Understanding the nuances of your equipment is essential for optimal performance and longevity. This section provides a comprehensive overview of maintenance techniques and troubleshooting tips, ensuring your tools operate smoothly and efficiently.

Every machine has its quirks and challenges, making it vital to delve into the specifics of its upkeep. With the right knowledge, you can enhance functionality and address any issues that may arise, avoiding costly replacements.

Whether you are an experienced user or a newcomer, grasping the ultimate strategies for maintenance will empower you to handle your device with confidence. This guide aims to equip you with the information needed for successful management and care of your equipment.

Overview of Stihl 026 Chainsaw

This section provides a comprehensive overview of a popular model of a portable cutting tool, renowned for its reliability and efficiency. Designed for both professional and amateur users, this device excels in various cutting tasks, making it a preferred choice for many woodworkers and landscapers.

Key Features

- Powerful engine for efficient cutting

- Lightweight design for easy handling

- Durable construction for long-lasting performance

- Advanced safety features to protect the user

- Easy-to-access controls for convenience

Applications

- Tree felling and limbing

- Firewood preparation

- Landscaping and maintenance tasks

- Emergency response for storm damage

With its robust specifications and user-friendly design, this cutting tool stands out as an essential asset for anyone engaged in outdoor projects.

Common Issues with Stihl 026

This section highlights frequently encountered problems with a popular model in the outdoor power equipment sector. Understanding these common issues can help users maintain optimal performance and extend the lifespan of their tools.

Typical Problems

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Hard Starting | Engine fails to start or requires multiple attempts | Check fuel mixture, inspect spark plug, clean air filter |

| Overheating | Excessive heat during operation | Ensure proper lubrication, clean cooling fins, check fuel lines |

| Loss of Power | Reduced cutting efficiency | Examine fuel filter, adjust carburetor, inspect chain tension |

Maintenance Tips

Regular upkeep is crucial for avoiding these issues. Adhering to a maintenance schedule, including cleaning components and checking settings, can prevent many common malfunctions and ensure smooth operation.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. A well-equipped workspace not only enhances efficiency but also ensures that tasks are performed safely and accurately. Understanding which tools are necessary can significantly simplify the process and lead to successful outcomes.

First and foremost, a set of high-quality wrenches and screwdrivers is indispensable. These tools are fundamental for loosening and tightening various components, making them essential for any mechanical work. A torque wrench is particularly important for ensuring that parts are secured to the manufacturer’s specifications, preventing damage from over-tightening.

Additionally, a sturdy set of pliers can aid in gripping, twisting, and cutting wires or small parts. For more intricate tasks, precision tools such as needle-nose pliers are invaluable. A well-stocked toolbox should also include a variety of cutting tools, including saws and shears, to handle different materials effectively.

Safety equipment cannot be overlooked. Protective eyewear and gloves are vital for safeguarding against potential hazards during maintenance tasks. Investing in a quality first-aid kit is also advisable, ensuring preparedness for any unexpected incidents.

Lastly, a comprehensive cleaning kit will help maintain the longevity of tools and equipment. Keeping work areas tidy not only promotes safety but also enhances overall productivity. With the right selection of tools and safety measures in place, any maintenance project can be tackled with confidence and precision.

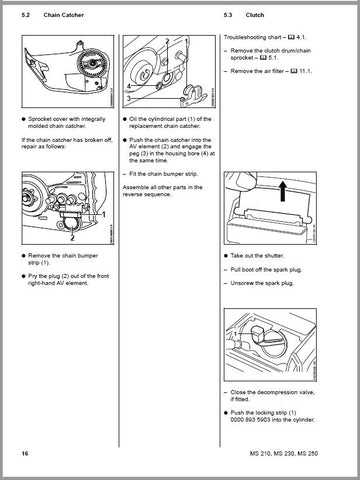

Step-by-Step Maintenance Guide

Regular upkeep of your equipment is essential to ensure optimal performance and longevity. This guide provides a clear pathway to maintaining your tool effectively, focusing on key tasks that contribute to its reliable operation.

Essential Maintenance Tasks

- Check and Clean the Air Filter

- Inspect the Spark Plug

- Sharpen the Cutting Chain

- Examine Fuel Lines for Damage

- Clean the Fuel Tank

- Inspect and Tighten Bolts and Screws

Maintenance Procedure

- Air Filter: Remove the cover and take out the air filter. Clean it with compressed air or replace it if necessary.

- Spark Plug: Unscrew the spark plug, inspect for wear, and replace it if it’s dirty or damaged.

- Cutting Chain: Use a file to sharpen the chain teeth, ensuring even sharpening on each side.

- Fuel Lines: Look for cracks or leaks in the lines; replace them if any damage is found.

- Fuel Tank: Empty the tank and clean it thoroughly to remove any residue or debris.

- Bolts and Screws: Use a wrench to check for tightness; retighten any loose components.

Following these steps regularly will help maintain your equipment in peak condition, allowing for efficient and safe operation.

