Maintaining heavy machinery is essential for ensuring optimal performance and longevity. Understanding the intricacies of these complex machines can significantly enhance their functionality and reliability. This section provides invaluable insights into the procedures necessary for keeping your equipment in top-notch condition.

In the realm of industrial machinery, proper upkeep can prevent costly breakdowns and extend the lifespan of vital components. By following detailed protocols and guidelines, operators can navigate the challenges of maintenance with confidence. This resource is designed to equip users with the knowledge needed to perform essential tasks effectively.

Whether you are an experienced technician or a newcomer to the field, having access to comprehensive information is crucial. This guide covers a wide range of topics, from routine checks to troubleshooting common issues, ensuring that you are well-prepared to tackle any maintenance challenge that may arise.

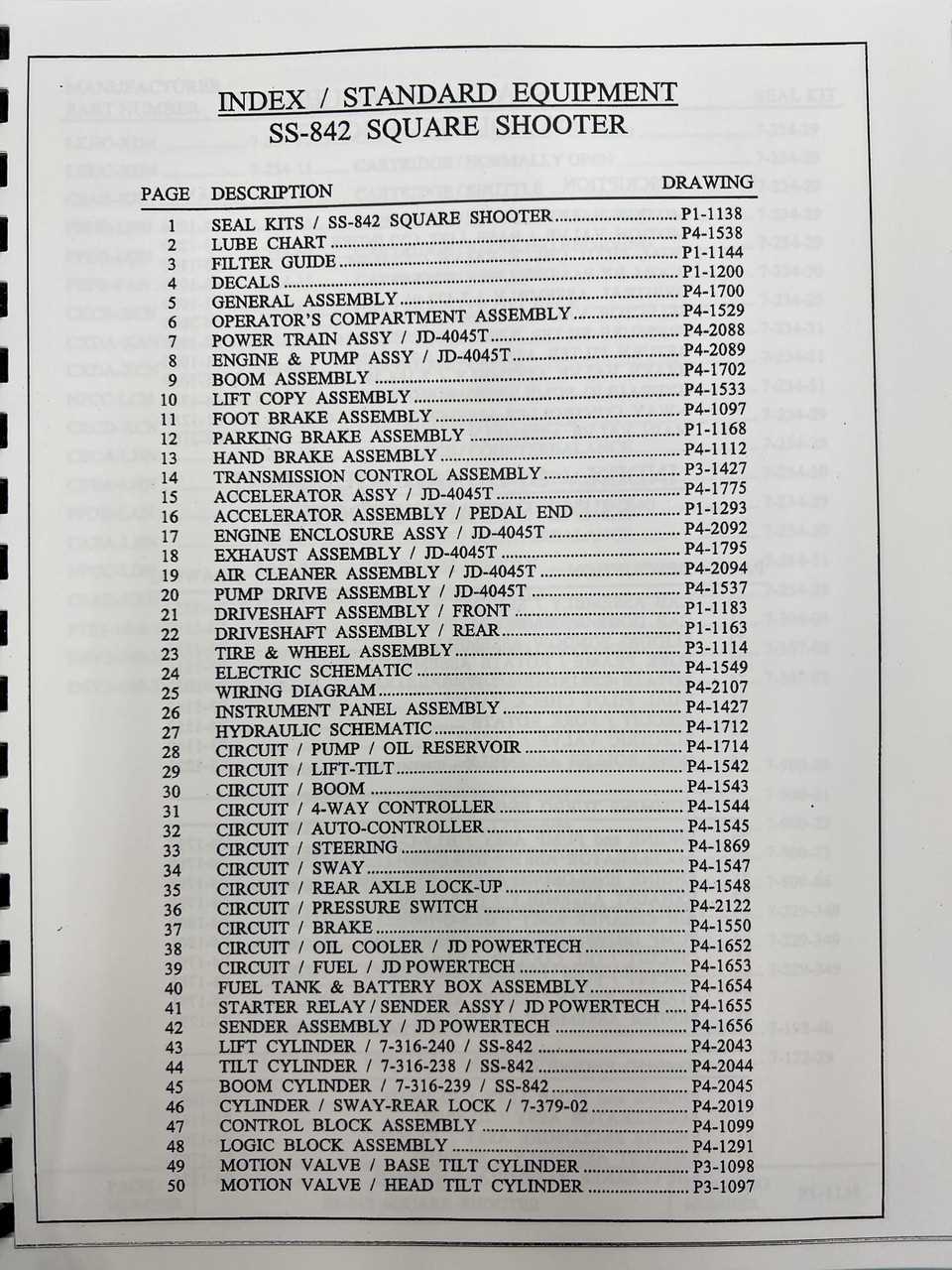

Overview of Terex SS842

This section provides a comprehensive examination of a specific model designed for various industrial applications. Renowned for its robust construction and versatility, this equipment is a vital asset in the realm of heavy machinery. Its innovative design integrates advanced technology, ensuring high efficiency and reliability in challenging environments.

Key Features

The machine boasts a range of standout characteristics that enhance its operational capabilities. With a powerful engine and durable components, it excels in lifting and transporting heavy loads. User-friendly controls and a well-thought-out layout contribute to improved safety and ease of use, making it accessible for operators of varying skill levels.

Applications

This model finds utility across numerous sectors, including construction, mining, and infrastructure development. Its adaptability allows it to tackle diverse tasks, from lifting materials to maneuvering in tight spaces. The ability to perform effectively under different conditions makes it an indispensable tool for professionals seeking efficiency and performance.

Common Issues with Terex SS842

When operating heavy machinery, encountering problems is often an inevitable part of the experience. Understanding the frequent challenges can enhance efficiency and prolong the lifespan of the equipment. This section explores some of the typical concerns operators may face, along with tips for addressing them effectively.

Hydraulic System Failures

One of the most common complications involves the hydraulic system. Operators may notice a decrease in power or responsiveness, often attributed to leaks or low fluid levels. Regular inspections and timely maintenance can prevent these issues from escalating, ensuring optimal performance during operations.

