Maintaining your snow-clearing equipment is essential for ensuring optimal performance and longevity. This section provides valuable insights and guidelines tailored to assist you in troubleshooting common issues and executing necessary maintenance tasks effectively.

Understanding the key components of your machinery is crucial. By familiarizing yourself with each part’s function, you can identify potential problems more easily and implement appropriate solutions. Regular inspections and prompt attention to wear and tear can prevent minor issues from escalating into significant repairs.

Additionally, adhering to systematic procedures during maintenance not only enhances the reliability of your equipment but also promotes safety during operation. By following these best practices, you will be better equipped to manage challenges and enjoy a smooth snow removal experience every winter season.

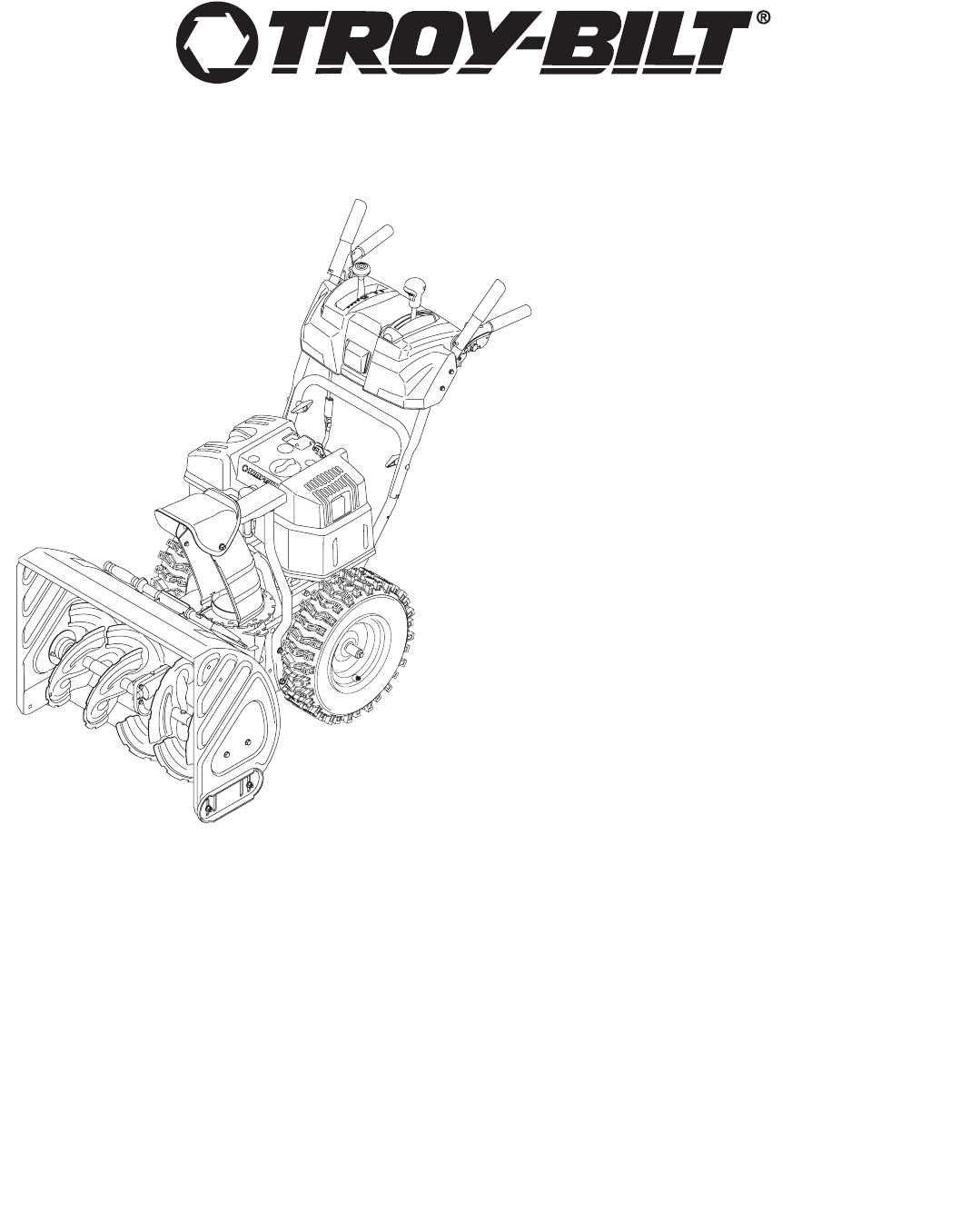

Overview of Troy Bilt Storm 2620

This section provides an insight into a specific model of snow removal equipment, designed for efficient operation in challenging winter conditions. The machine is built to handle various snow depths and offers features that enhance user convenience and performance.

The equipment is equipped with a powerful engine that ensures robust performance, allowing for effective snow clearing across driveways and sidewalks. Its design focuses on ease of use, with intuitive controls and adjustable features to suit different user preferences.

With a strong emphasis on durability, this model incorporates high-quality materials that withstand harsh weather elements, ensuring a long lifespan. The operational efficiency is complemented by innovative technologies that improve maneuverability and snow displacement.

Common Issues and Solutions

When operating a snow-clearing machine, various challenges may arise that can hinder performance. Identifying and addressing these common problems is essential for ensuring efficiency and longevity. Below are frequent issues encountered and their corresponding solutions.

-

Engine Fails to Start:

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for damage or wear.

- Examine the battery charge and connections.

-

Machine Not Clearing Snow Effectively:

- Ensure that the auger is not obstructed by ice or debris.

- Adjust the chute direction for optimal snow discharge.

- Verify that the belts and cables are in good condition and properly adjusted.

-

Unusual Noises During Operation:

