Keeping equipment in peak condition can often seem challenging, but understanding the essential aspects of routine servicing is crucial. This guide offers a clear approach to maintaining and addressing common issues, ensuring that your machine remains reliable and efficient. Through these insights, you will gain the knowledge needed to extend the lifespan of your equipment and keep it functioning at its best.

The following sections delve into key maintenance practices, from regular cleaning techniques to in-depth diagnostics for identifying performance issues. Each part of this guide is designed to empower you with practical skills, whether you’re tackling preventative care or solving mechanical problems. Familiarize yourself with these processes to manage and resolve any arising challenges effectively.

For those who frequently use this type of machinery, understanding its mechanisms can save both time and resources. By following a structured approach to upkeep, you can prevent potential issues and reduce the likelihood of interruptions. This guide emphasizes straightforward, actionable steps to assist you in maintaining smooth operation season after season.

Troy Bilt Super Bronco Repair Guide

When maintaining outdoor equipment, understanding essential upkeep procedures and adjustments can significantly extend its operational life. This section provides insights on effectively handling routine checks, replacements, and calibrations to ensure optimal performance. Following these guidelines will help achieve reliability and longevity.

Key Maintenance Tips

Regular upkeep is crucial for preserving efficiency and safety. Focusing on areas like fluid levels, belt tension, and blade sharpening can enhance the machine’s functionality. Below is a quick-reference table outlining common areas to inspect and suggested maintenance intervals.

| Component | Inspection Frequency | Suggested Action |

|---|---|---|

| Oil Level | Every 10 hours of operation | Top up or replace as needed |

| Blades | Monthly | Sharpen or replace if dull |

| Battery | Seasonally | Clean terminals and check charge |

| Belts | Annually | Adjust or replace if worn |

Preparing for Se

Understanding the Tractor’s Key Components

Grasping the function of primary systems can significantly enhance maintenance and troubleshooting efficiency. Each essential part works in unison to support smooth operation and dependable performance.

- Engine System: This powerhouse drives the machinery forward and enables key functions. It typically includes a carburetor, spark plug, and fuel line, each requiring periodic checks to maintain optimal power output.

- Transmission: Responsible for converting engine power into movement, the transmission allows speed adjustments and precise control. Regular lubrication and gear inspections are crucial to its longevity.

- Cutting Deck: The deck houses the blades that trim vegetation. Keeping the blades sharp and ensuring the deck is clear of debris aids in achieving clean and consistent cuts.

- Steering and Tires: Ensuring ease of navigation, the steering assembly and tires require inspection for wear. Proper tire inflation and alignment adjustments contribute to stability and handling.

- Battery and Electrical System: The battery supplies electrical power to ignition and auxiliary features. Testing connections and keeping terminals clean can prevent common electrical issues.

Common Issues and Their Solutions

This section addresses frequent mechanical and operational concerns, offering practical solutions to keep your equipment running smoothly. Regular upkeep can significantly improve performance, minimize downtime, and extend the lifespan of your machine.

- Starting Problems

-

Check the battery for a full charge and secure connections. Ensure terminals are clean and free from corrosion.

-

Inspect the spark plug for wear and replace if necessary. Clean or replace the air filter to prevent airflow restriction.

-

- Engine Overheating

-

Regularly check and clean debris around the engine to ensure adequate cooling. Verify that cooling fins are free from obstructions.

-

Replace the oil periodically and ensure it’s at the proper level to maintain efficient engine temperature regulation.

-

- Transmission Issues

-

For difficulties with movement, inspect the drive belt for wear or looseness. Replace if needed.

-

Check for proper lubrication in the transmission area, as lack of lubrication can lead to reduced mobility.

-

- Uneven Cutting

-

Ensure blades are sharpened and balanced to achieve a uniform cut. Replace or repair damaged blades immediately.

-

Adjust the deck level according to the manufacturer’s guidelines to prevent uneven ground contact.

