Maintaining and troubleshooting your sewing equipment can greatly enhance your crafting experience. Understanding the intricacies of your device not only ensures its longevity but also empowers you to tackle minor issues without professional assistance. This section aims to provide essential insights into common problems, maintenance tips, and practical solutions.

Regular care and attention to your sewing tool can prevent frustrating interruptions during projects. Whether you’re an experienced seamstress or a novice enthusiast, knowing how to address typical complications will enhance your skills and confidence. Through this guide, you will discover helpful advice that promotes optimal functionality and performance.

Equipped with the right knowledge, you can easily navigate through the various components and functions of your machine. Familiarity with its operation will allow you to maximize your creativity and efficiency. Join us as we delve into the specifics that will make your sewing journey smoother and more enjoyable.

Overview and Features

This versatile sewing machine is designed to meet the needs of both beginners and experienced crafters. It combines user-friendly functionality with advanced features, making it an ideal choice for a wide range of sewing projects. From simple alterations to complex creations, this device is built to deliver quality results.

Key Features:

Multiple Stitch Options: With a variety of built-in stitch patterns, this model allows users to choose the perfect stitch for any task, whether it’s straight stitching, zigzag, or decorative designs.

Automatic Needle Threader: A time-saving feature that simplifies the threading process, making it easy to get started on your projects quickly.

Adjustable Stitch Length and Width: Customization options enable you to tailor each stitch to your specific needs, enhancing creativity and precision.

Robust Build Quality: Designed for durability, this machine can handle heavy fabrics and frequent use without compromising performance.

Lightweight and Portable: Easy to transport, this model is perfect for sewing classes, crafting events, or simply moving from room to room.

Overall, this sewing machine is a reliable companion for anyone looking to enhance their sewing experience, offering both simplicity and versatility in a compact design.

Common Issues with Singer 4432

This section addresses frequent challenges users encounter with this particular sewing machine model. Understanding these common problems can help in identifying and resolving issues efficiently, ensuring a smoother sewing experience.

Mechanical Problems

- Thread Jamming: Often caused by incorrect threading or a tangled thread in the bobbin area.

- Needle Breakage: Can occur due to using the wrong type of needle or hitting hard surfaces while sewing.

- Uneven Stitching: May result from improper tension settings or issues with the feed dogs.

Electrical Issues

- Power Supply Failures: This can be attributed to damaged cords or faulty connections.

- Motor Overheating: Typically caused by prolonged use without breaks or dust accumulation.

- Control Malfunctions: Issues with settings or buttons not responding as intended can disrupt operation.

Step-by-Step Repair Guide

This section aims to provide a comprehensive approach to troubleshooting and restoring your machine to optimal working condition. Following a structured method will ensure you address any issues effectively and efficiently.

-

Identify the Problem: Start by observing any irregularities during operation. Common issues might include:

- Thread not catching

- Unusual noises

- Inconsistent stitching

- Machine not powering on

-

Gather Necessary Tools: Ensure you have the right tools at hand, such as:

- Screwdrivers (flathead and Phillips)

- Replacement parts (needles, bobbins)

- Cleaning supplies (brush, oil)

- Multimeter for electrical checks

-

Disassemble the Unit: Carefully take apart the components to access internal mechanisms. Follow these steps:

- Unplug the device before starting

- Remove any covers or panels

- Keep track of screws and small parts

-

Inspect Internal Parts: Look for any signs of wear or damage, including:

- Worn belts or gears

- Clogged thread paths

- Electrical connections

-

Perform Necessary Maintenance: Based on your inspection, carry out these actions:

- Clean dust and debris from moving parts

- Replace damaged components

- Lubricate moving parts as needed

-

Reassemble the Machine: Carefully put all parts back together, ensuring everything fits properly. Pay attention to:

- Reconnecting wires and electrical components

- Securing covers and panels

- Properly aligning moving parts

-

Test Functionality: After reassembly, plug in the machine and conduct a test run to ensure everything operates smoothly. Check for:

- Consistent stitching

- Quiet operation

- Responsive controls

By following this detailed guide, you can effectively troubleshoot and maintain your sewing apparatus, ensuring it continues to function efficiently for years to come.

Essential Tools for Repairs

Having the right equipment is crucial for effectively addressing issues that may arise in your machine. This section will highlight the fundamental instruments that can make the process smoother and more efficient.

