In the realm of mechanical care and upkeep, having access to comprehensive resources is essential. These documents serve as invaluable tools for individuals and professionals alike, offering insights into best practices, troubleshooting techniques, and systematic approaches to enhancing performance.

Through detailed descriptions and visual aids, this section aims to illuminate the intricacies of various components. Readers will discover a wealth of information designed to foster a deeper understanding of systems, ensuring effective management and longevity of equipment.

Whether you are seeking to enhance your skills or streamline processes, the knowledge contained within these resources will empower you to tackle challenges with confidence. Emphasizing precision and clarity, these guides facilitate a hands-on approach to addressing concerns and optimizing functionality.

Understanding Service Shop Manuals

This section explores the essential documents utilized in maintenance facilities, providing vital information for the upkeep and restoration of various machinery. These guides serve as comprehensive resources, detailing procedures, specifications, and troubleshooting techniques necessary for effective management of equipment.

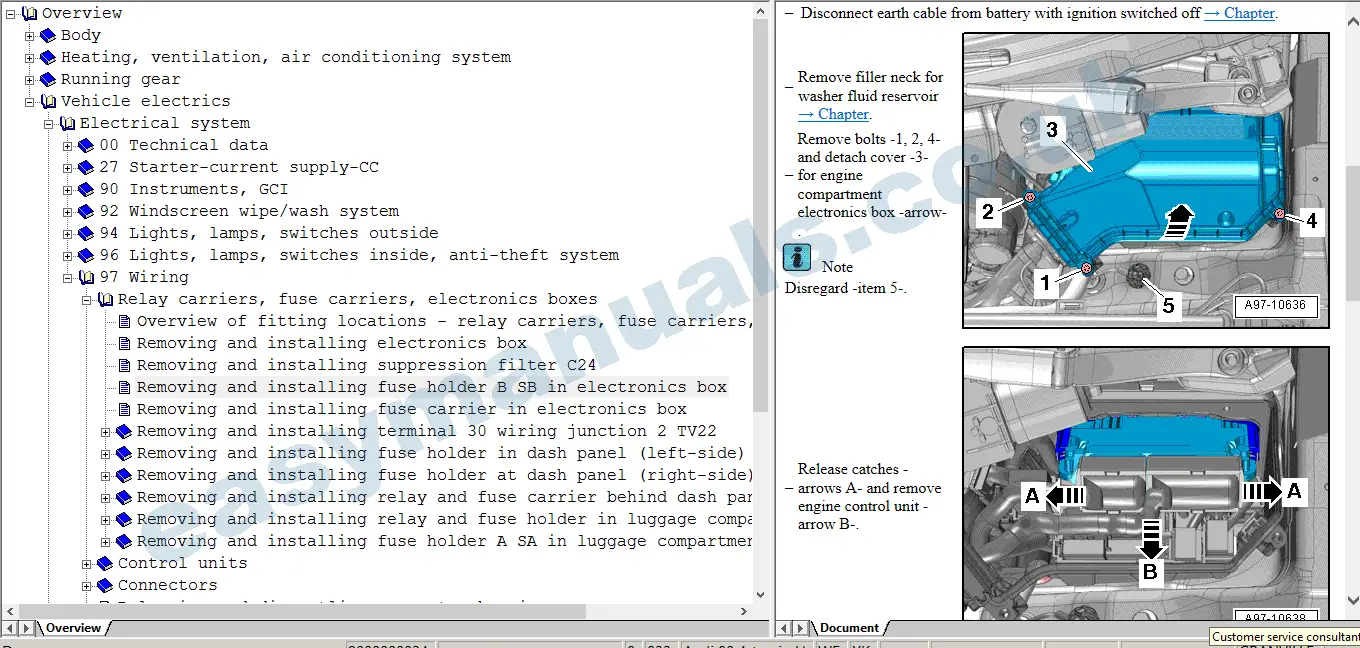

Typically organized into clear segments, these resources are designed to assist technicians in performing their tasks efficiently. They encompass a wide range of topics, including component identification, systematic approaches to diagnostics, and step-by-step instructions for handling common issues. The structured format allows for easy reference, ensuring that users can quickly locate the information they require.

