In the world of mechanical devices, ensuring optimal performance often requires thorough understanding and precise intervention. This section offers insights into the processes involved in maintaining and rejuvenating essential electrical components, focusing on methods that enhance functionality and longevity.

Detailed exploration of troubleshooting techniques and practical steps will empower individuals to diagnose issues effectively. By engaging with the intricacies of these systems, users can foster a deeper connection with their equipment, ensuring it operates smoothly and efficiently.

Whether for personal projects or professional endeavors, mastering the art of component rejuvenation can lead to significant improvements. This resource aims to equip enthusiasts with the necessary knowledge and skills to tackle challenges confidently, fostering a culture of innovation and sustainability.

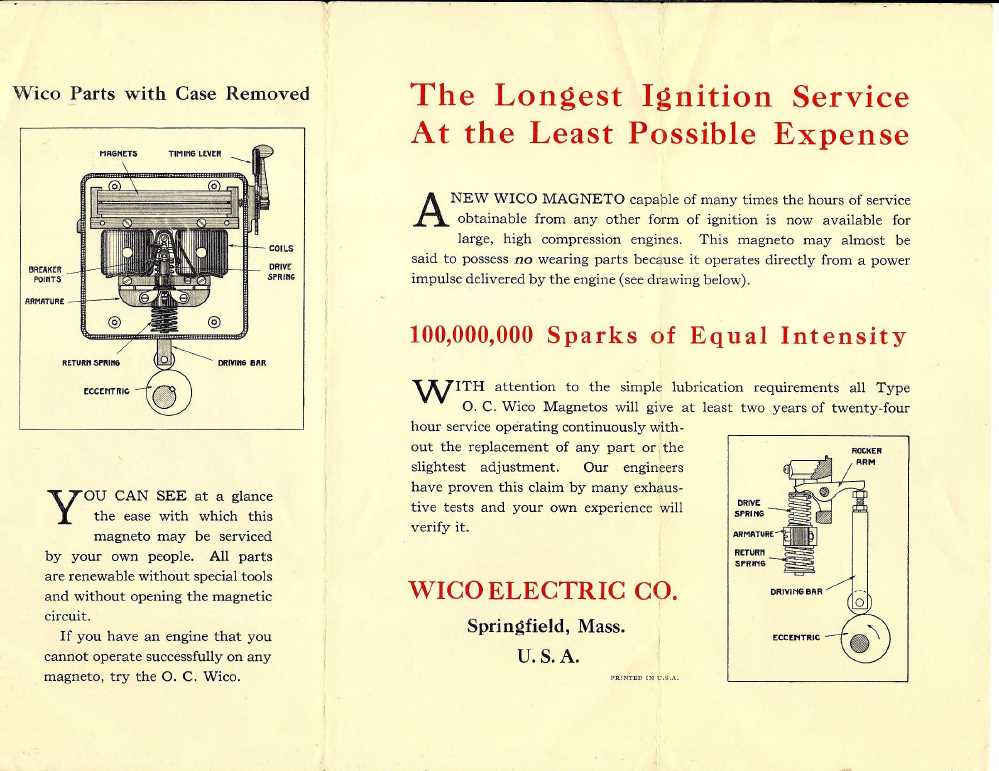

Understanding Wico Magneto Basics

This section explores fundamental concepts related to a specific type of electrical device commonly used for ignition purposes in various machinery. These units are essential for generating the necessary voltage to ignite fuel, ensuring efficient engine operation.

