In the realm of heavy machinery, ensuring optimal functionality is paramount. This section delves into the intricacies of maintaining vital industrial equipment, offering insights that empower operators and technicians alike. By understanding the nuances of upkeep, one can extend the lifespan of their machinery and enhance overall performance.

Comprehensive knowledge is crucial for tackling various challenges that may arise during the operation of complex equipment. From troubleshooting issues to implementing preventative measures, a thorough grasp of maintenance practices is essential. This guide aims to equip users with the necessary skills and information to address any mechanical concerns effectively.

In addition, the importance of adhering to established guidelines cannot be overstated. Following structured protocols not only minimizes downtime but also ensures safety for all personnel involved. By prioritizing proper techniques and resources, operators can achieve greater efficiency and reliability in their day-to-day operations.

Understanding Yale Forklifts

This section delves into the essential characteristics and features of a leading brand in the material handling industry. By exploring various aspects, users can gain a deeper appreciation for the machinery that enhances productivity and efficiency in various settings.

When considering such equipment, several key factors should be taken into account:

- Design and Build Quality: The robust construction ensures durability and reliability under heavy loads.

- Performance: These machines are engineered for optimal performance, capable of handling diverse tasks with ease.

- Technology Integration: Advanced technological features improve operation and monitoring capabilities.

- Safety Features: Built-in safety mechanisms help prevent accidents and ensure operator protection.

Understanding these elements is crucial for selecting the right equipment that meets specific operational needs. Users should also consider:

- Maintenance: Regular upkeep is vital for extending the lifespan of the machinery.

- Training: Proper training for operators maximizes efficiency and minimizes risks.

- Support Services: Access to reliable service and support can greatly enhance operational success.

In summary, recognizing the advantages and features of this type of equipment leads to more informed decisions and better performance in various industries.

Importance of Repair Manuals

Documentation that outlines maintenance procedures and troubleshooting steps is essential for ensuring the longevity and efficiency of machinery. Such resources empower operators and technicians with the knowledge needed to address issues swiftly, minimizing downtime and maximizing productivity. Clear instructions help in performing tasks correctly, which can prevent further complications and extend the life of the equipment.

Benefits of Comprehensive Documentation

Having access to detailed guides enhances the ability to conduct proper maintenance. Here are some key advantages:

| Advantage | Description |

|---|---|

| Time Efficiency | Quick reference helps technicians resolve problems faster. |

| Cost Savings | Preventive measures outlined can reduce the need for costly repairs. |

| Enhanced Safety | Guidelines promote safe practices during maintenance and operation. |

Conclusion

Overall, having a reliable resource for maintenance guidance is invaluable. It not only fosters better understanding and skill development but also creates a more efficient and safer working environment.

Common Forklift Issues

In any industrial setting, operational challenges with heavy lifting machinery are inevitable. Understanding the frequent complications that arise can significantly enhance efficiency and safety. Below, we explore several prevalent problems encountered in the use of such equipment.

Hydraulic System Failures: A malfunctioning hydraulic system is often a primary concern. This can manifest as slow or unresponsive lifting actions, indicating potential leaks or pump issues. Regular checks are crucial to maintain optimal performance.

Battery Troubles: Electrical power sources may experience difficulties, leading to reduced operational time or failure to start. Inspecting connections and ensuring adequate charge levels can prevent these setbacks.

Tire Wear: The condition of the wheels plays a vital role in stability and maneuverability. Uneven or excessive wear can result in compromised handling. Regular inspections can help identify when replacement is necessary.