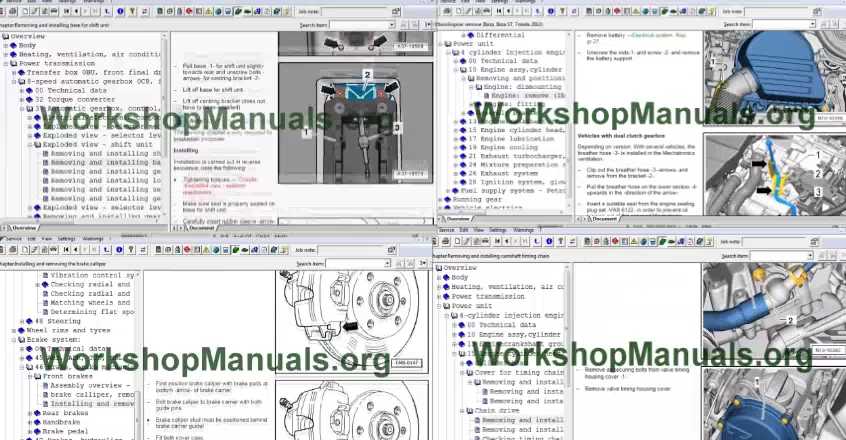

Additionally, these documents often include diagrams and charts that visually represent intricate systems. This visual aid enhances understanding, making complex processes more accessible. Regular updates are essential to maintain the accuracy of the information, reflecting changes in technology and industry standards.

Ultimately, these comprehensive guides are indispensable tools in any maintenance environment, facilitating informed decision-making and promoting best practices among technicians. Their role in ensuring the longevity and efficiency of machinery cannot be overstated.

Key Components of Repair Documentation

Effective documentation plays a crucial role in the maintenance and restoration process of various systems. It serves as a comprehensive reference that guides technicians through necessary procedures and ensures consistency in execution. The organization and clarity of information are vital to facilitate a seamless workflow and enhance understanding.

First and foremost, detailed descriptions of components are essential. This includes specifications, functions, and potential issues that may arise. Such information helps technicians quickly identify parts and understand their significance in the overall system.

Another important aspect is step-by-step instructions for diagnostic and corrective actions. Clear guidelines enable technicians to follow established protocols, minimizing errors and improving efficiency. Additionally, visual aids, such as diagrams and illustrations, significantly enhance comprehension and retention of information.

Incorporating troubleshooting tips is also beneficial. These insights allow technicians to address common problems effectively, streamlining the process and reducing downtime. Furthermore, documenting past experiences and solutions can serve as a valuable knowledge base for future reference.

Finally, maintaining an organized system for tracking updates and revisions ensures that all technicians have access to the most current information. This practice fosters collaboration and supports continuous improvement in techniques and processes.

Importance of Accurate Troubleshooting Guides

Having precise and detailed troubleshooting references is crucial for effectively addressing issues in various systems. Such resources provide step-by-step instructions that help in identifying and resolving problems efficiently, minimizing downtime and enhancing overall productivity.

These references not only aid technicians in diagnosing faults but also serve as valuable training tools for newcomers in the field. An accurate guide can significantly reduce the risk of errors, ensuring that each component is analyzed systematically.

| Benefits | Description |

|---|---|

| Efficiency | Streamlines the diagnostic process, leading to quicker resolutions. |

| Training | Acts as a learning resource for less experienced personnel. |

| Consistency | Promotes uniformity in addressing common issues across different scenarios. |

| Risk Reduction | Minimizes the likelihood of incorrect repairs or further damage. |

In conclusion, well-structured troubleshooting references are essential for maintaining high standards in technical operations, ensuring that issues are handled effectively and efficiently.

Tools Essential for Effective Repairs

Having the right instruments is crucial for achieving high-quality outcomes in any fixing process. The appropriate equipment not only enhances efficiency but also ensures that tasks are performed correctly and safely. This section highlights the key implements necessary for successful interventions across various scenarios.

