Maintaining an all-terrain vehicle is essential for ensuring its longevity and optimal performance. This guide aims to provide enthusiasts and owners with valuable insights into the intricacies of upkeep, enabling them to tackle common issues and enhance their riding experience. Proper care not only improves reliability but also enhances safety on diverse terrains.

Understanding the mechanics of your vehicle is crucial. From engine performance to suspension adjustments, every aspect plays a significant role in overall functionality. This resource will cover various components, offering practical advice on addressing typical malfunctions and performing routine checks. By familiarizing yourself with these elements, you empower yourself to keep your vehicle in peak condition.

In the following sections, we will delve into troubleshooting techniques and step-by-step procedures tailored for different scenarios. Whether you’re a seasoned rider or a newcomer, having access to reliable information can make all the difference. Embrace the journey of mastering your machine and enjoy the freedom that comes with well-maintained equipment.

Overview of the All-Terrain Vehicle

This section provides a comprehensive introduction to a popular model in the realm of all-terrain vehicles, highlighting its key features, specifications, and the overall riding experience. This vehicle is designed for enthusiasts who seek both performance and versatility in various environments.

Key Features

- Powerful engine designed for optimal torque and acceleration.

- Sturdy frame offering durability and stability on rugged terrain.

- All-wheel drive system enhancing traction and control.

- Comfortable seating designed for long rides.

- Efficient fuel consumption for extended adventures.

Specifications

- Engine Type: Single-cylinder, air-cooled

- Transmission: Automatic with reverse

- Braking System: Front and rear disc brakes

- Suspension: Independent front suspension with rear swingarm

- Weight: Lightweight design for easy maneuverability

Overall, this all-terrain vehicle combines functionality with a user-friendly design, making it an excellent choice for both novice riders and seasoned adventurers.

Common Issues with the Ozark 250

When it comes to all-terrain vehicles, certain challenges tend to arise, impacting performance and reliability. Identifying these common problems can help owners maintain their machines effectively and enhance their riding experience.

- Starting Difficulties:

Many users report trouble initiating the engine. This can stem from battery issues, faulty ignition systems, or problems with the fuel delivery.

- Overheating:

Excessive heat can be a concern, often caused by low coolant levels or a malfunctioning radiator. Regular checks are crucial to prevent engine damage.

- Transmission Issues:

Owners frequently experience shifting problems, which may result from worn components or low fluid levels. Maintaining proper fluid and component condition is essential.

- Suspension Problems:

Worn-out shocks or springs can lead to a rough ride. Regular inspections can help identify these issues early and improve handling.

- Electrical Failures:

Electrical systems can be prone to malfunctions, often due to corroded connections or damaged wiring. Routine maintenance can mitigate these risks.

Addressing these common challenges can significantly enhance the performance and longevity of your vehicle, ensuring enjoyable and trouble-free adventures.

Essential Tools for Repairs

Having the right equipment is crucial for effectively maintaining and fixing your vehicle. Proper tools not only make the job easier but also ensure that tasks are completed safely and efficiently. In this section, we will highlight the fundamental instruments every enthusiast should have in their toolkit for successful maintenance projects.

Basic Hand Tools

Starting with hand tools, a quality set of wrenches and sockets is indispensable for various fasteners. Pliers, screwdrivers, and a sturdy hammer should also be included, as they assist in a wide range of tasks. Don’t forget to have a reliable torque wrench, which is essential for applying precise force to bolts, ensuring they are neither too loose nor overtightened.

Diagnostic Equipment

In addition to hand tools, diagnostic devices play a significant role in identifying issues. An OBD-II scanner allows you to read trouble codes from your vehicle’s computer, providing insights into potential problems. A multimeter is also useful for electrical troubleshooting, helping you measure voltage, current, and resistance in various components.

Engine Maintenance and Care

Proper upkeep of your engine is crucial for ensuring longevity and optimal performance. Regular attention to key components can prevent potential issues and enhance overall functionality. This section will guide you through essential practices to maintain your powertrain effectively.

Regular Inspections: Conducting routine checks on the engine’s condition is vital. Look for leaks, cracks, or any signs of wear. Regular inspections can help catch problems early, saving time and money on repairs.

