Over time, kitchen appliances can encounter various issues that may disrupt their daily performance. Addressing these challenges efficiently requires a clear understanding of the appliance’s systems and components. This guide is designed to help you pinpoint and resolve common operational concerns, ensuring the longevity and effectiveness of your refrigeration unit.

Each section explores different methods to tackle potential challenges, from minor cooling inconsistencies to more advanced solutions that can enhance overall function. By understanding the intricacies of your appliance and applying appropriate maintenance steps, you can achieve smooth and reliable operation with minimal effort.

Recognizing specific issues early on not only prevents larger malfunctions but also saves both time and resources. Our guide offers practical advice and step-by-step solutions for managing your refrigerator’s most typical challenges. Dive in to learn how to care for and maintain your kitchen’s essential cooling system.

Troubleshooting Guide for Common Refrigerator Issues

This section provides a practical approach to identifying and solving typical issues that may arise with your appliance. Designed for convenience, this guide outlines steps for assessing various problems and restoring optimal performance without the need for complex tools.

- Temperature Fluctuations: If the unit isn’t cooling effectively or shows temperature inconsistencies, check that the vents are not blocked. Clear any items obstructing airflow, as restricted circulation can impact cooling.

- Excessive Frost Build-Up: When frost accumulates in the freezer compartment, inspect the door seal to ensure it is airtight. A compromised seal can allow warm air inside, causing excess frost. Clean the gasket or replace if worn out.

- Unusual Noises: Strange sounds often indicate that the appliance is working harder than necessary. Verify that it stands level on the floor, as tilting can cause motor strain. Also, ensure coils are clean, reducing the load on the compressor.

- Water Leakage: Puddles around the base may signal a clogged

Identifying Common Refrigerator Issues

Refrigerators play a crucial role in maintaining food freshness, but over time, they can develop various operational issues. Recognizing the signs of common malfunctions early on can help prevent further complications and ensure optimal functionality.

Issue Signs Possible Causes Insufficient Cooling Food spoiling faster than expected, interior feels warmer than usual Blocked vents, malfunctioning thermostat, or condenser issues Unusual Noises Rattling, buzzing, or hissing sounds Loose components, compressor problems, or fan motor wear Water Leaks Puddles beneath the Steps to Resolve Cooling Problems

When refrigeration units exhibit inadequate cooling, it is essential to address the issue systematically. Identifying the root cause can lead to effective solutions, ensuring optimal performance and prolonging the lifespan of the appliance.

1. Check Temperature Settings: Ensure that the temperature controls are set to the recommended levels. A simple adjustment can often rectify cooling issues.

2. Inspect Door Seals: Examine the door gaskets for any signs of wear or damage. A compromised seal can lead to temperature fluctuations, allowing warm air to enter.

3. Clean Condenser Coils: Dust and debris accumulation on condenser coils can hinder the cooling process. Regular cleaning can enhance efficiency and performance.

4. Assess Airflow: Ensure that vents inside the unit are not blocked. Proper airflow is crucial for maintaining consistent temperatures throughout the appliance.

5. Monitor Internal Components: Pay attention to the performance of fans and compressors. Any irregular sounds or behavior may indicate a need for further inspection or service.

6. Consult Professional Help: If the problem persists after following these steps, seeking assistance from a qualified technician is advisable for a thorough diagnosis and repair.

How to Fix Ice Maker Malfunctions

When your ice maker stops functioning properly, it can be quite frustrating. Fortunately, many issues can be resolved with some basic troubleshooting steps. Understanding common problems and their solutions can help restore your unit’s efficiency without the need for professional assistance.

Common Issues and Solutions

Several factors can contribute to ice maker malfunctions. Here are some typical problems and how to address them:

Problem Solution Ice maker not producing ice Check the water supply and ensure the valve is open. Inspect the water filter for clogs and replace it if necessary. Ice is too thin or small Adjust the freezer temperature to a colder setting. Clean the ice maker components to remove any buildup. Ice maker is noisy Inspect for any loose parts or ice jams. Tighten any loose screws and clear any obstructions in the mechanism. Preventive Maintenance Tips

To keep your ice maker in optimal condition, regular maintenance is essential. Here are some tips to prevent future malfunctions:

- Clean the ice maker and surrounding area periodically to prevent buildup.