Commonly Used Instruments

Several instruments stand out for their versatility and effectiveness. Below is a table showcasing these essentials along with their primary functions:

| Tool | Function |

|---|---|

| Screwdriver Set | Used for driving screws into various materials. |

| Wrench Set | Essential for tightening or loosening nuts and bolts. |

| Pliers | Helpful for gripping, twisting, and cutting wires or small objects. |

| Multimeter | Used to measure voltage, current, and resistance. |

| Hammer | Utilized for driving nails and breaking objects. |

Safety Equipment

In addition to general implements, protective gear is vital for maintaining safety during tasks. Essential items include gloves, safety glasses, and masks, ensuring that individuals remain safe from potential hazards while working.

Steps for Conducting Diagnostic Tests

Accurate assessment of equipment functionality is essential for effective troubleshooting. This section outlines a systematic approach to performing evaluations that can identify underlying issues. Following these steps ensures a thorough examination and aids in determining the necessary corrective measures.

Begin by gathering all relevant tools and resources that may assist in the testing process. Ensure that you have access to any required manuals, schematics, or diagnostic equipment. Familiarize yourself with the components that need evaluation, as this knowledge will guide your actions.

Next, visually inspect the device for any obvious signs of malfunction or damage. Look for loose connections, corrosion, or wear that could indicate a problem. This preliminary check often highlights issues that may not require complex testing procedures.

After the visual inspection, proceed to conduct basic functionality tests. Engage the equipment in its normal operating mode and observe its performance. Note any irregularities such as unusual noises, error messages, or failure to operate as expected.

Once initial tests are complete, utilize specialized diagnostic tools to carry out more detailed assessments. These tools can provide insights into the device’s internal workings and help pinpoint specific faults. Record the results for further analysis.

Finally, analyze the gathered data and compare it against standard operating parameters. This comparison will help you identify discrepancies and guide you in formulating a plan for any necessary adjustments or repairs. Document all findings for future reference and potential follow-up evaluations.

Maintenance Practices for Longevity

Ensuring the extended lifespan of any equipment requires consistent and attentive care. By adopting specific routines and practices, users can prevent premature wear and enhance performance over time. This section outlines effective methods that contribute to lasting functionality and reliability.

Regular Inspections

Routine checks are essential to identify potential issues before they escalate. Look for signs of wear, leaks, or unusual noises that may indicate underlying problems. Conducting these evaluations at scheduled intervals helps maintain optimal conditions and performance.

Proper Cleaning and Lubrication

Keeping components clean is vital for their functionality. Debris and dust can accumulate, leading to overheating and mechanical failures. Additionally, applying the correct lubricants ensures smooth operation and reduces friction, which is crucial for preserving the integrity of moving parts.

Safety Protocols During Repairs

Ensuring a secure environment while conducting maintenance tasks is essential for the well-being of personnel and the integrity of the equipment. Adhering to established safety guidelines minimizes the risk of accidents and promotes efficiency in operations.

Essential Safety Measures

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks.

- Keep the work area organized and free from hazards to prevent slips and falls.

- Ensure that all tools and equipment are in good working condition before use.

- Follow lockout/tagout procedures to ensure that machinery is properly shut down during maintenance.

Emergency Preparedness

- Familiarize yourself with the location of emergency exits and first aid kits.

- Know the procedures for reporting incidents and seeking assistance.

- Participate in regular safety drills to stay prepared for unforeseen situations.

By implementing these protocols, individuals can significantly reduce risks and create a safer environment for all involved in the maintenance processes.

Common Mistakes in Repair Procedures

In the realm of mechanical restoration and maintenance, errors can significantly impact the effectiveness and safety of the outcome. Understanding typical pitfalls can help practitioners avoid common setbacks, ensuring smoother processes and better results.

Typical Oversights

One of the most frequent errors involves neglecting the importance of proper diagnostics. Rushing into actions without thorough analysis often leads to misdiagnosis, which not only wastes time but can also exacerbate underlying issues.

