Understanding the nuances of garden equipment is essential for anyone looking to enhance their outdoor experience. Proper upkeep not only prolongs the lifespan of your tools but also ensures optimal performance during use. This section will delve into essential techniques and tips for maintaining a specific type of gardening equipment.

With the right knowledge and resources, any user can troubleshoot common issues and carry out necessary adjustments. Emphasizing routine checks and simple repairs can save both time and money, making the gardening process smoother and more enjoyable.

Whether you are a seasoned gardener or just starting out, familiarizing yourself with the operational intricacies of your tools can make a significant difference. This guide aims to empower you with the information needed to keep your equipment in top condition.

Troy Bilt String Trimmer Repair Manual

This section provides essential guidance for maintaining and troubleshooting a popular gardening tool. Proper care and timely adjustments can extend the lifespan of the equipment, ensuring efficient performance during use.

Understanding the key components and common issues can significantly simplify the upkeep process. Below is a summary of typical problems encountered, along with suggested solutions:

| Issue | Solution |

|---|---|

| Engine won’t start | Check fuel levels and ensure the spark plug is functioning properly. |

| Uneven cutting | Inspect the cutting head for wear and adjust the height settings. |

| Excessive vibration | Examine the attachment for damage and ensure it is securely mounted. |

| Fuel leaks | Replace damaged fuel lines and check for loose connections. |

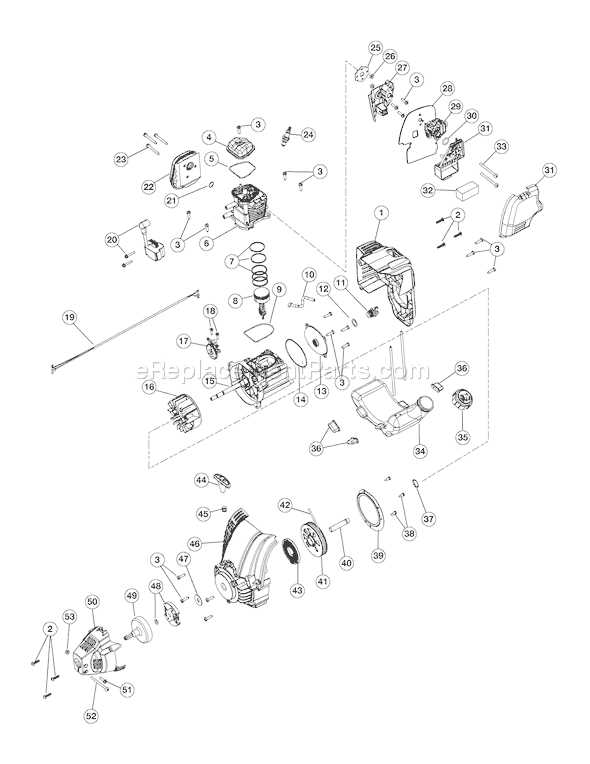

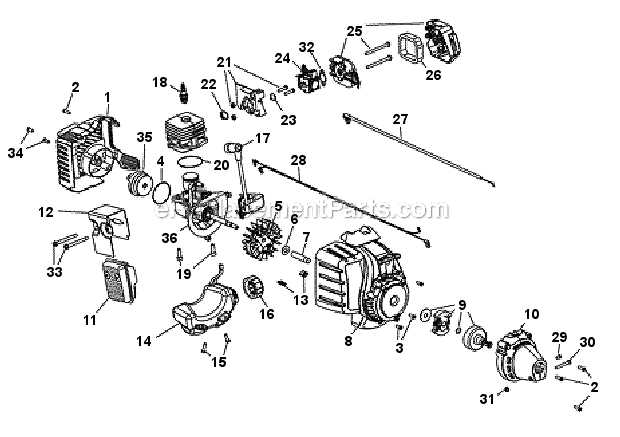

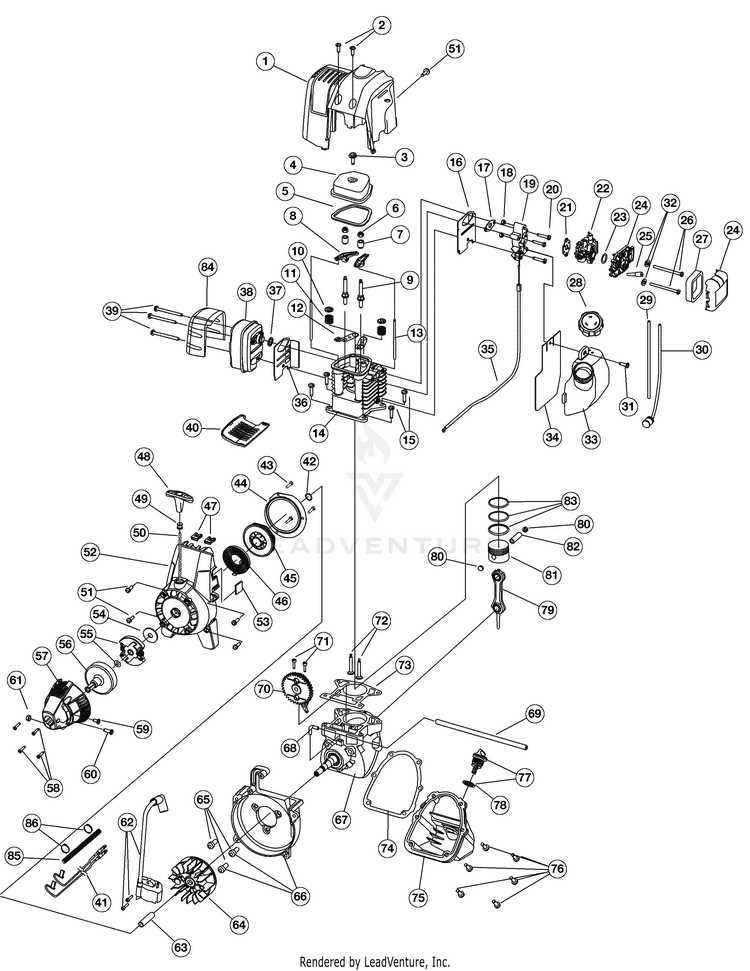

Understanding Your Trimmer Components

To effectively operate and maintain your cutting device, it’s essential to familiarize yourself with its various elements. Each part plays a crucial role in the overall performance and functionality, ensuring efficient operation during use.

Main Components

- Engine: The powerhouse of the device, providing the necessary energy for cutting.

