Outdoor equipment is essential for maintaining various landscaping tasks, and keeping such tools in peak condition ensures both their longevity and optimal performance. When these machines experience operational issues, understanding basic troubleshooting and upkeep can save time and prevent further complications. This section explores foundational maintenance and troubleshooting approaches for these types of devices, highlighting essential techniques and tools required for successful upkeep.

Recognizing common symptoms and identifying causes can be invaluable in maintaining smooth functionality. From cleaning specific parts to adjusting settings, these practices will help you address issues promptly, ensuring your equipment remains efficient and ready for the next task. Detailed guidance on each step offers clarity for users of all experience levels, empowering you to handle potential challenges with confidence.

Whether you’re a professional landscaper or a homeowner managing your own garden, regular care of outdoor equipment is key. This guide outlines effective methods to sustain equipment health, improve performance, and extend the lifespan of your tools, making them reliable companions for an

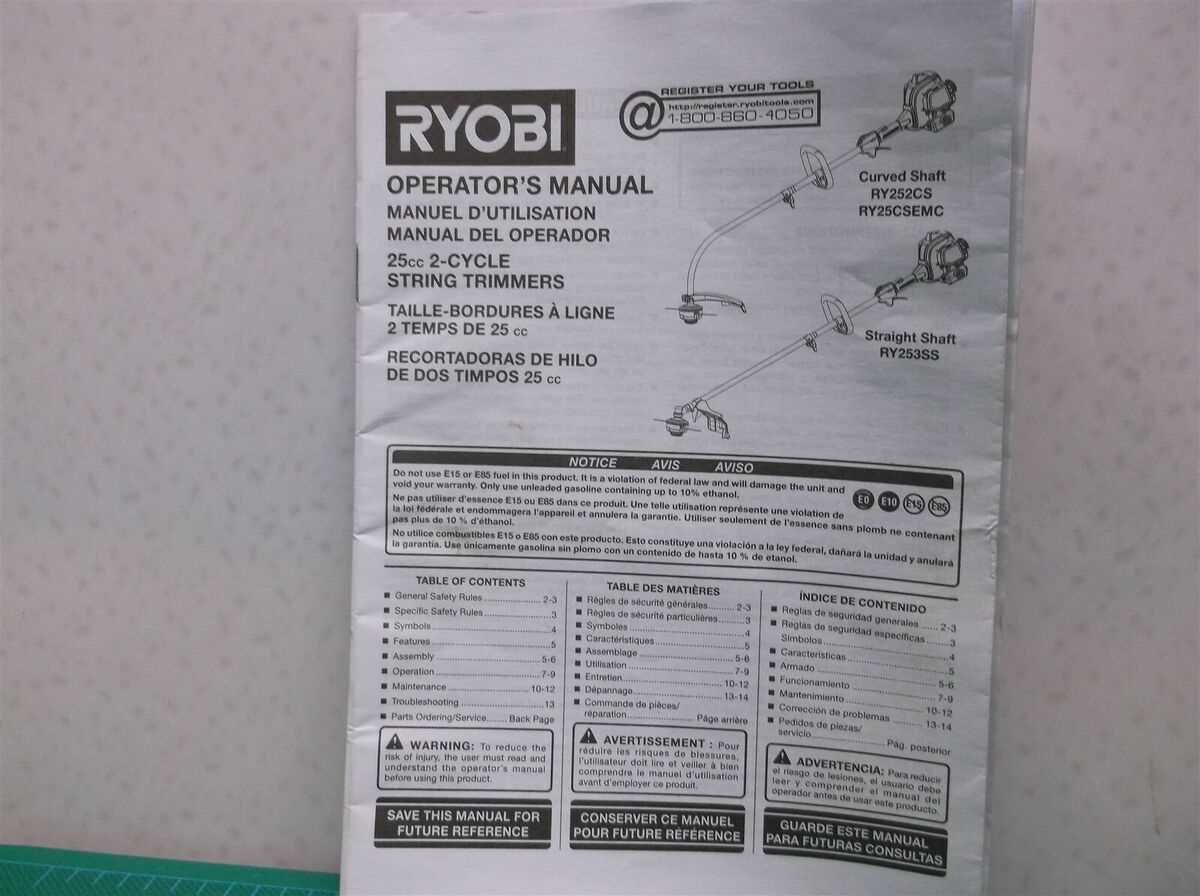

Equipment Maintenance Guide

Proper maintenance and care for outdoor machinery can significantly improve its performance and extend its lifespan. In this guide, we focus on essential techniques to keep your equipment operating smoothly, ensuring it withstands regular wear from intensive use.

Regular Cleaning and Inspection: Consistent upkeep starts with cleaning. Removing debris, dust, and grass from key components will help prevent blockages and overheating. Additionally, performing routine inspections helps identify signs of wear early, allowing for timely adjustments or replacements.

Fuel and Lubrication Tips: Ensuring your equipment has the right fuel mixture and fresh oil is essential for optimal functionality. Checking oil levels before each use helps avoid issues, and following recommended fuel ratios promotes smoother operation and engine health.

Air Filter Maintenance: Cleaning or replacing the air filter periodically keeps the engine running efficiently by allowing proper airflow. A clogged filter can reduce power and increase fuel consumption, so inspect it frequently and address any buildup.

Regular attention to these elements will help you achieve reliable performance, minimizing disruptions and maximizing durability.

Understanding Common Engine Problems

Small engine issues often stem from wear, inadequate maintenance, or environmental factors. Recognizing common symptoms can aid in identifying the source of a malfunction, enabling quick fixes and prolonging equipment life. This section explores typical problems that engines encounter, their causes, and how to address them effectively.

