This section offers essential insights for individuals seeking to enhance the longevity and efficiency of their laundry appliances. Understanding the intricacies of these machines is crucial for ensuring optimal performance and minimizing downtime.

Regular upkeep and troubleshooting can significantly reduce the likelihood of malfunctions, leading to a more efficient operation. By following systematic guidelines and recognizing common issues, users can effectively address potential challenges that may arise during use.

Moreover, possessing a comprehensive knowledge base empowers operators to handle various situations confidently. This familiarity not only streamlines the maintenance process but also enhances overall user satisfaction.

This section aims to provide insights into the functioning and components of your laundry appliance. By understanding the essential elements, you can better maintain its performance and troubleshoot common issues effectively.

Familiarizing yourself with the various parts of your unit is crucial. Knowing how each component interacts can significantly enhance your ability to diagnose problems. Below is a table summarizing the key features and their functions:

| Component | Function |

|---|---|

| Drum | Holds the items being dried, allowing them to tumble for effective drying. |

| Heating Element | Generates heat necessary for the drying process. |

| Control Panel | Allows users to select settings and monitor the drying cycle. |

| Vent System | Expels moisture and hot air, maintaining efficiency and preventing overheating. |

| Motor | Powers the drum’s rotation and drives the blower fan. |

Understanding these components will empower you to maintain and troubleshoot your laundry appliance, ensuring its longevity and efficiency in your daily tasks.

Common Issues with Commercial Dryers

In any high-usage fabric drying unit, several problems can arise that may affect performance and efficiency. Understanding these common challenges is essential for maintaining optimal functionality and prolonging the lifespan of the equipment.

One frequent issue is inadequate heat generation, which can lead to prolonged drying times and unsatisfactory results. This can be caused by faulty heating elements or obstructed airflow. Another common problem is improper drum rotation, which might stem from worn-out belts or malfunctioning motors. These failures can hinder the machine’s ability to dry effectively.

Additionally, electrical complications, such as tripped breakers or damaged wiring, can disrupt operation. Regular maintenance and prompt attention to these issues can help ensure consistent performance and reduce downtime.

Tools Needed for Repairs

To effectively address issues with your appliance, it is essential to have the right equipment at hand. Proper tools not only facilitate the repair process but also ensure safety and efficiency. This section outlines the necessary instruments that will aid in the maintenance and troubleshooting of your unit.

Basic Hand Tools: A selection of screwdrivers, including flathead and Phillips, is crucial for accessing various components. Pliers and wrenches are also beneficial for loosening or tightening connections.

Specialized Instruments: Depending on the specific faults encountered, additional devices like multimeters can assist in diagnosing electrical problems, while torque wrenches ensure proper tightness of screws and bolts.

Safety Gear: Don’t overlook the importance of personal protective equipment. Gloves and safety goggles should be worn to protect against potential hazards during the process.

Having the appropriate tools readily available will streamline the troubleshooting process, making it easier to identify and resolve issues effectively.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues encountered with laundry appliances. By following these steps, users can efficiently diagnose problems, ensuring optimal performance and longevity of the equipment.

| Issue | Possible Cause | Solution |

|---|---|---|

| No heat | Faulty heating element | Inspect and replace the heating element if necessary. |

| Strange noises | Worn drum bearings | Check bearings for wear and replace if needed. |

| Long drying times | Blocked vent system | Clean the vent and ensure proper airflow. |

| Appliance not starting | Defective door switch | Test the door switch and replace if faulty. |

| Lint accumulation | Clogged lint filter | Regularly clean the lint filter before each use. |

Replacing the Dryer Belt

When it comes to maintaining your appliance’s efficiency, one of the essential components to monitor is the belt. A worn or broken belt can lead to malfunction, making it crucial to address this issue promptly. This section will guide you through the process of replacing this vital part.

Before starting the replacement, gather the necessary tools:

- Screwdriver set

- Replacement belt

- Pliers

- Flashlight (optional)

Follow these steps to ensure a successful replacement:

- Unplug the appliance to ensure safety.

- Remove the outer casing to access the interior components.

- Locate the worn belt and assess the mounting points.

- Carefully detach the old belt from the motor and pulleys.