- Look for loose components or fasteners that may need tightening.

- Inspect the auger and impeller for damage or wear.

- Lubricate moving parts according to the maintenance guidelines.

-

Difficulty Maneuvering:

- Check tire pressure and tread condition for optimal traction.

- Ensure the drive system is functioning correctly.

- Examine the skid shoes for wear and proper adjustment.

Addressing these common issues can greatly enhance the effectiveness of the equipment. Regular maintenance and timely interventions are key to avoiding more significant problems in the future.

Maintenance Tips for Optimal Performance

To ensure your equipment operates at its best, regular upkeep is essential. Proper care not only prolongs the lifespan of the machine but also enhances its efficiency. Following a few simple practices can lead to significant improvements in performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check and clean air filter | Every 10 hours of use | A clean filter ensures proper airflow and engine efficiency. |

| Inspect spark plug | Every 25 hours of use | Replace if worn or fouled for reliable starting. |

| Oil change | Every 50 hours of operation | Fresh oil reduces friction and helps maintain engine temperature. |

| Check fuel system | Before each use | Ensure fuel is fresh and lines are clear to avoid performance issues. |

By adhering to these simple guidelines, you can maximize the functionality and reliability of your machine, ensuring it remains in top condition for years to come.

Tools Required for Repairs

When undertaking maintenance or fixing equipment, having the right instruments is essential for achieving effective results. Proper tools not only facilitate the repair process but also ensure safety and efficiency. Below is a list of commonly needed implements to tackle various tasks successfully.

First and foremost, a set of basic hand tools, including screwdrivers, wrenches, and pliers, is vital for loosening and tightening components. Additionally, a socket set can provide the necessary leverage for bolts in tight spaces. A torque wrench is crucial for applying the correct amount of force to fasteners, preventing damage.

Moreover, specialized equipment may be required depending on the specific issue. For instance, a multimeter can assist in diagnosing electrical problems, while a compression tester can evaluate engine performance. Safety gear, such as gloves and goggles, is also recommended to protect against potential hazards during the process.

