In the realm of heavy machinery, ensuring optimal performance and longevity is essential for any operator. This section delves into the critical aspects of upkeep and diagnostics, aimed at enhancing the functionality of your equipment. A well-structured approach to maintenance not only extends the lifespan of the machinery but also maximizes its efficiency on the job site.

Understanding the intricate details of your equipment is crucial for addressing potential issues effectively. This guide provides insights into various procedures, from routine checks to more complex troubleshooting techniques. By familiarizing yourself with these practices, you can proactively manage and resolve challenges, ensuring that your machinery operates at its best.

With a focus on clarity and accessibility, this resource is designed to empower operators and technicians alike. The structured information will assist in navigating common concerns and facilitate informed decision-making during maintenance tasks. By following the recommendations outlined herein, you can achieve greater reliability and performance from your machinery.

Understanding Bobcat T190 Overview

This section provides an insight into a compact and versatile machine designed for various tasks in construction and landscaping. Its robust structure and efficient operation make it suitable for both professional and DIY enthusiasts. Key features and specifications are essential for anyone looking to maximize the benefits of this equipment.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a high-performance engine, ensuring reliable power delivery. |

| Hydraulic System | Advanced hydraulic capabilities for optimal lifting and digging performance. |

| Operator Comfort | Ergonomic design with user-friendly controls for enhanced operator experience. |

| Versatility | Compatible with a range of attachments for various applications. |

| Size | Compact dimensions allow for easy maneuverability in tight spaces. |

Common Issues with T190 Models

In the realm of compact machinery, certain models can experience recurring challenges that affect their performance and longevity. Understanding these typical complications can aid operators in identifying symptoms early and taking appropriate action to maintain optimal functionality.

Hydraulic System Concerns

One of the most frequently reported difficulties involves the hydraulic system. Operators may notice reduced lifting capabilities or sluggish movement, often attributed to fluid leaks or contamination. Regular checks and maintenance of the hydraulic fluid levels and components are crucial to prevent further complications.

Engine Performance Problems

Engine-related issues can manifest as unusual noises, difficulty starting, or inconsistent power delivery. These symptoms might stem from fuel supply problems or air filter obstructions. Regular inspections and timely replacements of filters and fuel lines can significantly mitigate these issues.

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Reduced Hydraulic Power | Fluid Leak or Contamination | Inspect and replace fluid; check for leaks. |

| Engine Noise | Fuel Supply Issues | Check fuel lines and filters; replace as needed. |

| Difficulty Starting | Air Filter Blockage | Inspect and clean or replace air filter. |

Essential Tools for Repairs

When undertaking maintenance tasks, having the right instruments is crucial for efficiency and effectiveness. Proper equipment not only facilitates the job but also enhances safety and accuracy, allowing for thorough inspections and modifications.

Among the basic implements, a wrench set is indispensable, offering various sizes to accommodate different fasteners. Equally important is a screwdriver kit, which provides a range of heads for handling various screws, ensuring that components can be easily accessed and secured.

For more specialized tasks, a multimeter is invaluable, enabling users to measure electrical properties, diagnose issues, and ensure optimal functionality. Additionally, having a socket set allows for quick and efficient tightening or loosening of nuts and bolts in tight spaces.

Safety gear, such as gloves and safety glasses, should never be overlooked. These items protect against potential hazards while working, ensuring that maintenance can be performed with peace of mind.

Investing in high-quality tools will not only prolong their lifespan but also enhance the overall effectiveness of the maintenance process. With the right equipment at hand, tasks become more manageable, leading to successful outcomes and well-functioning machinery.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By adhering to systematic procedures, operators can prevent unexpected failures and maintain the machinery in peak condition. This section outlines detailed steps to guide users through essential maintenance tasks, promoting efficiency and reliability.

Daily Checks

Initiating each operational day with thorough inspections is crucial. Verify fluid levels, including hydraulic oil and coolant, to ensure proper functioning. Additionally, examine the exterior for any signs of wear or damage, and inspect the tracks and wheels for debris that may affect mobility.

Periodic Servicing

Scheduled maintenance is vital for long-term performance. Replace air filters at regular intervals to guarantee clean airflow to the engine. Furthermore, check and clean the radiator to prevent overheating. These tasks contribute significantly to the reliability of the equipment.

Engine Troubleshooting Tips

Troubleshooting engine issues can be a daunting task, but a systematic approach can simplify the process. Identifying symptoms and understanding their causes is essential for efficient problem resolution. This guide offers practical suggestions to diagnose and address common engine malfunctions.