- Cutting Head: The area where the cutting line is attached, essential for trimming tasks.

- Handle: Designed for user comfort and control, enabling precise maneuverability.

- Guard: Safety feature that protects the user from debris and accidental contact.

- Fuel Tank: Holds the mixture required for engine operation.

Understanding Each Part

- Engine: Different models may have varying types of engines, influencing power and efficiency.

- Cutting Head: Knowing how to replace or adjust the line can enhance your trimming experience.

- Handle: Ergonomic designs can reduce fatigue during extended use.

- Guard: Regularly check for any damage to ensure optimal protection.

- Fuel Tank: Proper fuel mixture is vital for engine longevity.

Common Issues and Troubleshooting Steps

This section addresses frequent problems that users may encounter with their gardening equipment and provides practical solutions to resolve them. By understanding these typical challenges, owners can effectively maintain their devices and ensure optimal performance.

One common issue is difficulty starting the machine. This can often be traced to fuel problems, such as stale gasoline or improper mixture ratios. Checking the fuel system for blockages and ensuring that the spark plug is in good condition can resolve many starting issues.

Another frequent concern is the equipment stalling during operation. This may result from debris clogging the cutting head or incorrect settings. Regularly cleaning the cutting mechanism and adjusting the settings according to the manufacturer’s recommendations can help prevent stalling.

Lastly, users might experience excessive vibration while using the tool. This can indicate wear and tear on the components or improper assembly. Inspecting the assembly and replacing worn parts can significantly reduce vibration and enhance user comfort.

Essential Tools for Repair Work

When it comes to maintaining outdoor equipment, having the right set of tools is crucial for effective servicing and troubleshooting. A well-equipped workspace can greatly enhance the efficiency of any maintenance task, ensuring that each component functions optimally.

