Exploring the rugged outdoors demands a well-prepared machine. Understanding essential upkeep for your off-road companion ensures it’s always ready for the challenges ahead. This guide focuses on essential insights into vehicle care, enhancing performance, and prolonging its lifespan.

In this article, you’ll find practical tips on maintaining mechanical efficiency, handling regular wear, and tackling the more complex adjustments required to keep everything in optimal condition. Whether you’re looking to make minor tweaks or prepare for more involved processes, these instructions will help you get started with confidence.

We’ll delve into the details of engine upkeep, suspension adjustments, and frame inspections, all with a focus on improving resilience and adaptability to any terrain. By understanding the ins and outs of maintenance, you’ll be better equipped to enjoy uninterrupted adventures and keep your machine in peak form.

Maintenance Guide for a High-Performance ATV

This section provides an overview of essential upkeep practices to ensure the longevity and efficiency of your all-terrain vehicle. By following regular maintenance routines, you can help keep the engine running smoothly, optimize fuel efficiency, and maintain safe operation under varying conditions.

Routine care involves checking key components, such as the powertrain, suspension, and brake systems, and addressing wear in a timely manner. Maintaining proper fluid levels, inspecting filters, and lubricating moving parts are all vital steps in preserving performance. Consistent checks and tune-ups not only support reliable operation but also prevent unexpected issues during rides.

For optimal care, it’s crucial to inspect the vehicle’s frame and joints for any signs of stress or corrosion, particularly after off-road excursions. Attention to these areas, alongside routine tire pressure checks, can enhance overall safety and handling, making each ride a smooth and enjoyable experience. Regular maintenance ensures that your vehicle remains in top shape, ready for any adventure.

Essential Tools for Servicing

To perform effective maintenance, having the right set of tools is crucial. These tools ensure each task is completed safely, efficiently, and with precision, minimizing potential issues. By understanding the primary equipment needed, you can prepare for various procedures and address any component or system adjustments confidently.

Basic Toolkit Essentials

A solid foundational toolkit is the backbone of any maintenance routine. These tools include standard items that are versatile and necessary for a range of tasks, from bolts and screws to minor adjustments. A good toolkit typically contains:

| Tool | Description |

|---|---|

| Socket Set | Helps in removing and tightening various types of fasteners, especially in hard-to-reach areas. |

| Torque Wrench | Ensures bolts are tightened to specific standards, preventing under- or over-tightening. |

| Screwdrivers (Flat and Phillips) | Useful for both major adjustments and smaller tasks requiring precision. |

Advanced Equipment

In addition to basic tools, certain specialized instruments can significantly improve efficiency, especially when handling more intricate procedures. Advanced tools not only save time but also improve the accuracy of each task. Examples include:

| ToolEngine Inspection and Care Tips

Regular engine check-ups are essential to maintain optimum performance and prevent potential issues from arising. Performing consistent and detailed inspections helps in identifying signs of wear or minor faults before they lead to larger, more complex problems. To keep the engine in top shape, consider the following tips:

By following these steps, you can enhance engine longevity and ensure reliable performance. Routine inspection not only protects the engine but also supports efficient and safe operation in various conditions. Suspension System TroubleshootingThe suspension system plays a crucial role in ensuring stability, comfort, and control during rides over varied terrains. When issues arise, addressing them promptly is essential to maintain optimal performance and safety. This section provides insights into identifying common issues in the suspension setup and offers methods to diagnose and rectify these challenges effectively. Uneven Ride Height If the ride height appears uneven, it may indicate a need to adjust or inspect the suspension springs or dampers. Start by checking the preload settings and ensure they are balanced. Adjust the settings according to specifications and re-evaluate the ride height. If the issue persists, the springs may be worn or damaged, requiring further inspection. Excessive Bouncing or Rebound Overly soft suspension or excessive rebound is often a sign of low damping. This can lead to a loss of control and increased wear on other components. Check the shock absorbers for leaks or damage. If no visible damage is present, consider adjusting the damping settings if possible. If adjustments don’t solve the problem, replacement might be necessary. Unstable Steering A wobbling or unstable steering feel is usually linked to the front suspension or steering components. Begin by examining the control arms, tie rods, and bushings for wear or damage. Tighten any loose components and test the steering response. In some cases, misaligned forks or uneven tire pressure can also contribute to instability. Suspension Noise If knocking or creakin Cooling System Maintenance GuideRegular maintenance of the cooling system ensures the engine runs at optimal temperatures, preventing overheating and enhancing performance. By following basic upkeep practices, you can prolong the system’s efficiency and avoid potential mechanical issues. Inspecting Coolant LevelsFrequent checks of the coolant level help prevent heat buildup, which can damage engine components. To do this, allow the engine to cool fully before opening the reservoir cap. Refill as necessary with a coolant mixture appropriate for the temperature conditions. Avoid overfilling, as this can lead to pressure imbalances within the system. Cleaning the Radiator and ComponentsThe radiator, hoses, and connections should be free from dirt and debris, which can reduce airflow and hinder cooling efficiency. Carefully clean the radiator with compressed air or water to remove buildup. Periodically inspect hoses for cracks or leaks and replace any damaged parts to maintain proper fluid circulation. By dedicating time to cooling system maintenance, you safeguard engine longevity and support consistent performance. Proper upkeep reduces the risk of heat-related malfunctions and maintains system stability. Battery Care and ReplacementProper maintenance and timely replacement of the power source are essential for the optimal functioning of your vehicle. A well-cared battery ensures reliability and longevity, preventing unexpected breakdowns. Understanding the signs of wear and knowing when to replace the unit can save you from inconvenient situations. Maintenance TipsRegular checks are crucial for maintaining battery health. Ensure the terminals are clean and free from corrosion, which can impede performance. Additionally, verify that the battery is securely fastened to avoid vibrations that may cause damage. Periodically check the water level in non-sealed batteries and top it up with distilled water when necessary. Replacement GuidelinesWhen it’s time to replace the battery, select a compatible unit that meets the specifications of your vehicle. Before removal, disconnect the negative terminal first, followed by the positive terminal to ensure safety. After installing the new battery, connect the positive terminal first and then the negative terminal. Always dispose of the old battery responsibly by taking it to a designated recycling center. Transmission Tuning TipsTuning the transmission of your all-terrain vehicle is crucial for optimizing performance and enhancing ride quality. Proper adjustments can lead to improved acceleration, smoother gear shifts, and better overall handling. This section provides valuable insights into effective tuning techniques to help you achieve optimal results. Adjusting Gear RatiosOne of the most impactful ways to enhance your vehicle’s performance is by adjusting the gear ratios. By fine-tuning these ratios, you can improve torque delivery and adjust the power band to suit specific riding conditions. Maintaining Fluid LevelsRegular maintenance of transmission fluid is essential for smooth operation. Ensure that the fluid is at the correct level and replace it periodically to prevent overheating and wear.

