Over time, even the most reliable household devices may encounter issues that impact their performance. Ensuring that these appliances run smoothly can save both time and resources, especially when minor troubleshooting can resolve the problem without professional assistance. This guide provides insights and practical advice for resolving common technical challenges you may encounter with similar equipment in your home.

Understanding Basic Maintenance can be essential in prolonging the life of your appliance. Regular care helps prevent unexpected issues and ensures that it operates at peak efficiency. Learning a few key techniques not only helps address potential disruptions but also empowers you to tackle minor fixes confidently.

With detailed steps on identifying common faults, this guide aims to walk you through simple solutions for getting your appliance back to optimal condition. Whether it’s adjusting settings or addressing minor part replacements, you’ll find practical tips to keep it running smoothly and consistently.

Understanding Common Ice Maker Issues

Reliable performance in cold drink dispensers is essential for maintaining a steady supply. However, various interruptions can hinder their functionality. By identifying the typical malfunctions, users can quickly address minor problems and ensure more consistent performance over time.

Frequent Malfunctions and Their Indicators

- Slow Production: This issue may arise due to blocked supply channels or lowered cooling capacity.

- Unexpected Shutdowns: Sometimes, power interruptions or sensor malfunctions can cause systems to stop without warning.

- Forming Irregularities: Uneven shapes or unusual textures can be signs of temperature imbalances or filter blockages.

Preventive Measures

- Regularly clean and inspect filters to avoid blockages.

- Ensure that the ventilation is adequate for optimal performance.

- Schedule routine checks for internal components to detect potential wear early.

Addressing these common issues promptly not only extends the unit’s lifespan but also promotes smoother operation, reducing the likelihood of extensive repairs in the future.

Step-by-Step Troubleshooting Guide

When an appliance starts showing signs of unusual operation, following a systematic troubleshooting approach can help identify and address the issues effectively. This guide provides clear steps to diagnose potential problems and suggests remedies to restore smooth functionality.

- Check Power Supply: Ensure that the unit is securely plugged in, and verify that the outlet is providing power. Try connecting another device to confirm.

- Inspect Water Connection: Verify that the water supply is on and that the hoses are free from any kinks or blockages.

- Assess Temperature Settings: Review the temperature controls, adjusting as necessary. A cooler setting may improve performance.

- Examine Filters and Lines: Check filters for clogs and ensure water lines are clear. Clean or replace filters if needed for optimal flow.

Essential Tools for Ice Maker Repair

For successful troubleshooting and maintenance of cooling appliances, having the right tools at hand is crucial. Each instrument serves a specific purpose, ensuring efficiency and accuracy during the work. In this section, we’ll explore some fundamental tools and their roles in achieving precise adjustments and smooth operation.

