In the world of household appliances, certain tools play a crucial role in maintaining cleanliness and efficiency. Understanding how to troubleshoot and enhance the functionality of these devices can save time and money, ensuring they perform optimally. This section aims to empower users with the knowledge needed to tackle common issues and extend the lifespan of their essential equipment.

Every user may encounter challenges, whether related to performance dips or unexpected malfunctions. By familiarizing yourself with the inner workings and typical problems of your cleaning apparatus, you can gain confidence in your ability to address these concerns. This guide will provide insights into diagnosing faults, implementing solutions, and maintaining the device for long-term use.

Equipped with practical tips and step-by-step instructions, this resource is designed for both novice and experienced users. A proactive approach to maintenance not only enhances efficiency but also ensures that your investment continues to serve you well. Let’s delve into the essential aspects of keeping your cleaning tool in top shape.

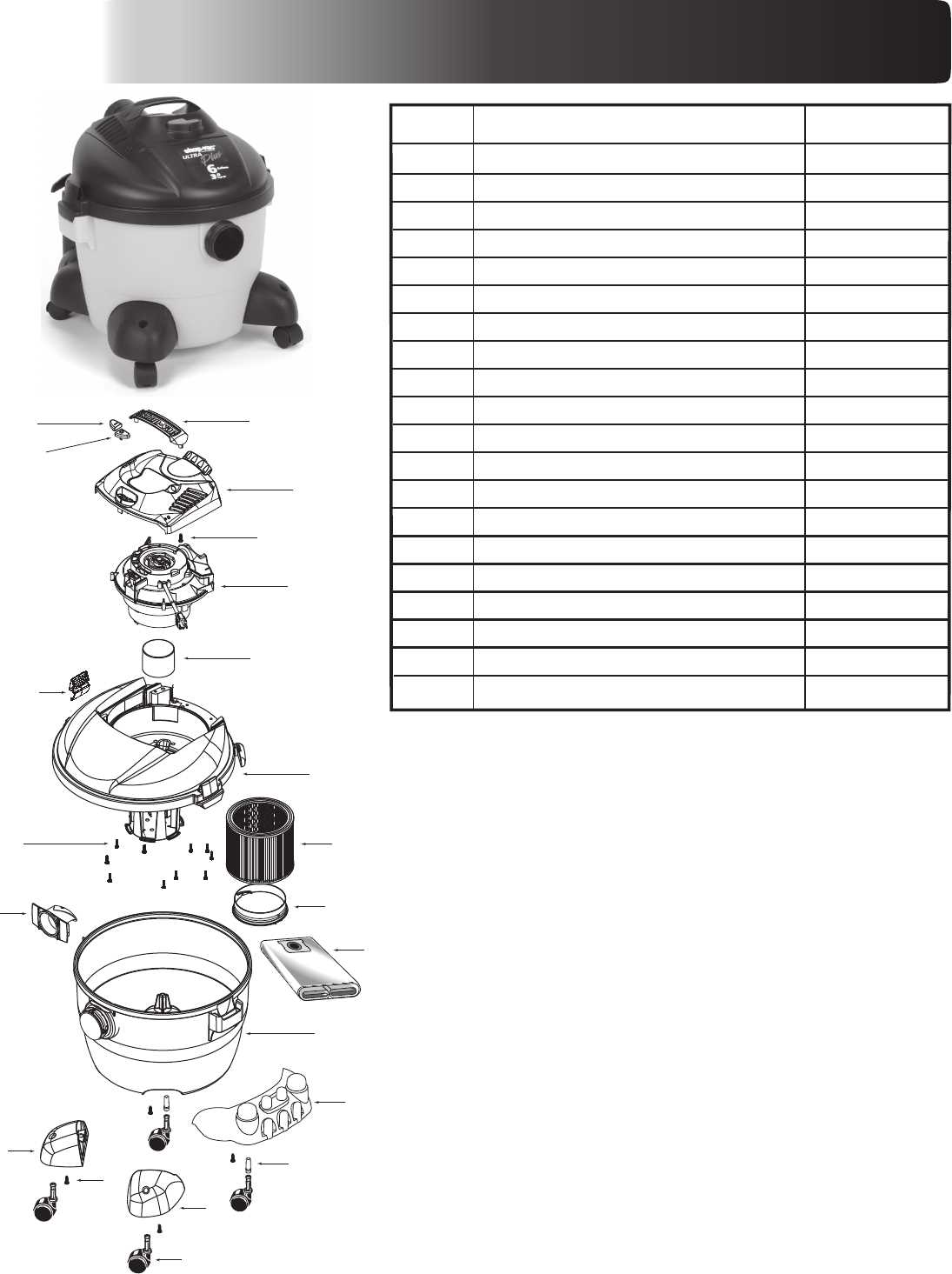

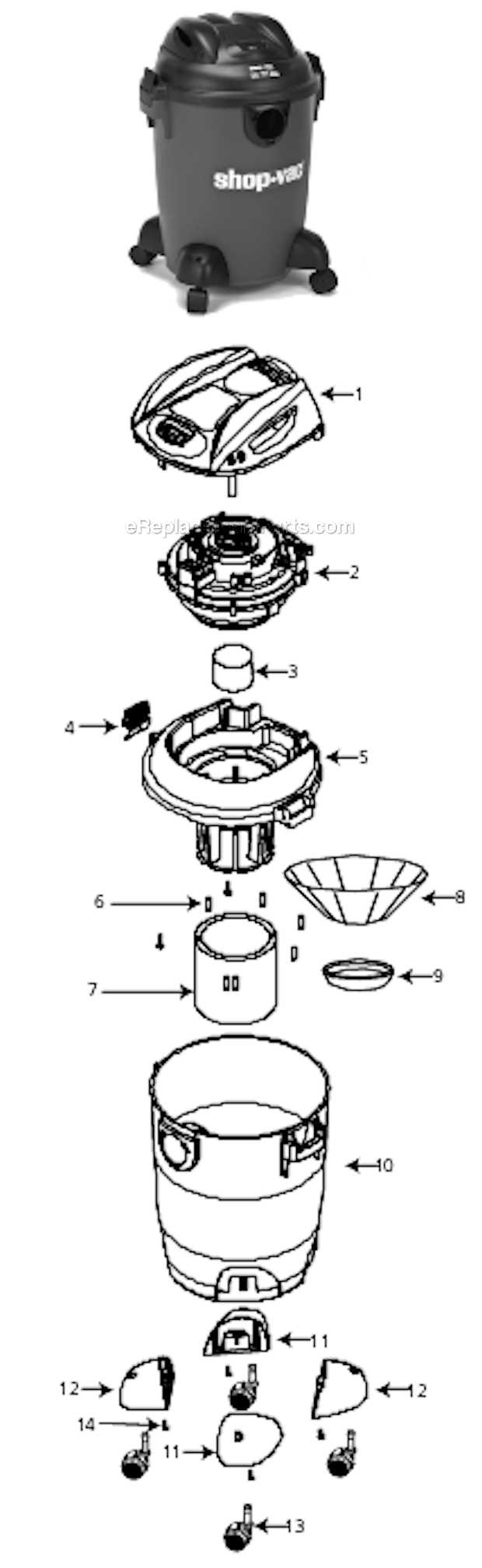

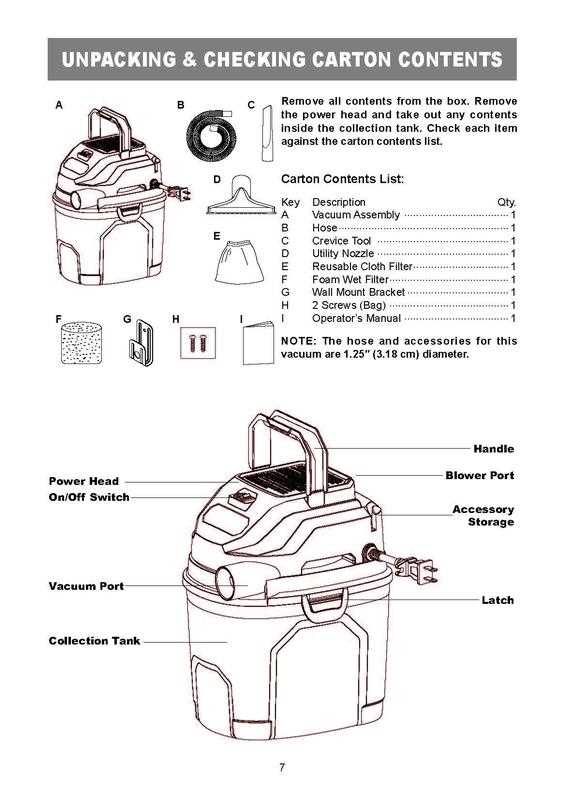

Understanding Shop Vac Components

To effectively maintain and troubleshoot a versatile cleaning device, it’s essential to familiarize oneself with its various elements. Each component plays a crucial role in the overall functionality, contributing to its ability to handle different types of debris and liquids. A clear understanding of these parts not only aids in optimizing performance but also enhances the longevity of the equipment.

The primary element is the motor, which provides the necessary power for suction. This component can vary in strength, affecting the machine’s efficiency. Next, the collection tank serves as the reservoir for gathered materials. Its size and design can impact the capacity and ease of disposal. Additionally, the filtration system is vital for trapping dust and particulates, ensuring clean exhaust air and maintaining a healthy environment.

