In the realm of outdoor equipment, understanding the intricacies of your machinery is essential for optimal performance. This section aims to provide essential insights into the upkeep and troubleshooting of a specific model renowned for its reliability and power. Whether you are a seasoned professional or an enthusiastic hobbyist, having a thorough understanding of your device can significantly enhance its longevity and efficiency.

Maintenance is not just about fixing issues; it involves a proactive approach to ensure your equipment operates smoothly. Familiarizing yourself with the various components and their functions can help you identify potential problems before they escalate. Regular attention to these details can save both time and resources in the long run.

Additionally, troubleshooting plays a critical role in managing your device effectively. Knowing the common signs of wear and tear allows you to address issues swiftly, preventing more significant malfunctions. This guide will equip you with the necessary knowledge to navigate both routine care and unexpected challenges, ensuring your machine remains a dependable partner in your outdoor endeavors.

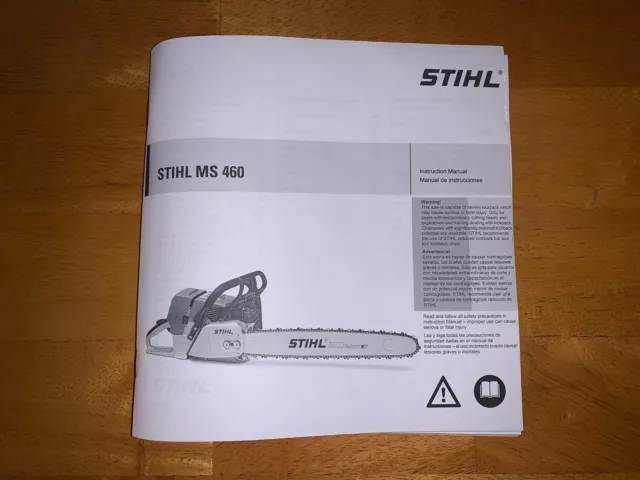

Understanding the Stihl MS 460 Chainsaw

This section delves into the essential aspects of a powerful cutting tool designed for efficiency and durability. Recognized for its robust performance, this model is a favorite among professionals and enthusiasts alike. Familiarity with its components and operational features is crucial for optimal use and maintenance.

Key Features

- Powerful engine designed for heavy-duty tasks

- Lightweight construction for improved handling

- Advanced anti-vibration system for user comfort

- Easy access to air filter and spark plug for quick maintenance

Common Applications

- Felling trees with precision

- Limiting and bucking logs efficiently

- Managing storm debris in residential areas

- Preparing firewood for winter use

Understanding the various functionalities and characteristics of this cutting device will enhance performance and prolong its lifespan, ensuring you get the most out of your investment.

Common Issues with Stihl MS 460

Every machine can experience problems over time, and chainsaws are no exception. Identifying and addressing frequent challenges can enhance performance and prolong the lifespan of your equipment. Here are some typical complications encountered with this particular model.

- Starting Difficulties:

Many users report challenges when attempting to start their equipment. Common causes include:

- Fuel issues, such as stale or contaminated gasoline.

- Problems with the spark plug, which may be dirty or worn out.

- Air filter blockages restricting airflow.

- Engine Stalling:

This issue often arises during operation and can stem from:

- Inadequate fuel supply due to a clogged fuel line.

- Malfunctioning carburetor settings.

- Excessive debris accumulation in the exhaust system.

- Chain Problems:

Chains can become problematic, leading to reduced efficiency. Consider the following:

- Chain tension that is either too tight or too loose.

- Worn-out or damaged cutting teeth.

- Inadequate lubrication, resulting in overheating.

- Vibration Issues:

Excessive vibration can affect user comfort and precision. Common causes include:

- Imbalanced cutting chain or bar.

- Worn-out anti-vibration mounts.

- Improper handling techniques.

lessCopy code

By recognizing these frequent challenges and addressing them promptly, users can ensure their equipment remains in optimal working condition and ready for any task.

Essential Tools for Repairs

When it comes to maintaining and servicing machinery, having the right equipment is crucial for effective troubleshooting and restoration. Proper tools not only enhance efficiency but also ensure that tasks are completed safely and accurately.

