Understanding how to maintain and troubleshoot machinery is essential for prolonging its functionality and achieving optimal performance. This guide offers detailed insights to help users navigate the upkeep and servicing processes, ensuring reliability and safety over time. We aim to empower users with practical knowledge for preserving the integrity and efficiency of their equipment.

Routine care and attentive checks can prevent unexpected breakdowns and extend the lifespan of any device. Within this section, we explore core maintenance tasks, from preventive inspections to diagnosing issues that may arise during operation. By following these recommendations, users can achieve smoother operations and minimize potential disruptions.

With clear instructions on both minor adjustments and extensive servicing, this guide is designed for those who value efficiency and reliability in their equipment. Following these methods will help users retain peak performance and foster a proactive approach to equipment care.

This section outlines essential maintenance practices to enhance the durability and performance of your outdoor machinery. A regular upkeep routine can help ensure smooth operation, reduce the likelihood of breakdowns, and extend the life of the equipment.

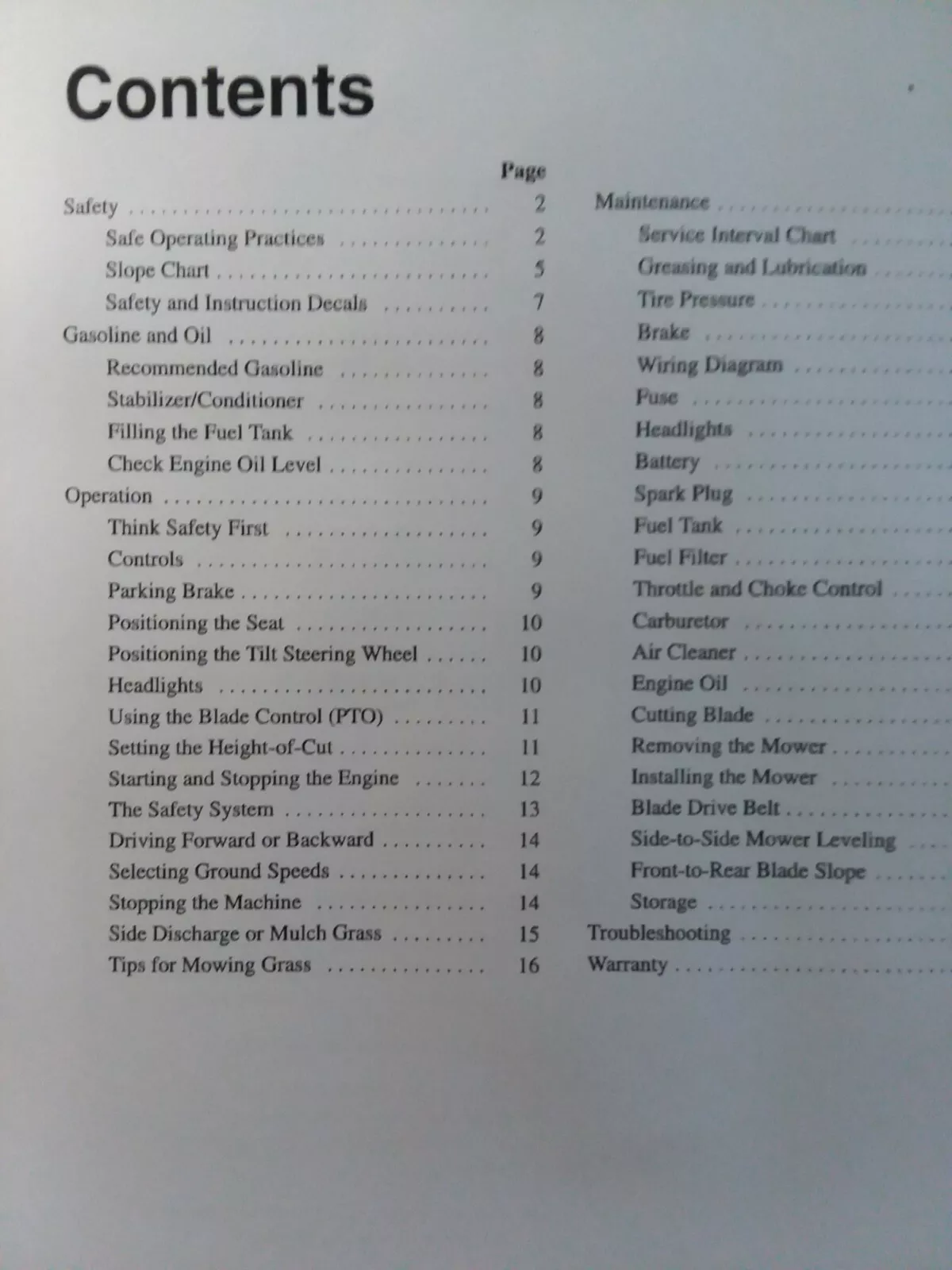

Key Maintenance Steps

Maintaining the machine involves several key practices to keep it in optimal condition. Here is a breakdown of essential tasks to follow:

| Task | Frequency | Purpose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inspect and clean air filters | Monthly | Ensures the engine receives clean air for combustion | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Check and replace oil | Every 3 months | Prevents engine wear and overheating | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Examine spark plugs | Twice a year | Improves ignition efficiency and fuel usage |

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Engine fails to start | Low fuel, clogged air filter, or faulty spark plug | Check fuel levels, clean the air filter, inspect and replace the spark plug if necessary |

| Uneven cutting | Blunt or damaged blades | Sharpen or replace the blades, ensuring they are balanced |

| Strange noises during operation | Loose parts or debris in moving components | Inspect and tighten any loose bolts, clear away any obstructive debris |

| Decreased power | Clogged fuel filter or carburetor issues | Replace the fuel filter, clean or adjust the carburetor |

Proper upkeep and periodic inspections can help ident

