In the world of outdoor machinery, ensuring optimal performance during the colder months is essential. This section focuses on the intricate aspects of maintaining a specific type of equipment designed for handling snow and ice. Understanding the mechanics involved can significantly enhance its efficiency and longevity.

Every piece of machinery requires attention to detail, especially when faced with challenging winter conditions. This guide provides valuable insights into troubleshooting common issues and performing essential upkeep tasks. By following these guidelines, users can ensure their equipment remains reliable and effective throughout the season.

From basic checks to more involved procedures, this resource aims to empower users with the knowledge necessary to tackle various maintenance challenges. Embracing a proactive approach will not only safeguard the functionality of the machine but also extend its service life.

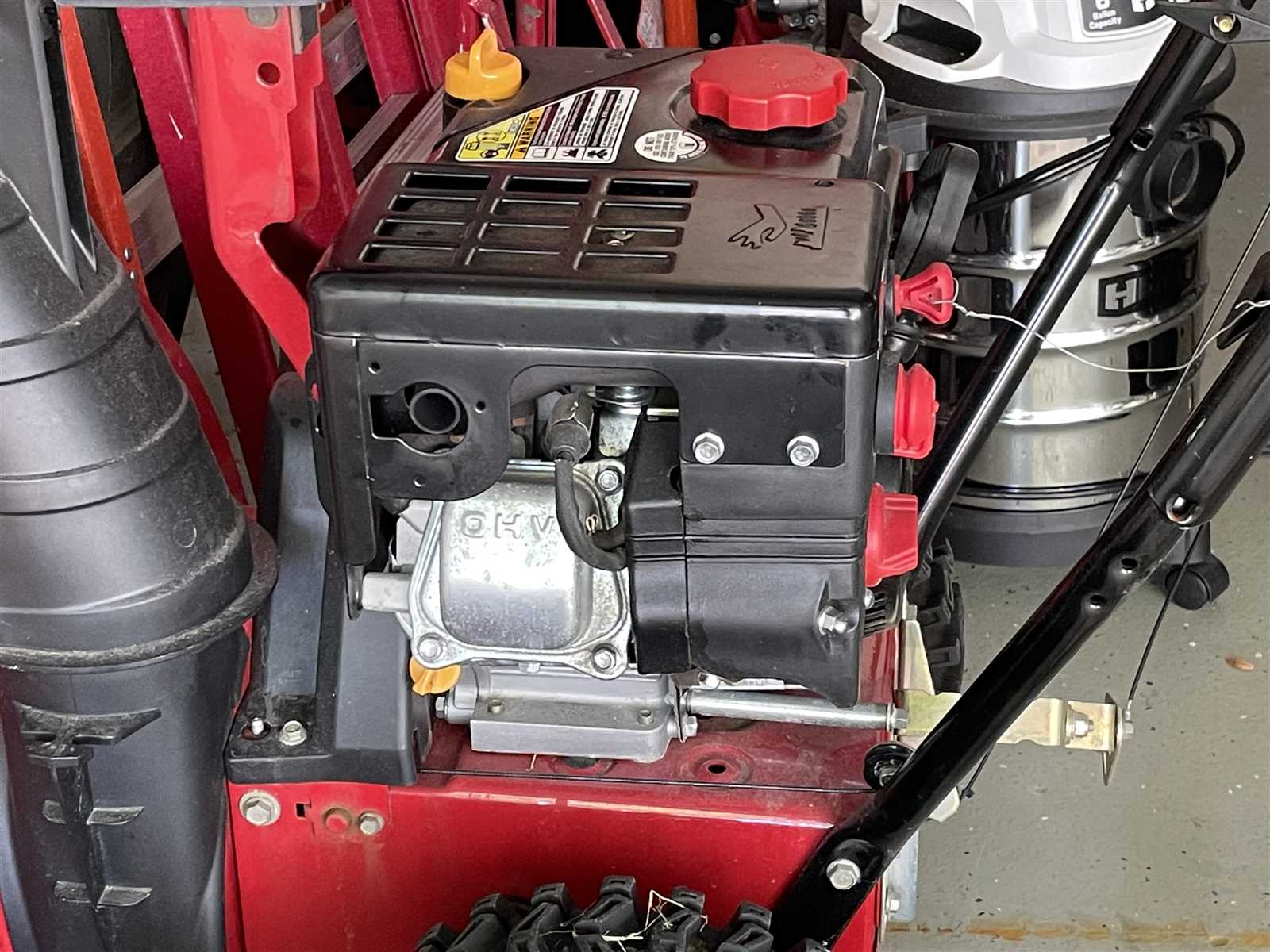

Troy Bilt 2410 Overview

This section provides a comprehensive introduction to a powerful outdoor machine designed for efficient winter maintenance. With its robust construction and advanced features, it is tailored to tackle various icy conditions with ease.

Equipped with a reliable engine, this equipment offers substantial performance, ensuring that users can clear pathways and driveways effectively. Its user-friendly design incorporates adjustable settings, allowing for customized operation depending on the depth and type of snow. Moreover, the innovative engineering enhances durability, making it a valuable investment for homeowners looking to manage seasonal challenges efficiently.

Understanding the various components and functions of this machine is crucial for optimizing its use. Regular maintenance and proper handling will ensure that it operates smoothly throughout the winter months, providing reliable service when needed most.

Common Issues with Snow Blowers

During the winter season, many individuals encounter a variety of challenges with their outdoor equipment designed for clearing pathways and driveways. Understanding these typical problems can help users maintain optimal functionality and prolong the life of their machines.

One frequent issue involves the inability of the equipment to start. This can stem from several factors, such as fuel problems, electrical failures, or a lack of proper maintenance. Regular inspections of fuel levels and electrical connections can often prevent these complications.

Another common concern is the performance during operation. Machines may struggle to effectively clear accumulated precipitation, leading to frustration. Clogged mechanisms or dull components are often responsible for this hindrance. Ensuring that all parts are clean and sharp is crucial for efficient functioning.