-

Maintaining the Engine for Longevity

Proper care of the engine is essential for extended service life, helping to avoid unexpected breakdowns and ensuring smooth operation over time. Regular attention to the key components and adherence to maintenance intervals contribute significantly to the overall health and reliability of the machine.

| Maintenance Task | Recommended Frequency | Description |

|---|---|---|

| Oil Check and Replacement | Every 50 hours or seasonally | Ensure the oil is clean and at the correct level. Replace oil to maintain lubrication and reduce wear. |

| Air Filter Inspection | Every 25 hours or seasonally | Inspect and clean the air filter to allow for proper airflow, improving fuel efficiency and power output. |

| Fuel System Cleaning | Annually or as needed | Remove sediment from the fuel system to prevent clogging, which can impact engine performance and starting reliability. |

| Spark Plug Replacement | Every 100 hours | Change the spark plug to ensure consistent ignition and efficient fuel combustion. |

| Cooling System Check | Every 50 hours | Examine cooling fins and other components for debris, maintaining proper engine temperature and avoiding overheating. |

Consistently following these maintenance steps will help sustain engine efficiency, reduce repair costs, and extend

Effective Techniques for Oil Changes

Maintaining optimal engine health relies heavily on timely and efficient oil changes. Properly managing this process can extend equipment lifespan and enhance performance. Understanding the most effective methods for an oil change simplifies the task, ensuring thorough lubrication and cleanliness in key components.

| Step | Description |

|---|---|

| Preparation | Warm up the engine slightly to ensure the oil flows easily, but avoid overheating. Set up a container to collect the used oil and have fresh oil ready. |

| Drain the Oil | Locate and open the oil drain plug, allowing the used oil to flow into the container. Ensure full drainage for optimal performance. |

| Replace the Filter | After draining, replace the oil filter to remove any contaminants that may reduce engine efficiency. Tighten securely to prevent leaks. |

| Refill with Fresh Oil | Close the drain plug and refill with the appropriate amount and type of fresh oil, checking the level with the dipstick for accuracy. |

| Check for Leaks | Start the engine briefly to circulate the new oil and inspect for any signs of leaks around the drain plug and filter area. |

Following these steps carefully promotes consistent engine function and minimizes the risk of wear or damage due to old or insufficient lubrication.

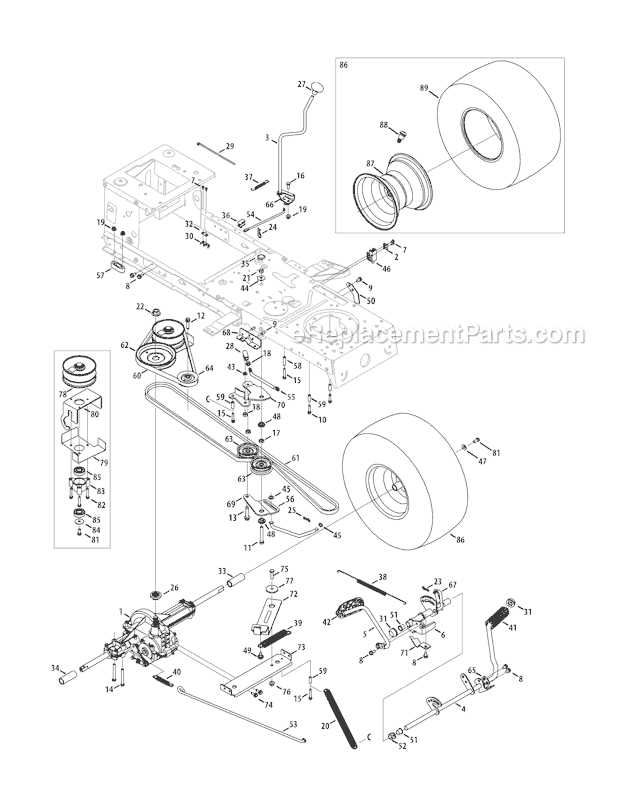

Troubleshooting Transmission Problems

Identifying issues within the drive system can enhance the efficiency and performance of your equipment. This section aims to guide users through common complications that may arise, ensuring a smoother operation and prolonging the lifespan of the machine.

