Keeping small engines in peak condition is essential for reliable operation, especially when they power essential outdoor equipment. With time and regular use, even the most resilient equipment can encounter performance issues, requiring a methodical approach to identify and resolve common concerns. This section provides an in-depth look at maintenance tips and effective troubleshooting techniques, enabling users to achieve better results and prolong the life of their machinery.

Understanding how to disassemble, clean, and examine critical components ensures that minor issues do not evolve into larger problems. Routine inspections and adjustments can help maintain optimal performance, prevent unnecessary wear, and detect potential failures early. This guide outlines practical steps to fine-tune and revitalize small engines, emphasizing core maintenance practices.

Beyond routine care, this section covers essential diagnostics, offering insights on common challenges and their solutions. From ignition and fuel system checks to component alignment and airflow adjustments, each section is designed to empower users with hands-on

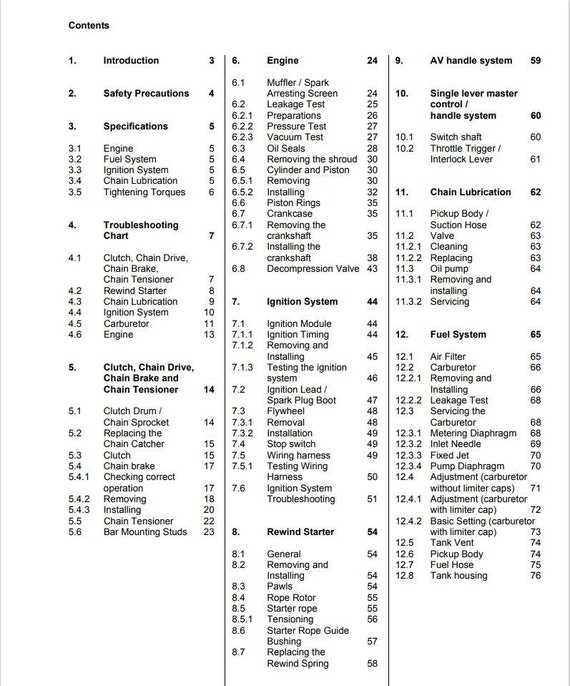

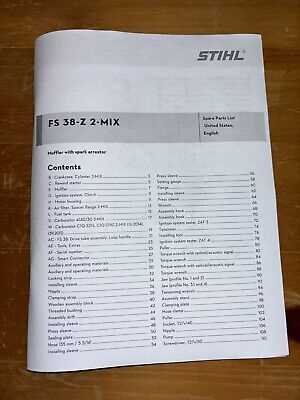

Stihl FS38 Repair Guide Overview

This section provides a comprehensive outline for those seeking to maintain and troubleshoot essential outdoor equipment. Covering various components, it helps readers understand critical areas of functionality and common issues that may arise over time. With the right approach, this guide aims to empower users to handle standard upkeep effectively, enhancing the durability and efficiency of their tools.

Key Areas of Maintenance

Focusing on primary maintenance tasks, this guide delves into essential areas like engine performance, fuel system integrity, and blade upkeep. For each part, specific steps and tips are outlined to prevent breakdowns and sustain smooth operation. Regular attention to these components not only extends

Essential Tools for FS38 Repairs

To effectively handle maintenance and fixes, having the right equipment is crucial. With a set of dedicated tools, performing adjustments and part replacements becomes straightforward and efficient. Here, we’ll highlight the essential instruments that will streamline tasks and ensure a smoother repair experience.

Basic Hand Tools

- Screwdrivers: Both flat-head and Phillips types are essential for working with various screws, from general parts to smaller, detailed components.

- Wrenches: A set of adjustable and socket wrenches is necessary to handle bolts of different sizes, allowing for effective fastening and loosening in tighter spots.