Lastly, unusual noises or vibrations may indicate underlying problems. Such symptoms should not be ignored, as they can signify wear or damage to essential components. Prompt attention to these signs can prevent more serious malfunctions and costly repairs.

Essential Tools for Repairs

To effectively maintain and fix outdoor machinery, having the right equipment is crucial. The right set of instruments not only simplifies the task but also enhances the efficiency and accuracy of the work. Below are some indispensable tools that should be part of every enthusiast’s toolkit.

- Wrench Set: A variety of wrenches, including adjustable and socket types, is vital for loosening and tightening various fasteners.

- Screwdrivers: Both flathead and Phillips screwdrivers in different sizes are essential for accessing screws that hold components in place.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires or small parts.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

- Safety Gear: Protective gloves and goggles should always be worn to ensure personal safety during maintenance tasks.

By equipping oneself with these fundamental tools, individuals can confidently tackle maintenance challenges and prolong the lifespan of their equipment.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. This section provides a comprehensive overview of essential procedures that can enhance functionality and prevent potential issues. Following these systematic steps will help maintain your machine in peak condition, ultimately prolonging its service life.

Routine Inspections

Begin by performing routine inspections to identify any signs of wear or damage. Check all moving parts for smooth operation and ensure that there are no loose connections. Pay close attention to the belts and cables, as they are vital components that can affect performance if compromised.

Cleaning and Lubrication

After inspections, proceed with cleaning the exterior and interior surfaces to remove debris and dirt. Utilize a soft brush or cloth for this task. Once clean, apply appropriate lubricants to all moving parts to reduce friction and enhance efficiency. Regular cleaning and lubrication can significantly contribute to the overall functionality and durability of the equipment.

How to Replace the Auger

Replacing the auger in your outdoor equipment can enhance its efficiency and extend its lifespan. This procedure involves several key steps that ensure proper installation and functionality. Follow these guidelines to successfully perform the replacement.