Basic Hand Tools

Fundamental hand tools are indispensable for any maintenance project. Items such as screwdrivers, wrenches, and pliers are essential for disassembling parts and performing adjustments. Quality hand tools not only provide better control but also minimize the risk of damaging delicate components during the process.

Specialized Equipment

In addition to basic tools, specialized equipment can significantly ease complex tasks. Torque wrenches and multimeters are invaluable for precise adjustments and electrical diagnostics, respectively. Investing in such tools ensures thoroughness and accuracy in every maintenance activity, leading to improved longevity and performance of the equipment.

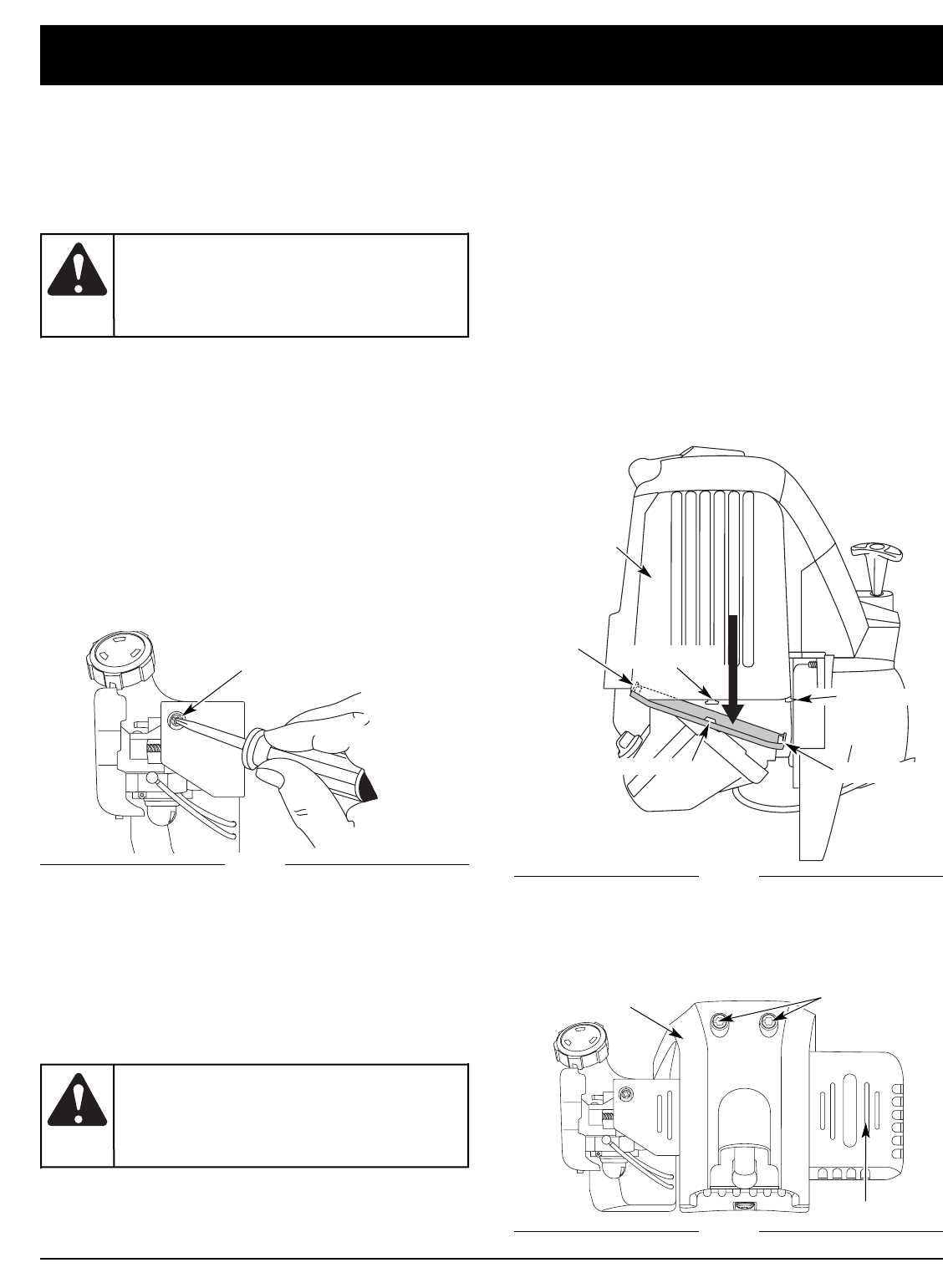

Step-by-Step Guide for Replacing Line

Maintaining the cutting mechanism of your outdoor equipment is essential for optimal performance. This guide provides a clear process for replacing the line, ensuring efficient operation and enhanced longevity of the device.

Gather Necessary Tools

Before starting the replacement, make sure to collect the required tools and materials:

| Item | Description |

|---|---|

| Replacement Line | A suitable length of line compatible with your equipment. |

| Scissors | For cutting the line to the appropriate length. |

| Gloves | To protect your hands during the process. |

| Screwdriver | If necessary, for opening any compartments. |

Replacement Process

Follow these steps to successfully replace the line:

- Turn off the device and disconnect the power source for safety.

- Remove the spool from the head, ensuring to follow the manufacturer’s guidelines.

- Cut the new line to the specified length, usually indicated in the product specifications.

- Insert the new line into the spool, making sure to wind it tightly in the correct direction.

- Reattach the spool to the head, ensuring it locks securely in place.

- Reconnect the power source and perform a test run to verify functionality.

Engine Maintenance and Care Tips

Maintaining the power source of your outdoor equipment is crucial for optimal performance and longevity. Regular attention to engine components ensures reliability and efficiency during operation. Adhering to simple maintenance practices can significantly enhance the lifespan of your machine.

Regular Cleaning

Keep the engine clean to prevent dirt and debris from affecting its functionality. Use a soft brush or compressed air to remove dust from cooling fins and other accessible areas. A clean engine runs cooler and operates more efficiently.

Oil Changes

