In modern home environments, ensuring that essential devices are well-maintained is key to consistent performance. One area that often requires attention involves the efficient operation of systems responsible for providing a steady supply of chilled items. These systems are an integral part of daily convenience, and proper knowledge about their upkeep can make a significant difference in their durability and functionality.

Common Issues and Troubleshooting for such devices often revolve around internal mechanisms that may experience wear over time. From minor malfunctions to more complex component adjustments, understanding how to diagnose and address these challenges is vital. By examining some of the most typical operational issues, users can gain a better grasp on how to enhance the longevity of these helpful units.

For those who rely on consistent, well-functioning technology, regular maintenance and part adjustments ar

Cooling Unit Troubleshooting Guide

For those experiencing functionality issues with their cooling system, this guide provides essential steps to identify and resolve common problems. Diagnosing the root cause of operational failures can ensure consistent performance and longevity of the appliance. This section will cover troubleshooting steps, helping you understand typical malfunctions and solutions to restore your unit to optimal function.

Begin by checking for any error indicators or unusual sounds coming from the device. These often signal specific areas that need attention, such as power connections, water supply, or control settings. Following this, examine the control panel for misconfigured options that could affect production cycles.

In cases where the device is not cooling or producing as expected, verify that the appliance is connected to a stable power source and that the internal temperature settings are correctly calibrated. If these steps do not resolve the issue, a deeper inspection of the internal components may be necessary to ensure all parts are functioning properly.

If troubleshooting proves challenging, consider consulting a specialist or referring to the manufacturer’s guidance for detailed maintenance procedures. Regular upkeep and immediate attention to minor issues can prevent larger problems, ensuring your cooling unit operates reliably over time.

Common Ice Maker Problems and Causes

Understanding why certain cooling units experience malfunctions can help prevent or resolve issues efficiently. This section covers frequent disruptions and the typical underlying reasons, offering insights into maintaining optimal functionality and troubleshooting when the unit’s output is affected.

Inconsistent Production Volume

One prevalent issue users encounter is an irregular or insufficient supply. This can often be linked to fluctuations in the water flow, blocked inlets, or temperature irregularities within the machine’s system. Examining the water source and ensuring unobstructed tubing may help maintain consistent production.

Unusual Sounds or Vibrations

Another common concern involves unexpected noises or vibrations, which could point to issues with internal mechanisms, such as misaligned components or wear on essential parts. Regularly checking for secure connections and proper alignment can minimize these occurrences and prolong the equipment’s lifespan.

Identifying Signs of Malfunction

Understanding when a cooling appliance isn’t performing optimally can prevent more serious issues. Recognizing common warning signals helps to address potential problems early, ensuring reliable performance and longer equipment lifespan.

Common Indicators

- Unusual Noises: Persistent humming, buzzing, or clicking sounds may indicate mechanical wear or component misalignment.

- Inconsistent Temperatures: Frequent changes in internal temperature often signal a sensor issue or airflow obstruction.

- Leaking or Excess Moisture: Water pooling near the unit or within compartments can suggest drainage or condensation issues.

Functional Disruptions

- Tools Needed for Ice Maker Repair

To restore functionality to your cooling appliance’s freezing feature, certain tools are essential for assessing and addressing issues effectively. These items allow for safe handling of components and precise adjustments, helping to ensure that your equipment works efficiently after repairs.

- Screwdriver Set: A variety of screwdrivers, especially flathead and Phillips types, will be necessary for detaching panels and accessing internal parts.

- Multimeter: A crucial device for checking electrical continuity and diagnosing any faults in circuits, helping pinpoint specific issues within the system.

- Pliers: Both needle-nose and standard pliers are useful for gripping and manipulating small parts, as well as for tightening and loosening connectors.

- Wrench Set: Different sizes of wrenches are helpful for

Steps to Reset the Ice Maker

Sometimes, restoring a cooling appliance’s functionality involves a quick reset, which can address minor issues with its production system. This process can be done in a few straightforward steps, helping to recalibrate the unit’s performance and resolve common glitches without the need for more intensive intervention.