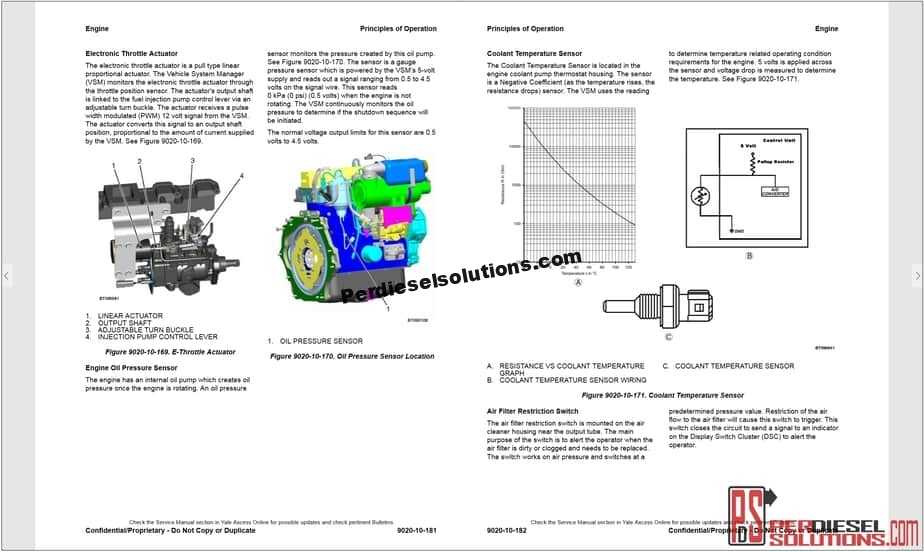

Engine Performance Issues: In combustion-powered units, issues such as rough idling or stalling can arise. These symptoms may point to fuel system blockages or ignition troubles. Routine maintenance is essential to keep engines running smoothly.

Operational Error Indicators: Warning lights or beeping sounds often signal underlying problems. Being attentive to these alerts can aid in early diagnosis, potentially avoiding more serious damage.

By being aware of these common complications, operators can take proactive steps to mitigate risks and ensure a safe working environment.

Diagnostic Procedures Explained

Effective troubleshooting is essential for maintaining the efficiency and safety of heavy machinery. This section outlines systematic approaches that help identify and rectify issues, ensuring optimal performance. By following structured methods, operators can minimize downtime and enhance productivity.

The diagnostic process typically involves a series of steps designed to isolate the problem. Each step requires careful observation and assessment, leading to informed decisions regarding repairs or adjustments. The following table summarizes common diagnostic techniques and their applications:

| Technique | Description | Application |

|---|---|---|

| Visual Inspection | Examining components for wear, damage, or misalignment. | Initial assessment to identify obvious issues. |

| Functional Testing | Operating the machine to observe its behavior under load. | Determines operational integrity and reveals performance issues. |

| Error Code Retrieval | Accessing the control system to retrieve diagnostic codes. | Identifies specific faults indicated by the system. |

| Component Testing | Testing individual parts with specialized equipment. | Validates the functionality of critical components. |

By employing these techniques, technicians can efficiently diagnose problems, leading to effective solutions that restore equipment to its full operational capacity.

Maintenance Tips for Longevity

Ensuring the longevity of your industrial vehicle requires a dedicated approach to upkeep and care. Regular maintenance not only enhances performance but also extends the lifespan of the equipment. Below are essential tips to help you maintain optimal condition over time.

- Perform routine inspections to identify wear and tear early.

- Keep the vehicle clean to prevent dirt buildup, which can lead to mechanical issues.

- Check fluid levels regularly, including hydraulic fluid, oil, and coolant.

- Monitor tire pressure and tread condition to ensure proper traction and stability.

Following a structured maintenance schedule can significantly reduce the risk of unexpected breakdowns.

- Schedule monthly comprehensive checks to assess all vital components.

- Replace filters and fluids according to the manufacturer’s recommendations.

- Lubricate moving parts frequently to minimize friction and wear.

- Train operators on proper usage techniques to prevent unnecessary strain on the machinery.

Implementing these strategies will not only enhance performance but also safeguard your investment in the long term.

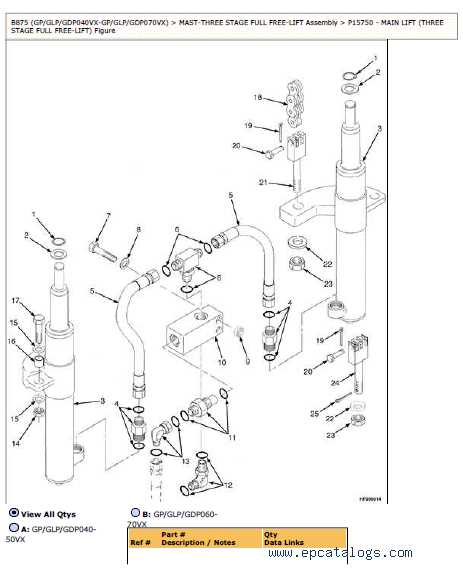

Components of Yale Forklifts

This section explores the essential parts that contribute to the functionality and efficiency of these material handling machines. Understanding these elements is crucial for effective operation and maintenance.

Key Elements

- Chassis: The robust frame that provides stability and support.

- Powertrain: The system responsible for propelling the equipment, typically including the engine and transmission.