Common Symptoms and Their Solutions

When facing performance issues, look for signs such as unusual noises, decreased power, or irregular idling. These symptoms often indicate underlying problems. For instance, if you notice strange sounds, check the fluid levels and listen for signs of wear in engine components. Regular maintenance is crucial to prevent these issues from escalating.

Diagnostic Procedures

Utilizing diagnostic tools can greatly enhance your troubleshooting efforts. Start by examining error codes with a scanner, which can provide valuable insights into specific malfunctions. Additionally, inspect connections and wiring for any visible damage. Conducting thorough checks on filters and fluids can also reveal potential sources of trouble. Remember, a proactive approach often leads to quicker resolutions.

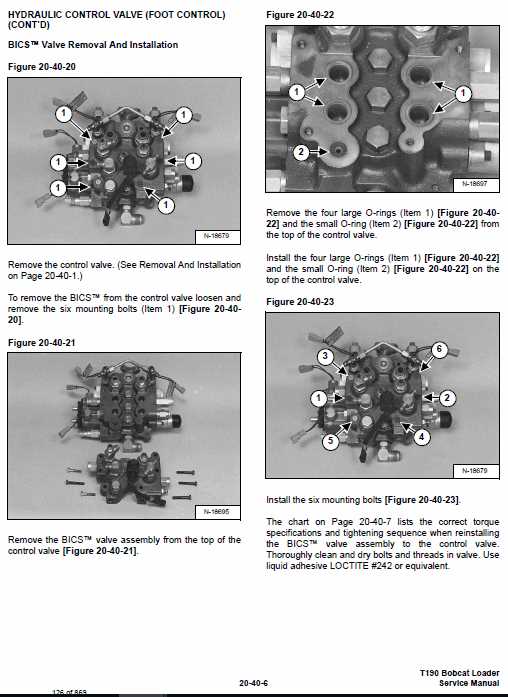

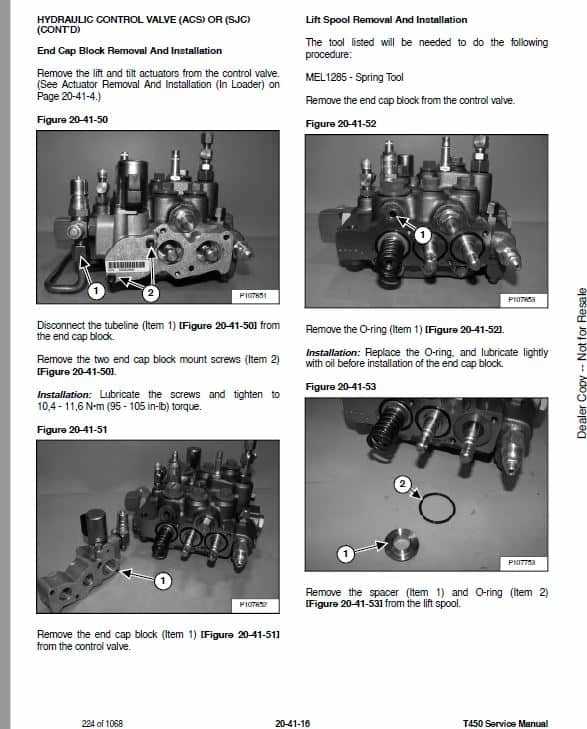

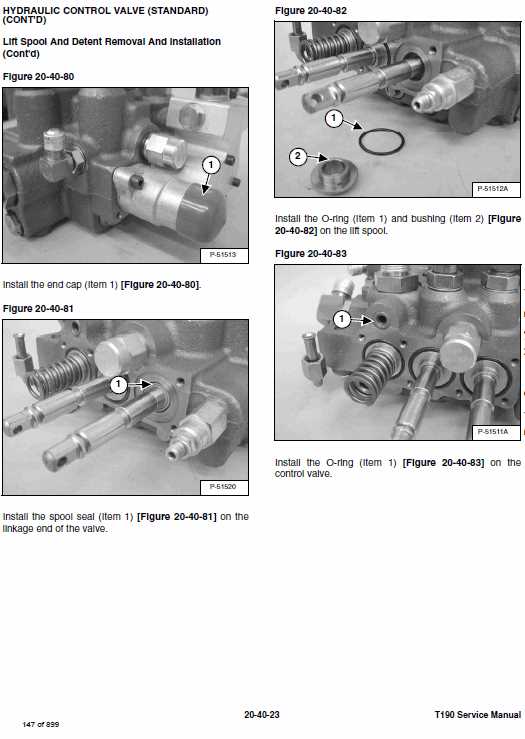

Hydraulic System Checks and Repairs

The functionality of hydraulic systems is vital for the efficient operation of machinery. Regular inspections and maintenance of these systems ensure optimal performance and longevity. Understanding the various components involved, along with effective troubleshooting techniques, is essential for addressing any issues that may arise.