Step Description 1 Ensure the appliance is plugged in and has stable power. Check if any indicators are showing errors or malfunctions. 2 Locate the reset button or a similar feature often found on the control panel or near the production mechanism itself. This button may be marked or slightly recessed for safety. 3 Press and hold the reset button for several seconds. This action initiates a recalibration process, potentially resolving minor interruptions. How to Check Water Supply Issues

Ensuring an adequate flow of liquid to your cooling unit is essential for optimal performance. Problems with the water supply can lead to inadequate functionality and may hinder the appliance’s effectiveness. Here are some steps to diagnose potential supply issues.

- Inspect the Source: Verify that the primary water source is turned on and supplying liquid. Check for any visible leaks or damage in the plumbing.

- Examine the Connection: Ensure that the connection between the water line and the unit is secure. Look for kinks or obstructions in the hose that could impede flow.

- Check Filters: If your setup has a filter, ensure it is clean and free of debris. A clogged filter can significantly reduce water flow.

- Monitor Pressure: Use a pressure gauge to assess the water pressure coming into the unit. Low pressure can affect performance and may require adjustment or repair of the supply line.

- Look for Freezing: Examine the line for any signs of freezing, particularly in colder environments. Insulation may be necessary to prevent this issue.

By following these steps, you can identify and address any issues with the water supply, ensuring your cooling unit operates effectively.

Cleaning and Maintenance Tips

Regular upkeep of your appliance is essential for optimal performance and longevity. By implementing a consistent cleaning routine and following maintenance guidelines, you can ensure efficient operation and minimize the risk of issues arising.

Here are some key practices to keep in mind:

- Perform a thorough cleaning of all components at least once every few months to prevent buildup of residues.

- Utilize a mild detergent and warm water solution to wipe down surfaces and removable parts.

- Ensure that the water supply is free from impurities by replacing filters as recommended by the manufacturer.

- Regularly inspect hoses and connections for leaks or signs of wear, replacing them as needed.

Additionally, pay attention to the following:

- Unplug the unit before cleaning to ensure safety.

- Keep the surrounding area clean and free of debris to promote airflow and efficiency.

- Follow specific instructions for cleaning electronic components to avoid damage.

By adhering to these guidelines, you can maintain a high level of performance and extend the lifespan of your appliance.

Fixing Temperature Control Problems

Addressing issues related to temperature regulation is crucial for maintaining optimal performance in cooling appliances. When fluctuations or inconsistencies occur, it can lead to ineffective operation and compromise the overall functionality of the device.

Identifying Symptoms: The first step in resolving temperature control issues is recognizing the signs that indicate a malfunction. Common symptoms include inconsistent cooling, excessive frost buildup, or even a complete lack of cold air. Observing these factors can help pinpoint the root of the problem.

Inspecting the Thermostat: A malfunctioning thermostat often leads to temperature-related difficulties. Ensure that the thermostat is set correctly and functioning properly. If adjustments do not resolve the issue, consider replacing the thermostat to restore accurate temperature control.

Checking Airflow: Proper airflow is essential for effective cooling. Inspect the vents and ensure they are unobstructed by ice, dust, or other debris. Clear any blockages to allow for adequate circulation, which can help maintain a consistent temperature throughout the unit.

Examining the Cooling System: Investigate the cooling components, such as the condenser and evaporator coils. Clean these parts to remove dirt or buildup that could hinder their performance. A well-maintained cooling system is vital for efficient temperature regulation.

Assessing Electrical Connections: Faulty wiring or poor connections can disrupt the appliance’s temperature control system. Inspect all electrical connections for signs of wear or damage. Repair or replace any compromised components to ensure proper operation.

By following these steps, users can effectively troubleshoot and resolve temperature control challenges, leading to improved performance and longevity of the cooling appliance.

