This section offers detailed insights into the upkeep and servicing of specific engine types, emphasizing efficient performance and longevity. Understanding the intricacies of these power units can significantly enhance their reliability and functionality.

With a focus on troubleshooting and systematic care, readers will discover essential techniques to address common issues and ensure optimal operation. Mastering these methods can empower individuals to maintain their equipment effectively, minimizing downtime and maximizing productivity.

Utilizing proper procedures and knowledge is crucial for sustaining engine health. This guide aims to equip users with the necessary information and practical advice to tackle maintenance tasks confidently, fostering a deeper appreciation for mechanical systems.

This section outlines the foundational aspects of a specific type of engine known for its dual-cylinder configuration and overhead valve design. These engines are commonly utilized in various applications, offering a combination of performance and efficiency. Understanding their structure and function is essential for proper maintenance and troubleshooting.

Engine Configuration and Design

The dual-cylinder layout enhances power output while maintaining compactness. The overhead valve arrangement contributes to improved airflow and efficiency. Familiarity with these design features is crucial for effective handling.

Common Issues and Troubleshooting

Engine performance can be hindered by several factors, including fuel delivery problems and ignition system failures. Identifying symptoms early can prevent more severe complications and ensure optimal operation.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Poor starting | Engine cranks but does not start | Check fuel supply and spark plug condition |

| Loss of power | Engine struggles under load | Inspect air filter and fuel lines |

| Overheating | Excessive heat during operation | Examine cooling system and oil levels |

Common Issues and Troubleshooting Steps

This section addresses frequent problems encountered with small engines, offering practical solutions for effective resolution. Understanding these challenges can enhance maintenance and prolong the lifespan of the equipment.

One prevalent issue is starting difficulties, often caused by fuel supply problems or ignition system failures. Ensure the fuel tank is adequately filled with fresh gasoline and check for clogs in the fuel lines. Inspect the spark plug for wear or carbon buildup and replace it if necessary.

Another common concern is overheating, which may arise from insufficient lubrication or debris obstructing airflow. Regularly check oil levels and ensure the cooling fins are clean to promote efficient heat dissipation.

Noisy operation can indicate mechanical wear or misalignment. Listen for unusual sounds and inspect components for looseness or damage. Tightening bolts and replacing worn parts can restore normal functionality.

Finally, if performance drops, it might be due to dirty air filters or fuel injectors. Clean or replace these components to maintain optimal engine efficiency and responsiveness.

Essential Tools for Engine Repair

When tackling engine maintenance, having the right equipment is crucial for efficient and effective work. A well-equipped toolkit not only enhances productivity but also ensures precision during the process. Below is a list of fundamental instruments that every enthusiast should consider for successful engine work.

Key Instruments

| Tool | Description |

|---|---|

| Socket Set | A versatile collection of sockets to fit various fasteners, essential for disassembly and reassembly. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage. |

| Wrenches | Different sizes of open-end and box-end wrenches for gripping and turning nuts and bolts. |

| Diagnostic Tools | Electronic devices that help identify issues within the engine systems. |

Additional Considerations

In addition to the basic tools, consider including specialty items like compression testers and fuel pressure gauges for a more comprehensive approach. Investing in quality equipment pays off in the long run, ensuring that tasks are performed accurately and safely.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the prolonged performance and reliability of your engine. Implementing simple maintenance routines can significantly enhance its lifespan and efficiency, preventing costly repairs down the line.

Routine Inspections

Conduct frequent checks on key components such as filters, spark plugs, and belts. This practice allows for early detection of potential issues and ensures that all parts are functioning optimally. Clean or replace parts as necessary to maintain peak performance.

Proper Lubrication

Ensure that the engine is adequately lubricated to reduce friction and wear on moving parts. Use high-quality oils recommended for your specific model, and change them at regular intervals to keep the system running smoothly.

Parts Replacement: What You Need

When it comes to maintaining and enhancing the performance of your engine, understanding the essential components is crucial. Proper replacement of these parts ensures optimal functionality and longevity.

Essential Components play a vital role in the overall efficiency of your machinery. Regular checks and timely substitutions can prevent potential breakdowns and improve performance. Always keep an eye on wearable parts, such as gaskets, filters, and belts, as these are prone to deterioration.

Before initiating any replacement process, ensure you have the correct tools and supplies on hand. This includes not only the replacement parts but also necessary equipment like wrenches, screwdrivers, and safety gear to facilitate a smooth operation.

Additionally, consulting a comprehensive guide or seeking professional advice can greatly assist in identifying the right components required for your specific engine type. This knowledge empowers you to make informed decisions and execute replacements with confidence.