Replacing the Chain and Bar

Maintaining the cutting components of your tool is essential for optimal performance. Regularly replacing the chain and bar ensures efficiency and prolongs the life of the equipment. This section outlines the necessary steps to carry out this task effectively.

Tools and Materials Needed

- Replacement chain

- New guide bar

- Screwdriver

- Wrench or socket set

- Chain lubricant

- Protective gloves

Step-by-Step Instructions

- Ensure the tool is powered off and unplugged. Remove any fuel or battery source.

- Locate the tensioning screws and loosen them to relieve tension on the chain.

- Remove the chain from the guide bar by sliding it off the sprocket.

- Detach the guide bar by unscrewing the mounting bolts. Carefully remove the bar.

- Inspect the components for wear. Replace any damaged parts as necessary.

- Install the new guide bar, ensuring it fits securely in place.

- Thread the new chain onto the guide bar and sprocket, following the correct direction of rotation.

- Tighten the tensioning screws until the chain is snug, but not overly tight.

- Apply chain lubricant to ensure smooth operation.

- Reconnect the power source and test the tool for proper functionality.

Following these steps will help maintain the efficiency of your equipment and enhance safety during use. Regular checks will prevent potential issues and ensure a seamless experience with your tool.

Troubleshooting Engine Performance Problems

Engine performance issues can significantly impact the efficiency and functionality of your equipment. Identifying and addressing these problems early is crucial to ensure smooth operation. Common symptoms include poor acceleration, irregular idling, and difficulty starting, which may arise from a variety of factors.

Fuel Issues: One of the primary causes of engine performance decline is related to fuel quality. Old or contaminated fuel can lead to improper combustion. Always use fresh, high-quality fuel and ensure the fuel system is clean and free of blockages.

Air Supply: Adequate airflow is essential for optimal engine function. A clogged air filter can restrict airflow, leading to performance drops. Regularly inspect and replace the air filter to maintain proper ventilation.

Ignition System: Problems in the ignition system, such as worn spark plugs or faulty ignition coils, can hinder engine performance. Inspect these components regularly and replace them as necessary to ensure reliable ignition.

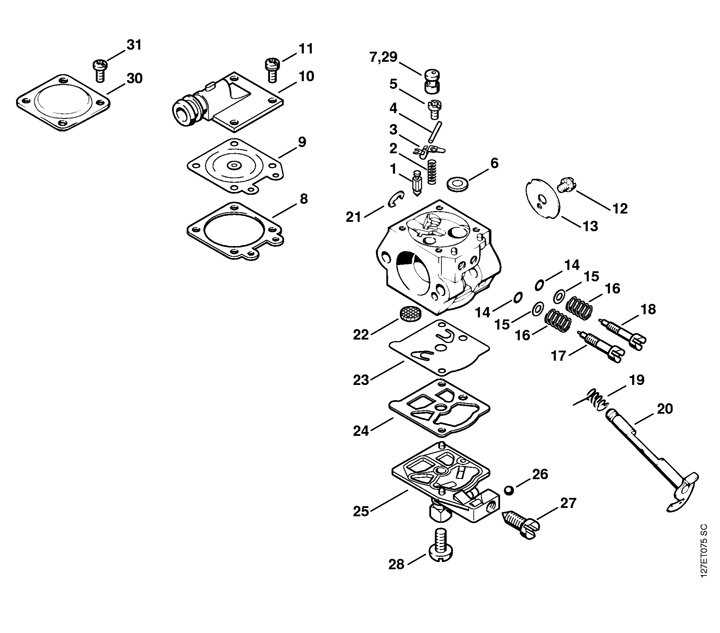

Carburetor Adjustment: An improperly adjusted carburetor can affect fuel-air mixture, resulting in either too rich or too lean conditions. This imbalance can lead to rough running and poor throttle response. Regular tuning and adjustment are recommended to achieve optimal settings.

Exhaust Blockages: Restrictions in the exhaust system can also impact engine performance. Check for any obstructions or damage that could prevent proper exhaust flow, which is vital for maintaining engine power.

By systematically addressing these common areas, you can effectively troubleshoot and resolve performance issues, ensuring your equipment operates at its best.

Fuel System Maintenance Tips

Maintaining the fuel system of your equipment is essential for optimal performance and longevity. Proper care ensures that the engine runs smoothly and efficiently, reducing the risk of breakdowns and enhancing fuel efficiency. Regular attention to this system can prevent common issues that may arise from fuel contamination or component wear.

First, always use high-quality fuel that meets the manufacturer’s recommendations. Stale or low-grade fuel can lead to clogs and poor combustion. It’s advisable to avoid leaving fuel in the tank for extended periods; empty the tank and replace it with fresh fuel as needed.

Check fuel lines regularly for signs of wear, cracks, or leaks. Damaged lines can cause fuel to escape, leading to reduced performance and potential safety hazards. If you notice any issues, replace the fuel lines promptly to maintain proper function.

Inspect the fuel filter periodically to ensure it is clean and free from debris. A clogged filter can restrict fuel flow and hinder engine performance. Replace the filter according to the recommended schedule to keep the system operating efficiently.