- Screwdriver Set: A variety of screwdrivers will help you tackle different fasteners.

- Pliers: Essential for gripping and bending wires or other materials.

- Wrench: Useful for loosening and tightening nuts and bolts.

- Seam Ripper: Perfect for removing stitches with precision.

- Lubricant: Keeps moving parts functioning optimally.

Having these essential tools at hand will enable you to handle most tasks with confidence and ease.

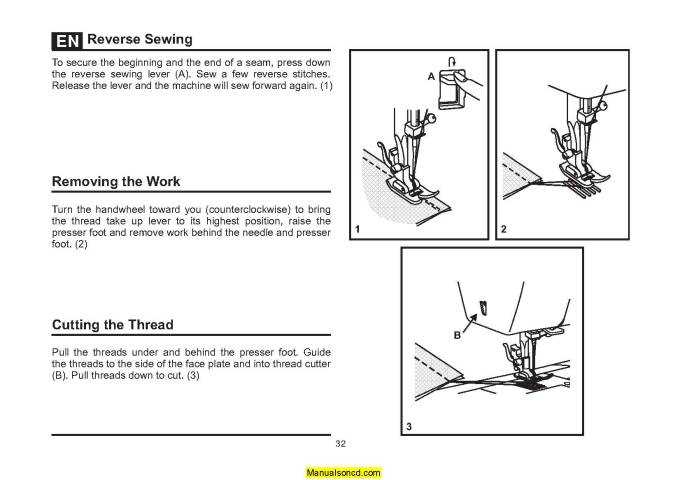

Threading the Singer 4432 Correctly

Properly setting up the thread is crucial for smooth operation and optimal stitching quality. Following the correct sequence ensures that the fabric feeds evenly and the stitches form as intended.

- Start by raising the needle to its highest position.

- Ensure the presser foot is lifted to allow for easy threading.

- Place the spool of thread on the spindle and secure it.

- Guide the thread through the tension discs, ensuring it sits properly.

- Run the thread through the take-up lever and down through the needle bar.

- Finally, thread the needle from front to back.

Double-check your threading to avoid common issues such as jams or skipped stitches.

Cleaning and Maintenance Tips

Keeping your sewing machine in optimal condition is essential for achieving the best results in your projects. Regular cleaning and maintenance not only enhance performance but also extend the life of the device. Here are some valuable tips to ensure your equipment remains in excellent working order.

- Dust Regularly: Make it a habit to wipe down the exterior and surrounding areas to prevent dust accumulation.

- Remove Lint: After each use, clear out lint and debris from the feed dogs and bobbin area using a soft brush or lint roller.

- Check the Needle: Inspect the needle for any signs of wear or damage, replacing it as needed to maintain stitching quality.

- Oil the Machine: Follow the manufacturer’s guidelines for oiling moving parts, ensuring smooth operation.

Additionally, consider these steps for deeper maintenance:

- Unplug Before Cleaning: Always disconnect the power before performing any cleaning tasks to ensure safety.

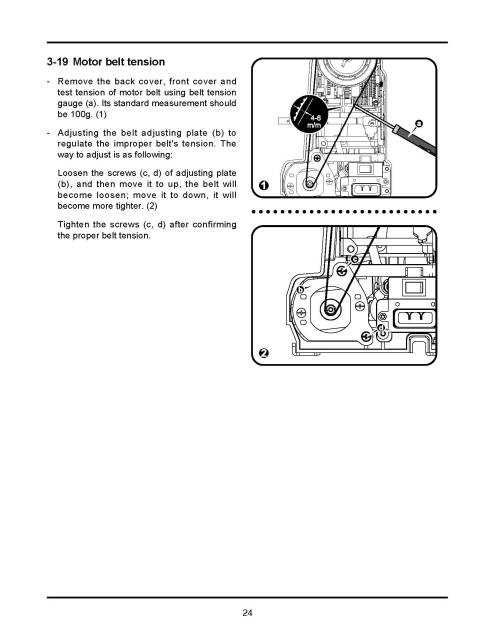

- Inspect the Belts: Check for any signs of wear on the belts, replacing them if they appear frayed or damaged.

- Service Annually: Schedule a professional servicing once a year to address any underlying issues and keep everything running smoothly.

By incorporating these practices into your routine, you can ensure that your sewing machine operates efficiently and remains reliable for all your creative endeavors.

