The upkeep of outdoor power tools is essential for ensuring their longevity and optimal performance. Understanding the intricacies of each component is crucial for effective troubleshooting and enhancement of efficiency. This guide serves as a comprehensive resource for those seeking to maintain their equipment in peak condition.

Delving into the specifics of this machine, users will find valuable insights into various aspects, including assembly, adjustment, and common issues. By following the instructions and recommendations provided, individuals can foster a deeper understanding of their tool’s functionality and address potential challenges proactively.

Whether you’re a seasoned user or a newcomer, this resource aims to equip you with the knowledge necessary to tackle routine maintenance tasks confidently. With the right approach, you can ensure that your equipment remains a reliable companion for all your outdoor endeavors.

Overview of Stihl FS 38

The FS 38 is a versatile tool designed for effective grass trimming and maintaining outdoor spaces. This equipment is particularly appreciated for its lightweight construction and user-friendly features, making it an ideal choice for both beginners and experienced users. With a reliable engine and well-engineered design, it offers efficient performance and ease of operation.

Key Features

One of the standout characteristics of this trimmer is its powerful engine, which allows for quick and precise cutting. The ergonomic handle provides comfort during extended use, reducing fatigue and improving maneuverability. Additionally, the adjustable cutting head ensures that users can tackle various types of vegetation with ease.

Maintenance and Care

To ensure optimal functionality, regular upkeep is essential. Checking the fuel levels and cleaning the air filter are simple yet effective ways to prolong the lifespan of the tool. Users are encouraged to refer to specific guidelines to maintain peak performance and reliability.

Common Issues and Solutions

This section addresses frequent problems encountered during the operation of garden equipment, along with practical solutions to enhance performance and longevity. Understanding these common challenges can significantly aid users in maintaining their tools effectively.

Typical Problems

- Engine Failure to Start

- Excessive Vibration During Operation

- Fuel Leaks

- Overheating

Effective Solutions

- Engine Failure to Start: Check the fuel level and ensure that the mixture is correct. Inspect the spark plug for damage or wear, and clean or replace it as necessary.

- Excessive Vibration: Ensure that the cutting attachment is securely fastened. Check for any damage or imbalance in the components.

- Fuel Leaks: Inspect the fuel lines for cracks or loose connections. Replace any damaged hoses to prevent leakage.

- Overheating: Clean the air filter and ensure that it is not clogged. Regular maintenance can prevent overheating and extend the tool’s life.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment involves regular care and attention. By following a few simple practices, you can enhance performance and reliability over time.

- Regular Cleaning: Keep the exterior and components clean to prevent dirt buildup.

- Inspect Components: Frequently check for wear and tear, especially on moving parts.

- Proper Storage: Store in a dry, cool place to avoid rust and corrosion.

- Use Recommended Fuel: Always opt for the manufacturer’s suggested fuel type to ensure optimal functioning.

- Follow Lubrication Guidelines: Apply lubricant as specified to reduce friction and wear.

In addition to these practices, be attentive to any unusual sounds or performance issues. Addressing minor problems promptly can prevent more significant issues down the line.