Before starting the replacement process, gather the necessary tools and materials:

- Socket wrench set

- Screwdriver

- Replacement auger

- Safety gloves

- Owner’s manual for reference

Once you have everything ready, proceed with the following steps:

- Disconnect the Power: Ensure that the equipment is completely powered off to avoid any accidents.

- Remove the Cover: Use the screwdriver to take off the cover that protects the auger assembly.

- Detach the Old Auger: Carefully unfasten the bolts or screws that hold the auger in place. Keep them in a safe location for reinstallation.

- Install the New Auger: Position the replacement auger in the same location as the old one and secure it with the previously removed bolts or screws.

- Reattach the Cover: Once the new auger is in place, reattach the cover to protect the assembly.

- Reconnect the Power: Finally, turn the power back on and test the equipment to ensure everything is functioning correctly.

Regular maintenance, including replacing the auger, will help keep your equipment in top condition. Following these steps will ensure a smooth replacement process.

Engine Troubleshooting Techniques

Identifying issues with the engine can be a complex task, yet mastering effective strategies can simplify the process significantly. Whether it’s a lack of power, unusual noises, or difficulty starting, understanding the underlying causes is crucial for effective resolution.

Common Symptoms and Their Implications

Recognizing the signs of engine trouble is the first step toward diagnosis. Below are frequent issues encountered:

- Difficulty Starting: This may indicate battery failure, fuel delivery issues, or ignition problems.

- Overheating: Often a result of low coolant levels, a faulty thermostat, or issues with the radiator.

- Strange Noises: Unusual sounds can signal mechanical wear or loose components.

Step-by-Step Diagnostic Approach

To effectively troubleshoot engine problems, follow these systematic steps:

- Visual Inspection: Examine the engine for any obvious signs of damage or leaks.

- Check Fluid Levels: Ensure that oil, coolant, and fuel are at appropriate levels.

- Test Electrical Components: Utilize a multimeter to check battery and wiring integrity.

- Run Diagnostics: Use available diagnostic tools to identify error codes that may point to specific issues.

Adjusting the Chute Direction

Ensuring optimal performance of your equipment often involves fine-tuning various components. One crucial adjustment is the direction of the discharge chute, which controls where the cleared material is expelled. Proper alignment can significantly enhance efficiency and effectiveness during use.

To modify the chute direction effectively, follow these steps:

- Identify the Adjustment Mechanism: Locate the lever or crank that controls the chute. This mechanism is typically positioned near the operator’s station for easy access.

- Test the Current Position: Engage the equipment and observe the discharge angle. This will help you understand the initial setup and determine the desired direction.

- Make Adjustments: Gently operate the control to direct the chute towards the intended path. Ensure smooth movement to avoid any damage to the components.

- Verify the New Angle: After adjusting, conduct a short test run to confirm that the discharge is directed correctly. Observe how the material is being thrown and make further adjustments if necessary.

- Secure the Position: Once satisfied with the direction, ensure that all components are locked in place to prevent accidental shifts during operation.

Regularly checking and adjusting the chute orientation can lead to a more effective clearing process, minimizing the chances of material build-up and enhancing overall productivity.

Checking and Replacing Belts

Proper maintenance of the drive components is essential for optimal performance of your equipment. Belts play a crucial role in transmitting power from the engine to various parts, and regular inspection is necessary to ensure they remain in good condition. This section outlines the process of examining and substituting these vital components, helping to maintain efficient operation.

Inspecting the Belts

Begin by visually examining the belts for signs of wear, such as cracks, fraying, or stretching. A thorough check should include ensuring that the belts are correctly aligned and seated in their pulleys. Any abnormalities should prompt immediate action to prevent further damage.