Another important part is the hose, which facilitates the transfer of debris from the source to the collection tank. The diameter and length of the hose can influence the suction strength and maneuverability. Attachments and nozzles also play a significant role, offering specialized functions for different cleaning tasks, such as crevice cleaning or upholstery care.

Understanding these components provides a foundation for effective maintenance practices. Regular checks and replacements can prevent issues, ensuring optimal performance and extending the lifespan of the device. By becoming familiar with the inner workings, users can make informed decisions regarding upkeep and potential upgrades.

Common Issues with Shop Vacs

Many users encounter various challenges with their cleaning devices, impacting performance and efficiency. Understanding these typical problems can help in maintaining optimal functionality and extending the lifespan of the equipment.

Loss of Suction: One frequent issue is a noticeable decrease in power. This can result from clogged filters or hoses, which should be regularly checked and cleaned.

Strange Noises: Unusual sounds may indicate mechanical problems, such as a damaged motor or loose components. It’s essential to investigate any irregularities to prevent further damage.

Overheating: Devices may overheat due to blocked airflow or continuous use beyond recommended limits. Ensuring proper ventilation and taking breaks during operation can mitigate this.

Electrical Issues: Problems like tripped circuits or malfunctioning switches can hinder functionality. Regular inspection of electrical connections is crucial for safe operation.

By addressing these common difficulties promptly, users can enhance the performance and durability of their cleaning machines.

Basic Tools for Repairs

