The cold months can bring challenges that require reliable machinery to keep your property safe and accessible. Understanding the mechanics of these machines is essential for efficient operation and longevity. This section aims to provide comprehensive insights into troubleshooting and enhancing the performance of your winter apparatus.

In this guide, we will delve into various aspects of functionality, focusing on common issues and their solutions. Whether you are experiencing difficulties with performance or simply wish to optimize your equipment’s efficiency, the information presented here will empower you to take effective action. By becoming familiar with essential techniques and maintenance practices, you can ensure your machinery remains dependable throughout the season.

Equipped with practical knowledge, users will find it easier to tackle repairs and understand the inner workings of their equipment. With clear instructions and valuable tips, this guide serves as a resource for anyone looking to maximize the utility of their winter tools.

This section addresses typical challenges encountered with outdoor clearing equipment. Understanding these common problems can significantly aid in the maintenance and troubleshooting of your unit, ensuring it operates efficiently throughout the winter season.

Below are some prevalent issues and their potential causes:

- Starting Difficulties:

- Faulty spark plug

- Clogged fuel line

- Insufficient fuel or stale gasoline

- Reduced Performance:

- Worn or damaged blades

- Improperly adjusted throttle

- Blocked intake or exhaust

- Unusual Noises:

- Loose components

- Debris caught in the machinery

- Worn bearings or belts

- Difficulty in Maneuverability:

- Flat or damaged tires

- Improper tire pressure

- Worn control cables

Identifying these issues early can help prevent more severe problems and extend the life of your equipment. Regular maintenance and prompt attention to any signs of trouble are essential for optimal performance.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. Proper tools not only facilitate the process but also enhance safety and efficiency. Understanding which instruments are necessary can make the task much easier and more manageable.

Basic Hand Tools

Common hand tools such as wrenches, screwdrivers, and pliers are fundamental for any maintenance task. A well-stocked toolkit should include a variety of sizes to accommodate different fasteners and components. These tools provide the leverage and precision needed to disassemble and assemble parts efficiently.

Specialized Equipment

In addition to basic tools, certain specialized equipment may be required. This can include items like torque wrenches for precise fastening and diagnostic tools to identify issues. Investing in quality specialized tools ensures that maintenance tasks are completed accurately and prolongs the lifespan of the machinery.

Understanding Snowblower Components

When tackling the task of maintaining or fixing outdoor winter equipment, it’s essential to familiarize oneself with the various parts that contribute to its efficient operation. Each element plays a crucial role in ensuring smooth functionality, and recognizing their importance can greatly enhance troubleshooting and repair efforts.

Main Parts Overview

- Engine: The powerhouse that drives the entire system, converting fuel into mechanical energy.

- Auger: This component is responsible for gathering and moving snow toward the chute.

- Chassis: The framework that houses all other elements and provides stability during operation.

- Skids: These adjustable parts help control the height at which the equipment operates above the ground.

- Controls: The levers and buttons that allow the user to operate the machinery effectively.

Common Issues

- Engine failure, often caused by fuel problems or lack of maintenance.

- Auger jams, which can occur from debris or ice buildup.

- Chassis wear, leading to instability during operation.

- Control malfunction, which may result from electrical issues or worn components.

By understanding these components and their functions, users can approach maintenance tasks with confidence and ensure reliable performance during the winter months.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your outdoor equipment in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of the machine. Follow these systematic instructions to ensure that every aspect is addressed efficiently.

Preparation and Safety

Before commencing any tasks, it is crucial to gather the necessary tools and materials. Ensure that the work area is clear and free of obstacles. Always prioritize safety by wearing appropriate protective gear, such as gloves and goggles. Disconnect the power source to avoid accidental starts during maintenance.

Routine Checks

Start by inspecting the components for wear and tear. Check belts, cables, and blades for any signs of damage. Lubrication is essential for moving parts; apply the recommended grease to bearings and pivot points. Additionally, examine fluid levels and replace any filters as needed. Regular checks help identify issues before they become major problems.

Following these steps will ensure that your equipment remains reliable and efficient throughout its use.

Troubleshooting Engine Problems

Engine issues can arise unexpectedly, affecting the overall functionality of your equipment. Identifying the root cause of these problems is essential for effective resolution. This section provides a systematic approach to diagnosing common engine troubles.