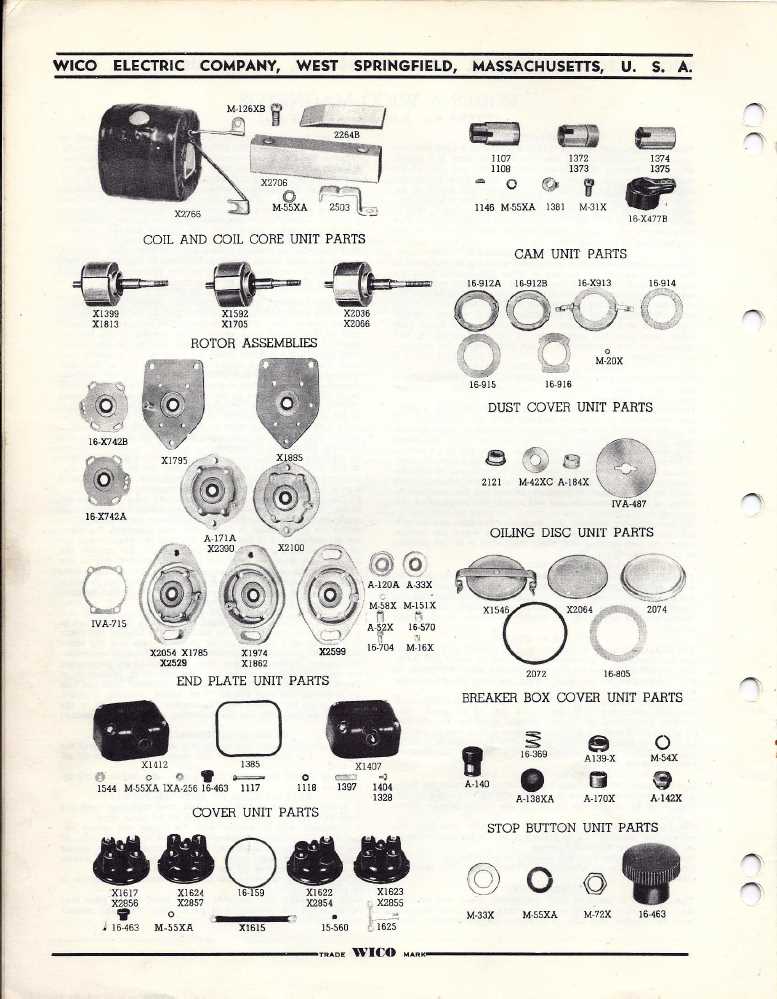

Key Components

The functioning of this device relies on several critical elements:

- Coil: The primary component responsible for voltage generation.

- Capacitor: Stores electrical energy to enhance ignition performance.

- Points: Act as a switch to control the timing of electrical discharge.

- Housing: Provides protection and support for internal components.

Operating Principles

Understanding how this apparatus operates involves recognizing its primary functions:

- As the engine runs, mechanical energy is converted into electrical energy.

- The coil generates a high-voltage pulse when the points open.

- This pulse travels to the ignition system, igniting the fuel mixture.

By grasping these basics, users can better appreciate the significance of maintenance and troubleshooting for optimal performance.

Common Issues with Wico Magnetos

In the realm of ignition systems, several challenges can arise, impacting performance and functionality. Understanding these frequent complications can assist in diagnosing problems and ensuring optimal operation.

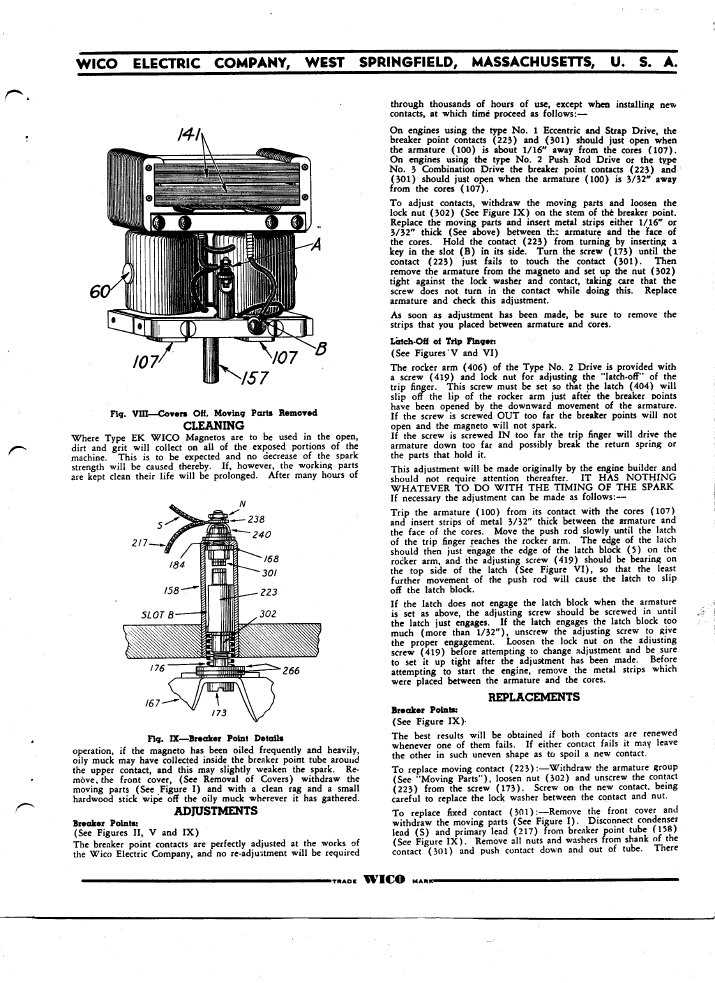

Insufficient Spark Production: A prevalent issue is inadequate spark generation, which can stem from various factors, including worn components or improper adjustments. This condition often leads to difficulty in starting the engine or inconsistent performance.