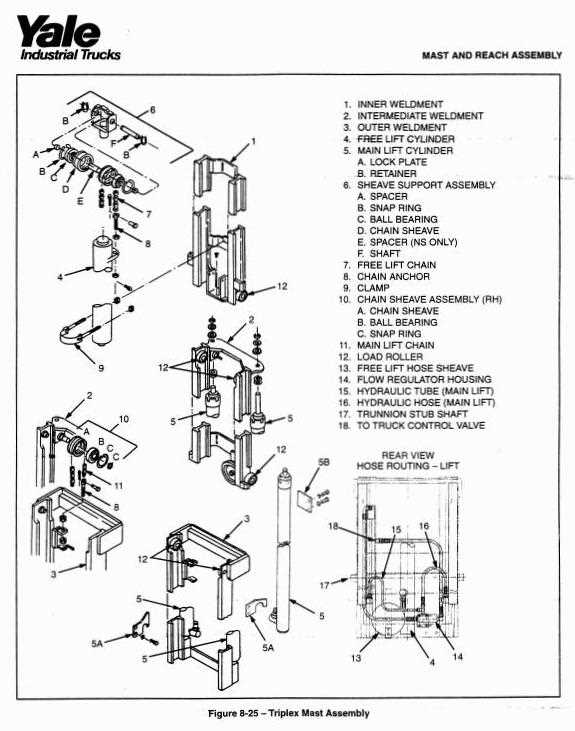

- Hydraulic System: This system facilitates lifting and lowering operations through fluid power.

- Steering Mechanism: Allows for maneuverability, enabling precise control in tight spaces.

- Lift Assembly: Comprising the mast and forks, this component is crucial for handling loads.

Safety Features

- Stability Mechanisms: Enhances balance to prevent tipping during operation.

- Operator Restraint Systems: Designed to secure the operator in place for safety.

- Lighting: Provides visibility in low-light conditions, ensuring safe operation.

- Warning Signals: Alerts nearby personnel to the movement of the equipment.