- Replace the water filter every six months to ensure clean water supply.

- Check for any signs of wear and replace parts as needed.

Adjusting Temperature Controls Properly

Ensuring optimal temperature settings is crucial for maintaining the freshness and quality of stored items. Properly configured controls can prevent spoilage and enhance energy efficiency. Understanding how to adjust these settings can significantly impact the performance of your cooling unit.

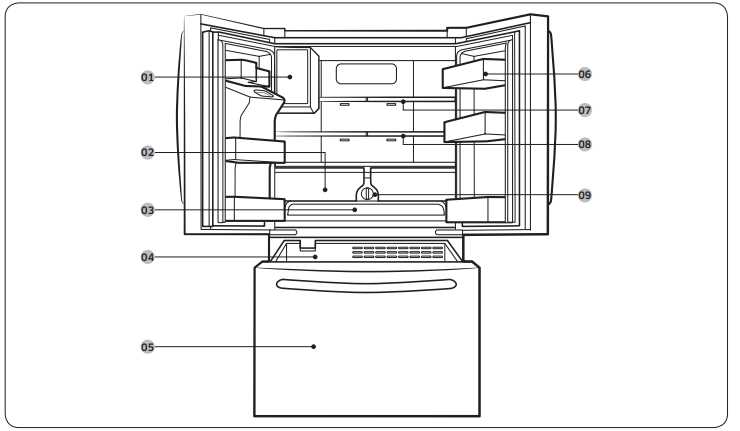

Begin by identifying the temperature zones within the appliance. Typically, the refrigerator section should be set between 34°F and 40°F, while the freezer compartment works best at 0°F. These ranges help create an environment that keeps food items safe and fresh.

To adjust the temperature, locate the control panel, usually found inside the refrigerator or on the exterior front. Use the designated buttons or dial to select your desired temperature. Allow the unit some time to stabilize after making adjustments before checking the internal temperatures with a thermometer for accuracy.

Regularly monitor the temperature settings and make necessary adjustments based on the amount and type of food stored. Frequent opening of the doors or changes in food load can affect internal temperatures, necessitating recalibrations to maintain ideal conditions.

Water Dispenser Repair Instructions

This section provides guidance on addressing common issues related to the water dispensing mechanism in refrigeration units. Proper troubleshooting and maintenance can help ensure consistent performance and prevent further complications.

Follow these steps to resolve typical problems:

- Identify the Issue:

- Check if water is dispensing at all.

- Observe for any leaks around the dispenser.

- Listen for unusual noises when attempting to dispense water.

- Inspect the Water Supply Line:

- Ensure the water supply is turned on.

- Look for kinks or blockages in the line.

- Examine connections for any signs of wear or damage.

- Examine the Dispenser Components:

- Remove the cover to access internal parts.

- Check the water filter for clogs and replace if necessary.

- Inspect the actuator mechanism for proper function.

- Test the Dispensing Mechanism:

- Reassemble components and ensure secure connections.

- Run a test to see if water flows freely.

- Monitor for any leaks during operation.

If issues persist after following these guidelines, consider seeking assistance from a qualified technician to ensure a thorough evaluation and resolution of the problem.

Replacing Worn Refrigerator Seals

Proper sealing is crucial for maintaining efficiency in cooling appliances. Over time, door seals may wear out, leading to temperature fluctuations and increased energy consumption. Addressing this issue promptly can enhance performance and prolong the lifespan of the unit.

Identifying Worn Seals

Recognizing signs of deterioration in seals is the first step toward effective replacement. Look for the following indicators:

- Visible cracks or tears in the rubber.

- Presence of mold or mildew around the edges.

- Doors that do not close tightly or leave gaps.

- Increased frost build-up in the freezer compartment.