Fluid Levels: Maintaining appropriate fluid levels is essential. Check the oil, coolant, and fuel regularly. Ensure that they are clean and at the recommended levels. Old or contaminated fluids can lead to decreased performance and engine damage.

Air Filter Care: The air filter plays a crucial role in engine efficiency. Clean or replace it as needed to ensure proper airflow. A clogged filter can hinder performance and increase fuel consumption.

Spark Plug Maintenance: Spark plugs should be inspected periodically for wear and carbon buildup. Replacing worn plugs enhances ignition efficiency and can improve fuel economy. Follow manufacturer recommendations for replacement intervals.

Cooling System Attention: The cooling system is vital for preventing overheating. Regularly check the radiator, hoses, and coolant levels. Address any leaks or damages promptly to maintain optimal engine temperatures.

Routine Servicing: Adhering to a scheduled maintenance routine is essential. Regular oil changes, filter replacements, and system checks will prolong engine life and performance. Consult the specific guidelines to ensure all maintenance tasks are completed on time.

By implementing these practices, you can ensure that your engine remains in excellent condition, providing reliable performance for years to come.

Transmission Troubleshooting Tips

When encountering issues with the shifting system of your vehicle, it’s essential to approach the problem methodically. This section provides valuable guidance for identifying and resolving common transmission-related complications. By following these steps, you can enhance the performance and longevity of your ride.

Common Symptoms of Transmission Issues

- Difficulty in changing gears

- Unusual noises during operation

- Fluid leaks beneath the vehicle

- Delayed engagement when shifting

- Warning lights on the dashboard

Troubleshooting Steps

- Check Fluid Levels: Ensure that the transmission fluid is at the appropriate level. Low fluid can lead to shifting problems.

- Inspect for Leaks: Examine the ground beneath your vehicle for signs of fluid leaks. Addressing leaks promptly can prevent further damage.

- Look for Warning Codes: Utilize a diagnostic tool to read any trouble codes that may indicate specific issues within the system.

- Evaluate Clutch Performance: For manual systems, ensure that the clutch is functioning properly. A worn clutch can hinder smooth shifting.

- Consider Professional Help: If basic troubleshooting does not resolve the issue, consulting a qualified technician may be necessary for advanced diagnostics.

Braking System Inspection Guide

Regular assessment of the braking system is essential for ensuring safety and performance. This guide outlines key steps to evaluate the components effectively, promoting optimal functionality and longevity.

Components to Inspect

- Brake Pads: Check for wear and thickness. Replace if less than recommended levels.

- Brake Discs: Inspect for warping or scoring. Look for uneven surfaces that may affect braking efficiency.

- Brake Fluid: Ensure fluid is at the correct level and free of contamination. Replace if dirty or discolored.

- Brake Lines: Examine for leaks or cracks. Ensure all connections are secure.

- Master Cylinder: Check for any signs of leaks and ensure proper functioning of the piston.

Inspection Process

- Begin with a visual examination of all components for obvious damage or wear.

- Test brake function in a safe area, noting any unusual noises or feelings.

- Measure the thickness of the brake pads and discs with appropriate tools.

- Flush and replace brake fluid if necessary, following manufacturer guidelines.

- Document findings and schedule necessary repairs or replacements promptly.