Replacing Worn Belts

When it becomes necessary to replace a belt, follow these steps:

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent accidental start-up. |

| 2 | Remove any covers or guards that obstruct access to the belts. |

| 3 | Loosen the tension on the existing belt using the appropriate adjustment mechanism. |

| 4 | Carefully remove the old belt from the pulleys. |

| 5 | Install the new belt, ensuring it is properly aligned and seated. |

| 6 | Tighten the tension and reattach any covers removed earlier. |

| 7 | Reconnect the power source and test the equipment to ensure proper functionality. |

Regular inspection and timely replacement of belts are critical for maintaining the effectiveness and longevity of your machinery. By adhering to these guidelines, you can ensure that your equipment operates smoothly and efficiently.

Winter Preparation Tips

As the cold season approaches, it’s essential to ensure that your outdoor equipment is ready to tackle the challenges that winter brings. Proper maintenance and preparation can enhance the efficiency of your tools and help you navigate through harsh weather conditions with ease.

Essential Equipment Check

- Inspect all machinery for wear and tear.

- Change the oil and replace filters as needed.

- Ensure fuel systems are clean and functional.

- Sharpen or replace any cutting or moving parts.

Winter Gear and Safety

- Invest in quality winter clothing to stay warm and dry.

- Keep safety gear, such as gloves and goggles, accessible.

- Have a first aid kit ready for emergencies.

- Review safety protocols to prevent accidents while working outdoors.

Safety Precautions While Repairing

When performing maintenance on outdoor machinery, adhering to safety measures is essential to ensure personal well-being and prevent accidents. Being mindful of potential hazards contributes to a secure working environment, allowing for efficient task completion.

Before commencing any work, it is advisable to wear appropriate protective gear. This includes gloves, goggles, and sturdy footwear. These items help shield against sharp components and potential debris that may arise during the process. Additionally, it is important to keep the workspace organized, minimizing clutter that could lead to slips or falls.

Furthermore, ensure that the equipment is powered off and disconnected from any energy sources before beginning any adjustments. This precautionary step significantly reduces the risk of unintentional activation. Familiarizing oneself with the specific components and functions of the machinery can also enhance safety awareness and facilitate smoother operation.

Lastly, remain attentive to surroundings while working. A distraction can lead to serious mishaps, so it is best to focus entirely on the task at hand. By implementing these precautions, individuals can foster a safer atmosphere for maintenance activities.

Understanding the User Manual

A user guide serves as a crucial resource for operating and maintaining various machinery. It offers essential information that enables users to effectively navigate their devices, ensuring optimal performance and longevity. By comprehending the contents of the guide, users can enhance their experience and avoid common pitfalls.

Key Components of the Guide

- Safety Precautions: This section outlines important safety measures that should be followed during operation.

- Specifications: Here, users can find detailed information about the device’s capabilities and features.

- Operation Instructions: This part provides step-by-step guidance on how to use the equipment correctly.

Benefits of Familiarity with the Guide

- Improved Safety: Understanding safety protocols reduces the risk of accidents.

- Enhanced Performance: Knowing how to operate the machinery properly leads to better efficiency.

- Informed Troubleshooting: Familiarity with common issues and solutions can save time and frustration.

Where to Find Replacement Parts

When it comes to maintaining your outdoor equipment, locating suitable components is crucial for ensuring optimal performance. Various resources are available to assist you in sourcing these necessary items.

Online Retailers: A multitude of e-commerce platforms specialize in parts for outdoor machinery. These sites often provide detailed specifications and compatibility information to help you find what you need.

Local Dealers: Authorized dealerships frequently stock original components. Visiting a nearby dealer can offer the advantage of expert guidance and immediate availability.

Salvage Yards: For those seeking budget-friendly options, salvage yards can be treasure troves. They often have a range of used parts that can be refurbished for continued use.

Manufacturer’s Website: Checking the official site of the equipment maker is an excellent way to find authentic parts. Many manufacturers offer an online catalog or ordering system for convenience.

Online Forums and Communities: Engaging with online communities dedicated to outdoor equipment can provide insights into where others have successfully sourced parts. These platforms often share recommendations and experiences.