Changing the oil regularly is essential for lubricating internal parts. Use the recommended oil type for your specific engine model and adhere to the suggested change intervals. This practice minimizes wear and prevents overheating, ensuring smooth operation.

Cleaning and Lubrication Procedures

Proper maintenance is essential for ensuring the longevity and efficient performance of your outdoor equipment. Regular cleaning and lubrication help prevent wear and tear, ensuring that all components function smoothly and effectively.

Follow these steps for effective cleaning and lubrication:

- Cleaning the Exterior:

- Use a soft brush to remove dirt and debris from the surface.

- Wipe down with a damp cloth to prevent buildup.

- Cleaning the Air Filter:

- Remove the air filter and tap it gently to dislodge dust.

- Wash it with mild soap and water if necessary, then let it dry completely.

- Lubricating Moving Parts:

- Apply a suitable lubricant to pivot points and gears.

- Ensure excess lubricant is wiped away to avoid attracting dirt.

- Inspecting Fuel System:

- Check fuel lines for cracks or wear.

- Replace fuel filters as needed to maintain performance.

Adhering to these procedures will enhance the functionality and extend the lifespan of your equipment.

Electrical System Diagnosis and Repair

This section focuses on the assessment and restoration of electrical components within outdoor power equipment. Understanding the functionality and interconnections of these parts is crucial for effective troubleshooting.

Identifying Issues: Start by examining the ignition system, battery, and wiring. Look for signs of wear, corrosion, or damage that could hinder performance. Using a multimeter can aid in measuring voltage and continuity, allowing for precise identification of faults.

Testing Components: Each element of the electrical system should be individually tested. For instance, checking the spark plug for proper firing and ensuring the battery holds charge are essential steps. If a component fails to meet specifications, replacement may be necessary.

Making Repairs: Once issues are pinpointed, proceed with necessary repairs. This may involve replacing faulty wires, securing loose connections, or installing new batteries. Ensure that all connections are tight and free from debris to maintain optimal functionality.

Final Checks: After completing repairs, perform a final inspection of the entire system. Re-test components to confirm that all electrical systems are operating correctly. This thorough approach will enhance reliability and extend the lifespan of the equipment.