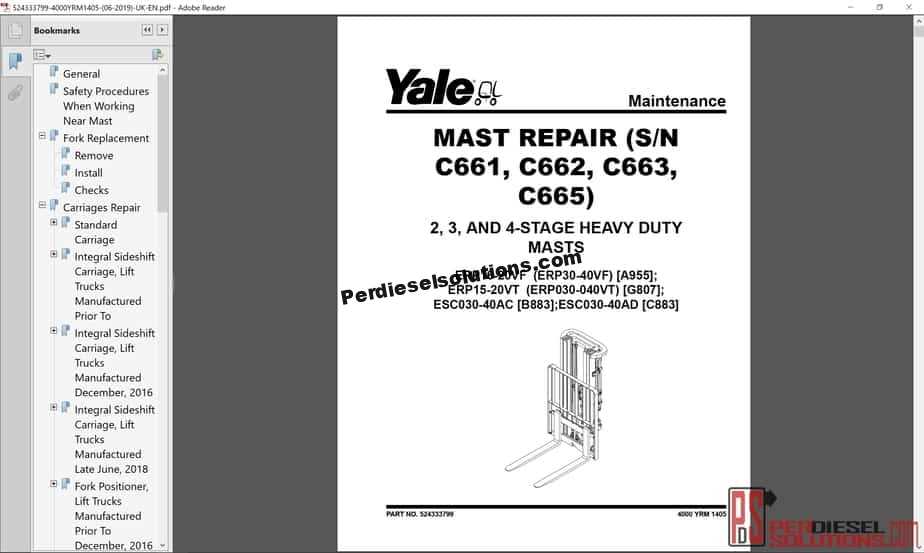

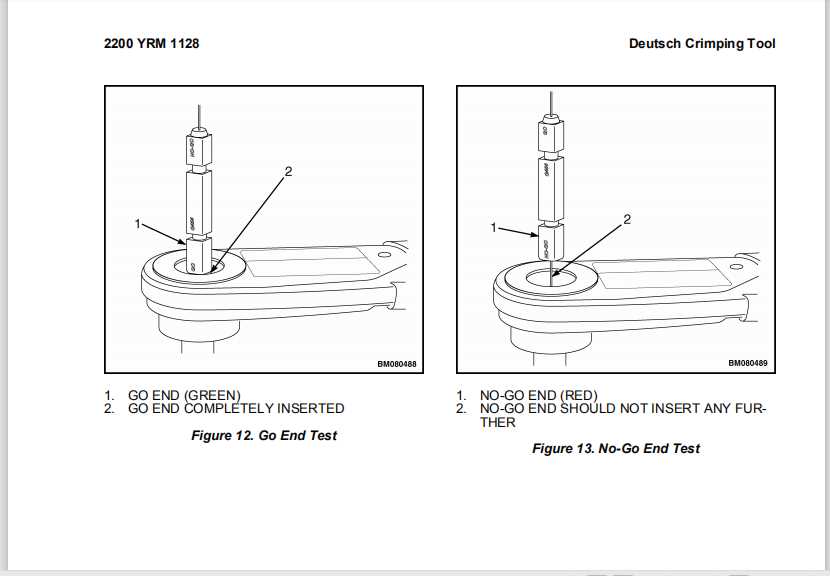

Step-by-Step Repair Guidance

This section provides a detailed approach to addressing mechanical issues effectively and systematically. By following these structured steps, you can ensure a thorough diagnosis and resolution of any challenges that may arise, ultimately enhancing the longevity and performance of your equipment.

Initial Assessment

Begin by conducting a comprehensive evaluation of the equipment. Look for any visible signs of wear or damage, and listen for unusual sounds during operation. Document any discrepancies to have a clear understanding of the problems that need addressing.

Tools and Techniques

Gather all necessary tools and materials before starting the work. This includes wrenches, screwdrivers, lubricants, and replacement parts. Follow the recommended techniques for disassembly and reassembly, ensuring that each component is handled with care to avoid further complications.

Safety Protocols During Repairs

Ensuring a secure environment is paramount when addressing maintenance tasks on heavy machinery. Adhering to established safety measures not only protects personnel but also enhances the overall effectiveness of the service process. A structured approach can significantly minimize the risk of accidents and injuries.

Before commencing any maintenance work, it is crucial to conduct a thorough assessment of the workspace. This includes verifying that all tools are in proper condition and that the area is free from hazards. Clear pathways and adequate lighting are essential for safe operations.

Personal protective equipment (PPE) must be worn at all times. This includes gloves, safety goggles, and appropriate footwear. Each piece of equipment plays a vital role in safeguarding against potential injuries from falling objects or sharp components.

Communication among team members is equally important. Establishing clear signals and guidelines can prevent misunderstandings and ensure everyone is aware of their surroundings during the task. Regular briefings can help reinforce these protocols.

Finally, ensuring that all machinery is properly shut down and isolated from power sources is a non-negotiable step. Lockout/tagout procedures should always be implemented to guarantee that no accidental operation occurs while maintenance is underway.

Finding Replacement Parts

Locating suitable components for machinery maintenance is crucial for ensuring optimal performance and longevity. Whether you’re dealing with a minor issue or a significant overhaul, sourcing the right parts can make all the difference. This section will guide you through effective strategies for finding high-quality replacements that meet your specific needs.

Identifying Compatible Components

Before you begin your search, it’s essential to identify the exact components required for your equipment. Refer to the specifications or documentation related to your machine to determine the model and part numbers. This information will streamline the process and help you avoid purchasing incorrect items.

Utilizing Reliable Sources

Once you have the necessary details, explore various sources for your components. Online marketplaces, specialized suppliers, and local distributors often carry a wide range of products. It’s beneficial to compare prices and check reviews to ensure the credibility of the source. Additionally, consider reaching out to manufacturers directly, as they can provide insights into the best options available.

Remember to evaluate the warranty and return policy of the parts you purchase. Investing in quality components not only improves performance but also enhances safety and reliability in the long run.

Utilizing Online Resources Effectively

In today’s digital age, harnessing the power of online tools can significantly enhance problem-solving and maintenance tasks. Leveraging the wealth of information available can streamline processes, improve efficiency, and support informed decision-making.

Identifying Reliable Sources

When searching for guidance, it’s crucial to distinguish between credible and unreliable resources. Consider the following tips:

- Look for official websites or well-known organizations in the industry.

- Check for user reviews and ratings of the information provided.

- Verify the qualifications of the authors or contributors.

Utilizing Online Communities

Engaging with online forums and communities can be invaluable for sharing experiences and solutions. Here’s how to make the most of these platforms:

- Participate actively in discussions to gain insights and advice.

- Share your own experiences to help others in similar situations.

- Network with professionals to expand your knowledge and resources.

By applying these strategies, individuals can navigate the vast sea of information available online, ensuring they access valuable and practical assistance for their needs.