Maintaining a small engine is crucial for ensuring optimal performance and longevity. A thorough understanding of the essential components and their functionality can greatly aid in troubleshooting and upkeep. This guide aims to provide insights into the common issues faced by engine users and the steps necessary to address them effectively.

In the world of outdoor equipment, familiarizing oneself with the intricacies of various models enhances the ability to perform necessary adjustments and replacements. By mastering these skills, users can not only save on repair costs but also gain confidence in their technical abilities. This resource serves as a valuable tool for both novices and seasoned enthusiasts alike.

Equipped with clear instructions and practical tips, this compilation covers everything from routine checks to in-depth component analysis. Emphasizing safety and efficiency, it empowers individuals to take control of their machinery, ensuring that every task is approached with precision and care. Whether faced with a minor glitch or a major overhaul, this guide provides the knowledge needed to tackle any challenge.

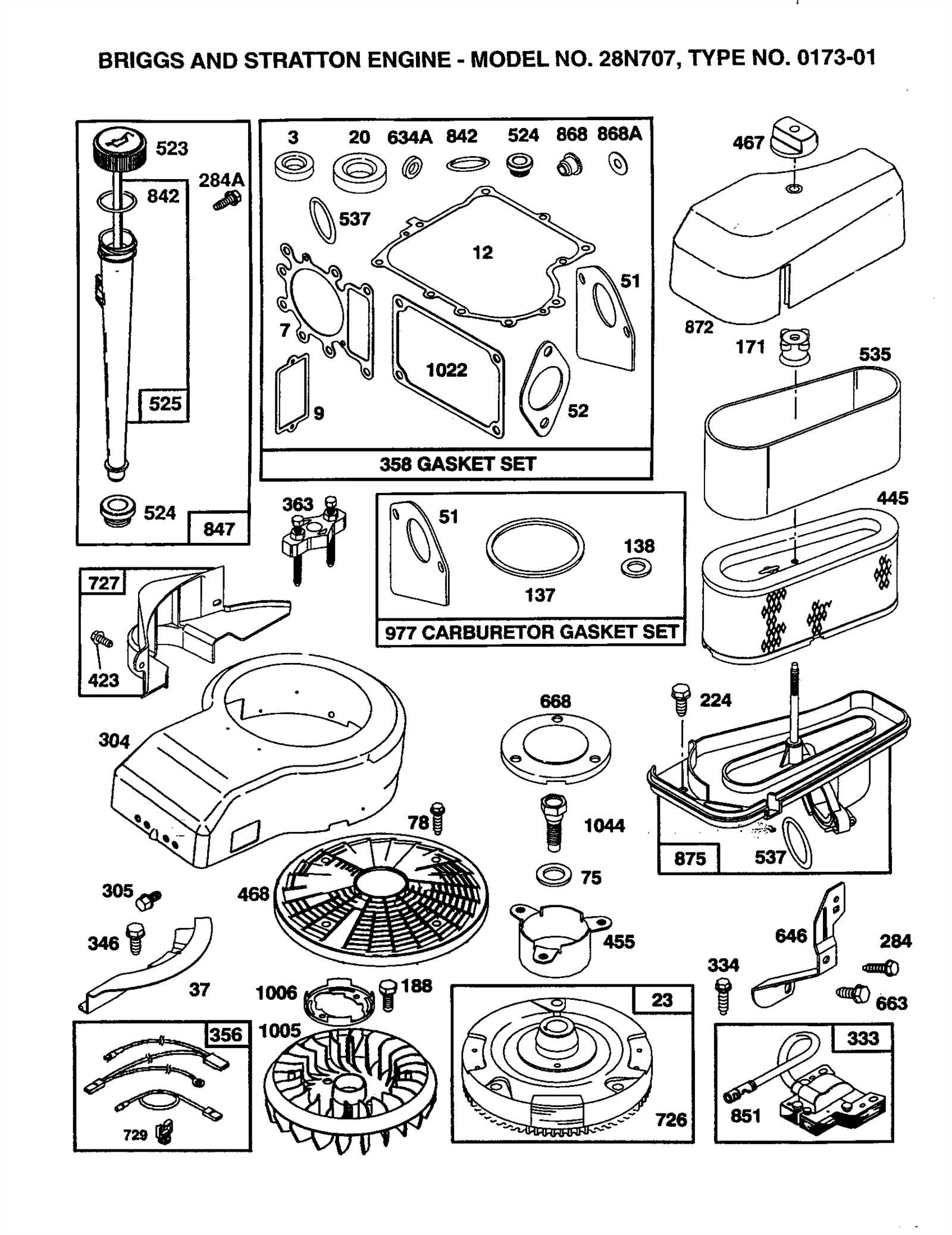

Understanding the Briggs and Stratton 28N707

This section delves into the essential aspects of a specific small engine model, emphasizing its functionality, maintenance, and troubleshooting techniques. Recognizing the fundamental components and operational characteristics is crucial for effective usage and longevity of the equipment.

Key Features

The engine is designed for versatility, powering various types of outdoor machinery. Its robust construction ensures durability, while innovative engineering contributes to fuel efficiency and ease of operation. Familiarity with these features aids users in maximizing performance and minimizing wear over time.