- Install the new belt by threading it through the designated path.

- Reassemble the outer casing and secure all screws.

- Plug the unit back in and conduct a test to ensure proper operation.

By following these instructions, you can restore your appliance’s functionality and enhance its lifespan.

Cleaning the Lint Filter Properly

Maintaining optimal performance in your appliance involves regular attention to specific components. One crucial task is ensuring that the lint filter is clean. A properly maintained filter not only enhances efficiency but also extends the lifespan of the unit.

Why Cleaning Is Essential

Removing lint build-up is vital for several reasons:

- Prevents overheating, reducing the risk of fire hazards.

- Improves airflow, allowing for better drying efficiency.

- Minimizes wear and tear on the machine, promoting longevity.

Steps to Clean the Filter

Follow these simple steps to effectively clean the lint filter:

- Locate the lint filter, usually found near the door or at the top of the appliance.

- Remove the filter by pulling it out gently.

- Use your hands to remove any lint accumulation. For stubborn particles, a soft brush can be helpful.

- Rinse the filter under warm water to eliminate any remaining debris.

- Allow the filter to dry completely before reinserting it into the unit.

By following these guidelines, you can ensure that your appliance operates smoothly and efficiently for years to come.

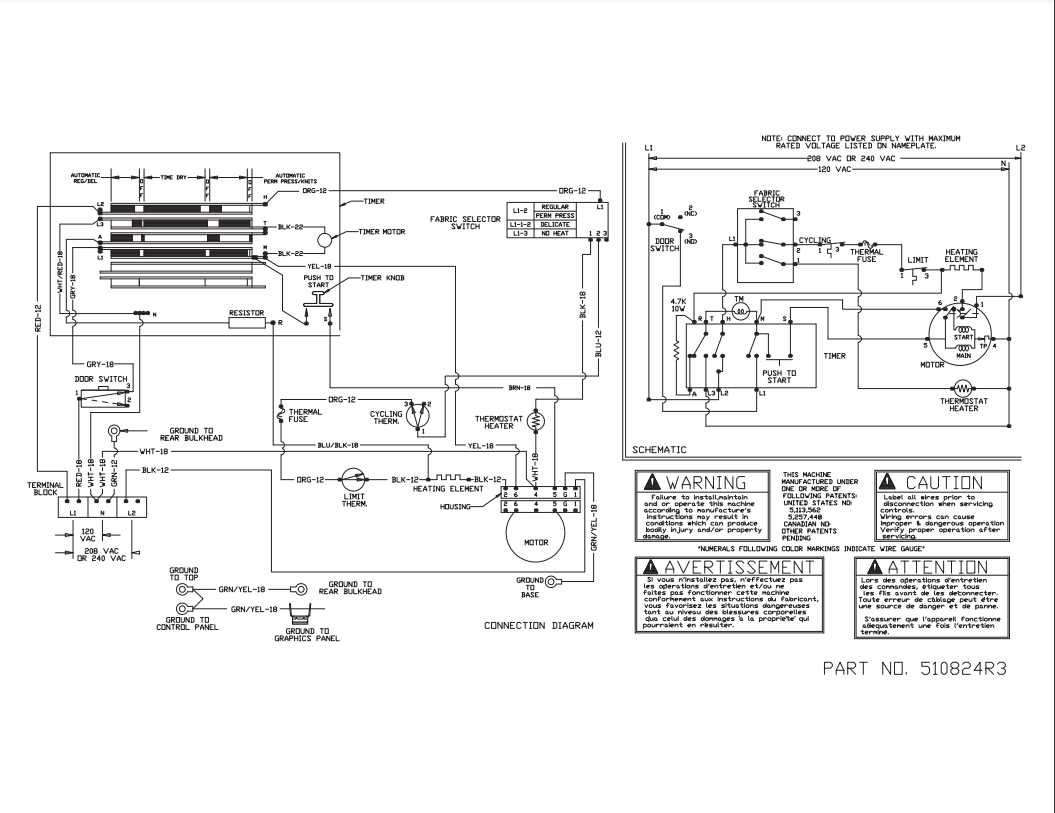

Addressing Heating Problems

When encountering issues with inadequate warmth during the drying process, it’s crucial to identify potential causes and solutions. Efficient operation relies on several key components functioning correctly, and addressing these factors can restore optimal performance.