- Pliers: Needle-nose and standard pliers help

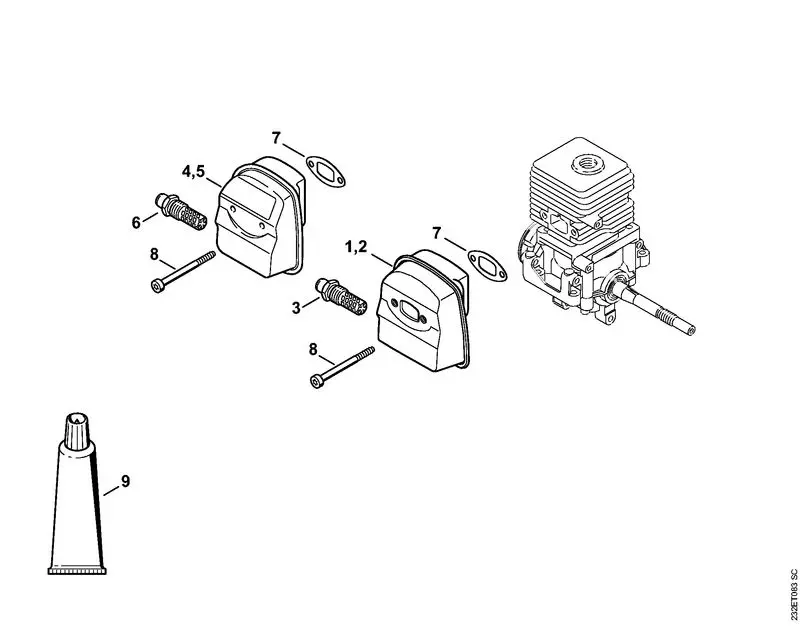

Engine Troubleshooting Techniques

Understanding how to effectively diagnose issues in small engines can prevent extended downtime and unnecessary repairs. By examining key components and identifying common symptoms, you can address engine concerns with confidence and precision.

Check for Fuel Flow: One of the primary causes of engine starting issues is fuel delivery. Ensure that the fuel line is free of clogs, and the fuel is fresh and suitable for the engine type. A clean carburetor is essential for optimal fuel-air mixture, so inspect it carefully if the engine sputters or fails to start.

Inspect the Spark Plug: The spark plug plays a crucial role in the ignition process. Remove and inspect it for signs of wear, fouling, or soot buildup. Clean or replace the spark plug if it appears dirty, as this can restore efficient firing and prevent misfires.

Evaluate the Air Filter: A clogged air filter restricts

Carburetor Cleaning and Adjustment

Maintaining a well-functioning carburetor is essential for the efficient operation of any small engine. Over time, buildup of dirt, fuel residues, and other debris can impede fuel flow, affecting performance. Regular cleaning and fine-tuning of this component helps ensure smooth starts, reliable idling, and consistent power.

Before beginning, it is important to disconnect the fuel line and carefully inspect the carburetor parts. For thorough cleaning, disassemble each accessible component, including jets and needle valves. Using a suitable carburetor cleaner, carefully remove any residue. Pay special attention to the jets, as they control fuel flow and are often clogged. A soft brush or compressed air may help to clear these tiny passages without causing damage.

After cleaning, reassemble and mount the carburetor back in place. Adjusting the carburetor involves calibrating the idle and high-speed screws to balance air and fuel intake. Begin by setting the screws to their factory-default positions, typically by tightening them gently