Lastly, ensure that the fuel cap is secure and in good condition. A damaged or loose cap can lead to fuel evaporation and contamination, affecting the overall operation of the engine. Regular checks and replacements will help maintain the integrity of the fuel system.

Importance of Regular Oil Checks

Maintaining the proper levels of lubrication in any machinery is crucial for its longevity and optimal performance. Regular inspections of oil not only prevent potential failures but also enhance efficiency and reduce operational costs. Ensuring that the lubricating fluid is at the correct level can significantly impact the overall functionality of the equipment.

Benefits of Regular Oil Inspections

1. Enhanced Performance: Regular checks ensure that the machinery operates smoothly, reducing friction and wear on moving parts. This leads to improved performance and reliability.

2. Prevention of Damage: By monitoring oil levels, users can identify leaks or contamination early, preventing serious damage and costly repairs. Timely detection can save time and resources in the long run.

Conclusion

In summary, routine oil evaluations are an essential aspect of equipment maintenance. They not only protect the machinery but also contribute to its efficiency and overall lifespan. Adopting this practice will result in a more reliable and productive operation.

Identifying Electrical Component Failures

Recognizing issues within electrical systems is crucial for maintaining optimal functionality. By understanding common signs of malfunction, users can prevent more severe problems and ensure efficient operation. This section explores methods to identify failures in electrical components.

Common Symptoms of Failure

Electrical component issues often present with specific indicators. Familiarity with these signs can help in early detection:

| Symptom | Possible Cause |

|---|---|

| Intermittent Operation | Loose connections or damaged wiring |

| Complete Loss of Function | Blown fuses or failed components |

| Unusual Noises | Defective switches or relays |

| Overheating | Short circuits or overloaded circuits |

Testing Methods

To accurately diagnose issues, several testing methods can be employed. Utilizing multimeters, inspecting visual connections, and assessing component integrity are effective approaches for confirming failures.

How to Clean the Air Filter

Maintaining a clean air filter is essential for optimal engine performance. A clogged filter can restrict airflow, leading to reduced efficiency and potential damage. Regular cleaning helps ensure the machine operates smoothly and prolongs its lifespan.

Follow these steps to effectively clean the air filter:

- Gather Necessary Tools:

- Clean, dry cloth

- Brush (soft-bristled)

- Soap and water solution

- Protective gloves

- Remove the Air Filter:

Carefully detach the air filter from its housing, following the manufacturer’s instructions. Be cautious not to damage any components during this process.

- Inspect the Filter:

Examine the air filter for any tears or significant wear. If it appears damaged, consider replacing it instead of cleaning.

- Clean the Filter:

Use a soft-bristled brush to remove any loose debris from the filter’s surface. For deeper cleaning:

- Submerge the filter in a soap and water solution.

- Gently agitate it to dislodge trapped dirt.

- Rinse thoroughly with clean water and allow it to air dry completely.

- Reinstall the Filter:

Once the filter is dry, carefully place it back into its housing, ensuring it fits securely. Double-check that all components are properly assembled.

By following these steps, you can maintain the air filter’s efficiency and ensure your engine operates at its best. Regular cleaning, ideally every few months, will enhance performance and extend the life of your equipment.

Upgrading Parts for Enhanced Performance

Improving the efficiency and functionality of your equipment can significantly enhance its overall performance. Upgrading specific components not only boosts power but also extends the lifespan of your machinery. By investing in high-quality parts, users can experience a marked improvement in operation, making tasks easier and more efficient.

Key Components to Consider

When looking to enhance performance, focus on crucial elements such as the air filter, spark plug, and carburetor. Upgrading the air filter can improve airflow, allowing the engine to breathe better and perform at its peak. A high-performance spark plug can lead to more efficient combustion, while a well-tuned carburetor ensures optimal fuel delivery, resulting in increased power output.

Benefits of Upgrading

Upgraded parts often lead to improved fuel efficiency and reduced emissions, contributing to a more environmentally friendly operation. Additionally, enhanced performance translates to increased productivity, allowing you to complete tasks more quickly and with less effort. Whether you are a professional or a hobbyist, these enhancements can provide a noticeable difference in your daily activities.

Safety Precautions During Repairs

When engaging in maintenance tasks, ensuring a safe environment is crucial. Following specific guidelines can prevent accidents and promote effective handling of equipment. Adhering to these precautions not only protects the individual but also enhances the longevity of the tools involved.

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and hearing protection.

- Ensure the workspace is clean and well-lit to avoid tripping hazards and improve visibility.

- Disconnect power sources or remove batteries before starting any work to prevent accidental activation.

- Keep all tools organized and within reach to minimize distractions and the risk of injury.

In addition to the above measures, it’s essential to be aware of your surroundings and the equipment’s condition:

- Inspect tools for any damage or wear before use.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Follow manufacturer instructions carefully to avoid improper handling.

- Have a first aid kit readily available in case of minor injuries.

By prioritizing safety, individuals can effectively maintain their equipment while minimizing risks. Implementing these practices fosters a secure environment for all involved.