Common Issues and Solutions

Like any mechanical system, challenges may arise during operation. Understanding typical malfunctions can help in swift diagnosis. Regular inspections and adhering to maintenance schedules can prevent many common problems. For instance, checking air filters and spark plugs regularly is essential for optimal performance. Emphasizing preventive measures not only enhances efficiency but also prolongs the lifespan of the engine.

Common Issues with the 28N707 Engine

Engines of this type often encounter several recurring problems that can affect their performance and longevity. Identifying these issues early on can save time and resources, ensuring smooth operation and reliability.

Fuel Delivery Problems: One of the most frequent issues is related to the fuel system. Clogged fuel lines, dirty filters, or malfunctioning carburetors can lead to inadequate fuel supply, causing stalling or difficulty starting.

Electrical Failures: Electrical components, including the ignition system, can fail over time. A faulty spark plug or a damaged ignition coil can prevent the engine from starting or cause it to run erratically.

Overheating: Excessive heat can result from various factors such as low oil levels, a blocked cooling system, or a malfunctioning thermostat. Overheating can lead to severe damage, so monitoring engine temperatures is crucial.

Oil Leaks: Leaks can develop due to worn gaskets or seals, resulting in decreased lubrication and potential engine failure. Regular checks for oil spots can help catch these issues early.

Noise and Vibration: Unusual sounds or excessive vibration may indicate problems such as loose components, worn bearings, or an imbalanced flywheel. Addressing these symptoms promptly can prevent further damage.