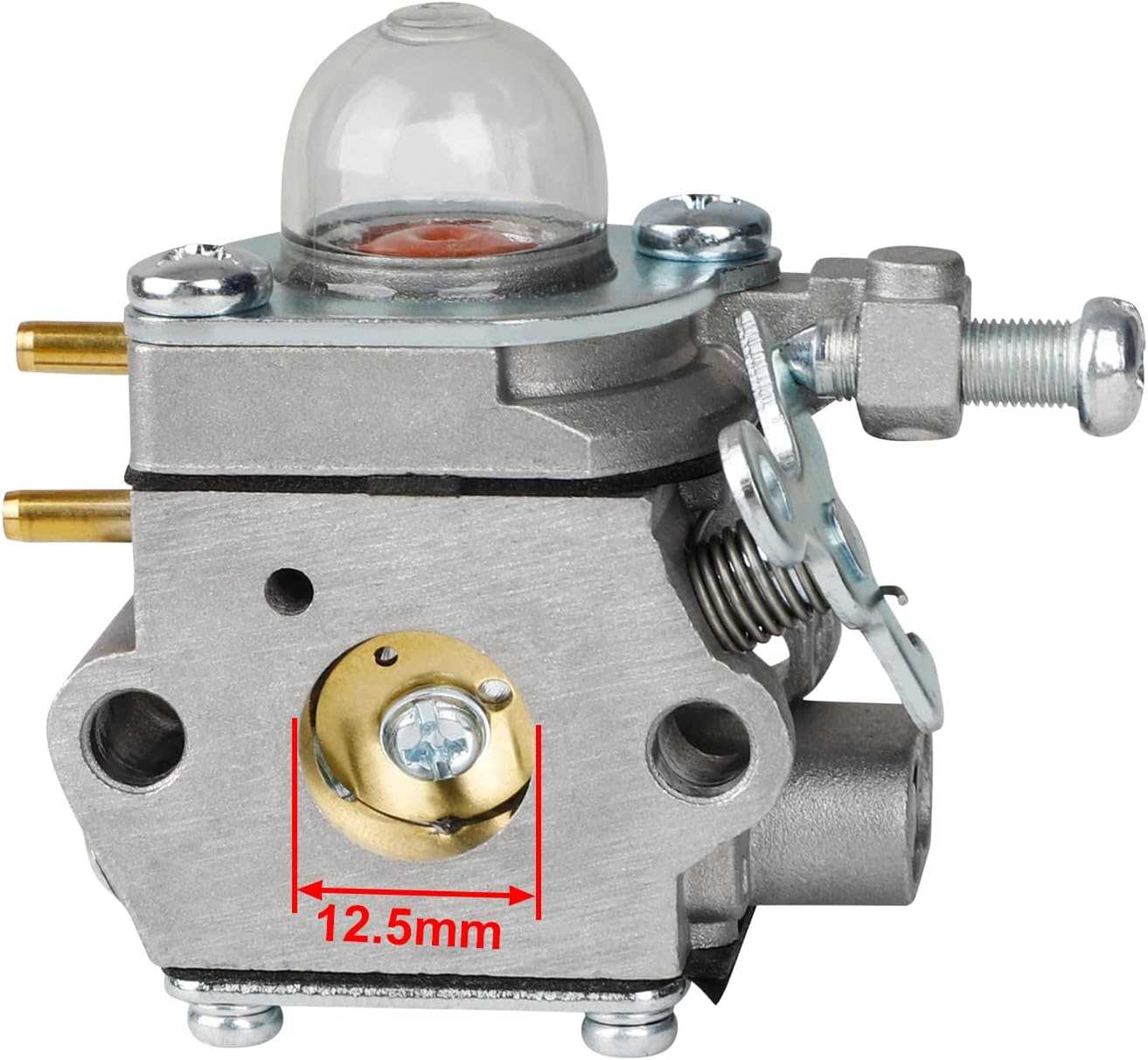

Fuel System Troubleshooting Techniques

Proper maintenance of the fuel system is essential for optimal performance of outdoor equipment. Identifying and resolving issues within this system can enhance efficiency and prolong the lifespan of the device. Below are effective methods to diagnose common fuel-related problems.