Exhaust System Cleaning and Upkeep

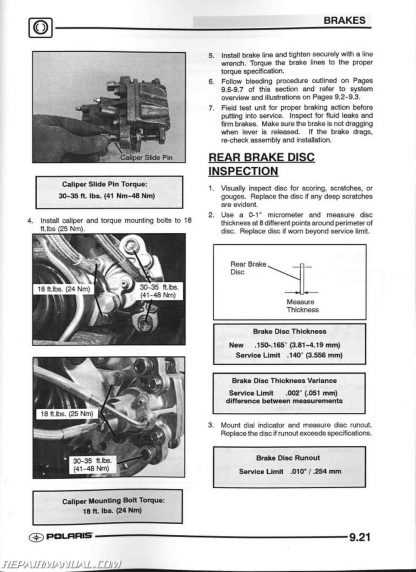

The exhaust system plays a crucial role in the overall performance and efficiency of your vehicle. Regular maintenance and cleaning of this component are essential to ensure optimal functioning and to prevent buildup that can lead to performance issues. This section will provide insights into effective practices for maintaining and cleaning the exhaust system. Routine Inspection: Begin with a thorough inspection of the exhaust system. Look for any signs of corrosion, leaks, or unusual noises. Pay attention to the condition of the pipes, muffler, and connections, as these can significantly affect performance if neglected. Cleaning Methods: Depending on the extent of dirt and debris buildup, various cleaning methods can be employed. For light cleaning, a mixture of soap and water can be used with a soft brush to gently scrub the surfaces. For tougher deposits, specialized exhaust cleaners may be necessary. Always follow the manufacturer’s guidelines for any cleaning products used. Checking for Blockages: Ensure there are no obstructions within the exhaust system. Blockages can cause back pressure, leading to engine inefficiency. Use a flashlight to inspect the interior of pipes and mufflers for any signs of blockage, such as soot or carbon buildup. Regular Maintenance: Establish a routine maintenance schedule to keep the exhaust system in top shape. This should include regular checks, cleanings, and immediate attention to any issues that arise. Consistent upkeep will prolong the life of the exhaust system and enhance the overall performance of your vehicle. Brake System Safety Checks

Ensuring the functionality of the braking mechanism is vital for safe operation. Regular inspections can help identify potential issues before they escalate into serious problems. This section outlines essential checks to maintain optimal performance and enhance safety. Visual Inspection

Functional Checks

By adhering to these safety checks, operators can significantly reduce the risk of brake failure and ensure a safe riding experience. Electrical Components InspectionThe examination of electrical parts is crucial for ensuring optimal functionality and safety of the vehicle. Regular assessments help identify potential issues before they escalate, maintaining performance and extending the lifespan of the system. During the inspection process, several key aspects should be addressed:

Following these guidelines will facilitate a thorough assessment of the electrical system, helping to prevent unexpected breakdowns and ensuring reliable operation. Fuel System Cleaning InstructionsMaintaining the cleanliness of the fuel system is essential for optimal performance and longevity of your vehicle. Regular cleaning helps prevent the buildup of deposits that can hinder fuel flow and affect the engine’s efficiency. This section outlines the steps necessary to effectively clean the fuel system. Preparation Steps

Cleaning Procedure

After completing these steps, monitor the vehicle’s performance for any improvements in fuel efficiency and responsiveness. Regular maintenance will help extend the life of your fuel system components. Regular Lubrication and Greasing

Proper maintenance of your off-road vehicle involves routine application of lubricants to ensure optimal performance and longevity. Regular greasing is essential to minimize friction between moving parts, reduce wear, and prevent rust and corrosion. To maintain the efficiency of your machine, follow these key practices:

Additionally, consider these tips for effective lubrication:

By adhering to these lubrication practices, you will enhance the performance and lifespan of your vehicle, ensuring it remains in peak condition for all your adventures. |

|---|