Proper upkeep of your lawn equipment is essential for ensuring optimal performance and longevity. Understanding the various components and their functions can help you effectively address common issues that arise during use. By following comprehensive guidelines, you can maintain your equipment in peak condition, allowing for efficient operation throughout the seasons.

In this section, we will explore detailed instructions and insights that will empower you to tackle maintenance tasks with confidence. From troubleshooting typical challenges to performing essential servicing, this guide will serve as a valuable resource for anyone looking to enhance their skills in lawn care. Whether you’re a seasoned user or new to outdoor machinery, you’ll find practical tips and expert advice tailored to your needs.

This section addresses frequent problems encountered with lawn care equipment and offers practical solutions to enhance performance and reliability.

- Engine Won’t Start:

- Check the fuel level and ensure it is fresh.

- Inspect the battery for charge and connection.

- Examine the ignition switch and fuses for functionality.

- Uneven Cutting:

- Ensure the blades are sharp and not damaged.

- Check the tire pressure and adjust if necessary.

- Level the cutting deck according to the manufacturer’s specifications.

- Excessive Vibration:

- Inspect the blade for any obstructions or damage.

- Ensure all bolts and screws are tight.

- Check the engine mountings for wear or damage.

- Overheating:

- Clean the air filter and cooling fins.

- Check the oil level and quality; change if necessary.

- Inspect the fuel system for clogs or restrictions.

By following these troubleshooting tips, users can maintain their equipment in optimal condition and address common challenges effectively.

Essential Tools for Repairs

Having the right instruments is crucial for maintaining and fixing outdoor machinery effectively. A well-equipped toolkit can make the difference between a smooth process and a frustrating experience.

Below is a list of fundamental items that should be included in your toolkit:

- Wrenches: Adjustable and socket wrenches are essential for loosening and tightening various fasteners.

- Screwdrivers: A set of both flathead and Phillips screwdrivers in different sizes will help address a range of screws.

- Plier Set: Needle-nose and slip-joint pliers are useful for gripping and bending wires or components.

- Torque Wrench: Ensures that nuts and bolts are tightened to the correct specifications, preventing damage.

- Cutting Tools: Wire cutters and utility knives are necessary for trimming wires and cutting through various materials.

By assembling these essential tools, you’ll be well-prepared to tackle any challenges that arise during maintenance tasks.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to maintaining your equipment, ensuring it operates efficiently and lasts longer. Regular upkeep is essential for optimal performance and to prevent potential issues down the line.

Essential Tasks for Optimal Functionality

Performing routine tasks is crucial for keeping your device in top condition. Here are the primary activities to include in your maintenance routine:

| Task | Frequency | Description |

|---|---|---|

| Check Oil Level | Monthly | Ensure oil is at the correct level and change it if it appears dirty. |

| Inspect Blades | Every Use | Check for dullness or damage; sharpen or replace as necessary. |

| Clean Air Filter | Every Season | Remove dust and debris to ensure proper airflow. |

| Examine Tires | Monthly | Check tire pressure and tread for wear; inflate or replace as needed. |

Additional Tips for Longevity

Incorporating a few additional practices can significantly enhance the lifespan of your equipment. Always store it in a dry place and cover it when not in use. Regularly check for loose screws or parts to ensure everything remains secure.

Replacing Blades Effectively

Maintaining optimal performance of your equipment requires regular attention to the cutting components. Changing these elements ensures efficient operation and enhances the overall quality of your work. Proper replacement techniques not only extend the life of the blades but also contribute to achieving the best results in your tasks.

Begin by gathering the necessary tools, including wrenches and safety gear. It’s crucial to disconnect the power source to prevent accidental starts during the process. Once secured, locate the bolts that hold the blades in place and carefully remove them. Take note of the orientation of the blades for correct reinstallation.

When installing new cutting components, ensure they are aligned correctly and tightened securely. After the replacement, double-check all connections to avoid any loose parts during operation. Regular inspections of these components will help maintain performance and reduce the risk of unexpected issues.

Engine Care and Optimization

Maintaining optimal performance of a motor involves a series of essential practices. Regular attention to various components ensures longevity and efficiency, contributing to a smooth operation.

One key aspect is regular oil changes. Fresh oil minimizes friction, enhances lubrication, and supports overall functionality. Additionally, air filters should be checked frequently to ensure clean airflow, which is vital for combustion efficiency.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 50 hours of operation | Reduces friction, improves performance |

| Air Filter Inspection | Every 25 hours of operation | Ensures proper airflow, boosts efficiency |

| Spark Plug Check | Every 100 hours of operation | Enhances ignition, promotes smoother starts |

Furthermore, checking fuel quality and ensuring the correct type is used is crucial. Contaminated fuel can lead to poor performance and damage over time. Keeping the fuel system clean and free of debris will enhance reliability and reduce maintenance issues.

Battery Maintenance Procedures

Proper upkeep of the power source is essential for optimal performance and longevity. Regular checks and maintenance can prevent unexpected failures and extend the lifespan of the unit.

The following procedures outline effective practices for maintaining your energy storage system:

| Procedure | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Examine the battery for any signs of corrosion, leakage, or physical damage. |

| Cleaning Terminals | As Needed | Clean the terminals with a mixture of baking soda and water to remove any corrosion. |

| Fluid Levels Check | Monthly | Ensure electrolyte levels are adequate, topping up with distilled water if necessary. |

| Battery Charge | As Needed | Charge the battery according to the manufacturer’s specifications to maintain optimal performance. |

Following these maintenance guidelines will help ensure reliable operation and minimize the risk of failure during use.

