Maintaining your outdoor gear is essential for ensuring a smooth and enjoyable experience. Whether you are a novice or an experienced user, understanding the intricacies of your equipment can significantly enhance performance. This section aims to provide valuable insights into the common practices that will help extend the life of your tools.

By familiarizing yourself with the components and functionalities, you can address issues proactively. Knowing the right techniques and methods will empower you to tackle challenges effectively. This guide is designed to equip you with the knowledge needed to keep your gear in optimal condition.

Emphasizing regular upkeep not only improves efficiency but also contributes to overall satisfaction. Engaging in simple maintenance tasks can prevent larger problems down the line, allowing you to focus on your activities without interruption. Let’s explore the steps to ensure your equipment remains reliable for your adventures.

Understanding the Shakespeare Reel Design

This section explores the fundamental characteristics and construction of a popular angling apparatus, emphasizing its intricate mechanics and thoughtful architecture. Grasping the design principles can significantly enhance user experience and prolong the device’s lifespan.

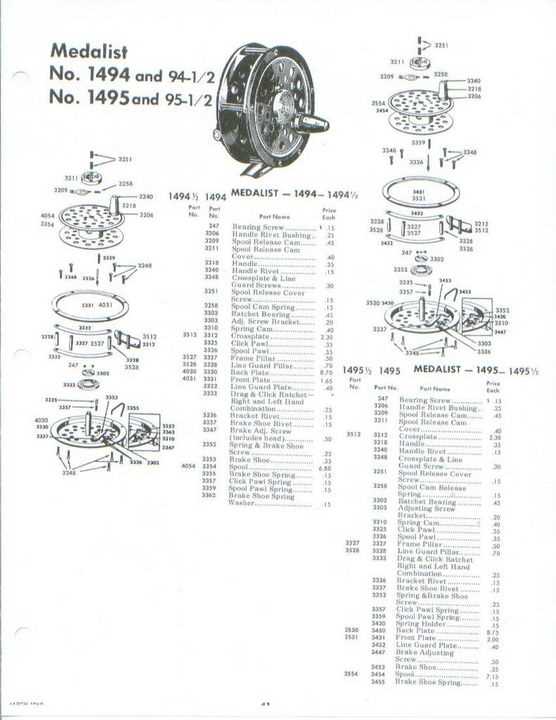

The primary components contributing to the effectiveness of this apparatus include:

- Body: The outer casing that provides durability and protection.

- Drag System: A mechanism allowing the user to adjust resistance, crucial for managing the tension during usage.

- Spool: A cylindrical part that holds the line, designed for smooth release and retrieval.

- Handle: The lever that enables the angler to control movement and retrieve efficiently.

Each element is meticulously crafted to achieve optimal performance, ensuring that users can enjoy their experience while engaging with nature. Understanding these features aids in effective maintenance and enhances overall functionality.

Common Issues with Fishing Reels

When engaging with angling gear, enthusiasts often encounter various challenges that can hinder their experience. Recognizing these typical problems is essential for maintaining optimal functionality and enjoyment. By understanding common pitfalls, users can take proactive steps to ensure their equipment operates smoothly.

Frequent Malfunctions

One prevalent concern involves the inability of the device to smoothly unwind or wind line. This issue may arise from accumulated dirt or inadequate lubrication. Regular maintenance, including cleaning and oiling, is vital to prevent this malfunction.

Noise and Resistance

Another issue that users often face is unusual sounds during operation. Excessive noise may indicate worn components or insufficient lubrication. It is crucial to address these signs promptly, as they can lead to more significant problems if ignored. A thorough inspection and timely intervention can enhance the longevity of the gear.

Essential Tools for Reel Repair

To effectively maintain and restore your equipment, having the right set of instruments is crucial. These items not only enhance your efficiency but also ensure a thorough job is done, allowing for seamless functionality post-maintenance. A well-equipped toolkit can make all the difference in achieving optimal results.

Basic Instruments

Start with fundamental items such as screwdrivers, pliers, and wrenches. These tools are necessary for loosening and tightening components, facilitating easy access to internal parts. A set of precision screwdrivers can help with intricate adjustments, while pliers offer a firm grip for handling small pieces.

Specialized Equipment

In addition to basic tools, consider incorporating specialized devices such as lubricants and cleaning agents. Proper maintenance often involves thorough cleaning and lubrication of moving parts to ensure smooth operation. Select high-quality products designed specifically for this purpose to enhance the longevity of your gear.

Step-by-Step Disassembly Process

This section outlines a systematic approach to dismantling a specific device effectively. By following these steps, users can ensure each component is handled properly, minimizing the risk of damage and facilitating easier reassembly.

Preparation and Tools

Before beginning the process, gather the necessary tools, including screwdrivers, pliers, and a clean workspace. Ensure that all components are organized to streamline the reassembly process later.

Removing the Outer Shell

Start by carefully unscrewing any screws that secure the outer casing. Gently pry apart the halves, taking care to avoid damaging any clips or latches. This initial step provides access to the inner workings, allowing for further disassembly.