Having the right instruments is essential for maintaining and fixing your equipment effectively. A well-equipped toolkit not only simplifies the troubleshooting process but also enhances your efficiency, allowing you to address issues with confidence. Understanding which tools are necessary can help streamline your efforts and ensure a successful outcome.

Essential Hand Tools

Hand tools are fundamental for various tasks. A set of screwdrivers, including both flathead and Phillips, is crucial for removing and securing screws. Pliers of different types, such as needle-nose and slip-joint, assist in gripping and bending materials. Additionally, a sturdy wrench set will help you tackle nuts and bolts with ease, ensuring everything is properly tightened or loosened.

Power Tools and Accessories

For more intensive work, power tools can significantly speed up the process. A reliable drill is indispensable for creating holes or driving screws quickly. A multitool, which offers various attachments, can be particularly useful for cutting and sanding. Always remember to use the appropriate safety gear when operating these devices to protect yourself during the maintenance process.

Step-by-Step Repair Process

This section provides a comprehensive guide to addressing common issues with your cleaning device. Following a systematic approach can significantly enhance the effectiveness of troubleshooting and ensure a successful outcome. Each step is designed to lead you through the process, making it accessible even for those with minimal experience.

1. Identify the Problem: Begin by observing the symptoms. Is the unit making unusual noises? Is it lacking suction? Understanding the specific issue will help narrow down potential solutions.

2. Gather Tools and Materials: Assemble the necessary tools such as screwdrivers, wrenches, and replacement parts. Having everything on hand will streamline the process and minimize interruptions.

3. Disconnect Power: Safety is paramount. Ensure the device is unplugged before attempting any disassembly or inspection to avoid electric shock or injury.