Here are some typical symptoms to watch for:

- Difficulty starting

- Unusual noises during operation

- Excessive smoke emissions

- Poor performance or power loss

To address these issues, consider the following steps:

- Inspect Fuel Supply: Ensure that there is sufficient fuel in the tank and that the fuel is fresh. Stale or contaminated fuel can lead to starting problems.

- Check the Spark Plug: Remove and examine the spark plug for wear or carbon buildup. Clean or replace it as necessary.

- Examine Air Filter: A clogged air filter can restrict airflow, leading to inefficient combustion. Clean or replace the filter if it appears dirty.

- Test Battery and Connections: Ensure that the battery is fully charged and connections are tight. Weak electrical supply can hinder starting.

- Inspect for Leaks: Look for fuel or oil leaks that may indicate a malfunctioning component.

By following these diagnostic steps, you can effectively troubleshoot engine problems and restore functionality to your equipment.

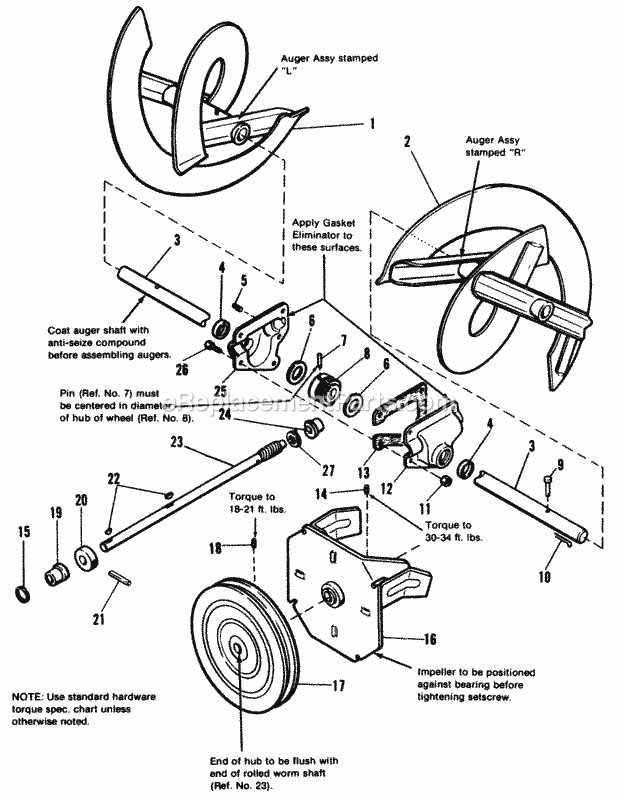

Fixing Auger and Chassis Issues

Addressing complications with the cutting mechanism and structural framework of your equipment is essential for optimal performance. Identifying and rectifying these issues can enhance efficiency and extend the lifespan of your machine. This section outlines common problems and solutions to help maintain peak operation.

Common Auger Problems

The cutting assembly can experience several challenges, including blockages, wear, and misalignment. Regular inspections can help detect these issues early.

| Issue | Symptoms | Solution |

|---|---|---|

| Blockage | Reduced cutting efficiency | Clear debris from the assembly |

| Wear | Noisy operation | Replace worn components |

| Misalignment | Uneven cutting | Adjust mounting bolts |

Chassis Maintenance Tips

The structural integrity of the frame is crucial for stable operation. Common issues may arise from rust or loose parts, leading to reduced performance.

| Issue | Symptoms | Solution |

|---|---|---|

| Rust | Visible corrosion | Sand down affected areas and repaint |

| Loose components | Vibration during use | Tighten bolts and screws |

Adjusting the Drive System

Properly calibrating the propulsion mechanism is crucial for optimal performance. This section will guide you through the essential steps to ensure smooth operation and responsiveness.

- Begin by inspecting the drive belts for wear and proper tension.

- Adjust the belt tension using the designated tensioner mechanism.

- Check the engagement of the drive components to ensure they operate smoothly without obstruction.

- Verify that all connections are secure and free of debris.

After adjustments, conduct a test run to assess functionality. If issues persist, further inspection of the drive components may be necessary.

Replacing Belts and Cables

Maintaining optimal performance of your outdoor equipment often involves the periodic replacement of essential components such as drive belts and control cables. These parts can wear out over time due to regular use and exposure to the elements, impacting the efficiency of the machinery. Understanding how to properly replace these elements can ensure smooth operation and extend the lifespan of your equipment.