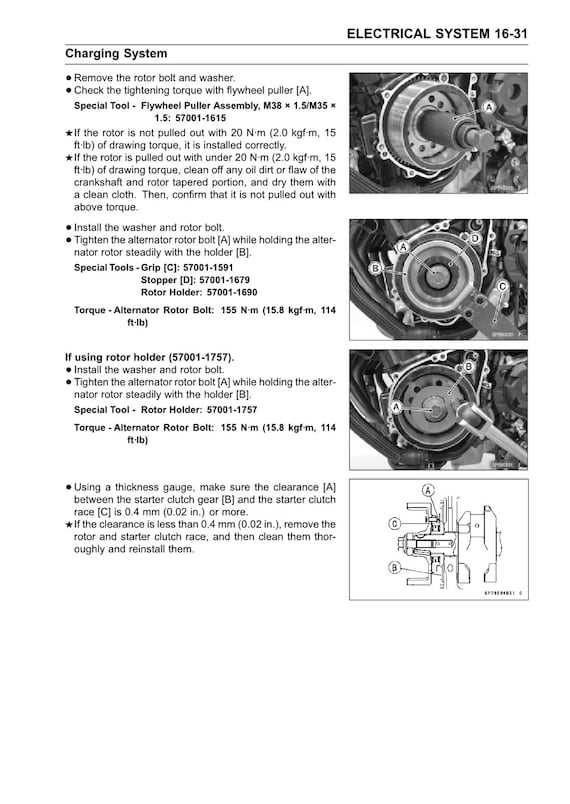

Electrical System Diagnostics

The electrical system of any all-terrain vehicle plays a crucial role in its overall performance and reliability. Diagnosing issues within this system requires a systematic approach to identify faults and ensure optimal functionality. This section outlines essential steps and considerations for effective troubleshooting of electrical components.

Common Issues and Symptoms

Identifying common electrical problems is the first step in diagnostics. Symptoms may include:

- Inconsistent starting or failure to start

- Dim or flickering lights

- Malfunctioning accessories

Each of these issues can indicate underlying problems such as battery failure, wiring faults, or faulty switches. Recognizing these symptoms early can prevent further complications.

Testing Procedures

To accurately diagnose electrical issues, a series of tests should be performed:

- Battery Voltage Check: Use a multimeter to measure the voltage across the battery terminals. A healthy battery should read around 12.6 volts when fully charged.

- Continuity Testing: Ensure that there are no breaks in the wiring by performing a continuity test on relevant circuits.

- Load Testing: Assess the battery’s ability to hold a charge under load conditions, as this can reveal weaknesses not evident during static tests.

By following these testing procedures, operators can isolate the source of electrical problems and determine the necessary corrective actions.

Suspension Adjustment Techniques

Proper suspension setup is essential for enhancing vehicle performance and rider comfort. Adjusting the suspension allows for customization based on terrain, riding style, and individual preferences. Understanding various adjustment techniques can significantly impact handling and stability, ensuring an optimal riding experience.

One of the primary aspects of suspension adjustment involves the compression and rebound settings. Compression controls how the suspension absorbs bumps, while rebound dictates how quickly it returns to its original position. Fine-tuning these settings can help maintain traction and control during different riding conditions.

Spring preload is another crucial factor, affecting ride height and weight distribution. Increasing preload can lead to a stiffer ride, which may be beneficial for handling in rough terrain, while decreasing it can improve comfort on smoother surfaces. It is important to find a balance that suits both the rider and the type of riding being undertaken.

Additionally, adjusting the damping characteristics can enhance overall stability. Riders may experiment with different settings to find the right combination for their specific needs. Regularly checking and adjusting the suspension will ensure optimal performance and prolong the lifespan of the components.

Lastly, taking the time to consult a professional or utilize a setup guide can provide valuable insights. Each vehicle may have unique requirements, and expert advice can facilitate better understanding and implementation of adjustment techniques. Proper maintenance and periodic checks will further enhance the effectiveness of the suspension system.

Replacing Tires and Wheels

Proper maintenance of your vehicle’s tires and wheels is essential for optimal performance and safety. This section will guide you through the steps necessary to replace these critical components, ensuring a smooth and efficient process. Whether you are dealing with wear and tear or seeking to upgrade for enhanced traction, understanding the replacement procedure is vital.

Preparation is the first step in this process. Before beginning, gather the necessary tools, including a jack, lug wrench, and possibly a tire pressure gauge. Ensure your vehicle is parked on a level surface, and engage the parking brake to prevent any movement during the procedure.

Next, removing the old tires involves loosening the lug nuts before raising the vehicle with the jack. Once elevated, take off the lug nuts completely and carefully remove the wheel. Inspect the wheel hub for any debris or damage, as this can affect the new tire’s performance.

After the old tire is removed, installing the new tire is straightforward. Align the new tire with the wheel hub and carefully slide it into place. Hand-tighten the lug nuts initially to secure the tire, then lower the vehicle back to the ground. Once the vehicle is stable, use the lug wrench to tighten the nuts in a star pattern, ensuring an even fit.