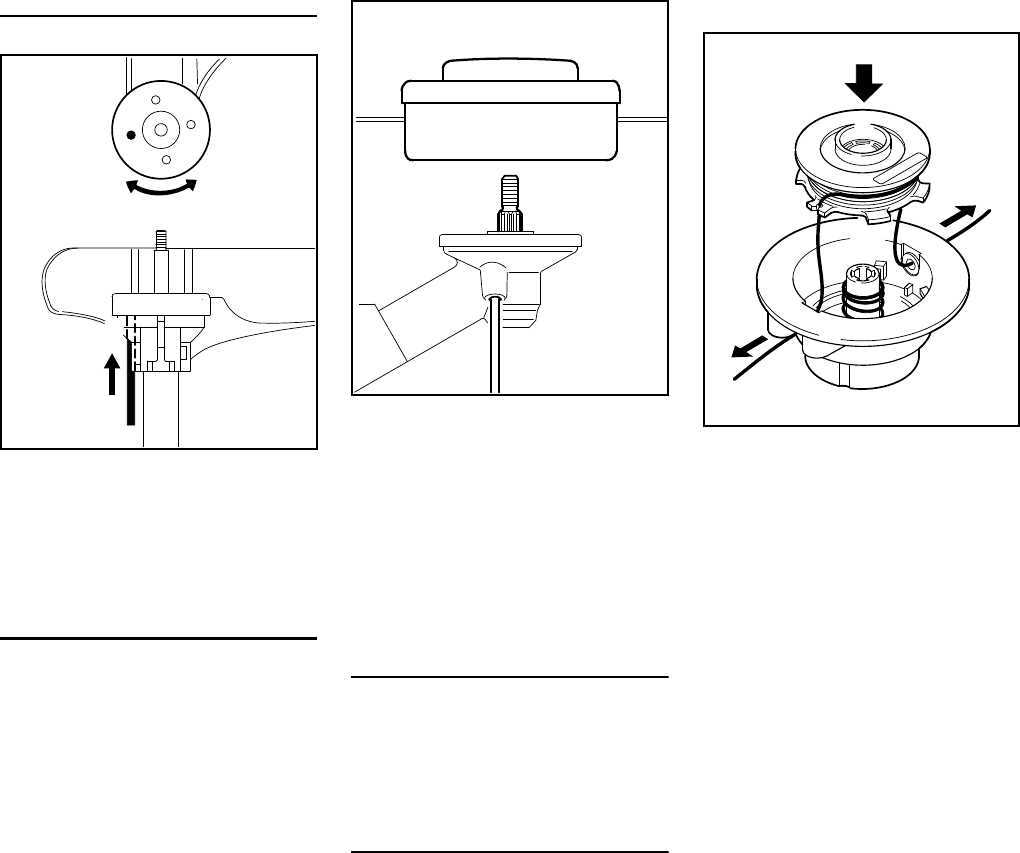

Step-by-Step Repair Procedures

This section provides detailed instructions for addressing common issues that may arise with your equipment. Following a systematic approach can help ensure effective troubleshooting and maintenance, making the process straightforward and manageable.

Identifying the Issue

Before beginning any work, it is crucial to accurately determine the problem. Common signs of malfunction may include:

- Difficulty starting the engine

- Inconsistent power output

- Unusual noises during operation

Once the issue is recognized, gather the necessary tools and replacement parts for the task ahead.

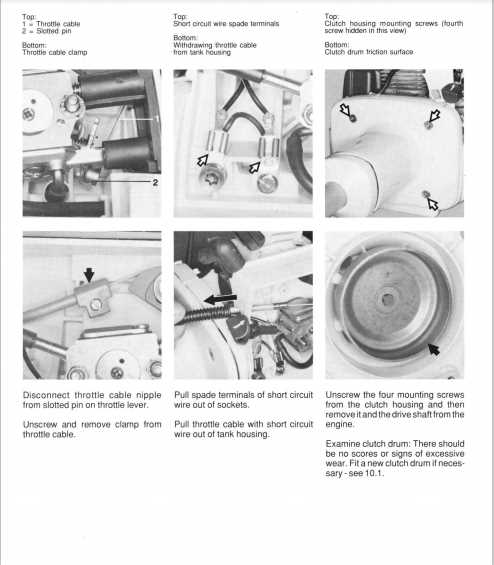

Disassembly Process

- Ensure the device is turned off and disconnected from any power source.

- Remove the protective cover carefully, taking note of any screws or fasteners.

- Detach the fuel tank and inspect for any blockages or leaks.

- Access the engine compartment by removing additional components as needed.

After disassembling the relevant parts, assess each component for wear or damage. Replacing faulty elements is essential for restoring optimal function. Reassembly should follow the reverse order of disassembly, ensuring all connections are secure.

Essential Tools for Repair

Having the right set of instruments is crucial for effective maintenance and restoration of your equipment. Proper tools not only simplify the process but also ensure a more precise and successful outcome. Below is a list of indispensable items you should consider for your toolkit.

Basic Tools

- Screwdrivers: A variety of sizes, including flathead and Phillips, will help tackle different fasteners.

- Wrenches: Both adjustable and fixed wrenches are essential for loosening and tightening bolts.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating small components.

- Socket Set: A comprehensive set with various socket sizes can make working with bolts easier.

Specialized Instruments

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Feeler Gauges: Helps measure gaps and clearances accurately.

- Multimeter: Essential for diagnosing electrical issues and testing continuity.

- Fuel System Cleaner: Aids in maintaining the efficiency of the fuel system.

Investing in these tools will not only enhance your capability to maintain and fix your equipment but will also contribute to its longevity and performance. Make sure to keep your toolkit organized and accessible for whenever you need to perform maintenance tasks.