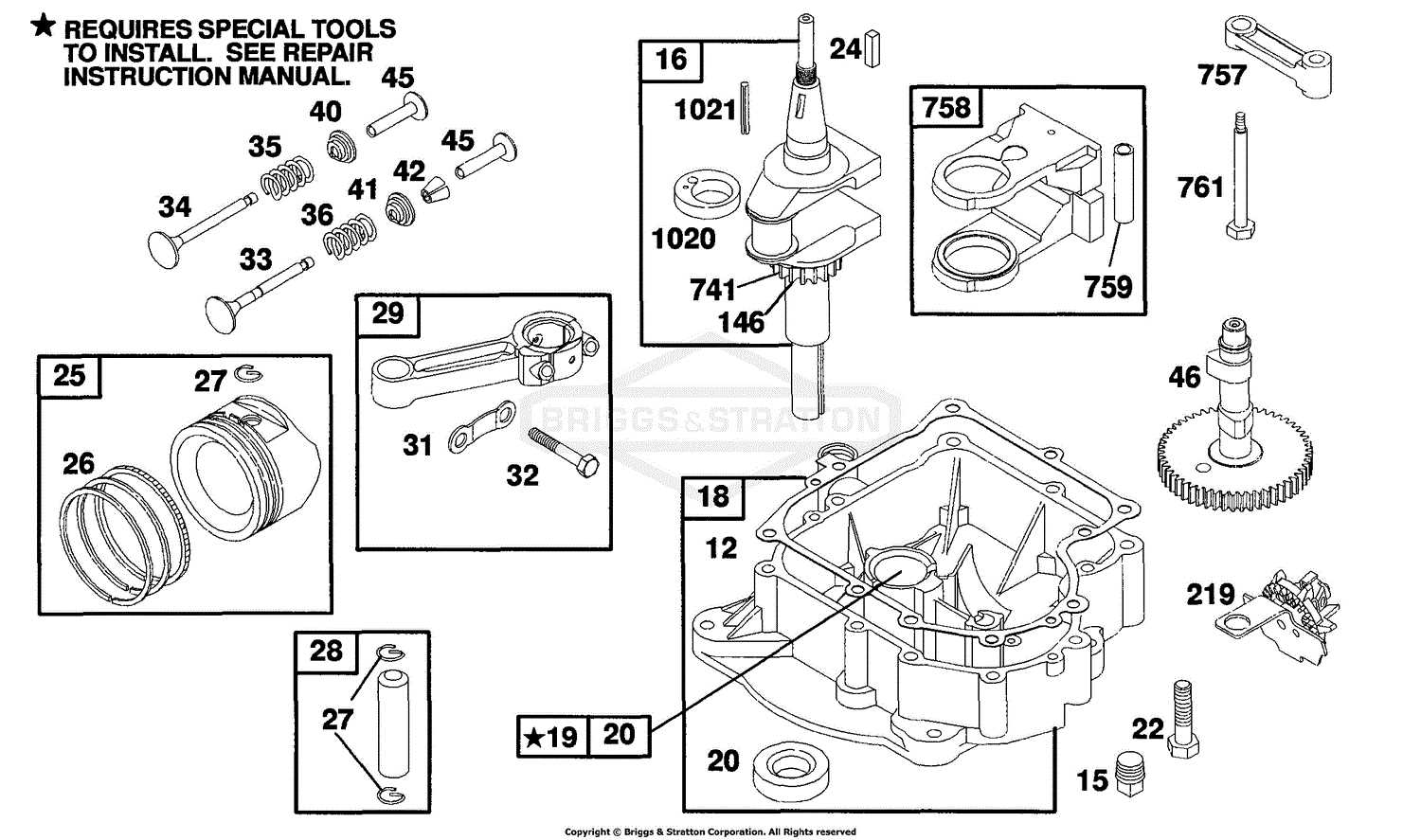

Essential Tools for Engine Repair

Maintaining and fixing small engines requires a specific set of instruments to ensure efficiency and precision. Having the right gear at your disposal can significantly enhance the quality of your work and streamline the entire process. From basic hand tools to specialized equipment, understanding what is necessary can make all the difference in achieving successful results.

Wrenches are fundamental for loosening and tightening various components. A good set includes both standard and metric sizes, allowing versatility for different fasteners. Additionally, screwdrivers with interchangeable heads can handle a variety of screws, making them indispensable in any toolkit.

Diagnostic tools such as multimeters and compression testers are crucial for troubleshooting. These devices help identify electrical issues and assess engine performance, ensuring any underlying problems are addressed promptly. Furthermore, a socket set is essential for reaching tight spaces, enabling more comprehensive access to parts that require servicing.

For those who engage in more intricate tasks, piston ring compressors and valve spring compressors are invaluable. These tools assist in the accurate assembly and disassembly of engine components, providing greater control during complex repairs. Lastly, having a reliable workbench equipped with a vice can enhance stability, making it easier to handle and manipulate parts during the maintenance process.

Step-by-Step Maintenance Procedures

Proper upkeep of your engine is crucial for ensuring optimal performance and longevity. This section outlines essential procedures that should be performed regularly to maintain efficiency and prevent potential issues. Following these steps will help you keep your machine in top condition and reduce the likelihood of costly repairs.

Begin by checking the oil level and quality. Use the dipstick to ensure the oil is at the recommended level. If it’s low, add the appropriate type of oil. If it appears dirty or contaminated, consider changing it completely. Next, inspect the air filter. A clean air filter allows for better airflow and improves engine efficiency. Remove any debris or replace the filter if it’s excessively dirty.

Next, examine the spark plug. Remove it and inspect for wear or carbon buildup. If necessary, clean or replace it to ensure smooth ignition. Additionally, check the fuel system for leaks and ensure that fuel is fresh. Old or contaminated fuel can lead to performance issues.