Corrosion and Debris Accumulation: Environmental factors can lead to the buildup of corrosion and debris, obstructing electrical connections. Regular cleaning and maintenance can help prevent these issues and maintain reliable functionality.

Faulty Wiring Connections: Loose or damaged wiring can disrupt the electrical flow, causing erratic behavior in the ignition system. It is crucial to inspect connections for signs of wear or damage to ensure a stable operation.

Timing Misalignment: Accurate timing is essential for efficient ignition. Any misalignment can result in backfiring or poor engine performance. Regular checks and adjustments are necessary to keep the timing in sync.

By addressing these common complications, users can enhance the reliability and efficiency of their ignition systems, ensuring better overall performance.

Tools Required for Repairing Magnetos

Having the right instruments is essential for effectively working on ignition systems. This section outlines the necessary equipment to ensure a successful process, providing clarity and efficiency while addressing common issues.

Essential Instruments

To start, you’ll need a selection of basic tools. These will aid in disassembling components, testing functionality, and making precise adjustments. Each item plays a crucial role in achieving optimal performance.

Specialized Equipment

In addition to general tools, certain specialized devices can enhance your capabilities. These tools are designed for specific tasks, offering increased accuracy and convenience during the maintenance process.

| Tool | Description |

|---|---|

| Screwdriver Set | Various sizes for removing screws from different components. |

| Multimeter | For measuring voltage and checking electrical continuity. |

| Torque Wrench | Ensures fasteners are tightened to specified levels. |

| Wire Strippers | For preparing wires for connections. |

| Timing Light | To check and adjust ignition timing accurately. |

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring functionality to your ignition device. Following these detailed steps will help ensure that each component is assessed and serviced effectively, leading to optimal performance.

-

Begin by disconnecting the power source to ensure safety during the inspection process.

-

Carefully remove the outer casing to gain access to internal components.

-

Inspect the wiring and connections for any signs of wear or damage.

- Look for frayed wires or loose connections.

- Replace any damaged components as necessary.

-

Examine the primary and secondary coils for continuity.

- Use a multimeter to check resistance levels.

- Replace coils that do not meet specifications.

-

Assess the condenser and ensure it is functioning properly.

- Check for leakage or other signs of failure.

- Replace if needed to restore efficiency.

-

Clean all components, removing dirt and debris that may affect performance.

-

Reassemble the unit carefully, ensuring all parts fit securely.

-

Reconnect the power source and conduct a test run to verify functionality.

By adhering to this structured approach, you can effectively restore your ignition device, ensuring it operates reliably and efficiently.

Testing Magneto Functionality

Assessing the performance of an electrical generating unit is crucial to ensure its efficiency and reliability. This process involves a series of evaluations that help identify any issues that may hinder its operation. Understanding how to perform these checks can prevent unexpected failures and maintain optimal functionality.

Initial Inspection

Begin by examining the unit for any visible signs of wear or damage. Look for cracks, loose connections, or corrosion that may affect performance. Ensure that all components are securely attached and that there are no foreign objects obstructing movement.

Functional Testing

Once the initial inspection is complete, proceed to functional tests. Using a multimeter, measure the output voltage to confirm it meets specified standards. If the voltage is lower than expected, further investigation into the coil condition and other internal components may be necessary. Regular testing is essential for maintaining reliability and performance.

Identifying Component Failures

Recognizing issues within electrical assemblies is crucial for restoring functionality. Understanding the signs of malfunction helps in diagnosing problems effectively, leading to a successful troubleshooting process.

Common Symptoms of Malfunction

Various indicators may suggest that a component is not operating as intended. Symptoms can include inconsistent performance, unusual noises, or complete failure to function. Paying attention to these signs is essential for timely intervention.

Diagnostic Techniques

Employing systematic testing methods can assist in pinpointing the root of the issue. Utilizing multimeters and oscilloscopes allows for detailed analysis of electrical signals. Visual inspections can also reveal physical damage, such as corrosion or burn marks, which often indicate a compromised part. Understanding these diagnostic techniques enhances the ability to restore operational integrity.

Rewinding the Magneto Coil

Rewinding the electrical component is a vital process that restores functionality to a failing unit. This task involves replacing the wire winding within the coil to ensure optimal performance. Proper execution can significantly enhance the efficiency and lifespan of the system.

