In the realm of accessibility solutions, ensuring the optimal functionality of lifting devices is paramount. This section aims to provide essential insights and procedures for maintaining and troubleshooting a specific model of a lifting platform, empowering users to address potential issues effectively.

Understanding the Components: A thorough comprehension of the various parts and their roles is crucial for effective upkeep. Familiarizing oneself with the structure and mechanisms will facilitate smoother operations and enhance longevity.

Common Issues and Solutions: This guide will delve into frequent challenges users may encounter, offering practical solutions and tips to restore functionality swiftly. With the right knowledge, users can tackle minor complications without the need for professional assistance.

Understanding the Stannah 420 Model

This section delves into a specific model designed for ease of mobility within homes and buildings. It showcases innovative features that enhance user experience, focusing on safety, comfort, and efficiency. This unit is a prime example of modern engineering aimed at providing reliable solutions for those with mobility challenges.

Key aspects include its intuitive controls, which allow users to navigate effortlessly. The design emphasizes user-friendliness, ensuring that individuals can operate it with minimal effort. Additionally, the structure is built with robust materials, promising durability and long-term functionality.

Safety features play a crucial role in the operation of this device. The integration of advanced technology ensures that potential hazards are minimized, providing peace of mind for users and their families. Regular maintenance is essential to uphold these safety standards and to ensure the longevity of the equipment.

Understanding the functionalities and components of this model can significantly enhance the overall experience. Users are encouraged to familiarize themselves with its capabilities to maximize its potential, ultimately improving mobility and independence in daily life.

Common Issues with the Stannah 420

In this section, we will explore frequently encountered problems that users may face with their lifting devices. Understanding these common challenges can aid in troubleshooting and ensure optimal performance.

Mechanical Malfunctions

Mechanical failures can arise due to wear and tear or improper usage. Regular maintenance is essential to mitigate these issues and prolong the life of the device.

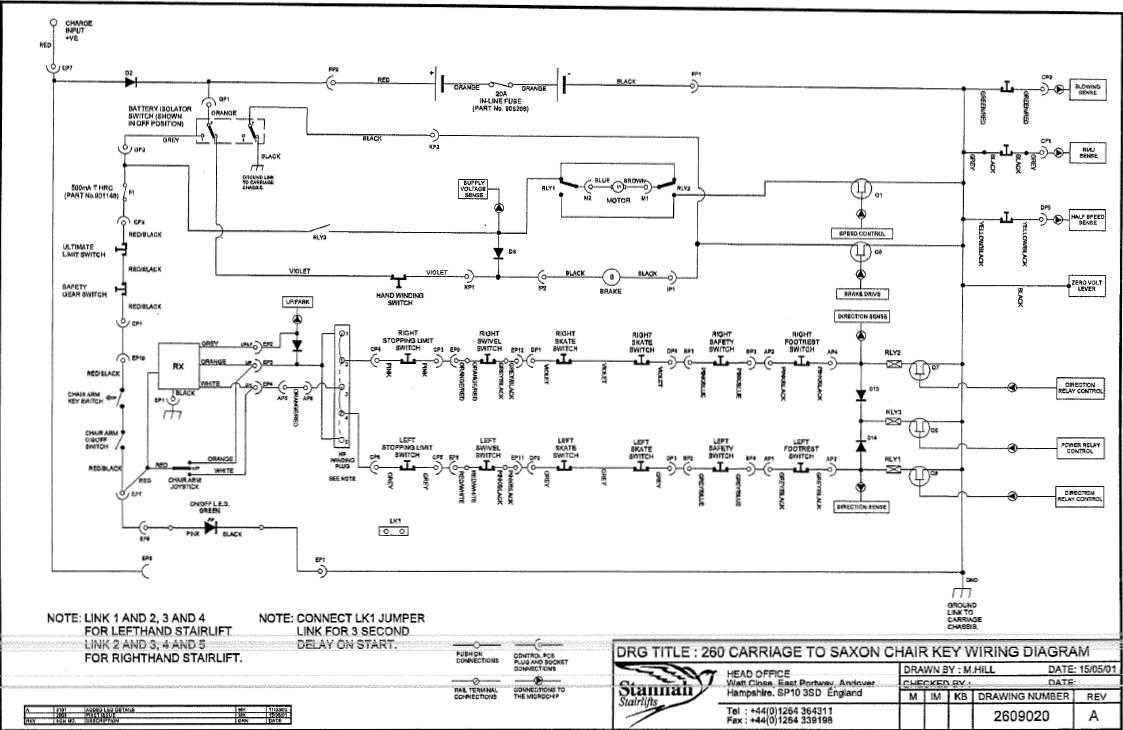

Electrical Problems

Electrical faults can also occur, impacting the functionality of the system. Identifying and addressing these problems promptly can prevent further complications.

