Ensuring the functionality of crucial water access systems is essential for public safety and emergency response. This section delves into the comprehensive procedures and best practices for maintaining these vital installations. Regular upkeep not only extends the lifespan of the equipment but also guarantees readiness during critical situations.

The following guide outlines essential techniques and troubleshooting strategies that aid in preserving these systems in optimal condition. By understanding the components and potential issues, operators can proactively address concerns, thus enhancing overall reliability and effectiveness.

Additionally, a thorough examination of tools and safety protocols is included to assist users in navigating common challenges. Empowering personnel with the right knowledge and resources will significantly reduce downtime and foster a more resilient infrastructure.

Overview of Waterous Fire Hydrants

This section provides a comprehensive understanding of a leading brand known for its high-quality products designed for essential public safety applications. These devices play a crucial role in emergency response, ensuring effective access to water resources in critical situations.

Key Features

The devices are characterized by robust construction and innovative designs that enhance their performance in various environments. Reliability and durability are paramount, making them suitable for both urban and rural settings.

Applications

These systems are utilized extensively by emergency services and are essential components of municipal infrastructure. Their design ensures that first responders can quickly and efficiently access water during emergencies.

| Feature | Description |

|---|---|

| Durability | Constructed to withstand harsh conditions and extensive use. |

| Accessibility | Designed for quick and easy operation in emergencies. |

| Innovative Design | Incorporates the latest technology for optimal performance. |

| Compatibility | Can be integrated with various water supply systems. |

Common Issues with Fire Hydrants

In the realm of public safety infrastructure, certain challenges frequently arise that can hinder effective operation. Understanding these common concerns is essential for maintaining optimal functionality and ensuring rapid response during emergencies.

- Corrosion: Over time, components can deteriorate due to exposure to moisture and harsh environmental conditions.

- Blockage: Accumulation of debris, dirt, or sediment can obstruct the flow of water, compromising efficiency.

- Leaking Valves: Wear and tear on valve seals may lead to unintended water loss, which can affect pressure levels.

- Damage from Vehicles: Accidental collisions with passing vehicles can cause physical damage to the structure.

- Frozen Components: In colder climates, freezing temperatures can immobilize parts, rendering them inoperative.

Addressing these issues promptly is crucial to ensure that the system remains ready for action when needed. Regular inspections and maintenance can help identify and mitigate potential problems before they escalate.

Essential Tools for Repairs

When it comes to maintaining and fixing essential infrastructure, having the right instruments is crucial. The proper toolkit not only facilitates effective work but also ensures safety and efficiency during the process. Below are the key implements that should be included in any maintenance kit for these systems.

Basic Hand Tools

At the foundation of any toolkit are the basic hand instruments. Wrenches, screwdrivers, and pliers are indispensable for loosening and tightening various components. A good set of adjustable wrenches will allow you to handle different sizes of fittings. Additionally, a sturdy pair of pliers can assist in gripping and manipulating parts securely.

Specialized Equipment

In addition to general hand tools, certain specialized equipment is necessary for more intricate tasks. Torque wrenches are essential for ensuring that all connections are tightened to the manufacturer’s specifications. Pipe cutters can help in making precise cuts without damaging adjacent areas. Moreover, a reliable sealant application tool ensures that all joints are properly sealed, preventing leaks and maintaining functionality.

Step-by-Step Repair Process

This section outlines a systematic approach to restoring a critical component in municipal water management systems. Following these steps will ensure optimal functionality and longevity of the unit.

1. Assessment: Begin by thoroughly examining the unit for any visible damage or leaks. Take note of any irregularities that may affect performance.