Basic Tool Requirements

Before diving into any maintenance task, it’s important to gather a set of fundamental tools. These items form the backbone of any repair operation:

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Socket set

- Pliers (needle-nose and standard)

- Torque wrench

- Utility knife

- Measuring tape

Specialized Equipment

In addition to basic tools, specific jobs may require specialized equipment to handle unique tasks. These tools can provide additional functionality and make complex procedures more manageable:

- Chain sharpener

- Fuel mixing container

- Cleaning brushes

- Diagnostics tool

- Protective gear (gloves, goggles)

Equipping yourself with these essential and specialized tools will not only facilitate a smoother maintenance process but also extend the lifespan of your machinery.

Step-by-Step Repair Process

This section provides a comprehensive guide to effectively addressing issues with your equipment. By following these structured steps, you can diagnose and resolve common problems, ensuring optimal performance and longevity.

Tools and Preparation

Before beginning the procedure, gather the necessary tools and materials:

- Wrenches and screwdrivers

- Replacement parts

- Lubricants and cleaning agents

- Protective gloves and eyewear

Ensure your workspace is clean and well-lit to facilitate an efficient process.

Step-by-Step Instructions

- Assess the Condition: Inspect the equipment for visible signs of wear or damage.

- Disassemble: Carefully take apart the components, noting the order and arrangement for reassembly.

- Clean the Parts: Remove dirt and debris using appropriate cleaning solutions.

- Replace Damaged Components: Identify parts that need replacing and install new ones as needed.

- Reassemble: Put the equipment back together, ensuring all parts are securely fastened.

- Test the Functionality: Start the device and verify that it operates smoothly and efficiently.

By adhering to this systematic approach, you can effectively maintain your machinery and enhance its performance.

Maintaining Your Chainsaw’s Performance

To ensure the longevity and efficiency of your cutting tool, regular upkeep is essential. Proper maintenance not only enhances performance but also extends the lifespan of the equipment, making it a reliable companion for any task. This section outlines key practices to keep your chainsaw operating at its best.

Essential Maintenance Practices

Routine checks and maintenance activities are crucial for optimal functioning. Below are some fundamental tasks to incorporate into your upkeep regimen:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Chain Tension Adjustment | Before each use | Ensure the chain is neither too tight nor too loose to prevent damage and improve cutting efficiency. |

| Sharpening the Chain | After 3-5 cuts or as needed | A sharp chain provides better performance and reduces the strain on the motor. |

| Air Filter Cleaning | Every 5-10 hours of use | Keep the air intake clear to maintain optimal engine performance and prevent overheating. |

| Fuel System Inspection | Monthly | Check fuel lines and filter for blockages or leaks to ensure smooth operation. |

Storage Tips

How you store your equipment can significantly impact its readiness for future use. Consider the following guidelines:

- Clean the chainsaw thoroughly before storage to remove sawdust and residue.

- Store in a cool, dry place to prevent rust and degradation of components.

- Consider using a protective cover to shield from dust and moisture.

By adhering to these maintenance practices and storage tips, you can ensure that your cutting tool remains in excellent condition, ready for any project that comes your way.

Parts Replacement Guidelines

Maintaining optimal performance of your equipment involves timely replacement of worn or damaged components. Proper guidelines ensure not only the longevity of the machine but also the safety of the user. Understanding when and how to replace parts is essential for effective upkeep.

When considering component substitution, always consult specifications to ensure compatibility. This includes checking dimensions, materials, and any specific features necessary for proper function. Following systematic procedures during the replacement process minimizes risks and enhances reliability.

| Component | Signs of Wear | Replacement Frequency |

|---|---|---|

| Chain | Dullness, damage, or excessive stretching | Every 20-30 hours of use |

| Guide Bar | Wear marks, bending, or cracking | Check every 50 hours, replace as needed |

| Air Filter | Visible dirt accumulation or clogging | Every 10-15 hours in dusty conditions |

| Fuel Filter | Reduced performance or fuel flow issues | Annually or as needed |

| Spark Plug | Misfiring or hard starting | Every 100 hours or annually |

Always use quality components from reputable suppliers to ensure safety and efficiency. Regular inspections and maintenance can prevent costly repairs and extend the life of your equipment.