| Issue | Description |

|---|---|

| No Movement | The device fails to operate when activated, possibly due to power loss or internal faults. |

| Unusual Noises | Strange sounds may indicate issues with gears or motors that require immediate attention. |

| Inconsistent Performance | Devices may operate erratically, suggesting potential electrical or mechanical problems. |

| Overheating | Excessive heat generation can signal internal issues, necessitating a thorough inspection. |

Tools Required for Repairing

When undertaking maintenance tasks, having the appropriate instruments is essential for ensuring efficiency and effectiveness. The right tools not only facilitate the process but also enhance safety during the operation.

Essential Instruments

To begin with, a standard toolkit containing basic items like screwdrivers, pliers, and wrenches is necessary. These instruments allow for the loosening and tightening of various components, making them indispensable for any service task. Additionally, a multi-meter is highly recommended for diagnosing electrical issues, ensuring all connections are secure and functioning correctly.

Specialized Equipment

In certain situations, specialized devices may be required to address specific issues. For instance, a torque wrench can be crucial for applying the correct force to fasteners, preventing damage from over-tightening. Furthermore, lubricant sprays can aid in the smooth operation of moving parts, reducing wear and tear over time.

Step-by-Step Repair Process

In this section, we will outline a systematic approach to addressing common issues that may arise in your lifting device. By following these steps, you can ensure a thorough assessment and effective resolution of problems, enhancing the longevity and functionality of your equipment.

1. Initial Assessment: Begin by conducting a detailed inspection of the unit. Check for any visible signs of wear, damage, or malfunction. Document your findings to guide the subsequent steps.

2. Safety Precautions: Before proceeding with any maintenance work, ensure that the device is powered off and properly secured. Use appropriate personal protective equipment to safeguard against potential hazards.

3. Component Disassembly: Carefully disassemble the relevant components as identified during the initial assessment. Use the correct tools to avoid damaging any parts. Keep all screws and small components organized for reassembly.

4. Diagnosis: Examine each part for functionality. Look for issues such as loose connections, worn-out gears, or damaged wiring. It may be helpful to consult a reference guide for troubleshooting specific problems.

5. Replacement and Repair: Once the faulty components have been identified, proceed with replacements or repairs as necessary. Ensure that all parts meet the required specifications to maintain optimal performance.

6. Reassembly: After addressing all issues, carefully reassemble the device, ensuring that all components are securely fastened and properly aligned. Double-check connections to prevent future problems.

7. Final Testing: Once reassembled, perform a thorough test to ensure the device operates as intended. Monitor its performance closely to confirm that all issues have been effectively resolved.

By adhering to this structured process, you can effectively troubleshoot and resolve issues with your lifting equipment, ensuring its reliable operation for years to come.

Safety Precautions During Maintenance

Ensuring a safe working environment is crucial when performing upkeep tasks. Proper precautions not only protect the technician but also prevent potential damage to the equipment being serviced. Adhering to safety guidelines is essential to mitigate risks associated with maintenance activities.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is fundamental. Technicians should wear gloves, safety goggles, and non-slip footwear to safeguard against injuries. This gear serves as a barrier against sharp objects, chemicals, and potential slips or falls, promoting a secure maintenance process.

Power Supply Management

Before commencing any maintenance tasks, it is vital to disconnect the power supply to the device. This prevents accidental activation and reduces the risk of electrical shock. Additionally, clearly labeling power sources and informing all personnel on site enhances overall safety during maintenance procedures.

Identifying Parts and Components

Understanding the various elements and their functions is essential for effective maintenance and troubleshooting. Each component plays a specific role in the overall operation, making it crucial to recognize them accurately. This section will guide you through the identification process of key parts, helping to enhance your familiarity and ease of handling.

Key Components Overview

Below is a list of essential components typically found in these systems. Familiarity with these parts can aid in better understanding how they interact and function together.

| Component | Description |

|---|---|

| Motor | Drives the movement of the platform, converting electrical energy into mechanical force. |

| Control Panel | Interface for the user, allowing operation and customization of settings. |

| Guide Rails | Provide support and stability, ensuring smooth movement along the designated path. |

| Safety Sensors | Detect obstacles and ensure safe operation by halting movement if necessary. |

| Battery | Supplies power to the system, especially useful during power outages. |

Recognizing Individual Parts

Each element can be identified by its distinct features and placement. Being able to pinpoint these characteristics not only aids in troubleshooting but also facilitates timely maintenance actions.