Begin by observing any unusual noises or vibrations during operation. Sounds such as grinding or clunking can indicate misalignment or worn components. Check for any leaks around the transmission casing, as fluid loss can lead to inadequate lubrication and potential failure.

Next, assess the responsiveness of the gears. Difficulty in shifting or slipping out of gear can suggest problems with the linkage or internal mechanisms. It may be beneficial to inspect the drive belt for signs of wear or damage, as a compromised belt can affect overall performance.

Ensure that the fluid levels are adequate and that the fluid itself is clean and free from contaminants. Dirty or insufficient fluid can lead to overheating and decreased functionality. If the issue persists, consulting a professional may be necessary to conduct a thorough examination of the transmission assembly.

Safety Tips for Working on Equipment

Ensuring safety while handling machinery is crucial for both personal protection and equipment longevity. Adopting proper practices minimizes the risk of accidents and injuries during maintenance tasks. Below are essential guidelines to keep in mind when working with mechanical devices.

Preparation and Awareness

- Always read the user guidelines before starting any work on the equipment.

- Wear appropriate protective gear, including gloves, goggles, and sturdy footwear.

- Ensure your workspace is clean and free of clutter to avoid tripping hazards.

- Be mindful of your surroundings, especially if working in a shared space.

Operational Safety

- Disconnect power sources or remove batteries before performing any repairs.

- Utilize tools and equipment that are in good condition and designed for the task.

- Keep children and pets away from the work area to prevent distractions and accidents.

- Never attempt to fix machinery while it is still running; always wait for it to cool down if it has been in use.

Optimizing Fuel System Performance

Ensuring the efficiency of the fuel delivery mechanism is crucial for enhancing overall engine functionality. A well-maintained fuel system not only improves performance but also extends the lifespan of the machinery. This section discusses key strategies to maximize the effectiveness of fuel management.

Regular Maintenance Practices

To achieve optimal performance, it is essential to follow routine upkeep procedures. Inspecting fuel filters regularly helps prevent blockages that can hinder flow. Replacing these components as recommended will ensure a steady supply of clean fuel to the engine. Additionally, checking fuel lines for leaks or wear is vital in maintaining the integrity of the system.

Fuel Quality Considerations

The type of fuel used plays a significant role in system performance. Always opt for high-quality fuel that meets the manufacturer’s specifications. Using additives designed to clean injectors can enhance combustion efficiency and prevent carbon buildup. Furthermore, keeping fuel tanks free from contaminants will contribute to smoother operation and reliable starts.