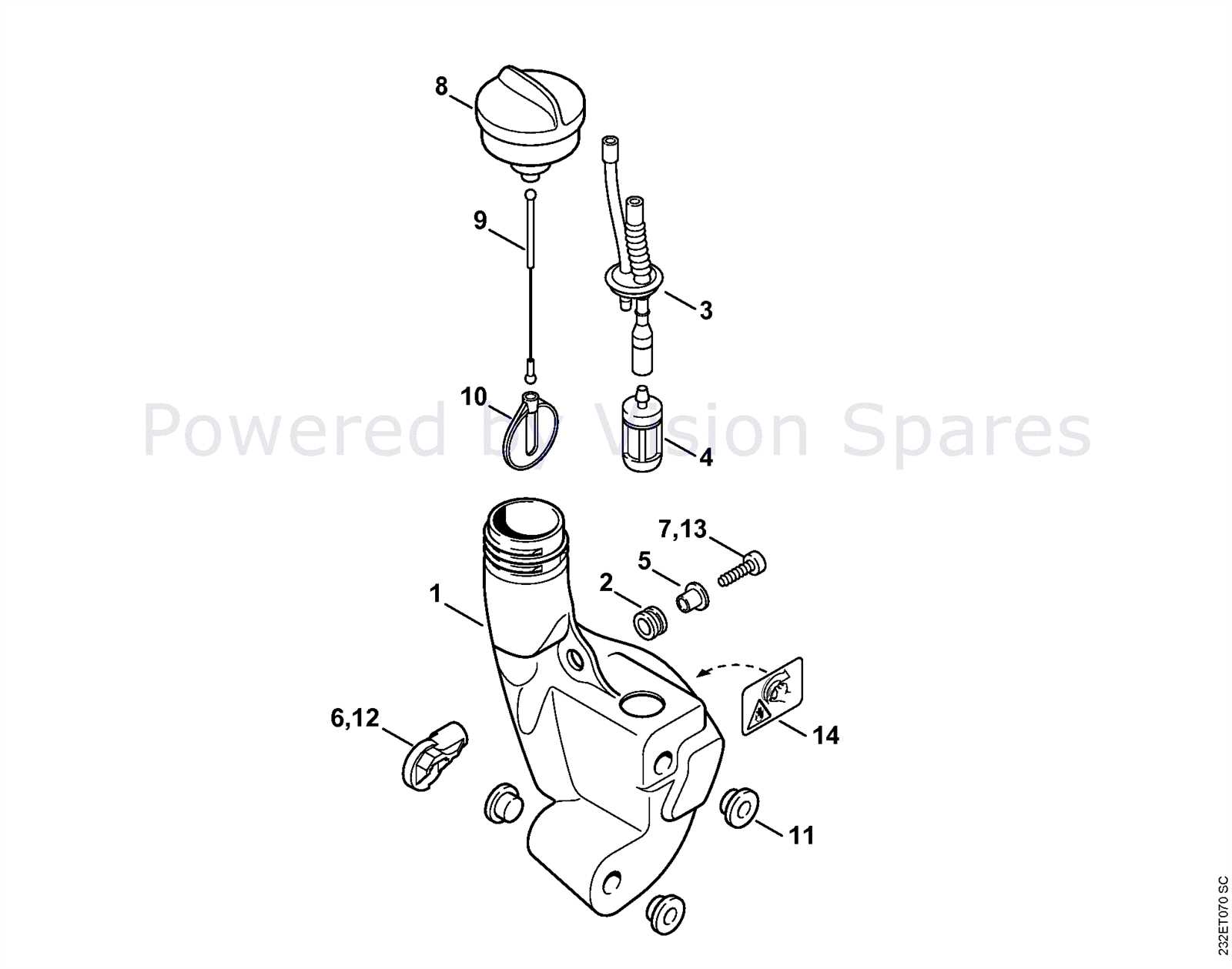

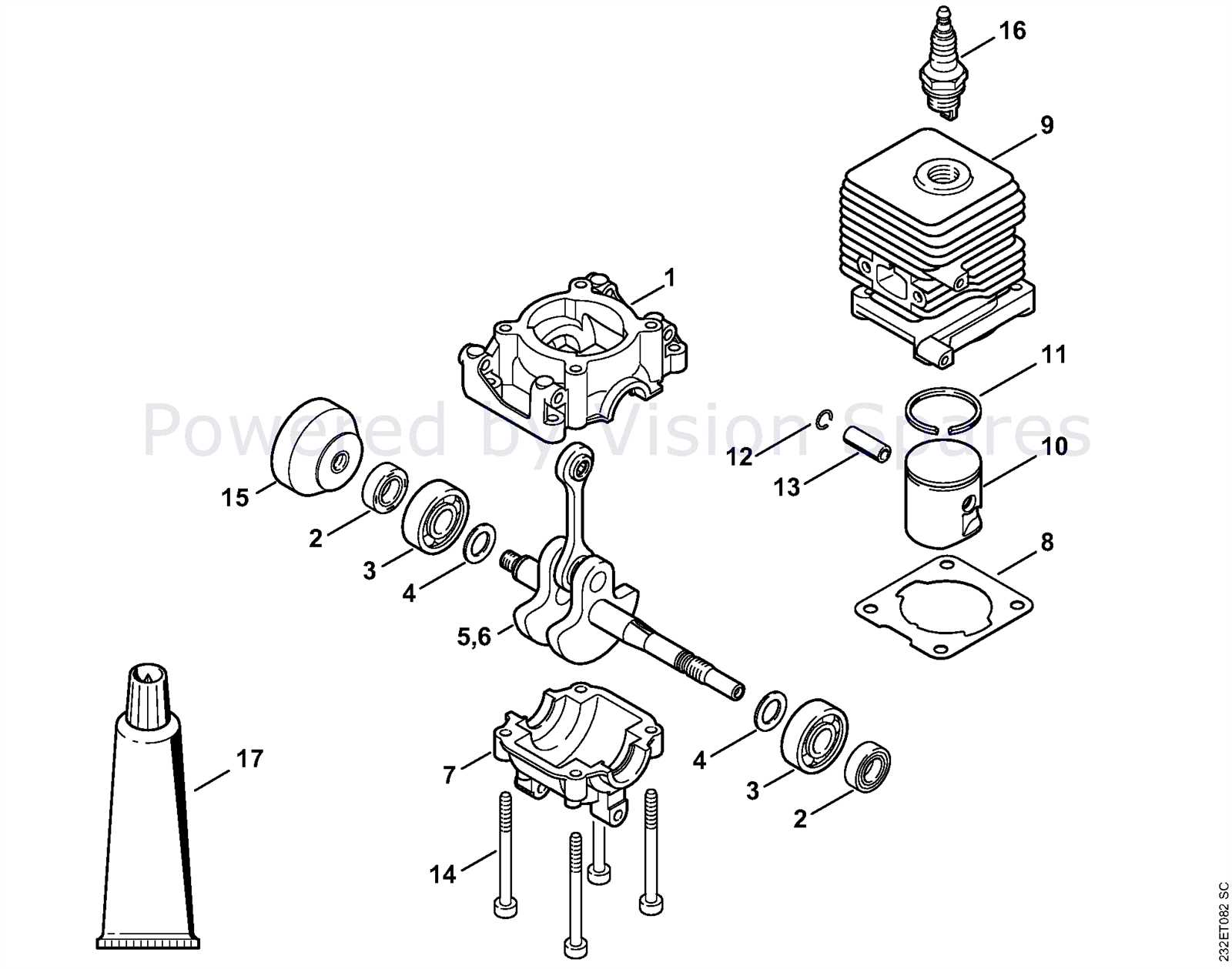

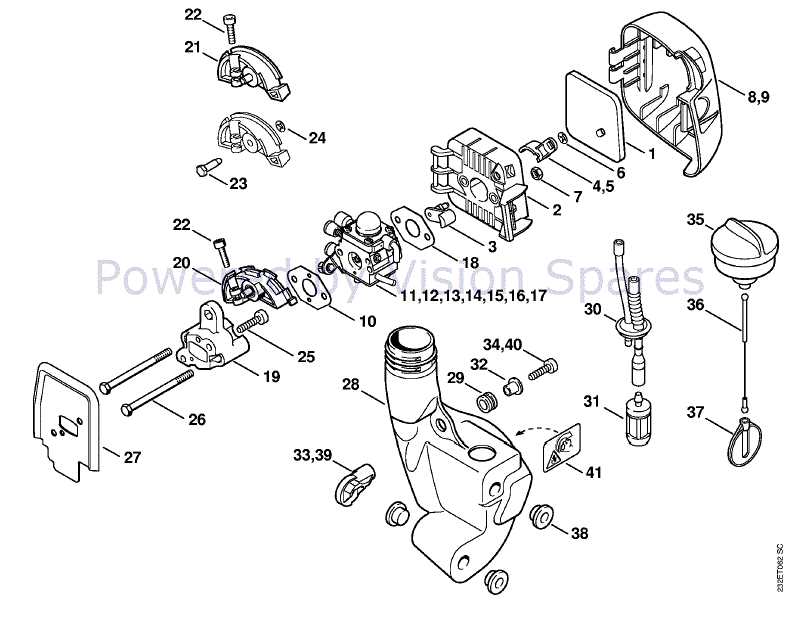

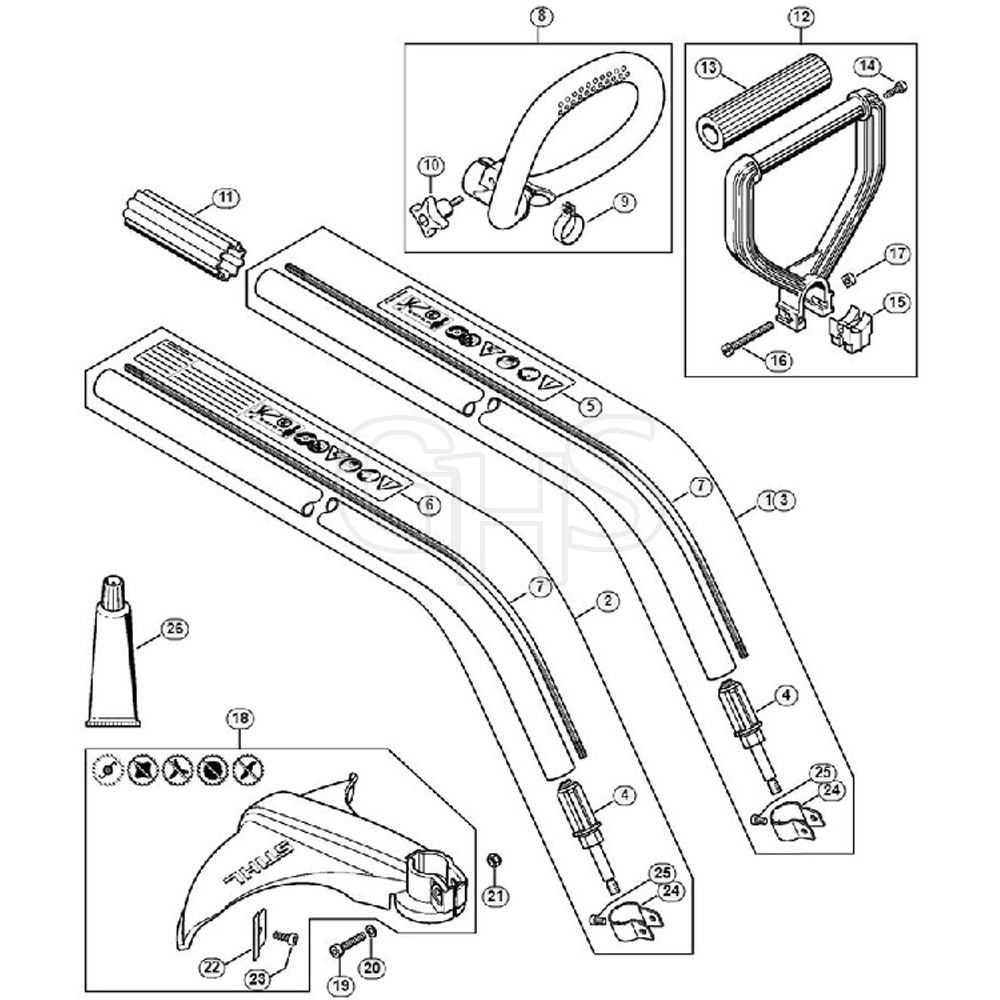

Identifying Parts and Components

Understanding the various elements and their functions is essential for effective maintenance and operation. This section focuses on recognizing key components that contribute to overall performance and usability.

Main Components

- Engine: The power source that drives the entire unit.

- Fuel Tank: Stores the necessary liquid for operation.

- Handle: Provides a grip for maneuverability.

- Cutting Head: Responsible for trimming vegetation.