Identifying Worn Components

Before initiating the replacement process, it is crucial to inspect the belts and cables for signs of wear or damage. Look for fraying, cracking, or any signs of looseness in belts, and check cables for fraying or stiffness. Identifying these issues early can prevent further complications and ensure safe operation.

Replacement Process

To begin the replacement, disconnect the power source to ensure safety. Remove any protective covers as necessary to access the belts and cables. Carefully detach the worn components, taking note of their arrangement for reinstallation. When installing new parts, ensure they are properly aligned and tensioned according to the manufacturer’s specifications. Reattach any covers and restore power to complete the process.

Cleaning and Storing Your Equipment

Proper maintenance of your machinery is essential to ensure its longevity and optimal performance. By taking the time to clean and store your equipment correctly, you can prevent damage and enhance its efficiency for future use.

Cleaning Procedures

Before storing your machine, it’s important to clean it thoroughly. Follow these steps for effective cleaning:

- Remove any debris or dirt from the exterior and undercarriage.

- Check and clean the air filter to ensure proper airflow.

- Inspect and clear the fuel system to avoid clogging.

- Wipe down all surfaces with a suitable cleaner to prevent rust.

Storage Tips

Storing your equipment properly will help maintain its condition. Consider the following tips:

- Find a dry, cool place that is protected from the elements.

- Use a cover to shield the machinery from dust and moisture.

- Ensure that fuel is stabilized or drained to prevent degradation.

- Check for any leaks or issues before the next season starts.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance on machinery is essential for both personal safety and effective functioning of the equipment. Adhering to specific guidelines minimizes the risk of accidents and enhances the repair process.

Before beginning any tasks, it’s crucial to prepare adequately. This involves gathering the necessary tools and protective gear, as well as understanding the specific features of the machinery involved.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, safety glasses, and appropriate clothing to shield against injuries from sharp objects or debris. |

| Disconnect Power Source | Before starting any work, ensure that the machine is completely disconnected from its power supply to prevent accidental activation. |

| Work in a Well-Ventilated Area | Conduct maintenance in spaces with adequate airflow to avoid inhaling fumes or dust that could be harmful. |

| Keep Work Area Organized | Maintain a tidy workspace to reduce the likelihood of tripping hazards and misplaced tools. |

| Read Instructions Carefully | Familiarize yourself with the device’s guidelines to understand the components and assembly methods before starting. |

Following these precautions not only protects the individual but also ensures the longevity and performance of the machinery. Prioritizing safety will lead to a more efficient and worry-free maintenance experience.

How to Diagnose Electrical Failures

Identifying issues within electrical systems is crucial for maintaining optimal performance. Recognizing the symptoms and understanding the underlying principles can simplify the troubleshooting process. By following systematic approaches, you can effectively pinpoint and resolve malfunctions, ensuring reliable operation.

Understanding Common Symptoms

Begin by observing the device for common indicators of electrical issues. Unresponsive controls, inconsistent power supply, and strange noises often suggest underlying electrical problems. Pay attention to any fluctuations in operation or unexpected behavior, as these can provide valuable clues to the source of the malfunction.

Testing Components and Connections

Utilize basic diagnostic tools such as multimeters to evaluate the functionality of various components. Start by checking wiring integrity and connections, ensuring there are no loose or corroded terminals. Next, assess the performance of fuses, relays, and other critical parts to confirm they are operating correctly. Document your findings to track progress and pinpoint areas needing attention.

Upgrading Snowblower Performance

Enhancing the efficiency of your outdoor clearing equipment can significantly improve its functionality and ease of use. By implementing several modifications, you can optimize its operation for various winter conditions. This guide explores practical upgrades that can lead to a more effective and powerful experience.

Engine Enhancements

Boosting the power of the engine is a key factor in improving overall performance. Consider upgrading the carburetor or air intake system to allow for better airflow and fuel mixing. Additionally, using a higher quality fuel can result in increased combustion efficiency, which translates to more power and improved throttle response.

Auger and Chassis Modifications

Adjusting the auger design or material can enhance the ability to break through ice and dense snow. Look for high-strength options or innovative shapes that facilitate better snow movement. Furthermore, reinforcing the chassis can reduce vibrations and provide more stability, ensuring that the machine operates smoothly even under heavy loads.