- Inspect Fuel Quality:

Ensure the fuel is fresh and free from contaminants. Stale or dirty fuel can lead to performance issues.

- Check Fuel Lines:

Examine the fuel lines for cracks, leaks, or blockages. Damaged lines can hinder fuel flow and affect functionality.

- Inspect the Filter:

A clogged fuel filter can restrict fuel supply. Regularly clean or replace the filter as needed.

- Examine the Carburetor:

A malfunctioning carburetor can disrupt the air-fuel mixture. Clean and adjust as necessary to ensure proper operation.

- Check for Air Leaks:

Inspect gaskets and seals for integrity. Air leaks can lead to improper combustion and reduced efficiency.

By systematically following these techniques, one can effectively troubleshoot and resolve common issues related to the fuel system, ensuring reliable operation of the equipment.

Adjusting the Cutting Height Properly

Ensuring the correct cutting height is essential for achieving optimal results in landscaping tasks. Proper height adjustment can enhance the efficiency of the equipment, leading to a cleaner and more precise finish. This process not only affects the appearance of the area being worked on but also contributes to the health of the vegetation.

To begin, identify the desired height for your specific application. Factors such as the type of plants, terrain, and intended results will influence this decision. Once you have established the target height, consult the equipment’s specifications for guidance on adjustment methods.

Typically, height adjustments can be made using a lever or dial located on the device. Make sure to perform adjustments when the equipment is off and on stable ground. After modifying the height, it is advisable to conduct a test run to ensure the setting meets your expectations. Fine-tuning may be necessary to achieve the ideal outcome.

Safety Practices During Repairs

Ensuring safety is paramount when undertaking maintenance on any equipment. Proper precautions help prevent accidents and injuries, allowing for a smooth process. This section outlines essential guidelines to follow during servicing tasks.

- Wear Protective Gear: Always utilize appropriate safety equipment such as gloves, goggles, and ear protection to shield against potential hazards.

- Work in a Well-Lit Area: Ensure your workspace is adequately illuminated to avoid accidents caused by poor visibility.

- Disconnect Power Sources: Before starting any maintenance, ensure that all power sources are disconnected to prevent unintended operation.

- Keep Workspace Organized: Maintain a clean and clutter-free environment to reduce the risk of trips and falls.

- Use Proper Tools: Employ the correct tools for the task to avoid injuries caused by incorrect usage.

By adhering to these safety practices, individuals can significantly minimize risks and ensure a successful maintenance experience.

Upgrading Parts for Better Performance

Enhancing equipment efficiency often involves replacing specific components with higher-quality alternatives. By selecting upgraded parts, users can significantly improve the overall functionality and longevity of their tools. This approach not only maximizes performance but also ensures a smoother operation during various tasks.

Benefits of Upgrading Components

Investing in premium parts provides numerous advantages. Enhanced durability, reduced wear and tear, and increased power output are just a few of the benefits that come with superior components. Users can experience fewer breakdowns and improved precision, making the work more enjoyable and efficient.

Recommended Upgrades

| Part | Upgraded Option | Benefits |

|---|---|---|

| Cutting Blade | High-carbon steel blade | Increased sharpness and longevity |

| Fuel Filter | High-performance filter | Better fuel flow and engine protection |

| Ignition Coil | Performance coil | Improved starting and efficiency |

When to Seek Professional Help

Understanding when to engage a specialist can significantly enhance the longevity and functionality of your equipment. While many issues can be resolved independently, certain complications may require the expertise of a trained technician to ensure proper resolution.

Signs of Serious Issues

If you notice persistent problems despite following maintenance guidelines, it may be time to consult a professional. Symptoms such as unusual noises, inconsistent performance, or frequent malfunctions often indicate deeper underlying issues that require expert attention.

Complex Repairs Beyond Your Skill Level

Some repairs necessitate advanced knowledge and tools that are typically not available to the average user. When faced with intricate mechanical failures or electrical concerns, seeking help from a qualified technician is advisable to prevent further damage and ensure safety.