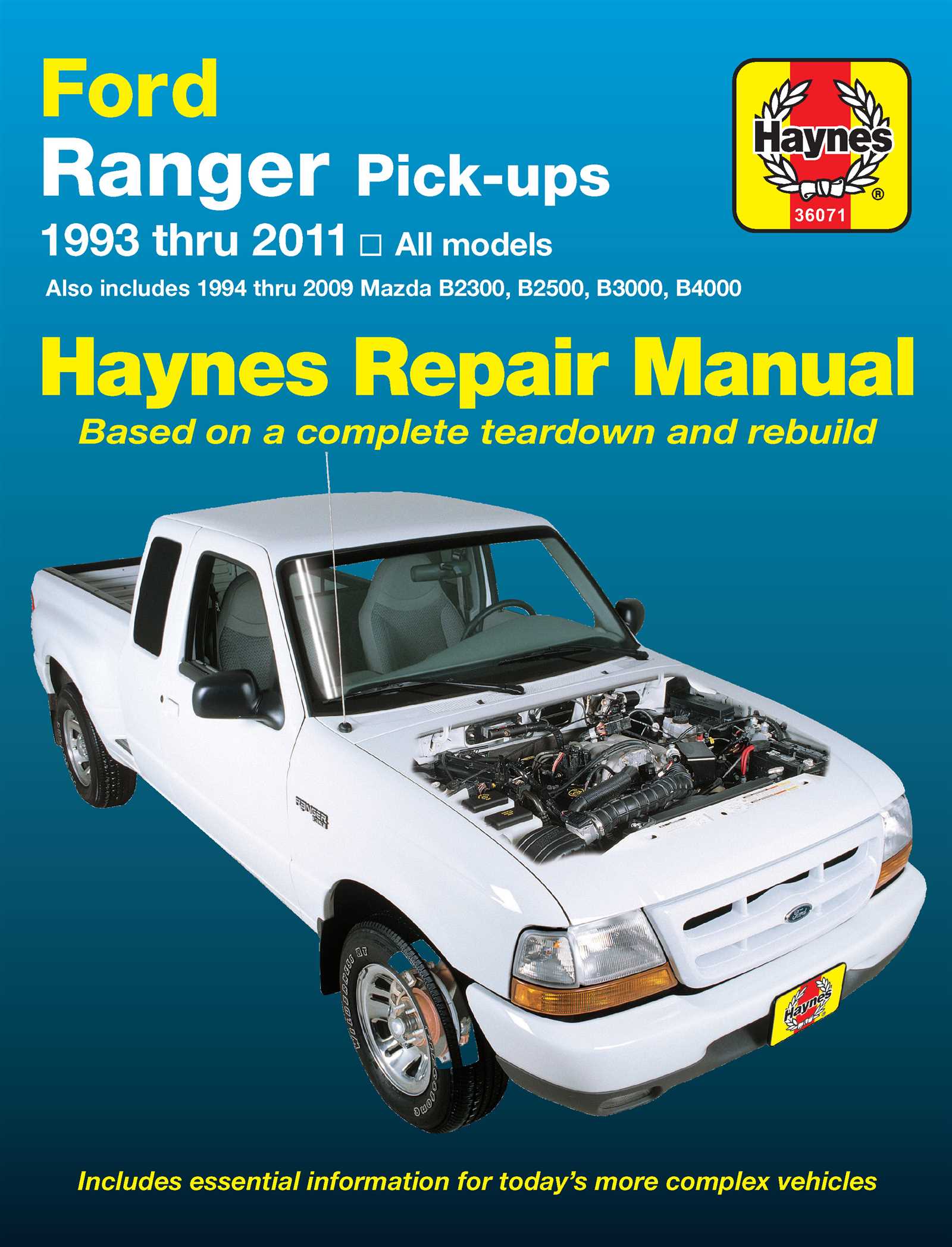

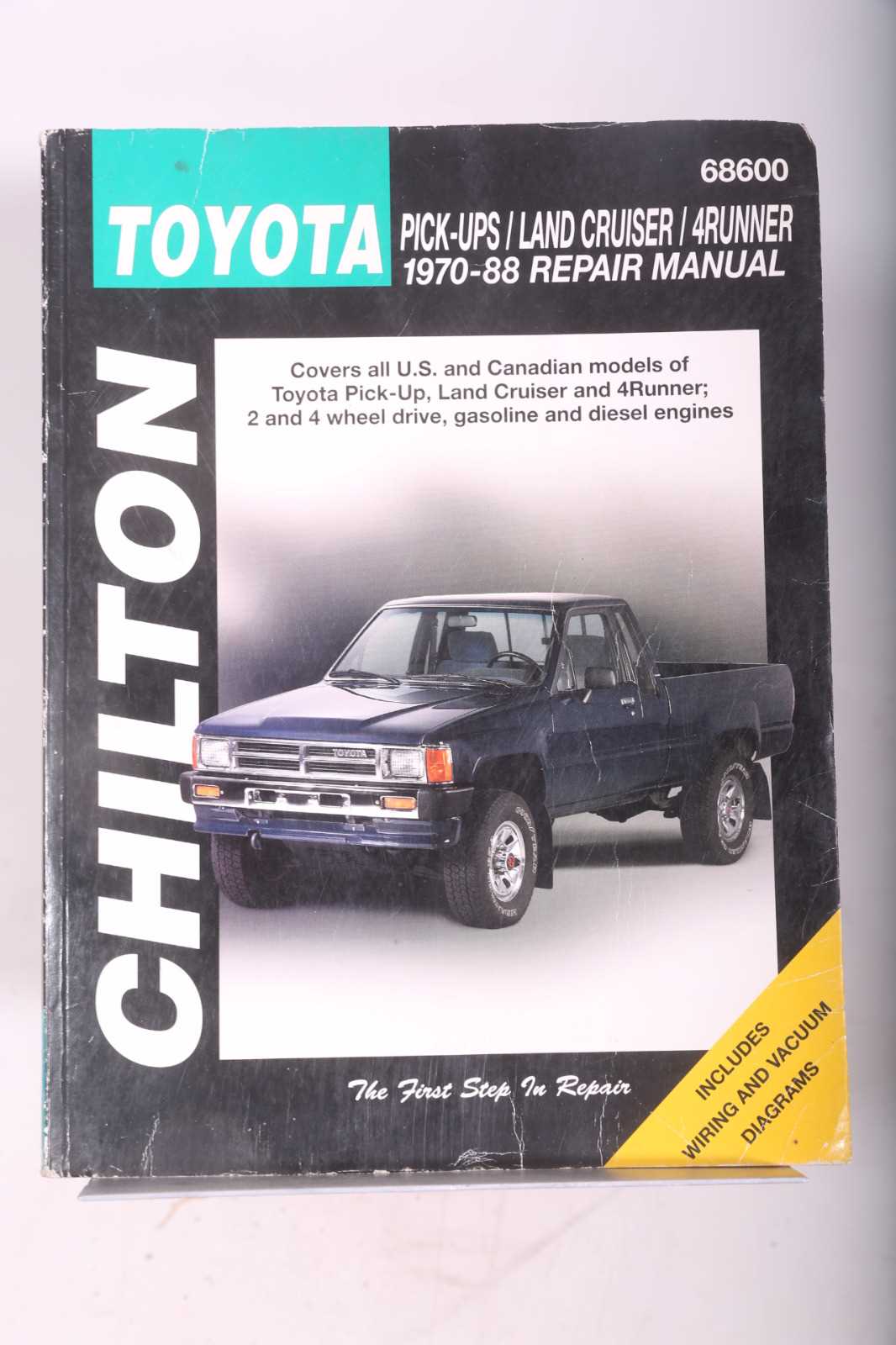

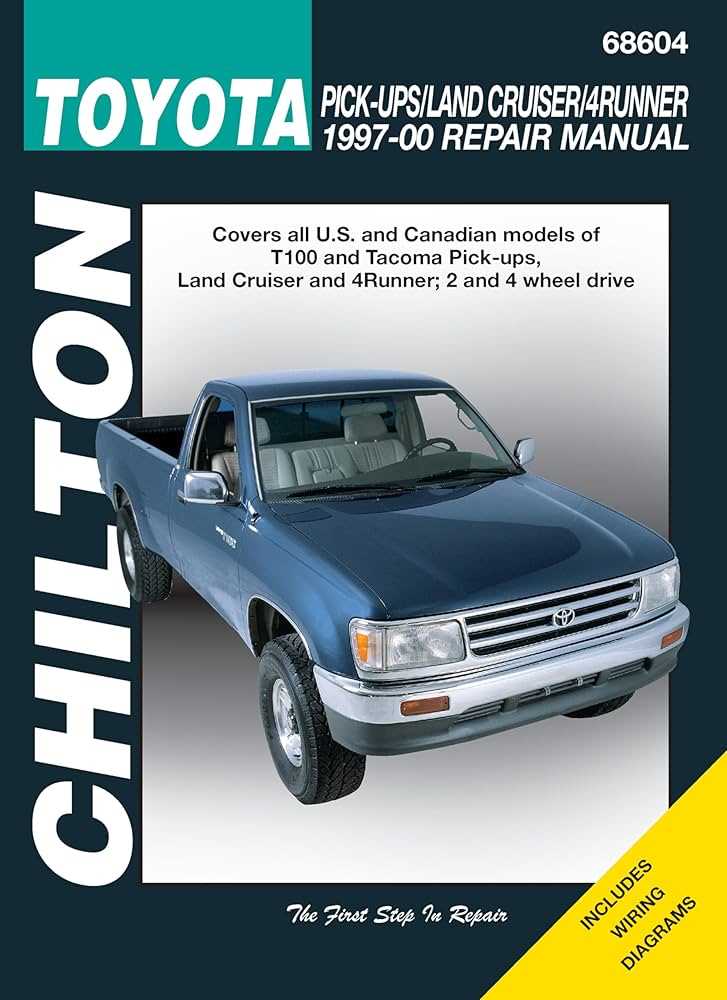

Resources for Repair Manuals and Guides

When it comes to maintaining and restoring vehicles, having access to reliable documentation is essential. Numerous sources offer comprehensive instructions and insights that can empower enthusiasts and professionals alike. These resources cover everything from routine maintenance to intricate troubleshooting, ensuring that you have the knowledge necessary to tackle any project.

Online Platforms: A variety of websites specialize in automotive information. Many provide free access to downloadable content, while others require a subscription for more extensive databases. These platforms often include forums where users can share experiences and solutions, creating a collaborative environment for knowledge exchange.

Printed Resources: For those who prefer traditional methods, numerous books and guides are available. Local libraries and bookstores typically carry a range of topics, offering both general overviews and detailed breakdowns of specific components and systems.

Video Tutorials: The rise of video-sharing platforms has transformed how individuals learn about vehicle upkeep. Many content creators produce step-by-step guides, making complex tasks more approachable. These visual resources can be invaluable for understanding the nuances of various repairs.

Community Support: Engaging with local clubs or online groups can provide additional insights. Fellow enthusiasts often have a wealth of knowledge and can recommend specific resources based on their personal experiences, fostering a sense of camaraderie within the automotive community.