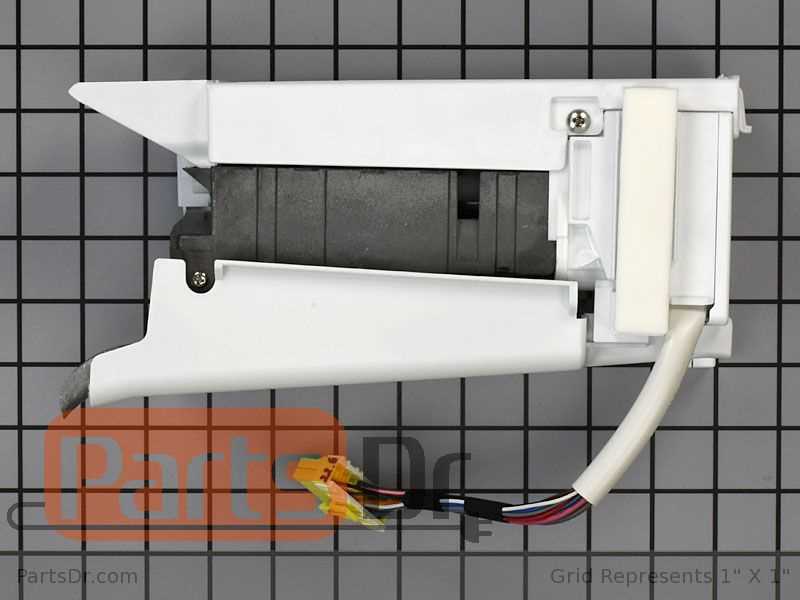

Understanding Ice Maker Components

In this section, we will explore the various elements that contribute to the functionality of a home refrigeration unit designed for producing frozen cubes. Each component plays a crucial role in ensuring efficient operation and reliable performance, making it essential to understand their purposes and interconnections.

At the heart of the system lies the freezing chamber, which is responsible for transforming liquid into solid form. Within this chamber, a specific device regulates the temperature, allowing for optimal conditions for the freezing process. Additionally, a water reservoir supplies the necessary fluid, while a distribution mechanism ensures even filling of the molds.

Control mechanisms, including sensors and timers, monitor the operation, allowing for precise management of the freezing cycles. Regular maintenance and understanding of these parts are vital for troubleshooting issues that may arise, ultimately extending the lifespan of the appliance.

Replacing Ice Maker Parts Safely

Ensuring the proper function of your freezing appliance often requires replacing components. This process should be approached with care to avoid injury and damage. Understanding the necessary precautions and steps is essential for a successful outcome.

Preparation Before Starting

Before proceeding, make sure to disconnect the appliance from its power source. This simple step minimizes the risk of electrical shock. Gather all required tools and replacement components to streamline the process and maintain efficiency.

Step-by-Step Replacement Process

Begin by examining the specific part that requires substitution. Follow the manufacturer’s guidelines for detaching the old component, ensuring you handle any sharp edges or fragile pieces with caution. When installing the new part, double-check that it is securely attached and properly aligned. Lastly, restore power to the unit and test its functionality to confirm that the new installation is effective.

Safety Tip: Always wear protective gear, such as gloves and safety goggles, during the replacement process to safeguard against potential hazards.

Tips to Prevent Future Issues

Maintaining optimal performance and extending the lifespan of your appliance requires proactive measures. Implementing simple practices can help you avoid potential malfunctions and ensure smooth operation.

Regular Cleaning: Keeping the device clean is essential. Accumulation of dirt and debris can hinder functionality. Regularly inspect and clean components to prevent buildup that may lead to inefficiencies.

Monitor Temperature: Ensure that the temperature settings are appropriate. Fluctuations can affect performance, so check regularly to maintain stability.

Inspect Water Supply: A consistent water supply is crucial. Regularly examine hoses and connections for leaks or blockages that could disrupt functionality.

Routine Maintenance: Schedule periodic check-ups with a qualified technician. Professional assessments can identify potential problems early and ensure that all components are working as intended.

Educate Yourself: Familiarize yourself with the operational guidelines. Understanding how your appliance works will help you identify issues and address them promptly, minimizing the risk of future complications.

When to Call Professional Support

There are situations when seeking assistance from a trained technician is advisable. Recognizing these moments can save time, prevent further damage, and ensure that your appliance functions efficiently.

Consider reaching out to a specialist in the following scenarios:

- Persistent Issues: If problems continue despite troubleshooting efforts, it may indicate a deeper underlying issue.

- Unusual Noises: Sounds that are out of the ordinary can suggest mechanical failure or malfunction.

- Temperature Fluctuations: Inability to maintain the desired conditions can lead to food spoilage and necessitates expert intervention.

- Leaks: Water accumulation around the unit may signify a serious problem that needs immediate attention.

- Error Codes: If the appliance displays error messages that you cannot resolve, professional guidance is essential.

Ultimately, ensuring the longevity and functionality of your appliance often requires the expertise of a qualified technician when issues escalate beyond basic maintenance.