Frequent Causes of Engine Malfunctions

Engines may experience issues related to airflow, fuel quality, and spark consistency. Dirty filters, stale fuel, or worn spark plugs can disrupt engine performance, leading to stalling or difficulty starting. Regular inspection and cleaning of these components prevent most malfunctions.

Troubleshooting Techniques

When an engine fails to start or runs unevenly, basic troubleshooting can reveal the underlying cause. Common checks include inspecting fuel lines, ensuring sufficient oil levels, and testing spark plug functionality. The table below outlines prevalent problems and practical steps for addressing each.

| Problem | Potential Cause | Solution | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Engine won’t start | Empty fuel tank, dirty air filter | Refill fuel, clean or

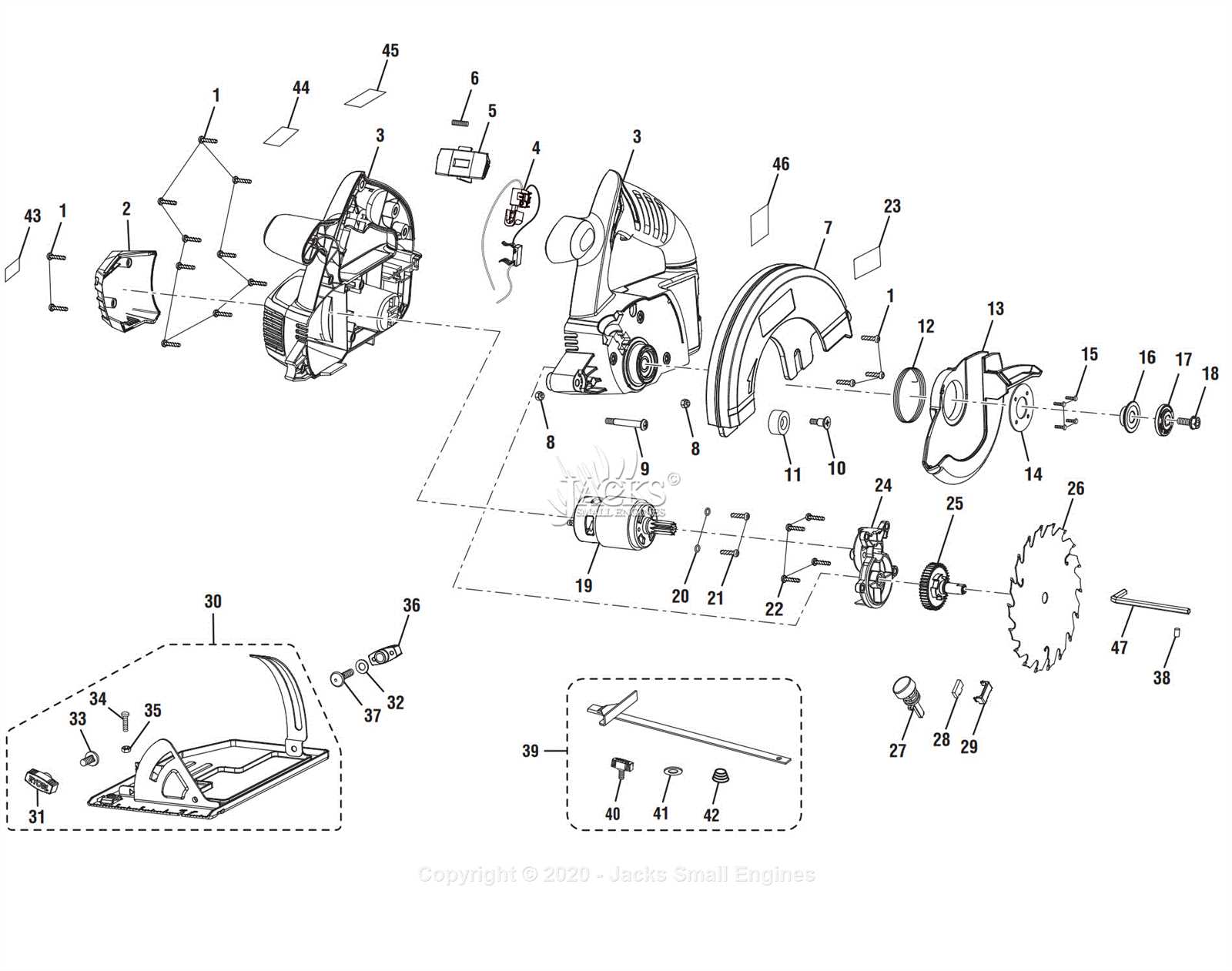

Inspecting the Carburetor for Issues

The carburetor plays a crucial role in ensuring the proper mixture of fuel and air reaches the engine. When issues arise, performance may drop, or the engine may struggle to start. Regular inspection helps in identifying potential problems early, preventing further complications. Checking for Blockages and Build-UpOne of the first steps in examining the carburetor is to look for any blockages or residue that could be obstructing fuel flow. Over time, debris and fuel deposits can accumulate, affecting the carburetor’s efficiency. Carefully detach the air filter and look into the carburetor openings, clearing any visible debris with a soft brush or compressed air. Testing the Diaphragm and GasketsInspect the diaphragm and gaskets for wear or cracks. These components should remain flexible and intact to maintain optimal pressure within the carburetor. Damaged or stiff gaskets can lead to air leaks, which impact fuel mixing. Replacing these parts when necessary can greatly enhance engine performance. Fuel System Troubleshooting TipsUnderstanding and maintaining the fuel system can help ensure smooth performance and avoid interruptions. Below are several approaches to help identify and resolve common fuel-related issues that may impact engine function. Common Issues and Causes

Steps for Diagnosing Fuel System Problems

|