Troubleshooting Stitch Problems

Addressing issues with stitching can enhance the quality of your sewing projects. Identifying the underlying causes of these problems is essential for achieving perfect results. Here, we will explore common stitch-related difficulties and provide guidance on how to resolve them effectively.

Common stitch issues may include uneven tension, skipped stitches, or thread bunching. Understanding the various factors that contribute to these problems will help in finding the right solutions. Below are some typical scenarios and their respective troubleshooting steps:

- Uneven Tension:

- Check the thread tension settings on your machine.

- Examine the thread path for any obstructions or misalignments.

- Ensure you are using the correct type of thread for your fabric.

- Skipped Stitches:

- Inspect the needle for damage or wear; replace if necessary.

- Ensure the needle is correctly inserted and suitable for the fabric type.

- Check for any lint or debris around the bobbin area that may impede function.

- Thread Bunching:

- Verify that the upper thread is properly threaded through the machine.

- Examine the bobbin for proper winding and installation.

- Ensure that the fabric is not being pulled or pushed excessively while sewing.

By following these troubleshooting steps, you can effectively address and rectify stitch problems, ensuring your sewing projects meet your expectations. Regular maintenance and careful observation will lead to improved performance and enjoyment in your crafting endeavors.

Replacing the Needle and Presser Foot

Maintaining the sewing machine’s performance involves periodic replacement of key components, such as the needle and presser foot. This process ensures optimal stitching quality and adaptability to different fabric types. Understanding how to properly change these parts is essential for achieving the best results in your projects.

Steps to Replace the Needle

- Turn off the machine and unplug it for safety.

- Raise the needle to its highest position using the handwheel.

- Loosen the needle clamp screw with a screwdriver.

- Remove the old needle by gently pulling it downwards.

- Take the new needle and insert it into the clamp with the flat side facing the back.

- Tighten the needle clamp screw securely.

Steps to Replace the Presser Foot

- Ensure the machine is turned off and unplugged.

- Lift the presser foot lever to release the current foot.

- Remove the existing presser foot by pushing the release button.

- Align the new presser foot with the attachment mechanism.

- Press down until you hear a click, securing the foot in place.

- Lower the presser foot lever to check the attachment.

Following these guidelines will help maintain the efficiency of your sewing tasks. Regular checks and replacements will prolong the life of your machine and enhance your crafting experience.

Adjusting Tension Settings

Properly calibrating the tension of your sewing machine is essential for achieving optimal stitch quality. Tension influences how the thread interacts with the fabric, affecting both the appearance and durability of your seams. An incorrect setting can lead to a variety of issues, including uneven stitches and puckering.

To adjust the tension, first, consult your device’s specific guide for the recommended settings based on the type of thread and fabric being used. Begin by testing on a scrap piece of the same material. Observe the stitch formation closely; the upper and lower threads should meet seamlessly at the fabric’s center. If you notice loops on one side, it’s a clear indication that adjustments are necessary.

To increase tension, turn the tension dial clockwise; to decrease it, turn counterclockwise. Make small adjustments, typically in increments of one or two numbers, and test again. Remember, achieving the right balance may require several trials, especially when switching between different materials or thread types.

Maintaining correct tension is vital not only for the quality of your work but also for the longevity of your machine. Regular checks and adjustments will help ensure smooth operation and beautiful results in every project.

Where to Find Replacement Parts

Finding the right components for your sewing machine can significantly enhance its performance and longevity. Whether you’re looking for basic supplies or specific pieces, knowing where to search can save you time and effort.

Start by checking local fabric and craft stores, as they often carry a selection of essential parts and accessories. These shops can provide immediate availability and personal assistance to help you find what you need.

Online marketplaces are another excellent resource. Websites dedicated to sewing supplies typically offer a vast array of components, often at competitive prices. Be sure to read reviews and confirm the seller’s credibility before making a purchase.

Additionally, consider exploring specialized retailers that focus exclusively on sewing equipment. These stores may have an extensive inventory, including hard-to-find items and high-quality options.

If you’re looking for second-hand or discontinued parts, online auction sites or classified ads can be valuable. Many enthusiasts sell their surplus or unused items, and you might discover just what you need.

Lastly, manufacturer websites can be a great source for original components. They often provide detailed catalogs and direct purchasing options, ensuring that you receive parts that meet the specifications of your machine.