Finally, inspect all belts and hoses for signs of wear or damage. Replace any that appear frayed or cracked. Keeping these components in good condition will help avoid breakdowns and maintain overall functionality. Regular maintenance will extend the life of your engine and enhance its performance.

Troubleshooting Engine Performance Problems

When facing issues with engine operation, identifying the root cause can be a challenging task. Several factors may contribute to decreased efficiency, irregular running, or failure to start. This section provides guidance on common performance-related concerns, helping you systematically diagnose and resolve these issues.

1. Inspect Fuel Supply: A frequent culprit behind poor performance is inadequate fuel delivery. Check for blockages in the fuel line, ensure the tank is filled with clean fuel, and verify that the fuel filter is not clogged.

2. Examine Air Filtration: Proper airflow is crucial for optimal engine function. Clean or replace the air filter if it appears dirty or damaged, as restricted airflow can lead to inefficiency and potential overheating.

3. Check Spark Plug Condition: The spark plug is essential for ignition. Remove it and inspect for wear, carbon buildup, or damage. Replacing a worn or faulty spark plug can significantly improve engine responsiveness.

4. Evaluate Engine Oil: Maintaining the correct oil level and quality is vital. Low or contaminated oil can lead to increased friction and overheating. Change the oil according to the manufacturer’s recommendations.

5. Assess Electrical Components: Issues with the ignition system can prevent proper starting and performance. Check the battery, ignition coil, and wiring for signs of wear or damage. Replacing faulty components can restore functionality.

6. Monitor Exhaust Emissions: Excessive smoke or unusual odors may indicate internal problems. Inspect exhaust components for blockages or leaks, and ensure that the engine is running within the recommended parameters.

By systematically addressing these areas, you can effectively troubleshoot and enhance the overall performance of your engine, ensuring reliable operation for your equipment.

Replacing Key Engine Components

Maintaining the efficiency and performance of a small engine often requires replacing critical components. Understanding the process and importance of these replacements can significantly extend the lifespan of the machinery and enhance its functionality. This section will provide a detailed overview of essential components that may need to be addressed during maintenance or repair.

Identifying Components for Replacement

Key elements such as the air filter, spark plug, and fuel filter play vital roles in ensuring optimal engine operation. A clogged air filter can restrict airflow, leading to reduced performance, while a worn-out spark plug may result in misfires or difficulty starting. Regular inspections will help in identifying these components early, allowing for timely replacements.

Steps for Component Replacement

To replace any engine part, first ensure the equipment is powered down and secured. Begin by removing any covers or shields to access the component. For example, when changing a spark plug, utilize a socket wrench for removal and install the new one, making sure it’s snug but not overly tightened. Always refer to specific guidelines for each component to avoid damage.

In conclusion, proactive replacement of key engine components is crucial for maintaining high performance and reliability. Regular maintenance checks and timely interventions can prevent more significant issues down the road.

Safety Precautions During Repairs

When working on machinery, ensuring safety is paramount. Adhering to appropriate guidelines can prevent accidents and injuries. This section highlights essential practices to follow while conducting maintenance and troubleshooting tasks.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and masks to shield against debris and harmful substances. |

| Disconnect Power Source | Before starting work, ensure that the equipment is completely powered down and unplugged. |

| Work in a Well-Ventilated Area | Ensure proper airflow to avoid inhalation of fumes and ensure a safe environment. |

| Keep Workspace Organized | A tidy workspace reduces the risk of tripping and helps locate tools easily. |

| Follow Manufacturer Guidelines | Refer to provided specifications and instructions to avoid mistakes and ensure safety. |

| Use Tools Properly | Utilize the correct tools for each task to minimize the risk of injury and damage. |

| Stay Alert | Maintain focus during the entire process to quickly respond to any unforeseen issues. |

Understanding Engine Specifications

Engine specifications play a crucial role in determining the performance, efficiency, and suitability of a power unit for various applications. These details provide insights into the engine’s design, capabilities, and operational parameters, enabling users to make informed decisions regarding maintenance and compatibility with different equipment.