4. Disassemble the Unit: Carefully take apart the device according to the manufacturer’s guidelines. Take notes or pictures to aid in reassembly, keeping track of screws and components.

5. Inspect Components: Examine each part for signs of wear, damage, or obstruction. Pay close attention to filters, hoses, and motors, as these are often the culprits in performance issues.

6. Replace or Repair Parts: If you identify faulty components, decide whether they can be repaired or if they need replacement. Use high-quality parts to ensure longevity and optimal performance.

7. Reassemble the Device: Once repairs are made, reassemble the unit carefully. Refer to your notes or pictures to ensure everything is placed correctly.

8. Test the Unit: Plug the device back in and conduct a test run. Observe its performance to confirm that the issue has been resolved and that it operates as expected.

9. Perform Maintenance: Regular upkeep can prevent future issues. Clean filters, check for blockages, and ensure all components are functioning smoothly.

Replacing Filters and Bags

Maintaining optimal performance of your cleaning device involves regular replacement of its internal components. Ensuring that filters and collection bags are fresh helps to enhance suction power and improve air quality. This section outlines the steps necessary to replace these essential parts effectively.

Choosing the Right Components

Selecting the appropriate filters and bags for your unit is crucial. Refer to the manufacturer’s guidelines to identify the correct specifications. Using compatible products not only guarantees proper fit but also maximizes efficiency and longevity of the machine.

Step-by-Step Replacement Process

Begin by unplugging the device to ensure safety. Open the compartment housing the filter and carefully remove the old unit. Inspect the area for any debris before placing the new filter in position. For bag replacement, detach the old bag from its slot and securely attach the new one, making sure it is sealed properly. Close the compartment and reconnect the power source, readying your appliance for use once more.

Fixing the Motor Problems

Addressing motor issues is essential for maintaining optimal performance of your cleaning equipment. Various symptoms may indicate that the motor is not functioning correctly. Understanding these signs can help you diagnose and resolve the problem efficiently.

Common motor-related issues include:

- No power or failure to start

- Unusual noises during operation

- Overheating

- Weak suction or airflow

To effectively troubleshoot these issues, follow these steps:

- Check the power supply: Ensure the device is plugged in and the outlet is functioning. Test the power cord for any visible damage.

- Inspect the motor housing: Remove the outer cover and look for signs of wear, debris, or blockages that may impede motor function.

- Examine internal components: Look at the brushes, bearings, and rotor for signs of wear or damage. Replace any faulty parts as necessary.

- Test the switch and circuitry: Ensure that all electrical connections are secure and that the switch is functioning properly.

- Monitor for overheating: If the motor becomes too hot, check for obstructions and ensure proper ventilation.

By following these steps, you can diagnose and fix common motor problems effectively, prolonging the life of your device and ensuring it operates at peak efficiency.

Troubleshooting Suction Issues

When facing difficulties with suction power, it’s essential to identify the underlying causes that may be affecting performance. Several factors can contribute to reduced effectiveness, and a systematic approach to diagnosing the problem can lead to effective solutions.

| Issue | Possible Cause | Solution |

|---|---|---|

| Poor suction | Clogged hose or filters | Inspect and clear any blockages; clean or replace filters as needed. |

| Unusual noise | Loose components | Tighten all connections and check for wear on parts. |

| Overheating | Blocked airflow | Ensure vents are unobstructed; allow the unit to cool down before use. |

| Inconsistent suction | Worn out motor | Test motor performance; consider professional assessment or replacement. |

By systematically addressing these common issues, users can restore optimal functionality and prolong the lifespan of their cleaning equipment.

Repairing Hose and Accessories

Maintaining the efficiency of your cleaning equipment often involves addressing issues with the flexible tubing and accompanying tools. Understanding common problems and solutions can enhance performance and longevity.

Identifying Leaks: One frequent issue is the presence of leaks in the tubing. Carefully inspect for any visible cracks or holes. If found, using a strong adhesive tape can provide a temporary fix until a more permanent solution is possible.

Clogs and Blockages: Clogs can severely hinder functionality. To resolve this, detach the tubing and use a long, flexible object to dislodge the obstruction. Regularly checking for buildup will help prevent future issues.