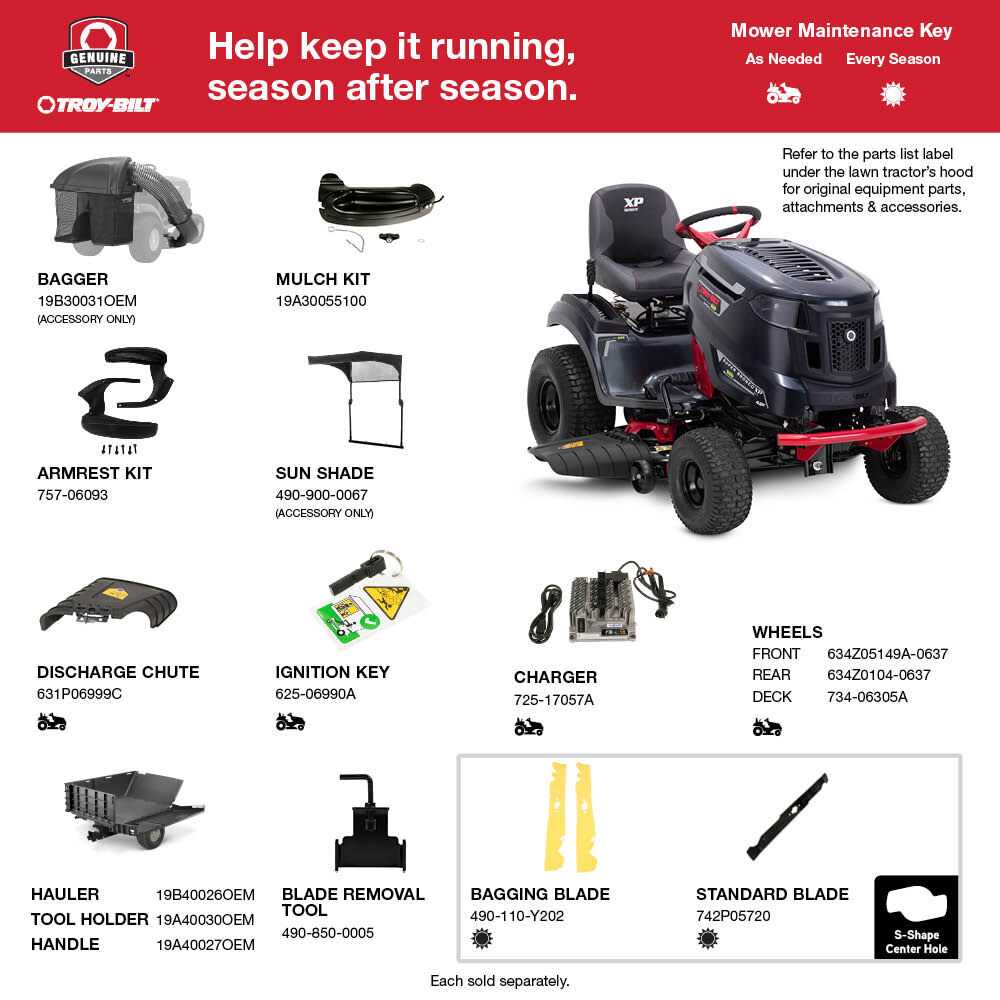

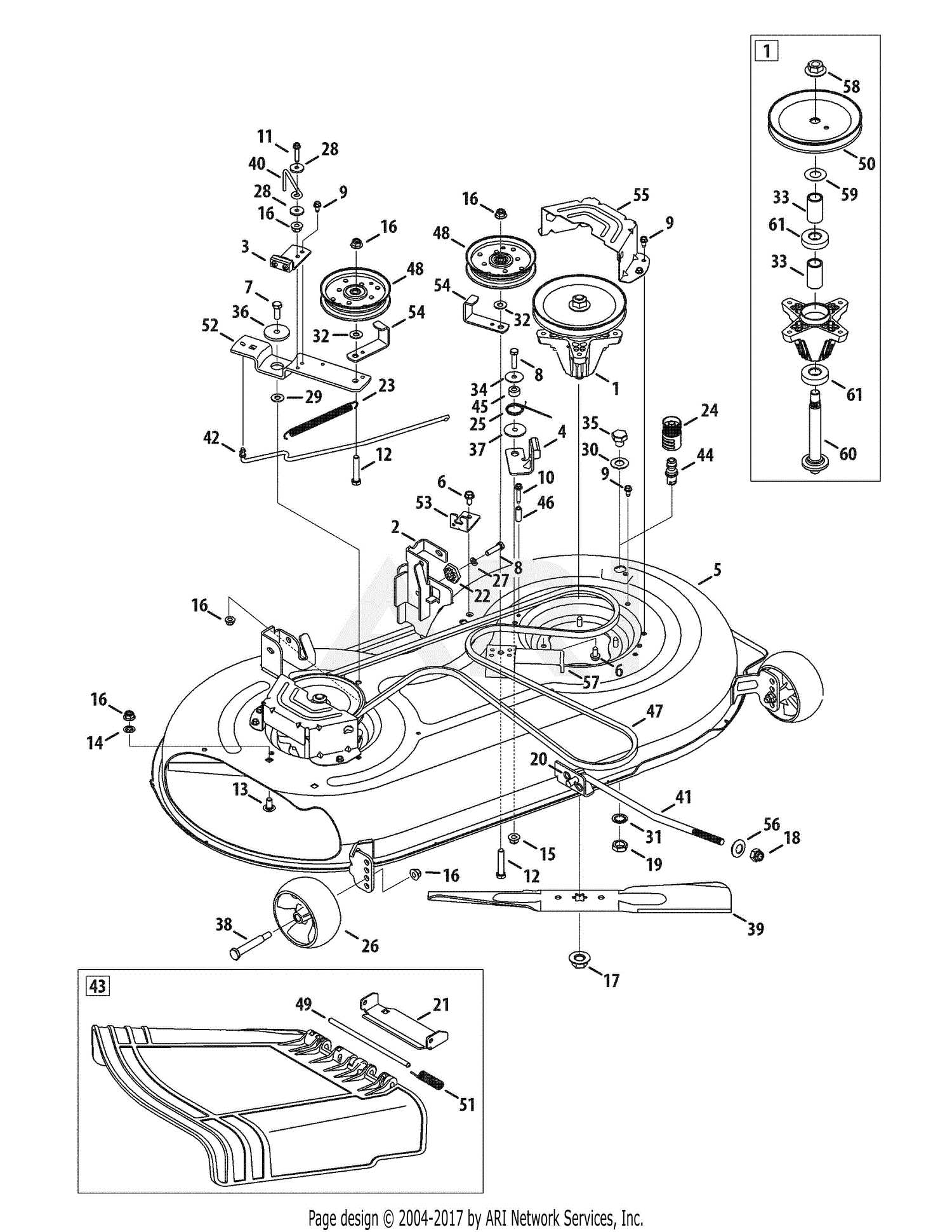

Replacing Blades and Belts Efficiently

Ensuring optimal performance in your equipment requires timely replacement of crucial components. Among these, the cutting edges and transmission belts play a significant role in maintaining efficiency and effectiveness. This section will guide you through the essential steps to efficiently swap out these parts, enhancing your machine’s longevity and functionality.

Essential Tools and Preparation

Before beginning the replacement process, gather the necessary tools and materials. A well-prepared workspace not only increases safety but also streamlines the task. Here’s a list of items you might need:

| Tool | Description |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Socket Set | Useful for accessing hard-to-reach fasteners. |

| Screwdriver | Required for any screws securing the covers. |

| Replacement Blades | New cutting edges compatible with your model. |

| Replacement Belts | New transmission belts for optimal performance. |

| Safety Gloves | To protect your hands during the process. |

Step-by-Step Replacement Process

Follow these straightforward steps to replace the cutting edges and belts effectively:

- Ensure the equipment is powered off and disconnected from any power source.

- Lift the deck carefully using the appropriate tools, giving access to the cutting edges.

- Remove the old blades by loosening the securing bolts, and replace them with new ones, tightening securely.

- For belt replacement, locate the worn-out belt and release any tension before removing it.

- Install the new belt following the manufacturer’s routing diagram to ensure proper fit.

- Reassemble any covers and securely tighten all fasteners before testing the equipment.

By adhering to these guidelines, you can enhance the efficiency and performance of your machinery, ensuring it operates at peak condition for all your tasks.

Electrical System Checks and Fixes

This section focuses on the importance of ensuring the proper functioning of the electrical components within your equipment. A well-maintained electrical system is crucial for optimal performance, as it directly impacts the overall reliability and efficiency. Here, we will outline key procedures for diagnosing and rectifying common electrical issues.