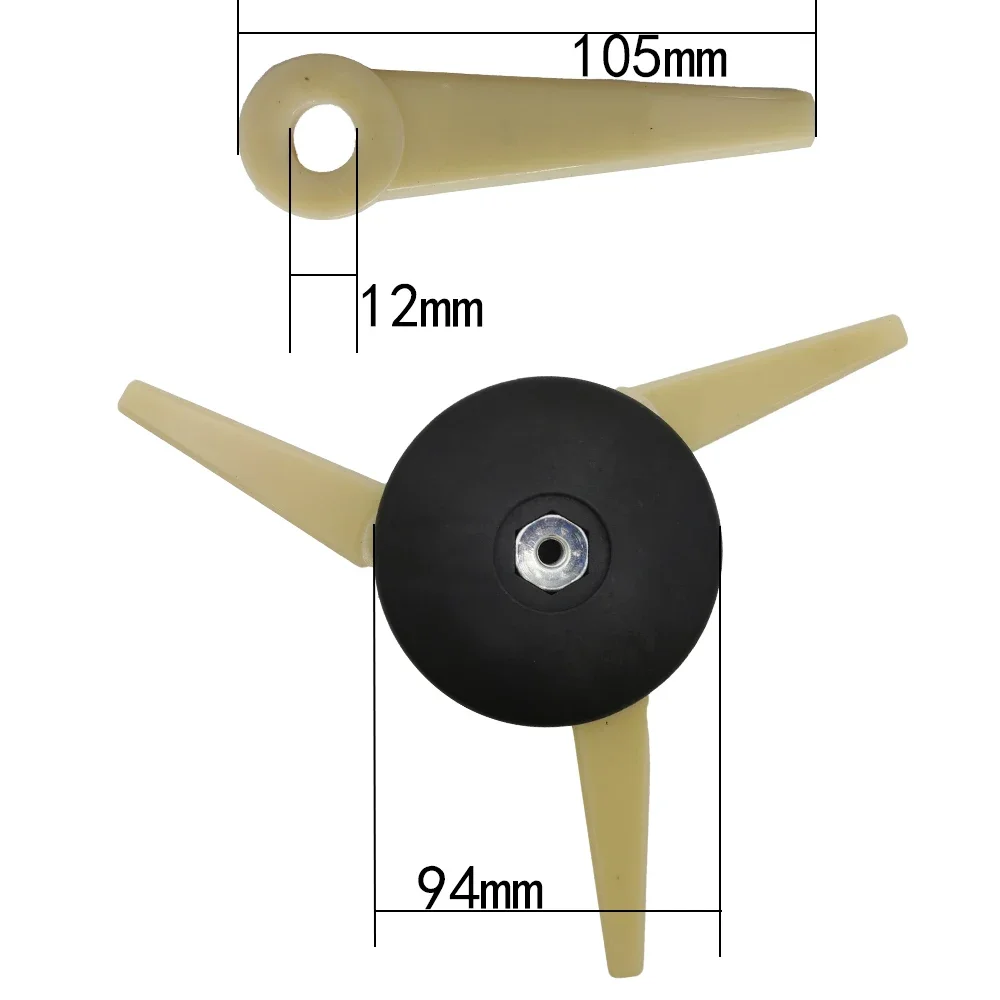

Replacing the Trimmer Head

Over time, the trimmer head can wear out or become damaged, which can impact the tool’s efficiency in clearing grass and weeds. This section outlines the essential steps to follow for safely removing the old head and installing a new one, ensuring the tool performs optimally in maintaining outdoor spaces.

Preparation Steps

Before beginning, ensure the tool is powered off and safely placed on a flat surface. Confirm that any leftover string or attachments have been removed from the trimmer head to prevent any accidental activation or injury during the replacement process.

Steps for Head Replacement

Step Action Description 1 Remove the Old Head Hold the base steady, then rotate the trimmer head counterclockwise to unscrew it Ignition System Diagnostics

The ignition system is crucial for the optimal performance of small engine equipment. Effective diagnostics of this system can help identify issues that lead to starting difficulties or poor engine operation. Understanding the components involved, as well as how to systematically check each part, is essential for troubleshooting and ensuring reliable function.

Begin by examining the spark plug. Remove it and inspect for wear, carbon buildup, or damage. A faulty spark plug can prevent the engine from igniting properly. Replace it if necessary, and always ensure the gap is set according to specifications.

Next, assess the ignition coil. Use a multimeter to measure resistance and ensure it is within the manufacturer’s guidelines. If the readings are outside acceptable ranges, replacement may be required. Additionally, check for any physical damage or loose connections, which can affect performance.

The magneto should also be inspected. Ensure it is clean and free from debris. Verify that it is properly aligned with the flywheel, as misalignment can cause inconsistent firing.

Lastly, evaluate the overall wiring and connections within the ignition system. Look for frayed wires, corrosion, or loose terminals that could disrupt the electrical flow. Ensuring all components are securely connected is vital for the system’s integrity and efficiency.

By following these diagnostic steps, you can effectively pinpoint ignition issues and enhance the operational reliability of your engine.

Fuel System Maintenance Tips

Proper care of the fuel system is essential for ensuring optimal performance and longevity of outdoor power equipment. Regular attention to this area can prevent issues such as fuel contamination, clogs, and starting difficulties. By following a few straightforward guidelines, users can maintain their equipment efficiently.

Regular Fuel Checks

It is crucial to inspect the fuel quality before each use. Stale or contaminated fuel can lead to engine problems. Always use fresh fuel that meets the manufacturer’s specifications. If the equipment has been stored for an extended period, consider draining the old fuel and replacing it with new, clean fuel.

Cleaning and Inspecting Components

Routine cleaning of the fuel filter and carburetor is vital for maintaining a smooth operation. Over time, debris can accumulate, obstructing fuel flow. Disassemble these components carefully, using appropriate cleaning solutions to remove any buildup. Ensure all connections are tight and free from leaks, as this can affect performance.

Incorporating these practices into your maintenance routine will help ensure that the fuel system remains in good working order, enhancing the efficiency and reliability of your outdoor equipment.

Cleaning the Air Filter

Maintaining optimal performance of outdoor power equipment requires regular attention to various components, including the air filter. This part plays a crucial role in ensuring the engine receives clean air, which is essential for efficient combustion. Over time, dust and debris can accumulate, obstructing airflow and potentially leading to engine performance issues. Thus, routine cleaning of the air filter is a vital task for preserving the longevity and functionality of your equipment.

Steps to Clean the Air Filter

To begin, remove the air filter cover, which is typically secured by screws or clips. Carefully detach the filter, ensuring not to damage any surrounding components. Inspect the filter for visible dirt and damage. If it appears excessively dirty but undamaged, proceed with cleaning.