Essential Tools for Effective Repairs

Having the right set of equipment is crucial for performing any restoration or maintenance task efficiently and safely. A well-prepared toolkit not only saves time but also ensures that each task is completed with precision, whether you’re handling small adjustments or tackling more involved mechanical fixes.

Basic Hand Tools

Screwdrivers, wrenches, and pliers form the backbone of any toolkit. With these tools, you can manage various fasteners, from bolts to screws, allowing you to disassemble and reassemble components with ease. It’s beneficial to have a variety of sizes and types on hand to suit different tasks and ensure compatibility with various hardware elements.

Power Tools and Specialized Equipment

For more extensive work, a few essential power tools can make a significant difference. Drills and impact drivers expedite disassembly, while tools like torque wrenches help apply the correct force during reassembly. Additional specialized items, such as a multimeter, are valuable for diagnosing electrical issues, ensuring both accuracy and safety in handling complex systems.

Replacing Worn-Out Parts

Maintaining the efficiency and longevity of outdoor equipment often involves periodic replacement of aging components. Over time, various elements may deteriorate due to constant exposure to environmental conditions and frequent usage. Identifying these areas for renewal ensures consistent performance and reduces potential issues.

Identifying Key Parts for Replacement

Some primary areas prone to wear include belts, bearings, and blades. Regular inspections can help determine when these parts are nearing the end of their functional life. Recognizing early signs, such as increased vibration, strange noises, or reduced cutting precision, can prevent more significant repairs later.

Recommended Replacement Schedule

To optimize equipment functionality, establish a replacement schedule for parts most susceptible to wear. This approach enhances reliability and avoids unexpected downtime. Below is a suggested guide for replacing common parts:

| Part | Recommended Replacement Interval |

|---|---|

| Belts | Every 100 operating hours or annually |

| Bearings | Every 150 operating hours or as needed |

| Blades | Sharpen every 50 hours, replace annually |

Troubleshooting Electrical Components

When diagnosing electrical issues, it’s essential to understand the basic connections and components that ensure seamless operation. Identifying faulty parts can prevent further damage and restore the system’s efficiency.