Cleaning Techniques for Smooth Operation

Maintaining optimal functionality of your equipment is essential for longevity and performance. Regular cleaning ensures that all components operate smoothly, preventing potential malfunctions and enhancing overall efficiency.

Begin by disassembling the unit carefully, following the manufacturer’s guidelines. Use a soft brush to remove dust and debris from all surfaces. Pay special attention to intricate areas where particles can accumulate, affecting movement and responsiveness.

For stubborn grime, a mild detergent mixed with water can be effective. Dampen a cloth with the solution and gently wipe the parts. Avoid soaking any components, as excess moisture can lead to corrosion. After cleaning, thoroughly rinse with clean water and dry immediately to prevent water spots or rust.

Finally, apply a lightweight lubricant to the moving parts. This will enhance performance and protect against wear over time. Regular upkeep not only improves functionality but also extends the lifespan of your equipment.

Replacing Worn-Out Components

Over time, the various parts of a device can experience wear and tear, leading to diminished performance. Identifying and substituting these fatigued elements is crucial for restoring optimal functionality. This section outlines the process and considerations involved in ensuring that each component remains in top condition.

Identifying Worn Parts

Recognizing which components have deteriorated is the first step. Signs of wear can include unusual noises, difficulty in operation, or visible damage. Regular inspections are advisable to catch issues early and prevent further complications.

Replacement Procedure

Once worn components are identified, the next step is to replace them. Follow these guidelines for a successful exchange:

| Step | Action |

|---|---|

| 1 | Gather necessary tools and replacement parts. |

| 2 | Carefully disassemble the unit to access the worn components. |

| 3 | Remove the damaged parts and dispose of them appropriately. |

| 4 | Install the new components, ensuring a secure fit. |

| 5 | Reassemble the device and conduct a performance test. |

By following these steps, one can ensure that the device functions smoothly, extending its lifespan and enhancing user experience.

Lubrication Best Practices

Proper maintenance of mechanical equipment is essential for ensuring longevity and optimal performance. A well-executed lubrication routine can significantly enhance the functionality and reliability of components, minimizing wear and tear. This section highlights the key techniques for effective lubrication.

Types of Lubricants

Choosing the right type of lubricant is crucial for achieving the desired outcomes. Different formulations offer unique benefits and are suitable for various applications. Below is a comparison of common lubricant types:

| Lubricant Type | Best Use | Benefits |

|---|---|---|

| Oil | High-speed components | Reduces friction, penetrates easily |

| Grease | Heavy-load applications | Stays in place, withstands pressure |

| Dry Lubricants | Dusty environments | Prevents build-up, non-sticky |

Application Techniques

Employing effective application methods ensures even distribution of the lubricant, enhancing its effectiveness. Here are some recommended techniques:

- Use a clean cloth to wipe surfaces before applying any lubricant.

- Apply lubricants sparingly to prevent excess buildup.

- Follow manufacturer guidelines for application frequency and amounts.

Troubleshooting Reel Performance Problems

When experiencing issues with your gear, identifying the root cause is essential for restoring optimal function. Various factors can contribute to subpar performance, and understanding these can help enhance your overall experience.

Here are common problems to consider:

- Inconsistent Casting: This may stem from improper line setup or tangled components.

- Dragging Issues: Insufficient lubrication or dirt buildup can lead to resistance when reeling in.

- Noisy Operation: Unwanted sounds often indicate wear or lack of maintenance in moving parts.

- Brake Problems: If braking mechanisms are malfunctioning, it can affect control during retrieval.

To effectively address these challenges, follow these steps:

- Inspect the line for tangles or twists and replace if necessary.

- Clean and lubricate all moving parts to ensure smooth operation.

- Check for any signs of wear on the braking systems and adjust settings accordingly.

- Test the gear under various conditions to determine if the issues persist.

By systematically analyzing each aspect of your setup, you can enhance functionality and prolong the lifespan of your equipment.

Reassembly Tips for Optimal Function

Ensuring the seamless reassembly of components is crucial for maintaining peak performance. This section provides valuable insights into the process, helping enthusiasts achieve the best possible outcomes after disassembly.

Preparation Steps

- Gather all components in a clean, organized space.

- Inspect each part for wear and tear before proceeding.

- Have necessary tools readily available to avoid interruptions.

Reassembly Process

- Start with the foundation, ensuring that all securing mechanisms are aligned properly.

- Carefully position each element, following the reverse order of disassembly.

- Apply appropriate lubricants where necessary to enhance functionality.

- Double-check that all fasteners are tightened to prevent future issues.

By following these tips, you can optimize the performance of your device, ensuring longevity and reliability in use.

Maintaining Your Fishing Gear

To effectively maintain your equipment, consider the following key practices:

| Task | Frequency | Description |

|---|---|---|

| Cleaning | After each use | Rinse components with fresh water to remove dirt and salt. |

| Lubrication | Monthly | Apply appropriate oils to moving parts to ensure smooth operation. |

| Inspection | Before major trips | Check for any signs of wear or damage to ensure safety and efficiency. |

| Storage | Off-season | Keep gear in a dry, cool place to prevent corrosion and deterioration. |

By following these guidelines, you can enhance the functionality of your equipment and ensure many successful outings in the future.