In conclusion, equipping oneself with the appropriate tools is fundamental for effective maintenance and troubleshooting. Ensuring you have the right instruments on hand will lead to a more straightforward and successful experience.

Step-by-Step Repair Process

This section outlines a comprehensive guide for troubleshooting and fixing common issues that may arise with your outdoor equipment. Following these sequential instructions will help you effectively address any malfunctions and ensure optimal performance.

1. Identify the Issue: Begin by diagnosing the problem. Observe any unusual sounds, lack of power, or other irregularities that could indicate a malfunction. Document your findings for reference.

2. Gather Necessary Tools: Before proceeding, collect all required tools and replacement parts. Having everything on hand will streamline the process and reduce downtime.

3. Prepare the Workspace: Ensure that your working area is clean and organized. A clutter-free environment enhances safety and efficiency during the repair process.

4. Disassemble Components: Carefully remove the parts that are affected by the issue. Follow any specific instructions related to the disassembly to avoid damaging components.

5. Inspect for Damage: Examine the disassembled parts for any signs of wear or breakage. Look for cracks, rust, or other damages that could affect functionality.

6. Replace or Repair Parts: If you identify damaged components, proceed to either replace them with new ones or repair them as necessary. Ensure that all replacements are compatible with your equipment.

7. Reassemble the Equipment: Once repairs are complete, reassemble the unit carefully. Make sure that all screws and fasteners are tightened securely to avoid future issues.

8. Test Functionality: After reassembly, conduct a test run to ensure everything is functioning properly. Monitor for any abnormalities during operation and make adjustments as needed.

9. Document the Process: Keep a record of the repairs performed, including any parts replaced. This information can be valuable for future reference and maintenance.

Understanding Engine Components

Grasping the functionality and roles of various engine elements is essential for effective maintenance and troubleshooting. Each part works in harmony to ensure optimal performance, contributing to the overall efficiency of the machine. A well-rounded understanding of these components can lead to better decision-making during servicing and repairs.

Key Components of an Engine

- Cylinder: The heart of the engine where fuel combustion occurs, generating power.

- Piston: A cylindrical piece that moves up and down within the cylinder, translating energy from combustion into mechanical movement.

- Crankshaft: Converts the linear motion of the pistons into rotational motion, driving the machine’s output.

- Valves: Regulate the intake of air and fuel as well as the expulsion of exhaust gases, ensuring efficient operation.

- Ignition System: Responsible for initiating combustion, typically utilizing a spark plug or glow plug.

Functionality and Importance

Understanding how these components interact is crucial. For instance, the synchronization between valves and pistons is vital for maintaining proper airflow and fuel efficiency. Regular checks on these parts can prevent mechanical failures and prolong the lifespan of the engine.

- Monitor piston movement for wear and tear.

- Ensure valves are functioning correctly to avoid leaks.

- Inspect the ignition system to maintain optimal firing conditions.

Safety Precautions During Repairs

Ensuring safety is paramount when performing maintenance tasks on any equipment. Proper precautions not only protect the individual conducting the work but also help preserve the integrity of the machine. Adhering to specific guidelines minimizes risks and promotes a secure working environment.

Before beginning any task, it is essential to equip yourself with the right tools and personal protective equipment. This preparation significantly reduces the likelihood of accidents and injuries.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Wear gloves, goggles, and sturdy footwear to shield yourself from potential hazards. |

| Work Area | Ensure the workspace is clean and well-lit to avoid tripping or misplacing tools. |

| Read Instructions | Familiarize yourself with guidelines before starting any work to avoid mistakes. |

| Disconnect Power | Always disconnect power sources before conducting any maintenance to prevent accidental starts. |

| Keep Children Away | Ensure that children and pets are kept at a safe distance from the work area. |

When to Seek Professional Help

There are instances when attempting to fix a device on your own may not yield the desired results. Understanding when to consult an expert is crucial for ensuring safety and effective resolution of issues. If problems persist despite following basic troubleshooting steps, it may be time to consider professional assistance.