Incorrect Tool Usage

Using the wrong instruments for specific tasks can result in damage to components or inadequate assembly. Proper tool selection is crucial for ensuring that each job is completed effectively and without complications.

| Mistake | Consequence |

|---|---|

| Neglecting diagnostics | Misdiagnosis and wasted resources |

| Using incorrect tools | Component damage and poor assembly |

| Skipping safety checks | Increased risk of accidents |

| Ignoring manufacturer guidelines | Potential for warranty voiding |

Integrating Technology in Service Shops

The incorporation of modern advancements in various facilities enhances efficiency, precision, and customer satisfaction. Embracing innovative tools and software solutions streamlines processes, enabling businesses to respond effectively to evolving market demands. This section explores key aspects of technological integration, focusing on its benefits and implementation strategies.

Enhancing Operational Efficiency

Utilizing advanced systems for task management and resource allocation can significantly improve daily operations. Automation of routine activities minimizes human error, while real-time data analytics provides valuable insights into performance metrics. This proactive approach facilitates informed decision-making and optimizes overall workflow.

Improving Customer Experience

Incorporating digital platforms for communication and service tracking enhances interaction with clients. Users can access information quickly and efficiently, fostering a sense of trust and reliability. Additionally, personalized solutions based on customer preferences can lead to increased satisfaction and loyalty.

Customer Communication and Service Quality

Effective interaction with clients plays a crucial role in enhancing the overall experience and satisfaction in any establishment. Establishing a strong rapport not only fosters trust but also leads to improved outcomes for both parties involved.

Key aspects of maintaining high-quality communication include:

- Active Listening: Understanding customer needs and concerns is fundamental. Engaging in thoughtful listening helps identify the specific issues that require attention.

- Clear and Concise Information: Providing straightforward and transparent details ensures that clients are well-informed about processes, expectations, and timelines.

- Empathy: Demonstrating genuine care and understanding can significantly enhance the client’s experience, making them feel valued and respected.

To further elevate the quality of interactions, consider the following practices:

- Regular follow-ups to address any outstanding questions or concerns.

- Utilizing feedback mechanisms to gather insights on client experiences.

- Training staff to ensure consistent and professional communication across all channels.

By focusing on these areas, establishments can cultivate a positive environment that encourages loyalty and fosters long-term relationships with clients.

Managing Inventory in Repair Shops

Efficient handling of stock is crucial for any establishment focused on fixing and maintaining equipment. A well-organized inventory system ensures that necessary components are readily available, reducing downtime and improving customer satisfaction. Proper management techniques not only streamline operations but also contribute to cost savings.

Key Strategies for Effective Inventory Management

- Regular Audits: Conducting frequent checks helps identify discrepancies and ensures that stock levels are accurate.

- Utilizing Software: Implementing inventory management software can automate tracking, making it easier to monitor stock levels and reorder when necessary.

- Establishing Supplier Relationships: Building strong connections with suppliers can lead to better pricing and quicker restocking.

- Forecasting Demand: Analyzing trends and historical data can assist in predicting future needs, helping to avoid overstocking or shortages.

Benefits of Effective Stock Control

- Improved operational efficiency.

- Enhanced customer satisfaction through timely service delivery.

- Reduction in holding costs associated with excess inventory.

- Increased visibility of stock levels, aiding in better decision-making.

In conclusion, mastering inventory management is vital for any establishment aiming for excellence in its field. By adopting strategic approaches, businesses can achieve significant improvements in their overall performance.

Training Staff for Service Excellence

Ensuring that employees are equipped with the necessary skills and knowledge is crucial for achieving outstanding performance in any establishment. A well-structured training program fosters a culture of excellence and enhances customer satisfaction.

Key Components of Effective Training

- Comprehensive Onboarding: New team members should undergo a thorough introduction to the organization’s values, objectives, and processes.

- Continuous Development: Ongoing training sessions should be provided to keep staff updated on best practices and emerging trends.

- Feedback Mechanisms: Regular feedback from both peers and management can help identify areas for improvement.

Benefits of Skilled Personnel

- Increased efficiency in operations.

- Enhanced customer loyalty and satisfaction.

- Higher employee morale and retention rates.

Investing in the growth of the workforce ultimately leads to superior performance and a stronger reputation within the community.