Diagnosing Engine Problems

Identifying issues within an engine is a crucial skill for ensuring optimal performance and longevity of the equipment. Understanding the symptoms and their potential causes can significantly enhance the troubleshooting process. This section will guide you through common signs of malfunction and offer strategies to pinpoint the underlying problems effectively.

Common Symptoms of Engine Malfunction

Engine difficulties may manifest in various ways, including unusual noises, loss of power, or difficulty starting. Strange sounds, such as knocking or rattling, often indicate internal wear or failure. A reduction in power may suggest fuel delivery issues or blockages in the exhaust system. Difficulty starting could be linked to battery problems, ignition failure, or issues with the fuel system.

Steps to Diagnose Issues

To accurately diagnose engine problems, begin by conducting a visual inspection of all components. Look for signs of wear, damage, or leaks. Next, test the ignition system and ensure the fuel supply is adequate and clean. Using diagnostic tools can provide further insights into engine performance metrics, helping to pinpoint specific issues. Always consult the manufacturer’s specifications for reference points and tolerances during your evaluation.

Safety Tips During Repairs

When undertaking maintenance tasks on mechanical equipment, prioritizing safety is crucial. Implementing proper precautions not only protects the individual performing the work but also ensures the longevity and effectiveness of the machinery. Awareness of potential hazards and adherence to safety protocols can significantly reduce the risk of accidents.

Personal Protective Equipment

Always equip yourself with appropriate protective gear. This includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp edges and chemicals, and sturdy footwear to prevent foot injuries. Additionally, consider using ear protection if the task involves loud machinery.

Workspace Organization

Maintaining an organized and clean workspace is essential. Ensure that all tools are easily accessible and that the area is free of clutter. Secure loose items to prevent tripping hazards and keep flammable materials away from the work zone. A well-structured environment enhances focus and reduces the likelihood of accidents.