Identifying Common Electrical Problems

Electrical malfunctions can manifest in various ways, from unresponsive switches to inconsistent power delivery. The most common causes include worn-out connections, degraded wires, or malfunctioning control units. Start by examining each component for visible wear and loose connections, ensuring that all cables and terminals are intact.

Testing Components for Continuity

Using a multimeter to check for continuity helps identify whether a circuit is closed or if there’s a break in the line. Testing is typically done by disconnecting the component and placing the probes on the terminals. This method is essential for pinpointing the exact location of a malfunction.

| Component | Common Issue | Testing Method | |||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Battery | Low charge or corrosion | Voltage check | |||||||||||||||||||||||||||||||||||||||||||||

| Starter Motor | No response when engaged | Engine Care and Optimization Tips

Maintaining optimal performance in your engine requires attention and care. By implementing a few essential practices, you can enhance efficiency and extend the lifespan of your power unit. Regular maintenance routines not only improve functionality but also prevent potential issues that may arise from neglect. Routine Maintenance PracticesEstablishing a consistent maintenance schedule is crucial. This includes regular oil changes, air filter replacements, and spark plug inspections. Keeping the oil clean and at the proper level ensures smooth operation, while a clean air filter promotes efficient airflow, enhancing overall performance. Performance EnhancementsTo further optimize engine performance, consider using high-quality fuels and additives designed for your specific engine type. These products can improve combustion efficiency and reduce deposits. Additionally, ensuring proper tire inflation and alignment can significantly affect the engine’s workload and fuel consumption. Preventing Transmission Failures

Ensuring the longevity and proper functioning of your equipment’s drivetrain is crucial for optimal performance. Taking proactive measures can help avoid common pitfalls that lead to significant issues. Regular maintenance, appropriate usage, and timely interventions are essential in preserving the integrity of the transmission system. One of the key strategies to prevent breakdowns is consistent inspection. Operators should regularly examine the components for signs of wear and tear. Lubrication should also be maintained, as it reduces friction and heat buildup, which can cause damage over time. Additionally, avoiding overloading the machinery is vital, as excessive stress can lead to premature failure.

Cleaning and Lubrication TechniquesMaintaining machinery involves regular cleaning and appropriate lubrication to ensure optimal performance and longevity. Proper techniques not only enhance functionality but also prevent wear and tear, making the equipment more efficient. This section explores essential methods for keeping your device in top condition. Cleaning ProceduresEffective cleaning begins with removing dirt, debris, and other contaminants. Use the following steps for a thorough clean:

Lubrication GuidelinesRegular lubrication is crucial to reduce friction and prevent component damage. Follow these guidelines for effective application:

Tire Maintenance and Replacement StepsProper upkeep of tires is essential for ensuring optimal performance and safety. Regular checks and timely replacements help in extending the lifespan of the equipment while enhancing its functionality. Regular Inspection

Replacement Process

Deck Adjustments for Precision CutsAchieving an impeccable cut requires careful attention to the settings of the cutting deck. Proper adjustments not only enhance the quality of the finish but also contribute to the longevity of the equipment. Here are some essential considerations for fine-tuning the deck for optimal performance.

By focusing on these key adjustments, users can significantly improve the precision and quality of their mowing experience, leading to a healthier and more attractive lawn. Preparing for Seasonal StorageWhen the time comes to put away your outdoor equipment for the season, proper preparation is crucial to ensure its longevity and functionality. Following a systematic approach to maintenance and storage can prevent damage and keep the machinery in optimal condition for the next use. Maintenance StepsBefore storing your equipment, conduct thorough maintenance checks. This includes cleaning, oil changes, and inspecting various components for wear and tear. Addressing minor issues now can prevent more significant problems later. Storage RecommendationsChoose a dry and well-ventilated area for storage. Cover the machinery to protect it from dust and moisture. Additionally, consider using fuel stabilizers to prevent fuel degradation during the storage period.

|