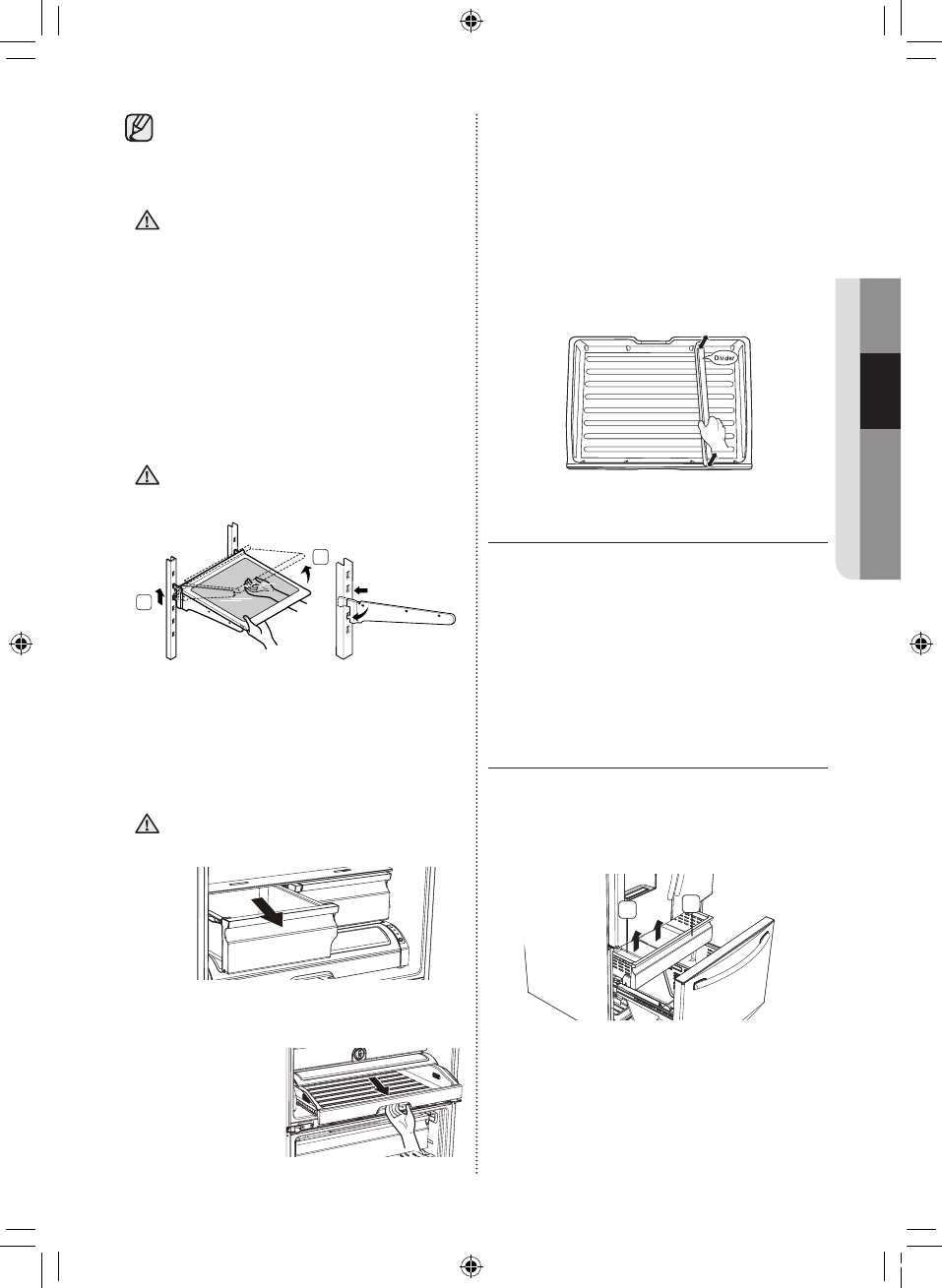

Steps to Replace Seals

Once you’ve determined that the seals need replacement, follow these steps to ensure a proper installation:

- Remove the old seal carefully by pulling it away from the door frame.

- Clean the area where the new seal will be attached to ensure proper adhesion.

- Align the new seal with the door frame, starting at one corner.

- Press the seal firmly into place, ensuring it fits snugly along the entire perimeter.