Key specifications typically include displacement, power output, torque ratings, and fuel requirements. Each of these elements contributes to the overall functionality and longevity of the engine, making it essential to understand them thoroughly.

| Specification | Description |

|---|---|

| Displacement | The total volume of all the cylinders in the engine, usually measured in cubic centimeters (cc) or cubic inches (ci). |

| Power Output | The maximum power the engine can produce, typically measured in horsepower (hp) or kilowatts (kW). |

| Torque | The rotational force generated by the engine, expressed in foot-pounds (ft-lb) or Newton-meters (Nm). |

| Fuel Type | The recommended fuel for optimal performance, which can vary from gasoline to diesel or alternative fuels. |

Understanding these specifications allows users to match engines with their intended tasks, ensuring efficiency and reliability in operation. Moreover, it aids in troubleshooting issues and optimizing performance through proper maintenance practices.

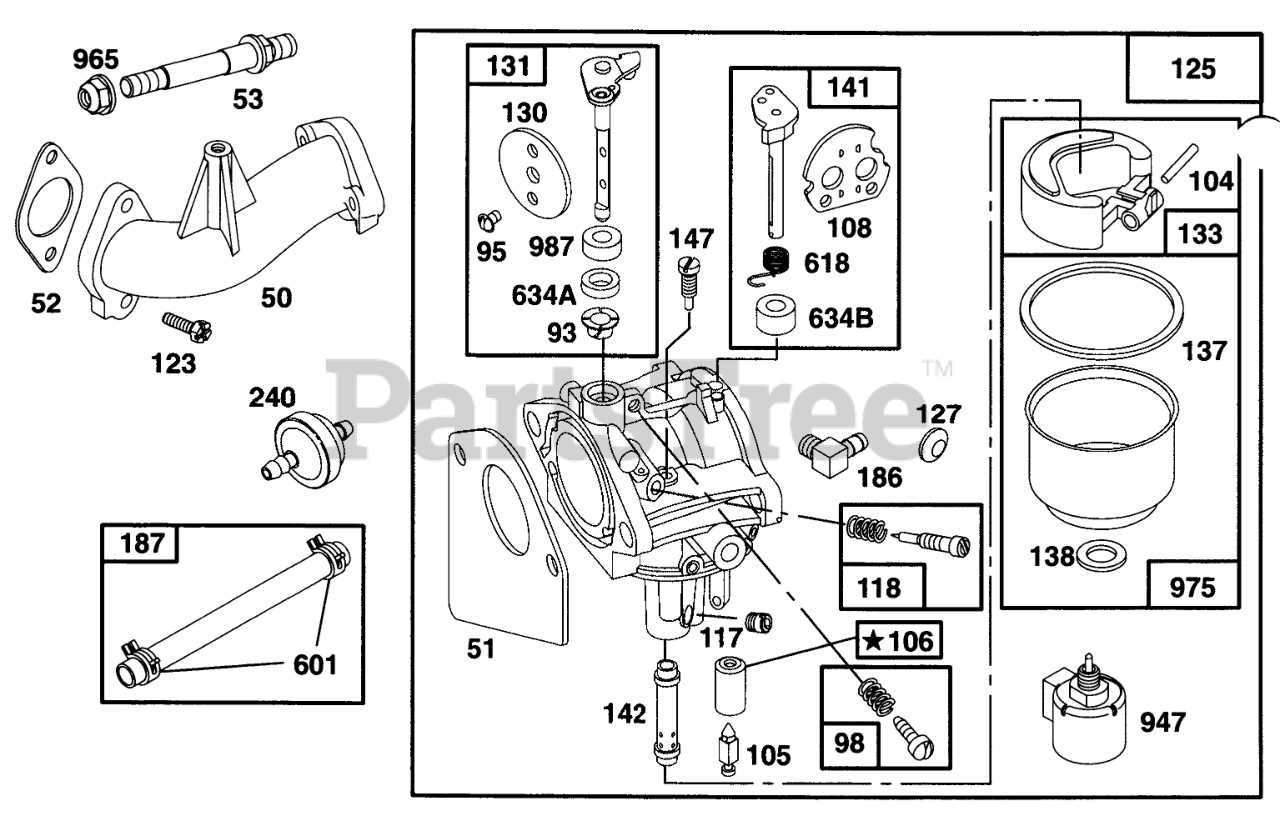

Fuel System Care and Maintenance

Proper upkeep of the fuel system is essential for optimal performance and longevity of your engine. Regular attention to this area ensures efficient fuel delivery, minimizes the risk of clogs, and promotes overall reliability. Adopting a systematic approach can prevent costly repairs and enhance the efficiency of your equipment.