Tips for Preventative Maintenance

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By implementing simple, routine practices, you can prevent potential issues and reduce the need for extensive repairs. This section outlines key strategies to help maintain the functionality and efficiency of your system.

Routine Inspections

Conducting frequent checks can help identify early signs of wear and tear. Inspect components for any signs of damage or misalignment. Regular assessments can prevent minor issues from escalating into major problems.

Cleaning and Lubrication

Keeping the machinery clean is crucial for its operation. Accumulated dirt can lead to inefficiencies and mechanical failures. Regularly lubricate moving parts to reduce friction and wear, ensuring smooth operation.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Look for signs of damage or wear. |

| Cleaning | Monthly | Remove dust and debris from all surfaces. |

| Lubrication | Quarterly | Apply appropriate lubricant to all moving parts. |

| Component Replacement | As Needed | Replace worn or damaged components immediately. |

How to Troubleshoot Effectively

Addressing issues with mechanical devices requires a systematic approach to identify and resolve problems efficiently. This section outlines essential steps to enhance your diagnostic process and ensure optimal functionality.

| Step | Description |

|---|---|

| 1. Observe | Carefully watch the operation to note any unusual sounds, movements, or errors that occur during use. |

| 2. Check Connections | Examine all connections and fittings to ensure they are secure and free from damage. |

| 3. Consult Documentation | Refer to available guides for troubleshooting tips and common problems associated with the device. |

| 4. Test Components | Isolate and test individual parts to identify faulty components that may affect performance. |

| 5. Seek Professional Help | If issues persist, consider contacting a specialist for expert assessment and repair. |

When to Call a Professional

There are instances when attempting to fix a device on your own may not be the best approach. Understanding when to seek expert assistance is crucial for ensuring safety and optimal functionality. Professionals possess the necessary skills and tools to address complex issues effectively.

If you encounter any of the following situations, it may be wise to consult a technician:

| Situation | Reason to Call a Professional |

|---|---|

| Persistent Issues | If problems continue despite basic troubleshooting, a specialist can identify underlying causes. |

| Safety Concerns | When dealing with electrical components or heavy machinery, the risk of injury increases, making expert help essential. |

| Warranty Considerations | Modifying or repairing a device without professional support may void any existing warranty. |

| Lack of Experience | If you are unfamiliar with the equipment, seeking professional guidance can prevent further damage. |

Recognizing these indicators can help you make informed decisions and ensure the longevity of your device.

Customer Support Resources Available

Access to reliable assistance and guidance is essential for ensuring the longevity and proper functioning of any product. Various channels are available to provide users with the necessary support, whether it involves troubleshooting issues or obtaining specific information regarding operation.

Here are some key resources that customers can utilize:

| Resource Type | Description |

|---|---|

| Online Help Center | A comprehensive platform featuring articles, FAQs, and troubleshooting guides to assist users with common inquiries. |

| Phone Support | Direct access to knowledgeable representatives who can offer personalized assistance and answer specific questions. |

| Email Support | A convenient way to communicate issues or requests for information, ensuring responses from experts within a designated timeframe. |

| Community Forums | A space for users to connect, share experiences, and seek advice from others who have encountered similar situations. |

Utilizing these resources can enhance user experience and provide valuable support for maintaining optimal performance.

Upgrades and Modifications Options

Enhancing the functionality and performance of lifting devices can significantly improve user experience and safety. Various upgrades and modifications can be considered to tailor the system to specific needs, ensuring optimal operation and increased efficiency.

One of the primary options for enhancement involves upgrading the control systems. Advanced controls may offer improved responsiveness and intuitive interfaces, allowing for smoother operation. Additionally, integrating smart technology can enable remote monitoring and diagnostics, providing users with valuable insights into the device’s performance.

Another aspect to consider is the installation of safety features. Adding additional sensors or alarms can help prevent accidents and ensure compliance with safety regulations. These enhancements not only protect users but also extend the lifespan of the equipment.

Moreover, customizing the design and aesthetics of the unit can be beneficial. Options such as varied finishes or personalized layouts can make the device more appealing and fit seamlessly into its environment.

Finally, regular assessments of performance and condition can guide necessary upgrades, ensuring that the system remains efficient and reliable. Emphasizing routine maintenance alongside these modifications will contribute to a more robust and user-friendly lifting solution.