Begin by inspecting the battery and connections, as these are often the source of power-related problems. Corrosion or loose connections can hinder performance, so it’s vital to ensure everything is secure and clean. Additionally, verifying the integrity of the wiring and components can prevent further complications.

| Issue | Check | Fix |

|---|---|---|

| Equipment won’t start | Inspect battery charge and connections | Recharge or replace battery; clean terminals |

| Dim lights | Examine wiring for damage | Repair or replace damaged wires |

| Intermittent power | Check switches and fuses | Replace faulty switches or blown fuses |

| Unusual sounds | Assess electrical components for wear | Lubricate or replace worn components |

By conducting these checks, you can enhance the longevity and functionality of your machinery. Regular maintenance and prompt attention to any irregularities will ensure a smooth and efficient operation.

Improving Steering and Maneuverability

Enhancing the handling capabilities of your equipment can significantly elevate its performance and usability. By focusing on specific adjustments and upgrades, you can achieve smoother navigation and increased precision during operation.

Regular Maintenance: Ensuring that all components related to the steering mechanism are in optimal condition is crucial. Regularly check for wear and tear on parts such as the steering gear, linkages, and wheel assemblies. Lubricating these areas can also help reduce friction, leading to a more responsive feel.

Adjusting Tire Pressure: Proper tire inflation is essential for effective maneuvering. Maintaining the correct pressure not only improves traction but also allows for better control. Check the manufacturer’s specifications to ensure that your tires are inflated to the recommended levels.

Upgrading Steering Components: Consider replacing outdated or worn steering components with high-quality alternatives. Improved steering arms, bearings, and other hardware can enhance responsiveness, making it easier to navigate tight spaces or challenging terrain.

Implementing Weight Distribution Techniques: Proper weight distribution can significantly affect maneuverability. Ensure that loads are evenly balanced to avoid tipping and to maintain control during operation. This can be achieved by strategically placing equipment and materials in designated areas.

Practice and Familiarization: Familiarizing yourself with the equipment’s handling characteristics can lead to improved performance. Spend time practicing maneuvers in different conditions to understand how adjustments impact steering and overall control.

Lubrication Tips for Moving Parts

Proper maintenance of mechanical components is essential for ensuring smooth operation and longevity. Regularly applying lubricants can significantly reduce friction, prevent wear, and enhance the performance of the system. This section provides essential insights into effective lubrication practices for various moving elements.

Types of Lubricants

Different applications require specific types of lubricants. Here is a brief overview of the common varieties:

| Type | Best Use |

|---|---|

| Oil | Ideal for high-speed components, providing excellent fluidity and heat resistance. |

| Grease | Suitable for heavy-load applications, offering superior adhesion and moisture resistance. |

| Dry Lubricants | Effective in dusty environments, reducing friction without attracting dirt. |

Application Techniques

Applying lubricants correctly is crucial for optimal results. Follow these best practices:

- Clean surfaces thoroughly before applying any lubricant to ensure maximum adhesion.

- Use the appropriate amount of lubricant to avoid over-application, which can attract dirt and debris.

- Focus on joints, bearings, and pivot points, as these areas are most susceptible to wear.

Seasonal Care and Storage Tips

Proper maintenance throughout the year ensures optimal performance and longevity of your outdoor equipment. By adhering to seasonal care guidelines, you can effectively prepare your machine for different weather conditions and minimize wear and tear. This not only enhances efficiency but also saves on costly repairs and replacements in the future.

Preparing for Winter

As the cold season approaches, it’s crucial to winterize your machinery. Begin by thoroughly cleaning the exterior to prevent rust and corrosion. Drain any fuel remaining in the tank and lines, as old fuel can degrade engine performance. Additionally, consider storing the equipment in a dry, sheltered area to protect it from moisture and freezing temperatures.

Spring Awakening

With the arrival of warmer weather, it’s time to spring into action. Start by inspecting the engine, checking the oil levels, and replacing any filters that may be clogged. Ensure that all moving parts are lubricated and that tires are properly inflated. Performing these checks will help to ensure that your equipment operates smoothly and efficiently as you prepare for the busy season ahead.