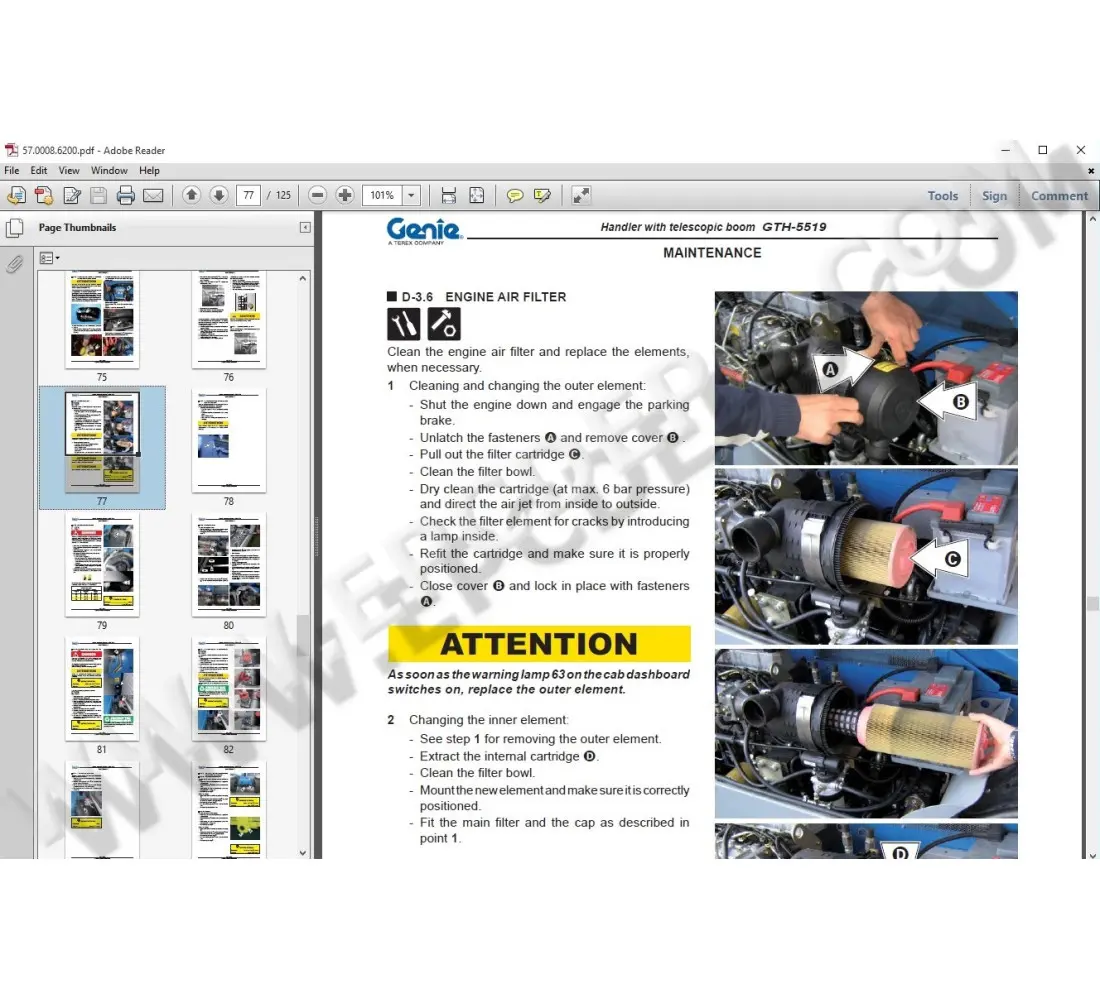

Engine Performance Issues

Another prevalent challenge is related to engine performance. Symptoms such as stalling, reduced power output, or unusual noises may indicate underlying problems. Routine checks of fuel quality, air filters, and spark plugs are essential steps in maintaining engine health and avoiding costly repairs down the line.

Essential Tools for Repair

Having the right equipment is crucial for maintaining and restoring machinery effectively. Each task may require specific implements to ensure safety and efficiency. Understanding which tools to utilize can significantly enhance the quality of the work performed and prolong the life of the equipment.

Basic Toolkit Components

A well-rounded toolkit should include a variety of instruments to address different aspects of maintenance. Below is a list of fundamental components that every technician should consider:

| Tool | Purpose |

|---|---|

| Wrenches | For tightening and loosening fasteners. |

| Screwdrivers | To drive screws in various applications. |

| Pliers | For gripping and manipulating objects. |

| Socket Set | For working with different sizes of nuts and bolts. |

| Multimeter | To measure electrical parameters. |

Specialized Instruments

In addition to basic tools, certain specialized instruments may be necessary for more complex tasks. These can enhance precision and effectiveness, ensuring a thorough approach to any undertaking:

| Tool | Purpose |

|---|---|

| Torque Wrench | To apply a specific torque to fasteners. |

| Diagnostic Scanner | For identifying issues in electronic systems. |

| Pressure Gauge | To measure fluid pressure levels. |

| Cutting Tools | For shaping and removing material. |

| Safety Gear | To protect against hazards during work. |

Step-by-Step Repair Process

This section outlines a detailed approach to address mechanical issues effectively. Following a systematic procedure ensures that each phase is executed with precision, leading to optimal performance and longevity of the equipment.

1. Assessment: Begin by evaluating the condition of the machinery. Identify any visible damage or malfunctioning components. Document the findings to have a clear understanding of what needs attention.

2. Disassembly: Carefully disassemble the affected parts. Use the appropriate tools to avoid causing further damage. Keep track of all components and fasteners to ensure a smooth reassembly.