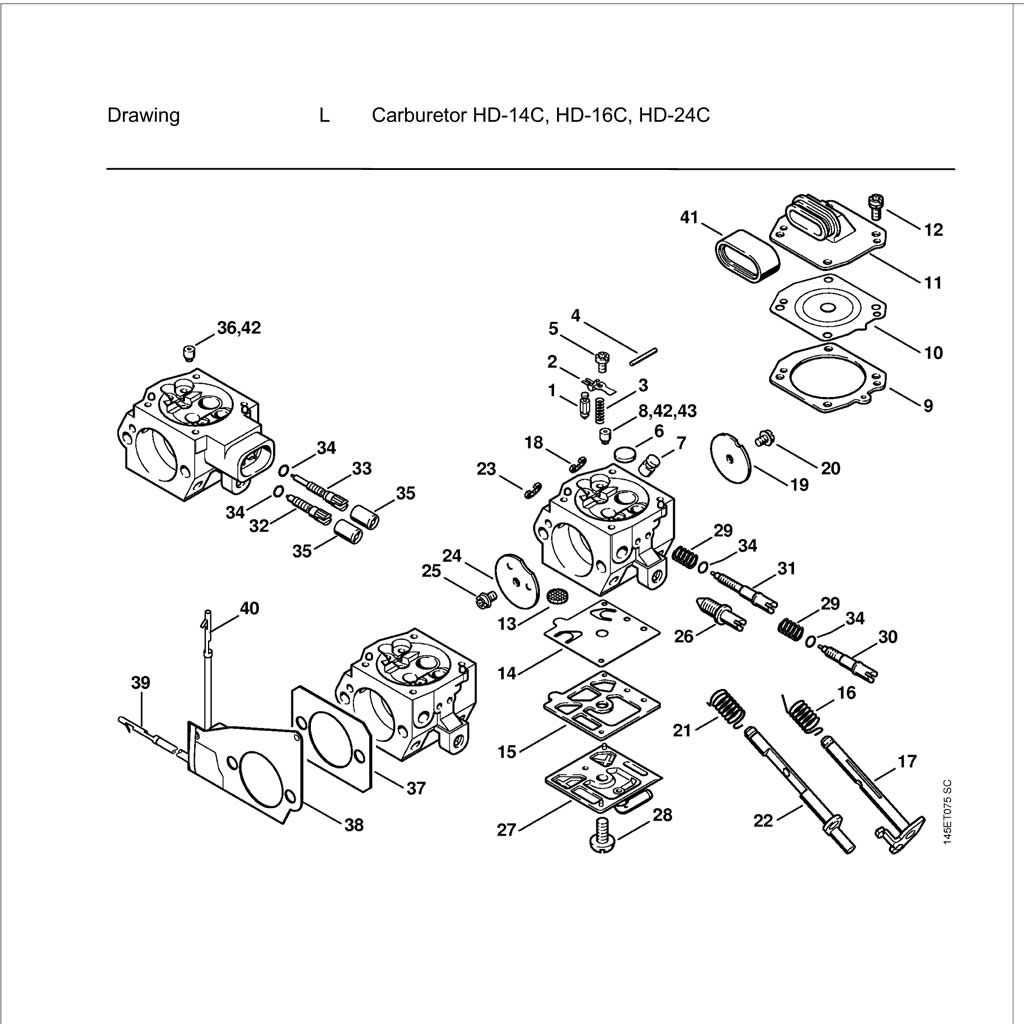

Adjusting the Carburetor Settings

Properly tuning the fuel delivery system is essential for optimal engine performance and efficiency. This process involves fine-tuning the air-fuel mixture to ensure the engine runs smoothly across various operating conditions. Adjustments may be necessary due to changes in environmental factors, wear and tear, or modifications made to the equipment.

Identifying the Adjustment Screws

Most models are equipped with several screws that control different aspects of the mixture. Typically, there are three main screws: the low-speed (L) adjustment, the high-speed (H) adjustment, and the idle speed (T) screw. Understanding the function of each screw is crucial for making precise modifications to the mixture and achieving the desired performance.

Making the Adjustments

To begin the tuning process, start with the low-speed adjustment. Turn the screw clockwise to enrich the mixture or counterclockwise to lean it out. After reaching the desired setting, proceed to the high-speed adjustment, following the same principles. Finally, adjust the idle speed to ensure a smooth and stable idle. Always test the equipment after each adjustment to assess the impact on performance and make further tweaks as necessary.

Identifying Wear and Tear

Recognizing signs of deterioration is crucial for maintaining optimal performance and longevity of equipment. Regular inspections can prevent minor issues from escalating into significant problems. This section outlines key indicators of wear that should be monitored.

- Visual Inspection: Look for any noticeable cracks, scratches, or discoloration on the surface. These can signal underlying damage.

- Performance Issues: Decreased efficiency or irregular operation often suggests mechanical fatigue or component wear.

- Unusual Noises: Listen for any grinding, rattling, or other abnormal sounds during operation. These may indicate internal damage.

- Vibration Levels: Increased vibration can be a sign of misalignment or worn parts, affecting both performance and safety.

By paying attention to these factors, users can identify early signs of wear and take corrective action, ensuring their equipment remains in good working condition.

- Regularly check for visual signs of damage.

- Monitor performance and operational behavior.

- Listen for irregular sounds during use.

- Assess vibration levels for abnormal increases.

Addressing wear promptly can save time and resources, contributing to a more efficient operation overall.

Where to Find Spare Parts

Finding components for your equipment can be a straightforward process if you know where to look. Various sources offer a range of options, ensuring that you can locate the necessary pieces to keep your tools functioning optimally. Understanding these avenues will enhance your ability to maintain and repair your machinery effectively.

Authorized Dealers

One of the most reliable options for sourcing parts is through authorized dealers. These establishments provide genuine components that are specifically designed for your equipment. Additionally, purchasing from these vendors ensures that you receive quality products backed by manufacturer warranties. Always check the dealer locator on the manufacturer’s website to find the nearest authorized outlet.

Online Marketplaces

The internet offers numerous platforms where you can find a vast selection of spare parts. Websites dedicated to tools and equipment often have extensive catalogs. Look for reputable online retailers that specialize in machinery components. Reading customer reviews and checking ratings can help ensure you are purchasing from trustworthy sources. Furthermore, consider joining online forums or communities, where enthusiasts share tips on where to find hard-to-locate parts.