Visual Inspection is the first step in evaluating the hydraulic system. Look for signs of leaks, cracks, or damaged hoses. Pay close attention to connections and fittings, as these are common points for potential failures. Any visible damage should be addressed promptly to prevent further complications.

Fluid Levels and Quality must be checked regularly. The hydraulic fluid plays a crucial role in system performance, so ensure it is at the appropriate level and in good condition. Contaminated or degraded fluid can lead to inefficiencies and system failure. If the fluid appears cloudy or discolored, consider replacing it and flushing the system to eliminate any debris.

Pressure Tests are essential for assessing the health of the hydraulic system. Using a pressure gauge, monitor the readings while the system is under load. If the pressure is lower than specified, it may indicate a leak or a failing pump. Conversely, excessively high pressure can signal blockages or malfunctioning components that need immediate attention.

Component Testing should also be conducted on key parts such as pumps, valves, and cylinders. Each component can be tested individually to identify any faults. For instance, check the pump’s operation to ensure it is providing the necessary flow and pressure. Valves must function correctly to direct fluid, while cylinders should extend and retract smoothly without any resistance.

In conclusion, thorough inspections and timely interventions can significantly enhance the reliability and performance of hydraulic systems. By implementing a systematic approach to maintenance, operators can prevent costly breakdowns and ensure the machinery operates efficiently.

Electrical System Diagnostics Explained

The effective evaluation of electrical systems is essential for maintaining optimal functionality in machinery. This process involves systematically identifying faults and ensuring all components operate within their designated parameters. Understanding the intricacies of this evaluation can lead to enhanced performance and longevity of the equipment.

During diagnostics, various tools and techniques are employed to analyze electrical components, circuit integrity, and overall system health. A structured approach helps in pinpointing issues that may arise from wear and tear, electrical interference, or component failures.

| Component | Diagnostic Tool | Purpose |

|---|---|---|

| Batteries | Multimeter | Check voltage and current output |

| Wiring | Continuity Tester | Ensure no breaks or shorts in the circuit |

| Connectors | Visual Inspection | Identify corrosion or loose connections |

| Sensors | Diagnostic Scanner | Read sensor data and error codes |

| Relays | Relay Tester | Test functionality and response time |

Utilizing these tools and methods effectively can lead to quicker identification of issues, minimizing downtime and enhancing productivity. Regular diagnostics not only aid in troubleshooting but also contribute to proactive maintenance strategies, ensuring sustained operational efficiency.

Parts Replacement Guidelines

This section provides essential instructions for effectively substituting components within your equipment. Understanding the proper methods and precautions can enhance performance and extend the lifespan of machinery.

General Recommendations

- Always refer to the manufacturer’s specifications for compatible parts.

- Ensure you have the necessary tools before starting any replacement procedure.

- Prioritize safety by wearing appropriate protective gear.

- Work in a clean environment to prevent contamination of parts.

Replacement Steps

- Identify the component that requires substitution.

- Disconnect any power sources to ensure safety.

- Carefully remove the faulty part, taking note of how it is installed.

- Install the new component, following the reverse order of removal.

- Reconnect power sources and test the equipment to verify proper functionality.

Preventive Maintenance Best Practices

Implementing regular upkeep is essential for enhancing equipment longevity and performance. By adhering to established routines, operators can prevent potential issues before they escalate, ensuring that machinery operates smoothly and efficiently.

Key Strategies for Effective Upkeep

- Regular Inspections: Conduct frequent checks to identify wear and tear. This includes examining critical components such as hydraulic systems and engine parts.

- Fluid Management: Monitor and replace fluids as recommended. Keeping hydraulic fluid, oil, and coolant at appropriate levels prevents overheating and reduces friction.

- Cleanliness: Maintain cleanliness by removing debris and contaminants from machinery surfaces. This practice can significantly improve performance and reduce the risk of failure.

Scheduled Maintenance Tasks

- Daily Checks: Inspect for leaks, unusual noises, and operational efficiency. Ensure all controls function properly.

- Weekly Maintenance: Tighten loose bolts and fittings, and clean filters to maintain airflow and fluid flow.

- Monthly Procedures: Replace air and fuel filters and perform a thorough inspection of the undercarriage and attachment systems.

Identifying Wear and Tear Signs

Recognizing the indicators of deterioration is crucial for maintaining equipment functionality and safety. Regular inspections can help prevent more extensive issues, ensuring optimal performance over time.