3. Inspection: Thoroughly inspect each part for wear and tear. Look for cracks, corrosion, or any signs of degradation. This step is crucial for determining whether components can be repaired or require replacement.

4. Cleaning: Clean all components to remove dirt, grease, and debris. Use suitable cleaning agents that won’t harm the materials. A clean workspace is essential for accurate evaluation and reassembly.

5. Replacement: If any parts are found to be irreparable, source high-quality replacements. Ensure that new components meet the necessary specifications for compatibility and performance.

6. Reassembly: Reassemble the machinery in the reverse order of disassembly. Follow the manufacturer’s guidelines for torque specifications and alignment to maintain integrity.

7. Testing: Once reassembled, conduct tests to ensure that the equipment operates as intended. Monitor for any unusual noises or vibrations during operation.

8. Documentation: Finally, record all actions taken during the process. Documenting repairs helps in future maintenance and provides valuable information for tracking the equipment’s history.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of heavy machinery requires regular upkeep and attention. By following a few essential practices, operators can significantly extend the lifespan of their equipment, minimizing the risk of unexpected failures and costly repairs.

- Regular Inspections: Conduct frequent checks on critical components to identify wear and tear early. This includes examining hydraulic systems, electrical connections, and mechanical parts.

- Fluid Levels: Maintain optimal fluid levels, including hydraulic fluid, engine oil, and coolant. Regularly changing these fluids will enhance performance and reduce friction.

- Cleanliness: Keep the machine clean from debris and contaminants. Regular washing can prevent rust and corrosion, especially in harsh environments.

- Tire Maintenance: Regularly inspect and maintain tire pressure and tread depth. Properly inflated tires improve fuel efficiency and handling.

- Follow Manufacturer Guidelines: Adhere to the recommended service intervals and specifications provided by the manufacturer to ensure optimal functioning.

Incorporating these maintenance practices into routine operations will not only enhance the equipment’s performance but also ensure safety and reliability in the long run.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when conducting maintenance and troubleshooting activities. Adhering to established safety guidelines minimizes the risk of accidents and injuries, fostering a secure atmosphere for technicians and personnel involved in the process.

Prior to commencing any work, it is essential to assess the workspace for potential hazards. This includes checking for any loose tools, inadequate lighting, or obstructions that could impede movement. Proper personal protective equipment, such as gloves, helmets, and safety goggles, should always be worn to safeguard against injuries.

It is also important to follow proper lockout/tagout procedures to prevent accidental machine activation. This practice ensures that equipment is properly shut down and cannot be inadvertently started during maintenance. Always verify that the equipment is de-energized before beginning any task.

Maintain clear communication with team members throughout the process. This includes notifying others of ongoing work, especially in shared spaces. Establishing a protocol for hand signals or verbal cues can further enhance safety and prevent misunderstandings.

Lastly, ensure that all tools and equipment are in good working order. Regular inspections and maintenance of tools reduce the likelihood of malfunction, which can lead to accidents. By prioritizing these safety measures, you create a reliable and secure environment for all involved in maintenance activities.

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in modern machinery by utilizing fluid power to generate movement and force. This technology allows for the efficient operation of various equipment, enabling them to perform complex tasks with ease. Understanding the components and functions of hydraulic systems is essential for effective maintenance and troubleshooting.

Key Components of Hydraulic Systems

Hydraulic systems are composed of several key elements that work together to create the desired mechanical motion:

- Hydraulic Fluid: The medium through which power is transmitted.

- Pumps: Devices that convert mechanical energy into hydraulic energy, moving fluid throughout the system.

- Actuators: Components that convert hydraulic energy back into mechanical motion.

- Valves: Control the flow and direction of the hydraulic fluid, regulating system pressure and movement.

- Reservoirs: Store hydraulic fluid, allowing for consistent supply and preventing contamination.