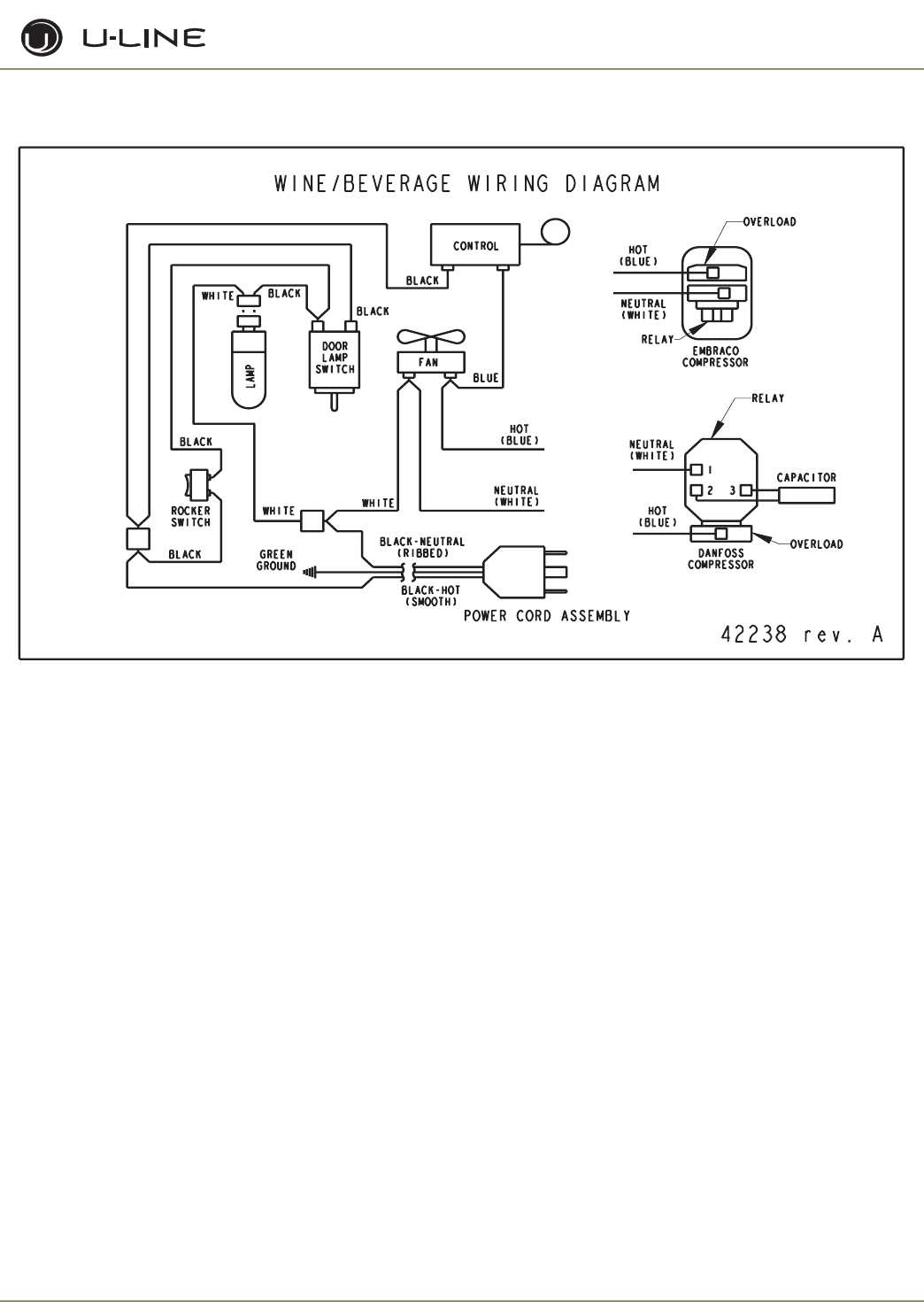

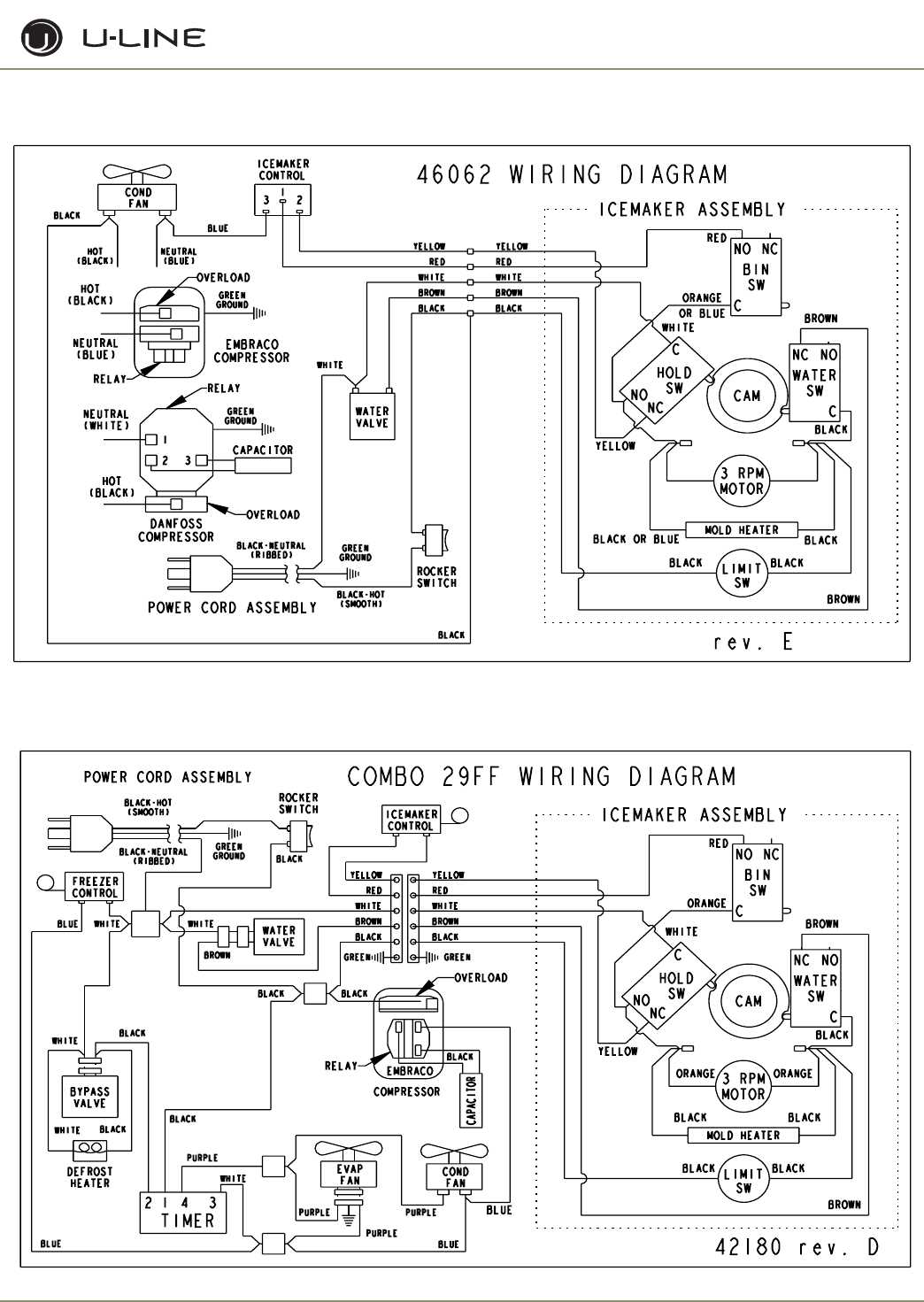

Multimeter is an indispensable device for diagnosing electrical issues, allowing you to measure voltage, current, and resistance. With it, identifying problematic connections or faulty circuits becomes significantly easier, minimizing the risk of electrical malfunctions.

Screwdriver Set is essential, as it accommodates various screws often used in appliance assembly. Both Phillips and flathead types come in handy, enabling precise removal or tightening during inspection or component replacement.

Needle-Nose Pliers are perfect for handling small parts or hard-to-reach wiring, enhancing control and grip. They allow for accurate positioning of wires or components within tight spaces, ensuring safety and avoiding potential hazards.

Thermometer is vital

How to Test Ice Maker Components

To ensure consistent functionality and avoid unexpected interruptions, testing each component is crucial. Proper evaluation can identify parts that need adjustment or replacement, enhancing overall performance. Regular checks also help prevent future issues by catching early signs of wear.

1. Inspect the Water Inlet Valve: Begin by examining the inlet valve. Disconnect the water supply and verify the valve’s condition by listening for any irregular sounds when it’s in operation. This component controls the water flow, so any blockages or malfunctions can disrupt the overall operation.

2. Examine the Thermostat: Use a multimeter to test the thermostat’s continuity. Place the probes on the terminals to check for a stable reading. A working thermostat is essential for temperature regulation, and irregular readings may indicate the need for replacement.

3. Assess the Control Board: The control board oversees the entire process, so a quick inspection here is vital. Look for visible signs of wear

Cleaning Techniques for Optimal Performance

Regular and thorough cleaning ensures the long-term reliability and efficiency of your appliance. A consistent maintenance routine prevents buildup, reduces wear, and maintains functionality.

Step 1: Start by disconnecting the device from the power source. This step is essential for safety, preventing any potential hazards during maintenance.

Step 2: Use a mild, non-abrasive cleanser to gently wipe down all surfaces, paying special attention to areas prone to residue buildup. Avoid harsh chemicals, as they can damage parts over time.

Step 3: Clean removable components separately, ensuring they are completely rinsed and dried before reassembly. This prevents moisture buildup that can interfere with the system’s efficiency.