Routine Inspection

Conducting periodic inspections can help identify potential issues before they escalate. Focus on the following components:

- Fuel lines: Check for cracks or leaks.

- Fuel filter: Ensure it is clean and replace it if necessary.

- Fuel tank: Inspect for debris or corrosion.

Cleaning Procedures

Keeping the fuel system clean is crucial for smooth operation. Consider implementing these practices:

- Drain old fuel: Regularly replace fuel that has been stored for an extended period.

- Flush the system: Use a suitable cleaning solution to remove any buildup.

- Check for water: Ensure no moisture is present in the fuel tank.

By following these guidelines, you can ensure that the fuel system remains in excellent condition, enhancing the performance of your engine and extending its lifespan.

Electrical System Diagnostics

Assessing the functionality of the electrical components in a small engine is crucial for maintaining optimal performance. Identifying faults in the wiring, ignition, and charging systems can prevent extensive damage and costly repairs. This section outlines the steps and tools necessary for effective diagnostics.

To accurately diagnose electrical issues, follow these key steps:

- Visual Inspection: Examine wiring for wear, corrosion, or disconnections.

- Check Connections: Ensure all connectors are secure and free of debris.

- Test Voltage: Use a multimeter to measure voltage at various points in the system.

- Inspect Components: Evaluate the functionality of the ignition coil, spark plug, and battery.

Essential tools for effective diagnostics include:

- Multimeter: For measuring voltage, current, and resistance.

- Spark Tester: To confirm spark generation at the spark plug.

- Battery Tester: To assess battery health and charge levels.

By systematically approaching electrical diagnostics, users can effectively pinpoint issues, ensuring reliable engine performance and longevity.

Seasonal Maintenance Tips

Proper upkeep is essential for ensuring the longevity and efficiency of your equipment. By implementing a few straightforward practices tailored to the changing seasons, you can prevent issues before they arise and maintain optimal performance. Regular attention to key components will help extend the lifespan of your machinery and enhance its reliability throughout the year.

Spring Preparation

As winter recedes, it’s vital to check for any damage caused by cold weather. Start by inspecting the fuel system; old fuel can lead to performance issues. Replace it with fresh fuel and consider adding a stabilizer to keep it in good condition for the upcoming months. Additionally, examine air filters and clean or replace them as necessary to ensure proper airflow.

Fall Shutdown

Before winter sets in, prepare your equipment for storage. Begin by thoroughly cleaning all surfaces and removing debris. Drain the fuel system to prevent deterioration during the cold months. It’s also advisable to change the oil and replace the spark plug to ensure a smooth start come springtime. Finally, cover your machinery to protect it from moisture and dust.

Finding Replacement Parts Efficiently

Locating suitable components for your outdoor power equipment can often seem daunting. However, with the right strategies, you can streamline the process and ensure that you acquire the necessary items without unnecessary delays. This section will guide you through effective methods to identify and obtain parts efficiently.

Utilizing Online Resources

The internet is a powerful tool when it comes to sourcing components. Numerous websites specialize in offering detailed catalogs and specifications for various models. You can search by model number or description to find exactly what you need.

Local Dealers and Distributors

In addition to online options, local retailers can be invaluable resources. Building a relationship with nearby dealers can provide insights into availability and compatibility of parts. Many distributors also offer expert advice, which can be beneficial when troubleshooting specific issues.

| Source | Advantages | Considerations |

|---|---|---|

| Online Retailers | Wide selection, competitive pricing | Shipping times, return policies |

| Local Dealers | Immediate availability, expert advice | Potentially higher prices |

| Manufacturer Websites | Direct access to original parts | Limited selection for older models |