Replacing Accessories: If tools like nozzles or brushes become worn out, replacing them is essential. Ensure compatibility with your device to achieve optimal results. Quality replacements can make a significant difference in cleaning efficiency.

Regular Maintenance: Routine inspection and care are crucial. Clean the tubing and attachments regularly to prevent dust and debris accumulation, ensuring smooth operation over time.

Electrical Safety Precautions

When working with devices powered by electricity, it is essential to prioritize safety to prevent accidents and ensure a secure environment. Understanding the inherent risks associated with electrical systems can significantly reduce the likelihood of injuries or damage. Proper precautions and awareness are key components of responsible handling and maintenance of these tools.

General Safety Guidelines

Always disconnect the power supply before performing any maintenance or troubleshooting. This simple action can prevent accidental starts and protect against electrical shock. Use insulated tools and wear appropriate personal protective equipment, such as gloves and goggles, to safeguard yourself while working. Additionally, ensure that your workspace is dry and free from clutter to minimize hazards.

Handling and Storage

Proper handling and storage of equipment can greatly influence safety. Avoid pulling on cords; instead, grasp the plug to disconnect. Store devices in a cool, dry place to prevent moisture damage. Regularly inspect cords and plugs for signs of wear or damage, and replace them as needed to maintain safety standards. Implementing these practices will help ensure that equipment remains in safe working condition.

Regular Maintenance Tips

Keeping your cleaning equipment in optimal condition is essential for ensuring its longevity and performance. Regular attention to specific aspects of the machine can prevent common issues and enhance its efficiency. Here are some crucial suggestions to maintain your device effectively.

Check and Clean Filters

Filters play a vital role in the overall functionality. It is advisable to inspect and clean them periodically to prevent clogging and ensure proper airflow. Replace filters as needed, especially if they appear damaged or heavily soiled. Regular maintenance of filters not only improves performance but also extends the lifespan of your equipment.

Inspect Hoses and Attachments

Regularly examine hoses and attachments for any signs of wear or damage. Clear any blockages that may have formed over time. Maintaining these components ensures that the device operates at peak efficiency. Additionally, check for secure connections to avoid air leaks that can diminish suction power.

Upgrading Your Shop Vac

Enhancing your cleaning equipment can significantly improve its performance and versatility. By making thoughtful modifications or additions, you can tailor the device to meet specific needs and tackle a wider range of tasks effectively. This section explores various ways to elevate your device’s functionality and efficiency.

Essential Accessories

Integrating additional components can greatly enhance your equipment’s capabilities. Here are some popular accessories that can provide a noticeable boost:

| Accessory | Benefit |

|---|---|

| Extended Hoses | Reach difficult areas without moving the unit |

| Specialized Nozzles | Improve efficiency for specific tasks like crevices or upholstery |

| Filtration Upgrades | Enhance air quality by trapping finer particles |

| Noise Reduction Kits | Minimize sound levels during operation |

Power and Performance Enhancements

In addition to accessories, you can also boost the overall performance of your device through various upgrades. Consider the following options:

| Upgrade | Description |

|---|---|

| Motor Replacement | Increase suction power for more effective cleaning |

| Improved Wheels | Enhance mobility for easier transport and maneuverability |

| Energy-Efficient Components | Reduce power consumption while maintaining performance |

When to Seek Professional Help

Understanding the limits of your abilities is essential when addressing equipment issues. While many tasks can be tackled independently, some situations require the expertise of a trained technician. Recognizing when to call for assistance can save time, resources, and prevent further complications.

Here are some indicators that professional intervention may be necessary:

| Indicator | Explanation |

|---|---|

| Persistent Problems | If issues persist despite attempts to resolve them, it’s time to consult an expert. |

| Complex Repairs | When the issue involves intricate components or requires specialized tools, professional help is advisable. |

| Safety Concerns | If there are risks of electric shock, fire, or other hazards, seek professional assistance immediately. |

| Warranty Issues | Contacting a technician may be necessary to maintain warranty coverage, especially for new equipment. |

| Time Constraints | If you’re pressed for time and unable to dedicate effort to fixing the issue, a professional can expedite the process. |

Ultimately, when in doubt, reaching out to an expert can ensure the longevity and proper functioning of your equipment.