How Hydraulic Systems Work

The operation of hydraulic systems is based on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted undiminished in all directions. This allows for the following:

- The pump generates pressure, pushing fluid through the system.

- Valves direct the flow of fluid to the actuators.

- Actuators move in response to the hydraulic pressure, producing mechanical work.

- Fluid returns to the reservoir, completing the cycle.

Understanding these principles is vital for anyone working with hydraulic machinery, as it facilitates effective operation and maintenance practices.

Electrical Components Troubleshooting

Identifying issues within electrical systems is crucial for maintaining operational efficiency and safety. A systematic approach can help diagnose malfunctions effectively, ensuring that all components are functioning as intended.

Begin by assessing the power supply. Confirm that voltage levels are within specified ranges, and inspect connections for signs of wear or corrosion.

- Check the circuit breakers for tripping or faults.

- Inspect fuses for continuity; replace any that are blown.

- Verify the condition of wiring and connectors, looking for frays or loose connections.

Next, focus on individual components such as switches, relays, and sensors:

- Test switches for functionality by measuring continuity in both on and off positions.

- Evaluate relays by checking their coil resistance and ensuring that they engage properly.

- Inspect sensors to ensure they are providing accurate readings and are free from obstructions.

Lastly, utilize diagnostic tools like multimeters and oscilloscopes for deeper analysis, enabling you to pinpoint specific issues more accurately.

Replacing Key Parts

When it comes to maintaining heavy machinery, the replacement of essential components is crucial for optimal performance and longevity. Understanding how to properly replace these parts ensures that the equipment operates smoothly and safely.

Identifying Components for Replacement

Before beginning the replacement process, it’s important to identify which components need attention. Common parts that may require replacement include:

- Hydraulic filters

- Seals and gaskets

- Belts and hoses

- Bearings

- Electrical connectors

Regular inspections will help you catch wear and tear early, making replacements easier and more efficient.

Steps for Replacement

Once you’ve identified the parts that need to be replaced, follow these steps for a successful procedure:

- Gather the necessary tools and replacement components.

- Ensure the machinery is powered down and secure.

- Remove the old part carefully, following any specific disassembly instructions.

- Install the new component, making sure it fits properly.

- Reconnect any electrical or hydraulic connections as needed.

- Test the machinery to ensure everything functions correctly.

By following these guidelines, you can effectively maintain your equipment and reduce the risk of future issues.

Importance of Regular Inspections

Routine assessments play a crucial role in ensuring the longevity and safety of machinery. By regularly evaluating equipment, potential issues can be identified early, minimizing the risk of unexpected breakdowns and costly repairs. This proactive approach not only enhances performance but also safeguards operators and other personnel.

Conducting frequent inspections allows for the detection of wear and tear that may not be immediately obvious. Timely maintenance can extend the lifespan of components, resulting in improved reliability. Furthermore, it fosters a culture of safety, as operators become more aware of their surroundings and the equipment they handle.

In addition to improving safety and efficiency, regular evaluations can lead to significant cost savings. By addressing minor concerns before they escalate, organizations can avoid major disruptions and the financial implications of extensive repairs. Overall, consistent attention to machinery health is essential for optimal operational performance and long-term success.

FAQs about Terex SS842 Repairs

This section aims to address common inquiries related to maintenance and troubleshooting of specialized lifting equipment. Understanding these aspects can enhance the longevity and performance of your machinery, ensuring smooth operations.

What are the common issues faced with this equipment?

Users often report challenges such as hydraulic system failures, electrical malfunctions, and wear on essential components. Identifying these issues early can prevent further damage and costly downtime.

How often should maintenance be performed?

Regular inspections and servicing are crucial. It’s recommended to follow a schedule based on usage frequency and operating conditions. A proactive approach can help in spotting potential problems before they escalate.

Note: Always consult a qualified technician for any significant issues or repairs to ensure safety and compliance with industry standards.