- Throttle Control: Regulates engine speed and cutting power.

Additional Parts

- Air Filter: Ensures clean air intake for efficient combustion.

- Spark Plug: Ignites the fuel-air mixture within the engine.

- Safety Guard: Protects the operator from debris and accidents.

- Shoulder Strap: Enhances comfort and support during use.

Familiarity with these components will aid in troubleshooting and enhancing performance. Proper identification ensures that users can address issues effectively and maintain optimal functionality.

Safety Precautions During Repairs

When conducting maintenance on outdoor power equipment, it is essential to prioritize safety. Proper precautions not only protect the individual performing the task but also ensure that the equipment functions efficiently and lasts longer.

- Wear Protective Gear: Always use appropriate safety equipment, such as gloves, goggles, and ear protection, to minimize the risk of injury.

- Work in a Well-Ventilated Area: Ensure that the workspace is adequately ventilated to prevent the accumulation of harmful fumes.

- Disconnect Power Sources: Before beginning any work, disconnect the ignition source or remove the spark plug to avoid accidental starts.

- Keep the Area Clean: Maintain a tidy workspace to prevent slips and falls, and make it easier to locate tools and parts.

- Follow Manufacturer Instructions: Always refer to guidelines provided by the manufacturer for specific safety measures relevant to the equipment.

By adhering to these safety guidelines, individuals can effectively reduce risks associated with maintenance tasks and enhance their overall experience.

Service Intervals and Recommendations

Maintaining equipment is crucial for optimal performance and longevity. Regular check-ups and timely interventions can prevent major issues and ensure smooth operation. This section provides essential guidance on maintenance frequency and best practices to keep your device in top condition.

Maintenance Schedule

To maximize efficiency, adhere to the following intervals for routine maintenance:

- Daily checks: Inspect for visible wear and tear, ensuring all components are secure.

- Weekly servicing: Clean air filters and check fuel levels.

- Monthly inspections: Examine spark plugs and replace if necessary.

- Seasonal overhauls: Conduct a thorough cleaning and lubrication of moving parts.

Best Practices

Implementing these recommendations will enhance performance:

- Use high-quality fuel and lubricants to prevent engine deposits.

- Store equipment in a dry place to avoid moisture-related damage.

- Follow the manufacturer’s guidelines for parts replacement.

- Keep an eye on wear indicators and address issues promptly.

By following these intervals and recommendations, you can ensure reliability and extend the life of your equipment.

Understanding Engine Specifications

Engine specifications play a crucial role in determining the performance and efficiency of any power equipment. A thorough understanding of these details can help users make informed decisions regarding maintenance, upgrades, and operational best practices.

Key specifications to consider include:

- Displacement: This refers to the total volume of all cylinders in the engine, typically measured in cubic centimeters (cc). Higher displacement often indicates greater power output.

- Power Output: Measured in horsepower (hp) or kilowatts (kW), this value indicates the engine’s capability to perform work. It is essential for assessing the tool’s effectiveness for specific tasks.

- Fuel Type: Understanding the required fuel type ensures optimal performance. Common options include gasoline and mixed fuels, each with its own implications for maintenance and efficiency.

- Weight: The weight of the engine affects the overall portability and ease of use of the equipment. Lighter engines may provide better maneuverability.

In addition to these primary specifications, it is also important to consider:

- Torque: This is the twisting force produced by the engine, usually measured in Newton-meters (Nm). It is vital for understanding how well the engine can handle load.

- Engine Type: The design of the engine, whether two-stroke or four-stroke, impacts its operation, efficiency, and maintenance needs.

By familiarizing oneself with these specifications, users can enhance their understanding of equipment capabilities, leading to more effective and efficient use in various applications.

Customer Feedback and Reviews

This section aims to highlight the experiences and opinions of users regarding their recent purchases. Understanding customer sentiment is crucial for prospective buyers looking for insights before making a decision.

Overall Satisfaction

Many users express a high level of contentment with their equipment, praising its reliability and performance. Feedback often emphasizes the ease of operation and efficiency, making it a popular choice among both casual users and professionals alike.

Common Issues

While the majority of reviews are positive, some customers report occasional challenges. Common concerns include maintenance needs and parts availability. However, users often note that these issues are manageable and do not significantly detract from their overall experience.

In conclusion, gathering insights from past users provides valuable context for potential buyers, helping them to make informed decisions and understand what to expect from their acquisition.