2. Preparation: Gather all necessary tools and replacement parts. Ensure a clean workspace to facilitate the process.

3. Disassembly: Carefully remove the component, following the manufacturer’s guidelines to avoid causing further damage.

4. Cleaning: Clean all parts with appropriate solutions to eliminate debris and buildup, which can hinder performance.

5. Replacement: Install any new parts as required, ensuring a snug fit to prevent future issues.

6. Reassembly: Put the unit back together, following the disassembly steps in reverse order.

7. Testing: Conduct a thorough test to ensure the unit operates smoothly. Check for leaks or any abnormal sounds.

8. Final Inspection: Perform a detailed check once more, confirming all components are secure and functioning as intended.

Maintenance Tips for Longevity

Ensuring the durability of essential equipment requires regular upkeep and attention. Adopting best practices in maintenance can significantly extend the lifespan of these vital installations. Here are some effective strategies to keep them in optimal condition.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect for leaks and damages | Monthly | Look for visible signs of wear or corrosion. |

| Clean the exterior surfaces | Quarterly | Remove dirt and debris to prevent buildup. |

| Test operational mechanisms | Biannually | Ensure all moving parts function smoothly. |

| Lubricate necessary components | Annually | Use appropriate lubricants to minimize friction. |

| Check for obstructions | Seasonally | Ensure surrounding areas are clear of blockages. |

By following these guidelines, you can help ensure that your equipment remains reliable and effective throughout its lifespan. Consistent attention to maintenance not only prevents issues but also promotes overall functionality.

Safety Precautions During Repairs

Ensuring safety is paramount when engaging in maintenance tasks. Proper precautions help prevent accidents and protect both the individual performing the work and the surrounding environment. By adhering to established guidelines, risks can be significantly minimized, leading to a more efficient and secure process.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes gloves, goggles, and hard hats to safeguard against potential hazards. Ensure that all gear is in good condition and properly fitted before starting any work.

Worksite Safety Measures

Before commencing any task, assess the worksite for potential dangers. Clear the area of unnecessary obstacles and ensure proper lighting. It is also vital to inform colleagues about the ongoing activity to avoid unexpected disruptions. Maintaining a clean and organized workspace further contributes to overall safety.

Diagnosing Hydrant Failures

Identifying issues with essential water access points requires a systematic approach. Effective troubleshooting not only ensures timely resolution but also enhances overall system reliability. Understanding the common symptoms of malfunction is crucial for accurate assessment and subsequent rectification.

Common Indicators of Malfunction

Several signs may indicate a malfunctioning unit. Unusual noises during operation, such as grinding or hissing, can suggest internal wear or leakage. Inconsistent water flow or pressure fluctuations often point to obstructions or valve issues. Additionally, visible corrosion or damage can signal structural problems that need immediate attention.

Systematic Diagnosis Process

A thorough inspection begins with a visual assessment. Check for signs of physical damage or corrosion. Following this, conduct a flow test to evaluate performance against expected standards. If discrepancies arise, further investigation into valve integrity and connectivity may be necessary. Documenting findings will aid in developing a comprehensive action plan for resolution.