- Check Power Supply: Ensure that the unit is properly connected to a power source and that the circuit breaker has not tripped.

- Examine Heating Elements: Inspect the heating elements for signs of damage or wear. Replacing faulty elements can often resolve warmth-related issues.

- Inspect Thermostats: Verify that the thermostats are functioning correctly. A malfunctioning thermostat can disrupt the heating cycle.

- Clean Ventilation: Clogged vents can restrict airflow, leading to insufficient heat. Regularly clean lint traps and ducts to maintain optimal airflow.

- Review Controls: Ensure that the settings are appropriate for the load type. Incorrect settings can impact the heating process.

By systematically addressing these areas, users can troubleshoot and resolve heating deficiencies effectively, ensuring reliable operation.

Electrical Components and Safety

This section delves into the crucial aspects of electrical systems within the appliance, emphasizing the importance of proper handling and safety measures. Understanding these elements ensures efficient operation and minimizes the risk of hazards during use and maintenance.

Key Electrical Elements

The primary electrical components include circuit boards, power supplies, and wiring systems that enable the unit to function effectively. Familiarity with these parts is essential for identifying potential issues and ensuring a seamless operational flow.

Safety Precautions

Adhering to safety protocols is paramount when working with electrical appliances. Always disconnect the power supply before performing any maintenance tasks. Additionally, using insulated tools and wearing protective gear can significantly reduce the risk of electrical shock or accidents.

When to Call a Professional

Knowing when to seek expert assistance can save time and prevent further issues. Certain situations may exceed your knowledge or capabilities, making professional help essential.

Unusual Sounds or Odors: If you notice strange noises or unpleasant smells during operation, it’s a sign that something may be wrong. These symptoms often indicate underlying problems that require specialized attention.

Persistent Issues: When a malfunction recurs despite your attempts to fix it, it may be time to consult a technician. Continuous problems often suggest deeper mechanical or electrical failures that necessitate professional intervention.

Safety Concerns: If you encounter any safety hazards, such as electrical issues or gas leaks, don’t hesitate to contact a qualified expert. Your safety should always be the top priority.

Maintaining Your Dryer for Longevity

Regular upkeep is essential for extending the lifespan of your appliance and ensuring optimal performance. By implementing simple practices, you can prevent potential issues and enhance efficiency, leading to better results and savings over time.

Routine Cleaning

Consistently clearing lint and debris from filters and vents is crucial. This not only improves air circulation but also reduces the risk of overheating, which can lead to malfunctions. Make it a habit to inspect and clean these areas frequently.

Periodic Checks

Conducting inspections of electrical connections and seals can help identify wear and tear early on. Addressing minor concerns promptly can prevent them from escalating into significant problems, ensuring your unit remains in top condition.