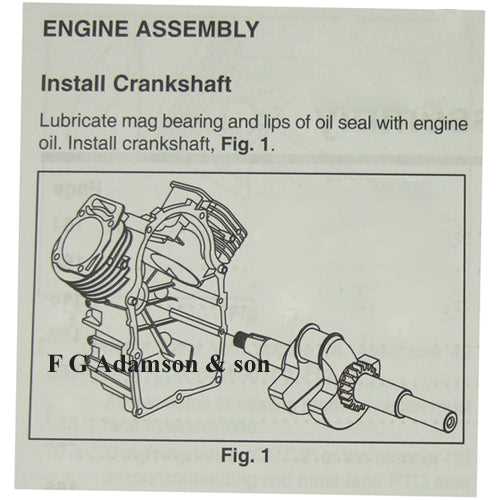

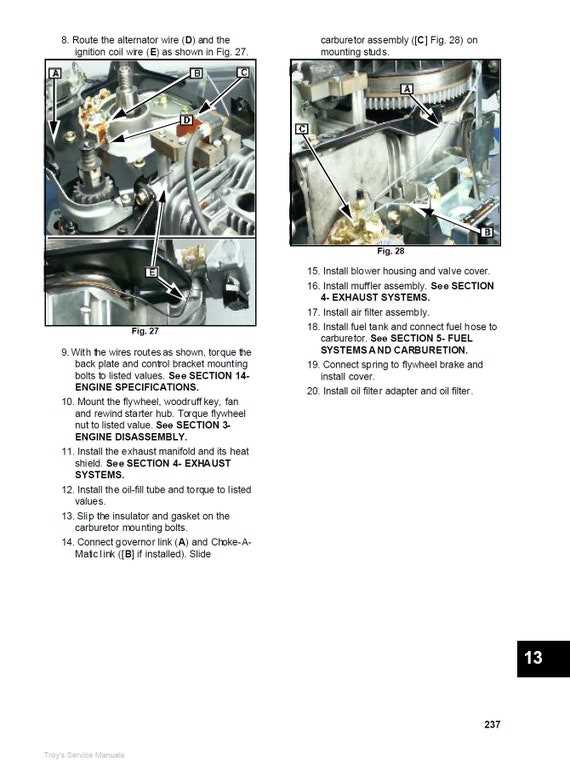

Detailed Repair Procedures Explained

This section delves into the essential techniques and methods required for addressing common issues in engine systems. Understanding these processes is vital for maintaining optimal performance and longevity of the machinery.

Key Steps in Maintenance

Following a systematic approach to maintenance enhances efficiency and ensures that potential problems are identified early. Regular checks and services contribute to smoother operation and prevent unexpected breakdowns.

Common Issues and Solutions

Several typical complications may arise during the operation of engine units. Below is a summary of these issues alongside effective remedies:

| Issue | Symptoms | Solution |

|---|---|---|

| Overheating | High temperature readings | Check coolant levels and ensure proper airflow. |

| Unusual Noises | Knocking or rattling sounds | Inspect for loose components and worn parts. |

| Starting Problems | Engine fails to start | Examine battery condition and electrical connections. |

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential to prevent accidents and injuries. Proper precautions not only safeguard the individual performing the work but also protect surrounding equipment and materials. Adhering to established safety guidelines enhances overall efficiency and effectiveness during the process.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is vital. This includes safety goggles to protect the eyes from debris, gloves to prevent cuts and abrasions, and sturdy footwear to guard against heavy objects. Additionally, using hearing protection may be necessary in noisy environments.

Work Area Management

Maintaining a clean and organized workspace minimizes hazards. Ensure that tools are easily accessible and that spills are cleaned promptly. Properly securing loose items and avoiding clutter helps to create a safer environment for all involved in the task.

Performance Enhancements for Your Engine

Improving engine performance can significantly enhance your vehicle’s efficiency and responsiveness. By implementing various modifications, you can achieve higher power output, better fuel efficiency, and an overall smoother operation. This section explores several effective strategies to elevate your engine’s capabilities.

Air Intake Modifications

Optimizing the air intake system is crucial for enhancing engine performance. By replacing the factory air filter with a high-flow variant and upgrading to a performance intake manifold, you can increase airflow and improve combustion efficiency.

Exhaust System Upgrades

An upgraded exhaust system can facilitate better airflow, reducing back pressure and allowing the engine to expel gases more efficiently. Consider installing a performance exhaust header and a high-performance muffler to maximize these benefits.

| Modification Type | Benefits |

|---|---|

| High-Flow Air Filter | Increased airflow and improved filtration |

| Performance Intake Manifold | Enhanced air distribution and throttle response |

| Performance Exhaust Header | Reduced back pressure and increased horsepower |

| High-Performance Muffler | Better sound and improved exhaust flow |

Frequently Asked Questions About Repairs

This section addresses common inquiries regarding maintenance and troubleshooting for specific engine types. Understanding these key points can facilitate effective handling of issues that may arise.

What are the signs that maintenance is needed?

Look for unusual noises, decreased performance, or visible leaks as indicators that attention is required. Regular checks can prevent more significant problems.

How often should inspections be conducted?

Routine evaluations should be scheduled based on usage frequency, typically every season or after extensive operation. This practice ensures optimal functionality.

Can I perform maintenance myself?

Yes, many tasks can be undertaken independently with the right tools and knowledge. However, complex issues may necessitate professional assistance to ensure safety and efficiency.

What common issues should I be aware of?

Common challenges include fuel system malfunctions, electrical failures, and overheating. Familiarity with these problems can aid in prompt identification and resolution.

Where can I find replacement parts?

Replacement components are often available through specialized suppliers, online retailers, or authorized dealers. Ensure compatibility with the specific engine type before purchasing.

Resources for Further Information

This section aims to provide additional resources that can enhance your understanding and troubleshooting skills related to specific engine types. Exploring various materials can offer valuable insights and practical knowledge for effective maintenance and support.

Books and Guides

- Comprehensive Engine Maintenance Guide

- Understanding Small Engine Operation

- Performance Optimization Techniques

Online Communities and Forums

- Small Engine Enthusiasts Forum

- DIY Mechanics Community

- Engine Performance Discussion Board

Utilizing these resources can empower you with the skills needed for effective engine management and troubleshooting.