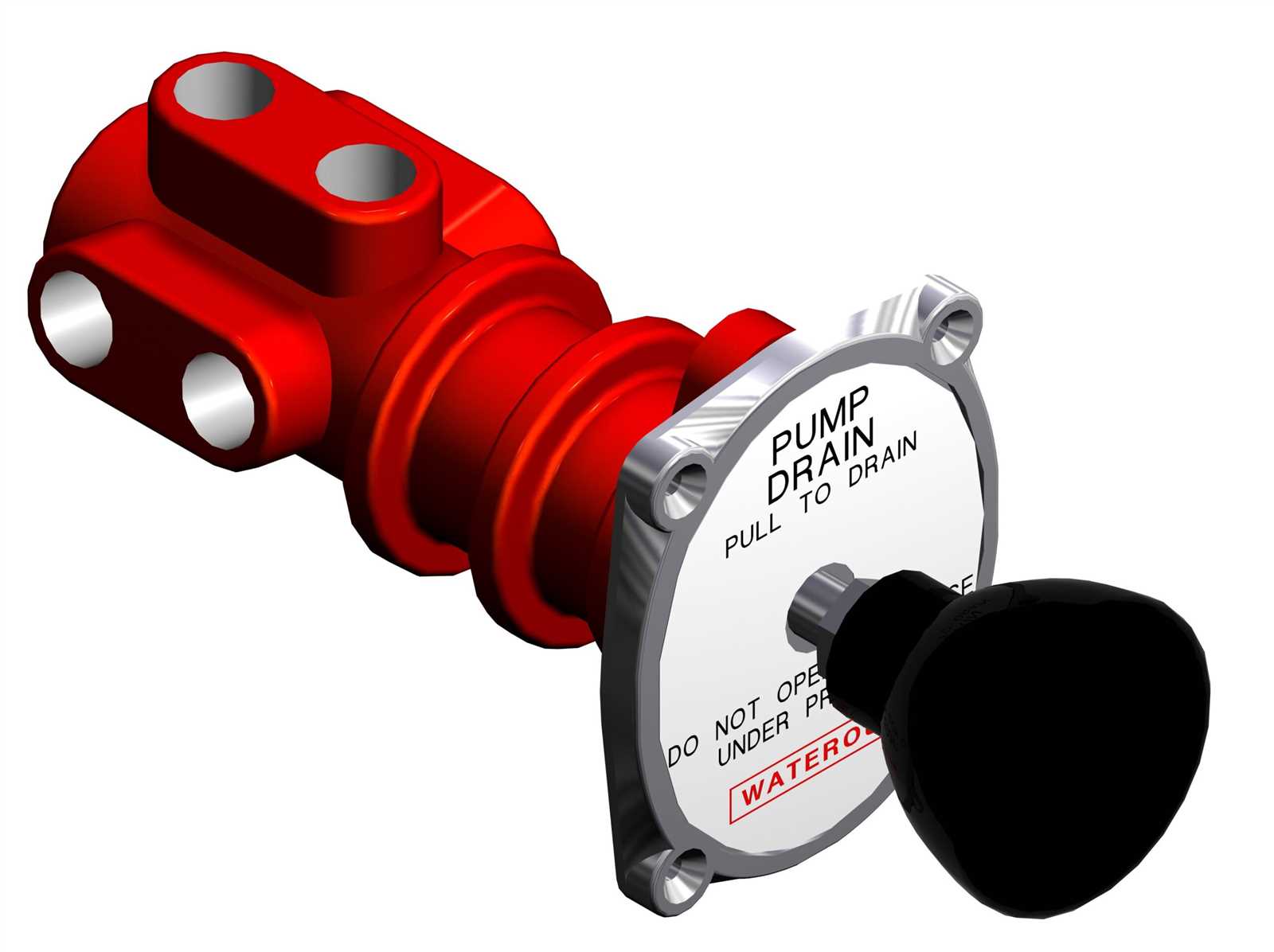

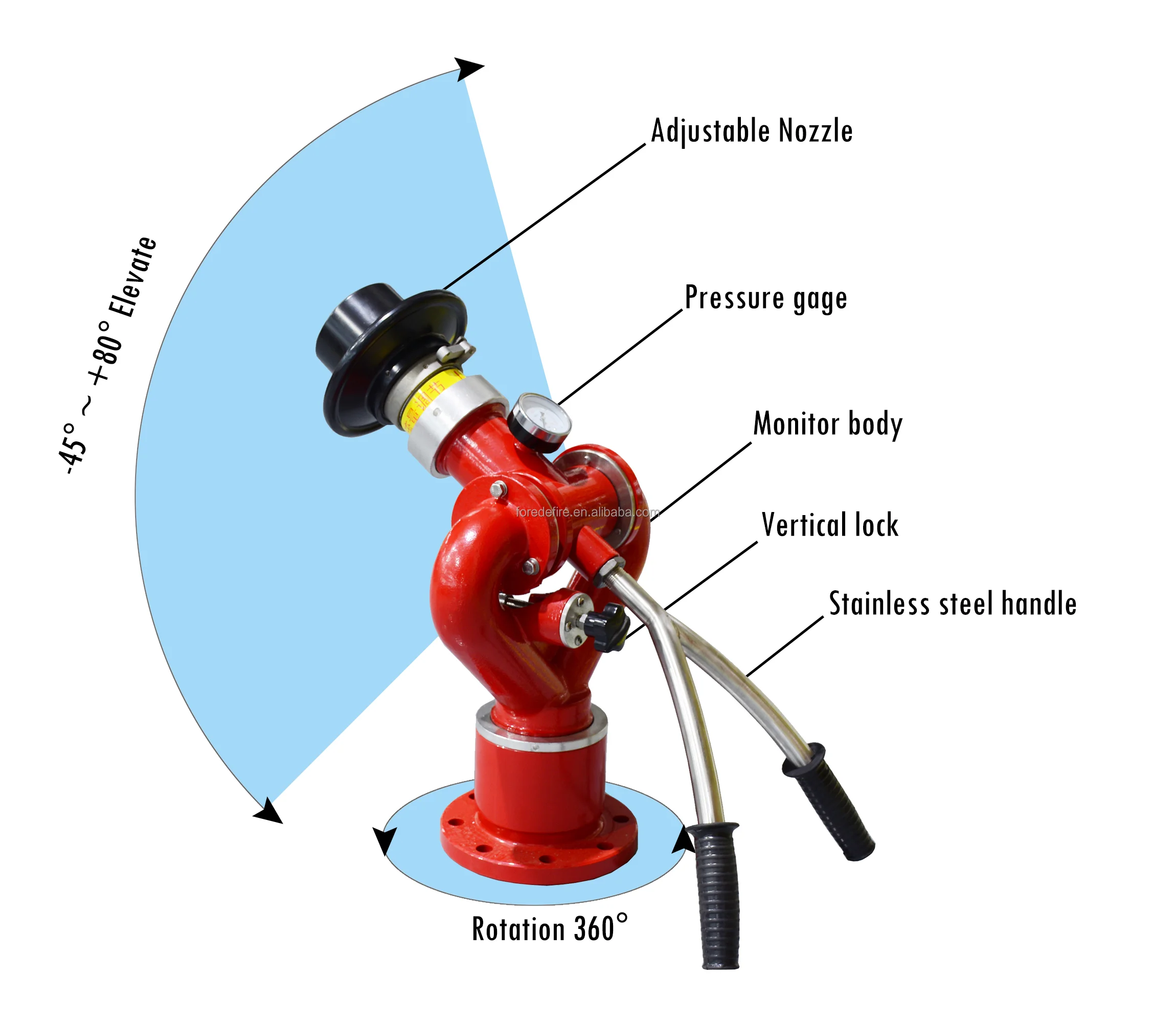

Understanding Hydrant Components

In the realm of emergency response equipment, a comprehensive grasp of the various elements is essential for efficient operation and maintenance. Each part plays a crucial role in ensuring functionality and reliability during critical situations. This section delves into the primary components, highlighting their importance and interconnectivity.

Body: The main structure serves as the core, housing essential mechanisms and providing stability. Its design is engineered to withstand extreme conditions, ensuring longevity and durability.

Valve: This crucial element regulates the flow of water. Its precise operation is vital for controlling pressure and directing the necessary supply during emergencies.

Nozzle: The output end is where the discharge occurs, enabling the effective application of water. Variations in design allow for different flow patterns, tailored to specific scenarios.

Cap: The protective cover ensures that internal components remain free from debris and damage. It also facilitates easy access for maintenance and operation.

Drainage System: This feature prevents the accumulation of residual water, which could lead to freezing or corrosion. Proper drainage is key to maintaining functionality over time.

Understanding these components not only aids in troubleshooting but also enhances overall performance during use. Familiarity with each part empowers users to respond effectively in times of need.