Cleaning Process

Utilize compressed air or a soft brush to eliminate loose dirt from the filter. For deeper cleaning, wash the filter in warm, soapy water and rinse thoroughly. Ensure the filter is completely dry before reinstallation. After cleaning, replace the filter and secure the cover, ensuring a tight fit to prevent contaminants from entering the engine.

Regularly checking and cleaning the air filter will help maintain peak engine performance and extend the lifespan of your outdoor power equipment.

Spark Plug Inspection and Replacement

The spark plug plays a crucial role in the operation of small engines, igniting the air-fuel mixture for combustion. Regular examination of this component is essential for maintaining optimal performance and ensuring longevity. This section covers the process of assessing the condition of the spark plug and the steps necessary for its replacement when needed.

Begin by removing the spark plug using a suitable wrench. Inspect the electrode for signs of wear, such as erosion or heavy carbon deposits. A healthy spark plug will have a light tan or gray appearance, indicating proper combustion. If the electrode is damaged or excessively dirty, it is time for a replacement.

When selecting a new spark plug, ensure it matches the specifications required for the engine. Install the new plug carefully, taking care not to cross-thread it. Once in place, tighten it to the manufacturer’s recommended torque settings to avoid any issues with sealing or performance.

After installation, reconnect the ignition wire securely. Finally, perform a test run to verify that the engine operates smoothly. Regularly checking and replacing the spark plug can significantly improve the efficiency and reliability of your equipment.

Inspecting the Throttle Cable

Proper examination of the throttle cable is crucial for ensuring the smooth operation of your cutting device. This component plays a vital role in controlling the engine’s power output, and any issues can lead to performance problems. Regular inspection helps in identifying wear, damage, or improper adjustments that can affect the functionality.

To effectively check the throttle cable, follow these steps:

- Visual Inspection: Start with a thorough visual examination of the cable. Look for signs of fraying, corrosion, or any physical damage.

- Check for Flexibility: Gently bend the cable to assess its flexibility. A stiff or kinked cable may indicate internal damage.

- Examine the Connections: Inspect the attachment points at both the throttle lever and the carburetor. Ensure that the connections are secure and free from debris.

- Adjust Tension: If the cable appears to be too loose or too tight, adjust the tension according to the manufacturer’s specifications.

- Test Operation: With the device off, manually operate the throttle lever to ensure smooth movement and proper cable retraction.

By conducting these inspections regularly, you can maintain optimal performance and prolong the lifespan of your equipment.

Lubrication Points for Optimal Performance

Ensuring that all moving components of your equipment are properly lubricated is crucial for maintaining efficiency and extending its lifespan. Regular attention to lubrication points can significantly enhance performance, reduce wear, and prevent premature failures. Identifying the key areas that require oil or grease will help keep your device operating smoothly.

Essential Lubrication Areas

Pay close attention to the engine components, such as the spark plug and cylinder, as these areas generate substantial heat and friction during operation. Applying the appropriate lubricant can minimize wear and tear. Additionally, the gear assembly should receive regular lubrication to ensure smooth transmission and to avoid mechanical binding.

Lubrication Frequency and Tips

It is advisable to check lubrication levels frequently, ideally before each use. Ensure that you are using the correct type of lubricant specified for each component, as this will optimize performance. Regular maintenance not only improves efficiency but also enhances the overall reliability of your machinery.

FS38 Storage and Long-Term Care

Proper preservation and maintenance of outdoor equipment are essential for ensuring its longevity and optimal performance. When the device is not in use for an extended period, following specific guidelines can help prevent deterioration and prepare it for future use.

Cleaning is the first step before storage. Remove any dirt, debris, or grass clippings from the exterior and the cutting components. This prevents buildup that could lead to rust or corrosion over time. Using a soft brush or cloth can effectively clean hard-to-reach areas.

Next, fuel management plays a crucial role. If the device has been running on fuel, consider emptying the tank before storage. Alternatively, adding a fuel stabilizer to the remaining gasoline can prevent it from degrading and causing starting issues later. Always ensure the fuel cap is tightly secured to avoid leaks.

After cleaning and fuel management, focus on lubrication. Apply appropriate lubricant to moving parts, as this will reduce wear and tear. Regularly inspect the spark plug and replace it if necessary, as this is vital for reliable starting.

Finally, store the equipment in a cool, dry place away from direct sunlight. Protect it from extreme temperatures and humidity to prevent damage. Using a cover can also provide additional protection against dust and pests.

By following these simple yet effective steps, you can ensure that your outdoor tool remains in excellent condition and is ready for use whenever needed.