Signs that indicate a need for expert intervention include:

- Persistent malfunctions after basic maintenance attempts.

- Unusual noises or vibrations that were not present before.

- Overheating or signs of electrical issues.

- Difficulty in accessing specific components or systems.

In such cases, contacting a qualified technician can prevent further damage and ensure that the necessary repairs are conducted safely and efficiently. Relying on professional expertise can also provide peace of mind and extend the lifespan of your equipment.

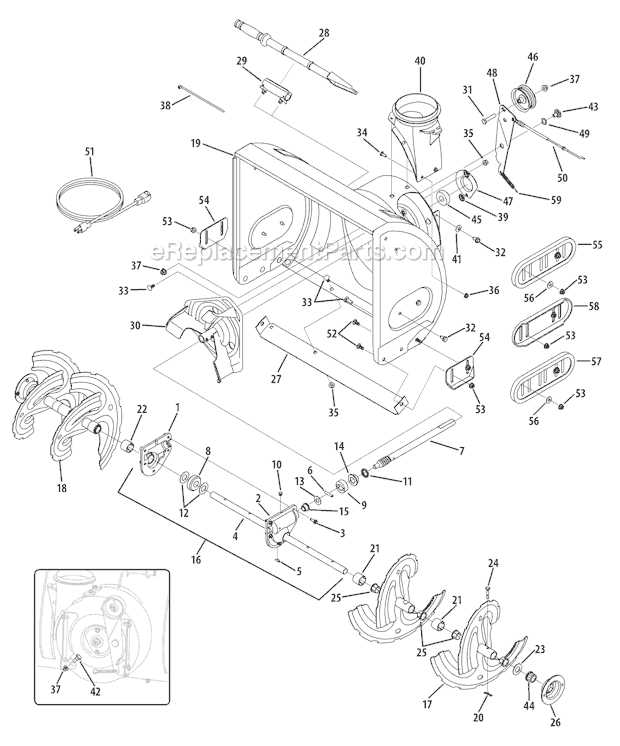

Parts Replacement Guide

This section provides essential guidance for exchanging components in your equipment. Understanding the process of part replacement ensures optimal functionality and longevity of your machine. Below, you will find detailed steps and tips to facilitate smooth component exchanges.

Common Parts to Replace

- Fuel Filter

- Oil Filter

- Spark Plug

- Belt

- Starter Motor

Replacement Steps

- Identify the component that needs replacement.

- Gather the necessary tools and new parts.

- Follow the specific instructions for disassembling the equipment.

- Carefully remove the old part and install the new one, ensuring a secure fit.

- Reassemble the equipment and perform a functionality check.

Regularly replacing worn or damaged components can significantly improve the performance and safety of your equipment. Always consult specific guidelines for the best practices tailored to your model.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues can significantly enhance the performance of your outdoor equipment. This section provides guidance on diagnosing common electrical malfunctions, ensuring that your machine operates efficiently and reliably.

Common Symptoms and Their Causes

Electrical failures may manifest through various symptoms, such as failure to start, intermittent operation, or unusual noises. The following factors may contribute to these issues:

- Battery Issues: A weak or dead battery is often the primary culprit, leading to inadequate power supply.

- Loose Connections: Corroded or loose wiring can disrupt electrical flow, causing malfunction.

- Faulty Components: Defective switches or fuses may prevent the equipment from functioning correctly.

Steps to Diagnose Electrical Issues

To effectively troubleshoot electrical problems, follow these steps:

- Inspect the Battery: Ensure the battery is charged and terminals are clean and secure.

- Check Connections: Examine all wiring for signs of wear or corrosion and tighten loose connections.

- Test Components: Use a multimeter to check switches and fuses for continuity and replace any faulty parts.

By following these troubleshooting steps, you can identify the source of electrical issues and take the necessary actions to restore functionality.