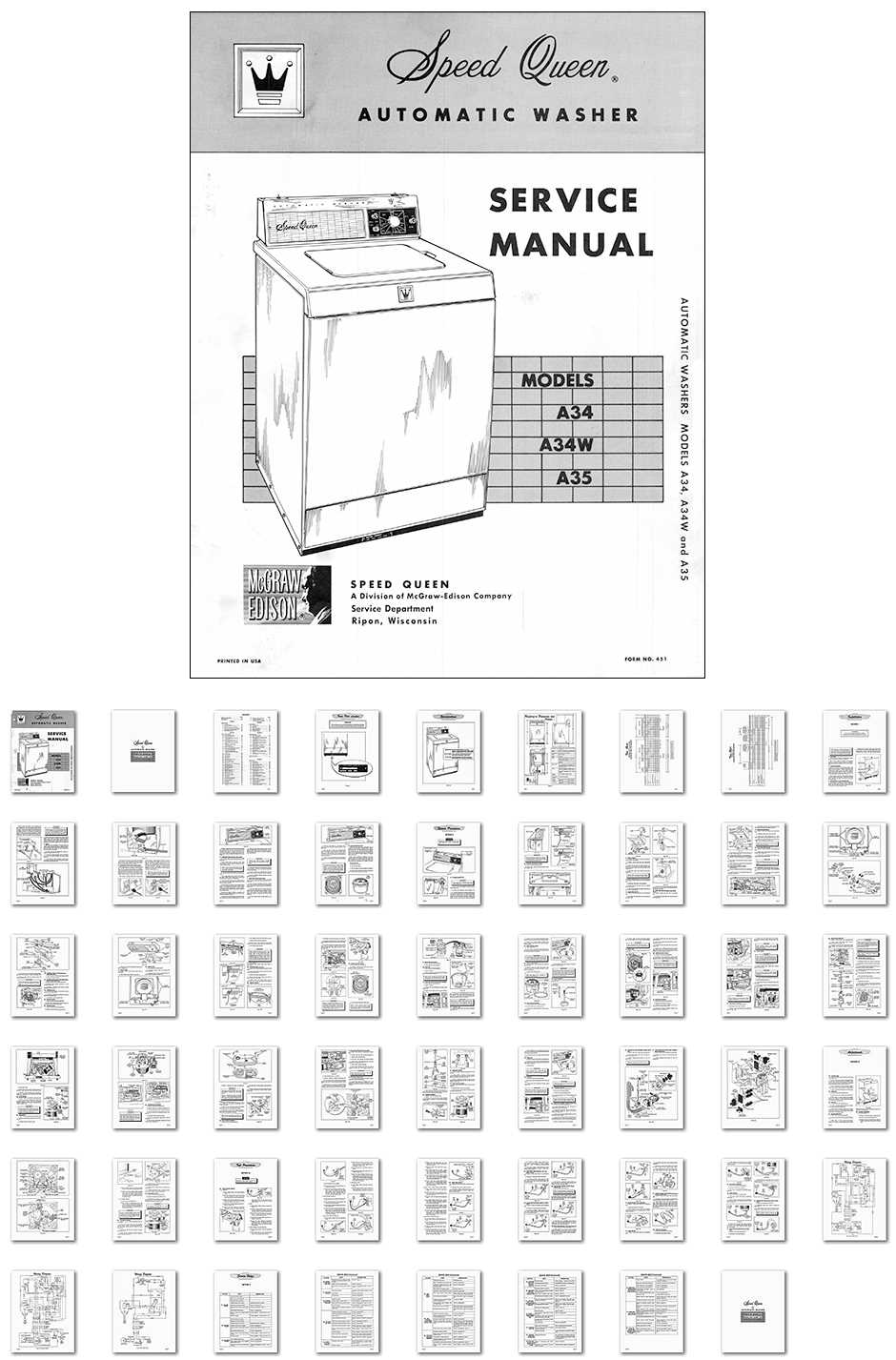

Accessing the Service Manual

Obtaining the service documentation is essential for effectively addressing issues and maintaining optimal performance of your appliance. This guide will provide you with the necessary steps to locate and utilize the information you need.

To start, it is important to identify the specific model of your unit. This ensures that you retrieve the correct documentation tailored to your equipment. Look for a label or plate, typically located on the door or rear panel, which contains the model number.

Once you have this information, you can explore various resources. Many manufacturers provide digital copies of their service documentation on their official websites. By visiting the support or downloads section, you can search for your model and access the relevant files.

In addition to online resources, consider reaching out to authorized service centers or technicians. They can provide guidance and may offer physical copies of the documentation. This can be particularly helpful for complex issues requiring professional expertise.

Lastly, always keep your service documentation in a safe and accessible location for future reference. This practice will streamline any troubleshooting or maintenance efforts, ensuring your unit remains in excellent condition.

Understanding Warranty Information

Having a clear grasp of warranty details is crucial for ensuring long-term satisfaction with your appliance. Warranties provide essential coverage that can protect your investment against unexpected issues, offering peace of mind for users. This section will explore key aspects of warranty agreements, including duration, coverage, and the process for filing claims.

| Warranty Type | Coverage Duration | What It Covers | Claim Process |

|---|---|---|---|

| Standard Warranty | 1 Year | Defects in materials and workmanship | Contact customer service with proof of purchase |

| Extended Warranty | 2-5 Years | Additional parts and labor | Registration required; follow guidelines provided |

| Limited Warranty | Varies | Specific components only | Check terms for details; contact authorized service centers |