Following these steps regularly will help keep your device operating at its best, prolonging its functionality and reducing the need for future repairs.

Identifying Water Supply Problems

Ensuring a consistent and adequate flow of water is crucial for the proper functioning of various appliances. When issues arise in this area, it can lead to significant performance challenges. Recognizing the signs of water supply complications is essential for troubleshooting effectively.

Common indicators of water supply issues include reduced output, unusual noises, or inconsistent operation. These symptoms may suggest blockages, leaks, or pressure fluctuations within the system. To address these challenges, it is important to inspect the entire water line thoroughly.

Begin by examining connections and fittings for signs of wear or damage. Any visible leaks or loose joints can disrupt the flow and should be tightened or replaced. Additionally, checking the water source for adequate pressure is vital; low pressure may hinder proper functionality.

In some cases, clogs in the supply line may also contribute to problems. Regular maintenance and cleaning of filters and hoses can prevent such blockages. Identifying these water supply concerns early can save time and resources, ensuring optimal operation of your appliance.

Replacing Key Parts in Ice Makers

Maintaining the functionality of a freezing unit is essential for ensuring optimal performance. When certain components fail, it becomes necessary to replace them to restore proper operation. Understanding how to identify and swap out these crucial elements can greatly enhance the longevity of the appliance.

Identifying Faulty Components

The first step in the replacement process is diagnosing which part is malfunctioning. Common issues may arise from the water supply, refrigeration system, or the electrical components. Regular inspections can help pinpoint these problems early, preventing further damage.

Step-by-Step Replacement Process

Once the defective component has been identified, the next step is to gather the appropriate tools and a compatible replacement part. It is advisable to follow the manufacturer’s guidelines during the replacement to ensure proper installation. This may involve disconnecting power sources, removing the faulty part, and carefully installing the new one. Always double-check connections and settings before reactivating the unit.

Resetting the Ice Maker Safely

Understanding the process of restoring functionality to your appliance is essential for maintaining its efficiency. Whether encountering an operational issue or simply performing routine maintenance, knowing how to safely initiate a reset can enhance performance and prolong the device’s lifespan.

Before proceeding, consider the following steps to ensure a smooth reset:

- Unplug the appliance from the power source to avoid any electrical hazards.

- Allow the unit to rest for a few minutes to clear any temporary settings.

- Replug the appliance and observe any indicator lights or sounds, which may signal its status.

- Consult the user guidelines to identify the specific reset button or combination that may be required.

After completing the steps above, monitor the appliance for proper functionality. Regular checks can help you detect issues early and maintain optimal operation.

Maintenance Tips to Avoid Future Repairs

Proper upkeep is essential for ensuring longevity and optimal performance of your equipment. By implementing regular maintenance routines, you can prevent common issues and extend the lifespan of your unit. Here are some effective strategies to help you maintain your device efficiently.

- Regular Cleaning: Keep the exterior and interior components clean to prevent build-up of dirt and debris.

- Check Water Supply: Ensure that the water source is clean and free from contaminants that may affect functionality.

- Inspect Seals and Gaskets: Regularly examine seals for wear and tear, replacing them as necessary to maintain efficiency.

- Monitor Temperature Settings: Maintain appropriate temperature settings to ensure optimal operation and energy efficiency.

- Schedule Professional Servicing: Consider regular inspections by a qualified technician to catch potential issues early.

By following these guidelines, you can minimize the risk of unexpected breakdowns and ensure smooth operation for years to come.

When to Call a Professional Technician

Knowing when to seek the expertise of a skilled technician can save time and prevent further complications. While many issues can be resolved with basic troubleshooting, certain signs indicate that professional intervention is necessary.

For instance, if the appliance exhibits persistent malfunctions despite following standard procedures, it may be time to consult an expert. Additionally, unusual noises, leaks, or inconsistent performance often signal underlying problems that require specialized knowledge. Attempting to address these issues without proper training can lead to more extensive damage and increased repair costs.

Furthermore, if you notice electrical issues or if the device fails to operate altogether, it’s advisable to reach out to a qualified professional. Experts possess the necessary tools and experience to diagnose and resolve complex issues efficiently, ensuring the longevity and optimal performance of your unit.