Several key signs can indicate that components are experiencing excessive wear. Below is a summary of these indicators and their implications:

| Indicator | Description | Possible Consequences |

|---|---|---|

| Cracks | Visible fractures on surfaces or joints. | Structural failure or decreased stability. |

| Discoloration | Changes in color due to heat or chemical exposure. | Potential loss of material integrity. |

| Excessive play | Looseness in moving parts or joints. | Decreased precision and control. |

| Unusual noises | Sounds such as grinding, squeaking, or rattling. | Indication of component failure or misalignment. |

| Leaks | Fluid escaping from seals or joints. | Loss of operational efficiency and potential damage. |

Monitoring these signs regularly can help in addressing issues promptly, extending the lifespan of the machinery and ensuring safe operation.

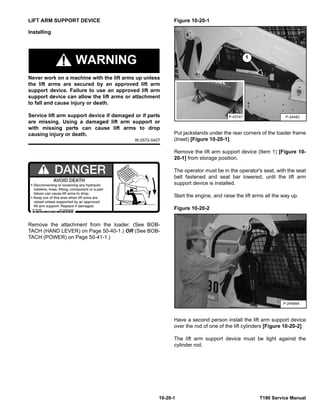

Safety Protocols During Repairs

When undertaking maintenance tasks, adhering to established safety measures is crucial for ensuring the well-being of both personnel and equipment. Proper precautions minimize the risk of accidents and injuries, facilitating a smoother and more efficient workflow.

1. Personal Protective Equipment (PPE)

Utilizing appropriate protective gear is essential. Always wear gloves, safety goggles, and steel-toed boots to shield against potential hazards. Depending on the nature of the task, additional gear such as ear protection or respirators may be required.

2. Workspace Organization

Keep the area tidy and free of clutter. Ensure that tools are organized and stored properly to prevent tripping hazards. A clean environment not only promotes safety but also enhances productivity.

3. Equipment Inspection

Before commencing any task, inspect the machinery for any signs of wear or damage. Identifying issues beforehand can prevent accidents and facilitate timely repairs. Ensure that all safety features are functioning correctly.

4. Proper Tool Usage

Always use tools that are appropriate for the task at hand. Familiarize yourself with the operational guidelines and ensure that tools are maintained in good condition. This practice reduces the likelihood of malfunction or injury.

5. Emergency Procedures

Be aware of emergency protocols and locations of first aid kits and fire extinguishers. Having a clear plan in place allows for swift action in case of an unexpected incident, ensuring the safety of all personnel involved.

Resourceful Repair Manuals and Guides

When it comes to maintaining and troubleshooting machinery, having access to comprehensive reference materials can be invaluable. These documents provide detailed instructions, diagrams, and tips that empower users to address issues effectively and enhance performance. Utilizing these resources not only saves time and money but also fosters a deeper understanding of the equipment’s mechanics.

Among the various types of resources available, some stand out due to their clarity and thoroughness. Below is a comparison of different types of guides that can assist in this endeavor:

| Type of Resource | Description | Benefits |

|---|---|---|

| Online Guides | Accessible documentation available on the web, often updated regularly. | Convenient access, often includes videos and user feedback. |

| Printed Manuals | Traditional hard copies that provide detailed illustrations and instructions. | Reliable offline access, easy to annotate and reference. |

| Community Forums | Platforms where users share experiences, solutions, and tips. | Real-world insights and support from fellow users. |

| Video Tutorials | Step-by-step visual guides that demonstrate various tasks. | Engaging format that caters to visual learners, showing techniques in action. |

By leveraging these diverse materials, users can effectively navigate challenges and maintain their equipment in optimal condition, ensuring longevity and reliability in performance.

Contacting Professional Service Technicians

When facing challenges with your machinery, reaching out to skilled technicians can be crucial for ensuring optimal performance. These experts possess the necessary knowledge and experience to diagnose and address various issues efficiently. Their proficiency can save time and prevent further complications, providing peace of mind to operators.

Identifying the Right Technician is essential. Look for professionals with a solid reputation in the industry. Reviews and recommendations from other users can guide you in selecting a qualified individual or service team. Additionally, consider their availability and responsiveness to ensure timely assistance.

Communicating Effectively with technicians is vital for a successful resolution. Clearly describe the symptoms and issues you’re encountering, providing as much detail as possible. This information will aid in diagnosing the problem accurately, allowing for a more effective solution. Don’t hesitate to ask questions about the process and expected outcomes to ensure you understand the necessary steps.

In summary, collaborating with qualified technicians can enhance the longevity and functionality of your equipment. By choosing the right professionals and maintaining clear communication, you can achieve satisfactory results and ensure your machinery operates smoothly.