When to Call a Professional

In certain situations, tackling a maintenance task on your own can lead to complications. Recognizing when it’s time to seek expert assistance is crucial for ensuring safety and efficiency. Understanding the limits of your skills and the complexity of the job can save you time, resources, and potential hazards.

Complex Issues: If you encounter a problem that involves intricate components or advanced technology, it’s advisable to consult a specialist. Tasks that require specialized knowledge or equipment often exceed the average person’s capabilities.

Safety Concerns: When the risk of injury or damage increases, professional help is essential. If you feel uncertain about handling the task safely, do not hesitate to call in an expert. Prioritizing safety is always the best approach.

Time Constraints: If you find yourself short on time or unable to commit the necessary hours to complete a job effectively, hiring a professional can be a wise investment. Their expertise can streamline the process, allowing you to focus on other priorities.

Persistent Problems: If issues persist despite your best efforts to resolve them, it may indicate a deeper underlying issue. In such cases, professionals possess the experience to diagnose and fix the root cause, ensuring lasting solutions.

Ultimately, knowing when to call in an expert not only protects your investment but also enhances overall performance and longevity. Don’t hesitate to reach out for help when needed.

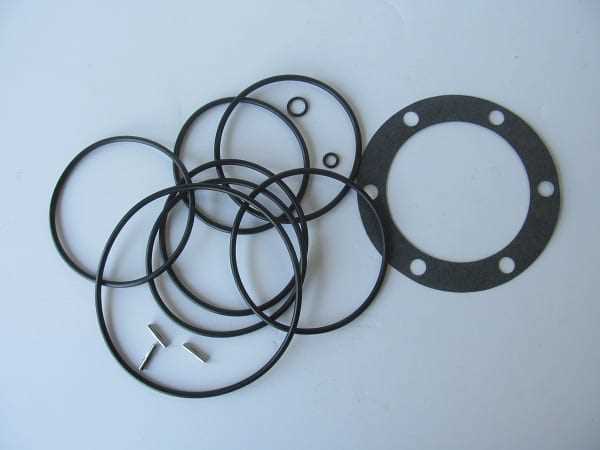

Parts Replacement Guide

This section aims to provide a comprehensive overview of the components involved in the maintenance and restoration of the water distribution apparatus. Understanding how to efficiently substitute parts is crucial for ensuring optimal functionality and longevity.

Identifying Components: Familiarize yourself with the various elements that make up the system. Each part plays a significant role in overall performance, and recognizing their function will aid in troubleshooting and replacement.

Assessment: Regularly inspect each component for signs of wear and tear. Look for cracks, corrosion, or any irregularities that may indicate a need for replacement. Early detection can prevent further damage and costly repairs.

Replacement Process: When a part is determined to be faulty, follow a systematic approach for replacement. Start by disconnecting the necessary sections and ensuring that all residual pressure is released. Carefully remove the damaged part and replace it with a compatible new component, ensuring a secure fit.

Reassembly: After replacing the necessary components, reassemble the unit in reverse order. Verify that all connections are tight and leak-free. It is advisable to conduct a functionality test to confirm that the replacement has restored operational efficiency.

Documentation: Maintain a record of all parts replaced, including dates and specific details. This practice not only assists in tracking the maintenance history but also helps in anticipating future needs for replacement.

Frequently Asked Questions

This section aims to address common inquiries related to the maintenance and functionality of essential water management systems. Here, we provide clear and concise answers to help users understand various aspects of their equipment.

What are the signs that indicate a need for maintenance?

Common indicators include inconsistent water flow, unusual noises during operation, or visible leaks around the unit. Regular inspections can help identify issues early on, preventing more significant problems.

How often should I conduct inspections?

It is recommended to perform thorough evaluations at least twice a year. However, if the system is subjected to heavy use or adverse weather conditions, more frequent checks may be necessary to ensure optimal performance.