- Check the seal’s effectiveness by closing the door and testing for any leaks.

By following these guidelines, you can improve your appliance’s efficiency and prevent future issues related to temperature control.

Cleaning and Maintaining Condenser Coils

Regular upkeep of the condenser coils is essential for ensuring optimal performance and energy efficiency of refrigeration units. Accumulated dust and debris can hinder heat exchange, leading to increased energy consumption and potential malfunction.

To effectively clean and maintain the condenser coils, follow these guidelines:

- Safety First: Always unplug the appliance before starting any maintenance work to prevent electrical hazards.

- Access the Coils: Locate the condenser coils, typically found at the back or underneath the unit. Move the appliance carefully if necessary to gain access.

- Remove Dust and Debris: Use a vacuum cleaner with a brush attachment or a soft brush to gently remove dust and dirt from the coils. Be cautious not to bend the fins.

- Check for Damage: Inspect the coils for any signs of damage or corrosion. If you notice any issues, consider consulting a professional for repairs.

- Reassemble and Test: After cleaning, reassemble any parts that were removed and plug the unit back in. Monitor its performance to ensure it is functioning correctly.

Performing these maintenance tasks regularly can extend the lifespan of the appliance and enhance its efficiency.

Inspecting and Repairing Door Hinges

Proper functioning of door hinges is essential for seamless operation. Regular inspection helps identify issues that may hinder the door’s movement, ensuring it opens and closes smoothly.

Begin by examining the hinges visually:

- Look for signs of wear or rust.

- Check for any misalignment that may prevent the door from closing properly.

- Listen for unusual noises when opening or closing the door.

If problems are detected, consider the following solutions:

- Apply lubricant to reduce friction and enhance movement.

- Realign the hinges by loosening screws and repositioning as needed.

- Replace damaged hinges with new ones to restore full functionality.

Regular maintenance of door hinges prolongs their lifespan and ensures the door operates effectively.

Power Supply and Wiring Checks

Ensuring a stable power supply and proper wiring connections is essential for the optimal performance of refrigeration units. These components are crucial in maintaining consistent temperatures and efficient operation. Without thorough checks, issues such as inadequate cooling or unexpected shutdowns may arise.

Begin by verifying that the appliance is correctly plugged into a functional outlet. Use a multimeter to measure the voltage at the outlet, ensuring it meets the manufacturer’s specifications. If the voltage is too low or fluctuates, consider checking the circuit breaker or consulting an electrician.

Next, inspect the power cord for any visible damage or wear. A frayed or damaged cord can lead to poor connections and may pose a safety hazard. If any issues are found, replacing the power cord is necessary to prevent further complications.

Additionally, examine all internal wiring connections. Ensure that all wires are securely attached and free from corrosion or damage. Pay special attention to connections at the compressor and control board, as these are critical for proper functionality.

By systematically checking the power supply and wiring, you can identify potential issues early and maintain the reliable operation of your cooling system.

Final Safety Tips for Repairs

When undertaking maintenance tasks on your appliance, ensuring personal safety and preventing further damage is paramount. Adhering to basic guidelines can significantly reduce the risk of accidents and enhance the effectiveness of your work.

Always disconnect the power source before starting any work. This simple step can prevent electrical shocks and protect you from injury. Make it a habit to check that the unit is unplugged or, if applicable, that the circuit breaker is turned off.

Use appropriate tools for the job. Having the right equipment not only makes the process more efficient but also minimizes the likelihood of accidents caused by using makeshift tools. Ensure all tools are in good condition and suitable for the task at hand.

Follow manufacturer guidelines where available. While you may be familiar with various components, specific instructions can provide valuable insights into the correct procedures and safety measures tailored to your device.

Wear protective gear such as gloves and safety glasses. This equipment shields you from potential hazards, including sharp edges and debris. Prioritizing your well-being during any maintenance work is crucial.

Be cautious of refrigerants and other substances used in cooling appliances. If you encounter any leaks or damage to the cooling system, consult a professional. Mishandling these materials can pose serious health risks.

By implementing these safety precautions, you can ensure a secure working environment while addressing any issues that may arise with your device.