Finally, checking the tire pressure is crucial. Utilize a tire pressure gauge to ensure that each tire is inflated to the manufacturer’s recommended specifications. Proper inflation not only enhances performance but also extends the lifespan of your tires.

Following these steps will ensure that your vehicle is equipped with reliable tires and wheels, ready to take on any terrain with confidence.

Fuel System Cleaning Procedures

Maintaining the fuel delivery system is essential for optimal engine performance. Regular cleaning helps to eliminate contaminants that can impede fuel flow and reduce efficiency. This section outlines effective techniques for ensuring a clean fuel system, enhancing both reliability and longevity.

Preparation Steps

Before commencing the cleaning process, ensure you have all necessary tools and materials at hand. Here are the recommended preparatory actions:

| Step | Description |

|---|---|

| 1 | Disconnect the battery to prevent electrical issues. |

| 2 | Drain the fuel tank and remove any remaining fuel. |

| 3 | Gather cleaning agents and equipment required for the procedure. |

Cleaning Process

Once preparations are complete, follow these steps to clean the fuel system effectively:

| Step | Action |

|---|---|

| 1 | Flush the fuel lines with a specialized cleaner to remove deposits. |

| 2 | Inspect and clean the fuel filter, replacing it if necessary. |

| 3 | Clean the injectors using an ultrasonic cleaner for thorough removal of build-up. |

Following these procedures will contribute to a well-functioning fuel system, ensuring that your engine runs smoothly and efficiently.

Routine Maintenance Checklist

Regular upkeep is essential for ensuring optimal performance and longevity of your all-terrain vehicle. By adhering to a systematic checklist, owners can identify potential issues before they escalate, maintain peak functionality, and enjoy a safe riding experience.

Essential Tasks

Implementing routine checks can help in maintaining various components of the vehicle. Below is a list of vital tasks to consider:

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 500 miles or every season | Use the recommended oil type. |

| Air Filter Inspection | Monthly | Clean or replace if necessary. |

| Tire Pressure Check | Every ride | Ensure proper inflation for safety. |

| Brake System Check | Every 1000 miles | Inspect pads and fluid levels. |

| Chain Lubrication | Every 300 miles | Keep the chain clean and well-lubricated. |

Seasonal Inspections

In addition to regular tasks, seasonal inspections are crucial for comprehensive vehicle care. Consider the following:

| Inspection | Frequency | Recommendations |

|---|---|---|

| Battery Check | At the beginning of each season | Clean terminals and check for corrosion. |

| Cooling System Inspection | Before summer | Ensure fluid levels are adequate. |

| Fuel System Check | Before winter | Stabilize fuel for long-term storage. |

| Electrical System Test | Every six months | Inspect wiring and connections. |

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on any vehicle is paramount. Proper precautions can prevent accidents and injuries, creating a safer environment for everyone involved. This section outlines essential guidelines to follow for a secure working experience.

- Personal Protective Equipment (PPE):

- Always wear safety goggles to protect your eyes from debris.

- Use gloves to prevent skin contact with harmful substances.

- Consider wearing a mask if you are working with chemicals or dust.

- Work Area Preparation:

- Ensure the workspace is well-ventilated to avoid inhaling fumes.

- Keep the area clean and free of clutter to prevent tripping hazards.

- Use appropriate lighting to clearly see the task at hand.

- Tools and Equipment:

- Inspect all tools before use to ensure they are in good condition.

- Use the correct tool for each task to avoid accidents.

- Store tools safely when not in use to prevent injuries.

- Handling Fluids:

- Be cautious when dealing with oils and chemicals; follow proper disposal methods.

- Use absorbent materials for spills to maintain a safe working area.

- Never mix different types of fluids unless specified by the guidelines.

- Emergency Preparedness:

- Keep a first aid kit accessible in case of minor injuries.

- Familiarize yourself with emergency procedures in case of serious incidents.

- Have a fire extinguisher nearby when working with flammable materials.

By adhering to these precautions, you can help ensure a safer and more efficient maintenance process. Prioritize safety to protect yourself and others around you.