Checking and Adjusting Tire Pressure

Maintaining optimal tire pressure is essential for ensuring the longevity and performance of your equipment. Properly inflated tires contribute to better traction, fuel efficiency, and overall stability while in use. Regular checks can prevent uneven wear and enhance safety during operation.

Importance of Correct Pressure

Adhering to the recommended pressure levels plays a critical role in how your vehicle handles various terrains. Under-inflation can lead to poor maneuverability and increased tire wear, while over-inflation might cause a harsh ride and reduced traction.

Steps to Check and Adjust

To maintain ideal pressure, follow these straightforward steps:

| Step | Action |

|---|---|

| 1 | Use a reliable tire pressure gauge to measure the current pressure. |

| 2 | Compare the reading with the manufacturer’s specifications, usually found on a label or in the owner’s guide. |

| 3 | If necessary, inflate the tires to the recommended level using an air compressor. |

| 4 | Re-check the pressure to ensure accuracy after inflation. |

Regularly checking and adjusting tire pressure not only extends the life of your tires but also enhances overall performance, making it a crucial aspect of maintenance.

Fuel System Troubleshooting

Addressing issues within the fuel system is crucial for ensuring optimal performance and reliability of your equipment. Various factors can contribute to malfunctions, and identifying them early can save time and resources.

Common Symptoms

- Difficulty starting the engine

- Unusual engine noises

- Poor acceleration or stalling

- Decreased fuel efficiency

Troubleshooting Steps

- Check the fuel level in the tank.

- Inspect the fuel lines for cracks or leaks.

- Examine the fuel filter and replace it if clogged.

- Ensure the fuel is clean and free from contaminants.

- Test the fuel pump for proper operation.

By systematically evaluating these components, you can identify and resolve issues within the fuel system, enhancing overall functionality.

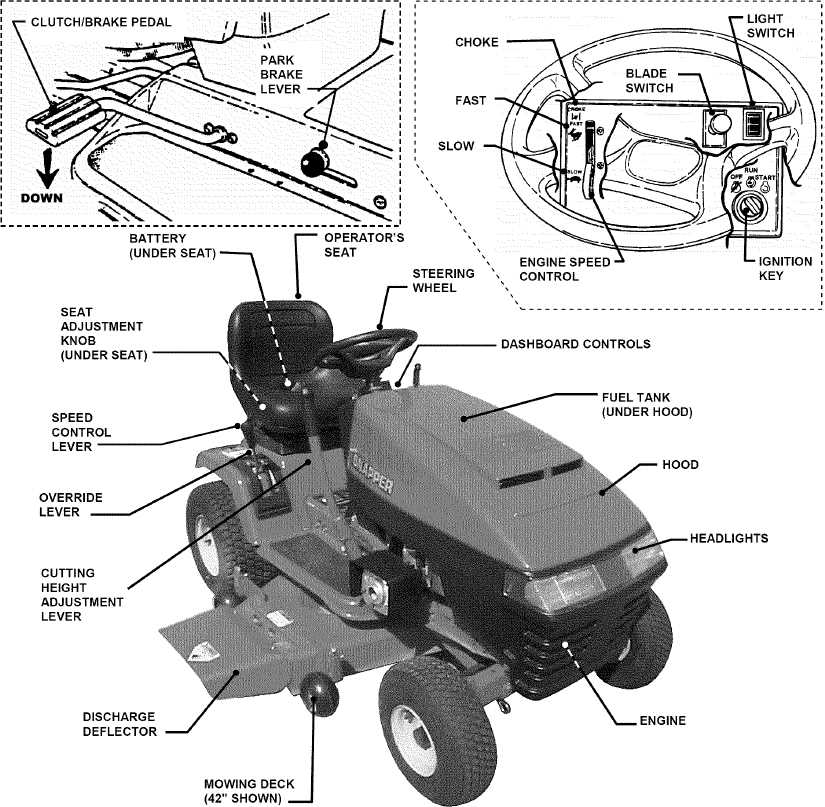

Electrical Components Overview

This section provides a comprehensive understanding of the various electrical parts essential for efficient operation. These components play a crucial role in the functionality and performance of the equipment.

Key electrical elements include:

- Battery: Stores energy for starting the engine and powering electrical systems.

- Ignition System: Initiates the combustion process, ensuring the engine runs smoothly.

- Wiring Harness: Connects different electrical parts, allowing communication and power distribution.

- Switches: Control various functions, including starting the engine and activating lights.

- Fuses: Protect the electrical system from overloads and prevent damage to components.

Understanding these elements is vital for troubleshooting and maintaining optimal performance. Each part contributes to the overall efficiency and reliability of the machinery.

Winterizing Your Riding Mower

Preparing your machine for the colder months is essential for maintaining its performance and longevity. Properly protecting your equipment can prevent damage caused by frost, moisture, and inactivity during winter. This process involves several key steps to ensure that all components are safeguarded and ready for use when the warm weather returns.

Start by cleaning the exterior thoroughly to remove dirt, grass clippings, and debris. A clean surface prevents rust and corrosion. Afterward, change the oil to remove impurities that could cause engine wear over time. Replacing the oil filter is also recommended to ensure optimal performance.

Next, inspect and maintain the battery. Disconnect it and store it in a cool, dry place to avoid freezing. Consider using a battery maintainer to keep it charged during the off-season. Additionally, check the tires for proper inflation and condition, as flat spots can develop when they remain stationary for extended periods.

Lastly, fill the fuel tank and add a fuel stabilizer to prevent the gasoline from deteriorating. Run the engine for a few minutes to circulate the mixture. This precaution helps avoid starting issues in the spring. Following these steps will help ensure that your equipment remains in top shape, ready to tackle the tasks ahead when the season changes.