Tools and Materials Needed

- Insulated wire of appropriate gauge

- Wire cutter and stripper

- Soldering iron and solder

- Insulation tape

- Multimeter for testing

Steps to Follow

- Carefully disassemble the unit, taking note of the original configuration.

- Remove the old winding from the coil assembly.

- Prepare the new wire, ensuring the length is sufficient for multiple turns.

- Begin wrapping the wire around the coil, maintaining even tension and direction.

- Secure the ends of the wire, ensuring a strong connection.

- Reassemble the unit, double-checking all connections.

- Test the functionality using a multimeter to confirm proper operation.

Maintaining Your Magneto System

Ensuring optimal performance of your ignition system requires regular attention and care. By adhering to a systematic maintenance routine, you can enhance efficiency and prolong the lifespan of your components.

Inspection: Regularly examine all parts for signs of wear or damage. Look for frayed wires, corrosion, or loose connections that could hinder functionality.

Cleaning: Keep the system free from dirt and debris. A clean environment prevents malfunctions and ensures reliable operation. Use appropriate cleaning solutions for different materials.

Adjustment: Periodically check and adjust the alignment of your components to ensure proper functioning. Small misalignments can lead to significant performance issues.

Testing: Utilize diagnostic tools to assess the performance of the system. Regular testing can identify potential issues before they become major problems, saving time and resources in the long run.

Documentation: Maintain a detailed log of inspections, cleanings, adjustments, and any repairs made. This history can be invaluable for future reference and troubleshooting.

Upgrading Wico Magneto Components

Enhancing the performance and longevity of your ignition system can significantly improve the overall efficiency of your engine. This section discusses essential components that can be upgraded to achieve better reliability and functionality, ensuring optimal operation for years to come.

Key Components for Enhancement

- Coil: Replacing the coil with a high-performance version can lead to a stronger spark, improving combustion efficiency.

- Capacitor: Upgrading to a capacitor with a higher voltage rating can provide greater stability and enhance overall performance.

- Points: Installing modern contact points can reduce wear and improve spark consistency.

Benefits of Upgrading

- Increased ignition reliability, reducing misfires and enhancing starting efficiency.

- Improved fuel efficiency due to better combustion processes.

- Extended lifespan of the ignition system components, minimizing the need for frequent replacements.

Tips for Successful Repairs

Achieving effective fixes requires a combination of knowledge, patience, and the right tools. This section offers valuable insights to enhance your approach, ensuring that your efforts yield satisfactory results and extend the lifespan of your equipment.

Understanding the Components

Familiarize yourself with the various elements involved in the system. Knowing how each part interacts will enable you to identify potential issues more efficiently. Pay close attention to connections, wiring, and any signs of wear or damage.

Gathering the Right Tools

Having the appropriate instruments is crucial for a successful outcome. Ensure your toolkit includes not only basic hand tools but also specialized devices tailored to your project. This will streamline the process and minimize the risk of further complications.

Attention to Detail is essential throughout the entire process. Carefully inspect each component and follow all procedures meticulously. Documenting your steps can also be beneficial, providing a reference for future tasks and helping to track progress.

Common Mistakes to Avoid

When undertaking the restoration of electrical components, certain missteps can lead to frustrating setbacks and even further complications. Recognizing these common pitfalls is essential for achieving a successful outcome and ensuring longevity in performance.

Neglecting Thorough Inspection

One of the most frequent oversights is failing to conduct a comprehensive examination before beginning the restoration process. This includes checking for wear, corrosion, or any signs of damage that may compromise functionality. Addressing these issues early can save time and resources down the line.

Using Incorrect Tools

Another critical error is utilizing inappropriate instruments for the task at hand. Each component often requires specific tools for optimal handling and adjustment. Employing the right equipment not only facilitates more precise work but also minimizes the risk of damaging sensitive parts.

Resources for Further Learning

Expanding your knowledge in the field of mechanical systems can be incredibly rewarding. There are numerous avenues available for enthusiasts and professionals alike to deepen their understanding and skills.

- Online Courses: Platforms such as Coursera and Udemy offer specialized classes on mechanical engineering and restoration techniques.

- Books: Consider reading comprehensive guides and textbooks focused on mechanical components and their functions.

- Forums: Joining online communities like Reddit and specialized forums can provide valuable insights and practical advice from fellow hobbyists and experts.

- Workshops: Look for local workshops or maker spaces that focus on hands-on learning experiences.

- YouTube Channels: Many creators share detailed tutorials and projects that can enhance your practical skills and knowledge.

Utilizing these resources can greatly enhance your ability to tackle various projects and understand the intricacies of mechanical devices.