In the realm of textile craftsmanship, having the right equipment is essential for achieving high-quality results. However, like any mechanical device, tools designed for fabric manipulation can experience issues over time. Understanding the nuances of these intricate devices not only enhances their longevity but also elevates the overall sewing experience.

This guide aims to provide a thorough exploration of common challenges faced by enthusiasts and professionals alike. With a focus on troubleshooting and upkeep, readers will discover valuable insights that will empower them to tackle a range of problems effectively. From minor adjustments to more complex malfunctions, this resource is designed to demystify the process and instill confidence in users.

Equipped with practical advice and clear instructions, this article will serve as an indispensable companion for anyone looking to optimize their crafting tools. Emphasizing a hands-on approach, it seeks to cultivate a deeper understanding of the mechanics involved, ultimately leading to more enjoyable and productive creative sessions.

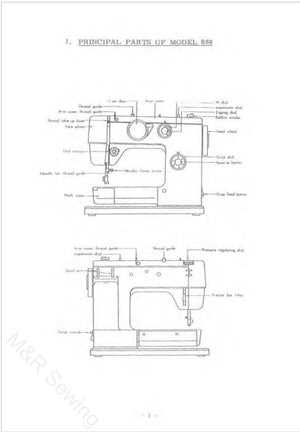

Overview of Riccar Sewing Machines

In the realm of textile crafting, certain brands stand out for their commitment to quality and innovation. This section provides an insightful look into a well-regarded name known for its reliability and user-friendly designs. Enthusiasts and professionals alike appreciate the combination of performance and versatility that these products offer.

The offerings are designed to cater to a wide range of needs, from simple alterations to intricate projects. With a focus on functionality, these tools are equipped with features that enhance creativity while ensuring ease of use. Durability is a hallmark, making them suitable for both casual users and seasoned artisans.

Furthermore, the brand emphasizes customer support, ensuring that users can access assistance and guidance whenever necessary. This commitment to service complements the high standards of craftsmanship, fostering a loyal community of creators. Overall, this name represents a blend of tradition and modernity, making it a go-to choice for those passionate about fabric arts.

Common Issues with Riccar Models

Users often encounter various challenges with their devices, ranging from operational inconsistencies to mechanical malfunctions. Understanding these frequent problems can help in diagnosing and addressing issues effectively. Awareness of typical faults allows for more efficient troubleshooting and maintenance.

One prevalent concern involves thread tension, which can lead to uneven stitching or thread breakage. This issue typically arises from misadjusted tension settings or the use of inappropriate thread types. Regularly checking and calibrating these settings can prevent such complications.

An additional common problem is the accumulation of lint and debris in the feed dogs and bobbin area. Neglecting regular cleaning can result in performance issues, including skipped stitches or jamming. It is advisable to incorporate routine cleaning into the upkeep process to maintain optimal functionality.

Another issue that frequently arises is the needle misalignment. A bent or dull needle can cause significant disruptions in operation, leading to poor quality work. Ensuring the needle is correctly installed and replacing it when necessary is essential for smooth performance.

Finally, electrical problems can also occur, often manifesting as power failures or erratic behavior. Checking connections and ensuring that the power supply is stable can help mitigate these concerns. Keeping an eye on any unusual signs can lead to prompt solutions, ensuring the longevity of the device.

Essential Tools for Repairing Machines

When it comes to maintaining and fixing devices, having the right equipment is crucial. A well-equipped toolkit not only facilitates the process but also enhances efficiency and effectiveness. Below are the indispensable instruments every technician should have at their disposal.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, is essential for loosening and tightening components.

- Wrenches: Adjustable and socket wrenches allow for proper handling of nuts and bolts.

- Pliers: Needle-nose and standard pliers help in gripping, twisting, and cutting wires or small parts.

- Multimeter: This device is crucial for diagnosing electrical issues by measuring voltage, current, and resistance.

- Lubricants: Oils and greases are necessary for ensuring smooth operation of moving parts.

- Cleaning supplies: Brushes and cloths keep the device free from dust and debris, which can affect performance.

Having these fundamental tools on hand not only simplifies the process but also allows for a more thorough and effective approach to addressing any challenges that arise.

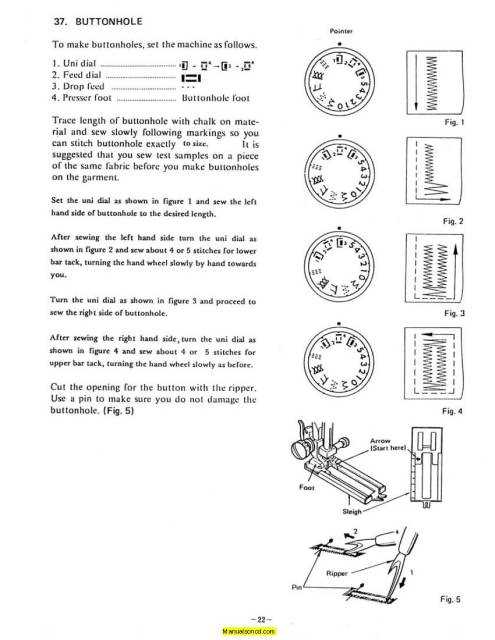

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to identify and resolve common issues encountered during the operation of your crafting device. By following these steps, you can efficiently diagnose problems, ensuring smooth performance and optimal results.

Identifying Common Issues

Begin by observing any irregularities during use. Look for symptoms such as inconsistent stitching, unusual noises, or difficulty in handling materials. Document these issues, as they will guide you through the troubleshooting process. Understanding the nature of the problem is crucial for effective solutions.

Step-by-Step Diagnosis

1. Check the Power Supply: Ensure the device is plugged in and the outlet is functional. A faulty connection can lead to operational failures.

2. Inspect the Threading: Incorrect threading is a frequent cause of performance issues. Re-thread the device, following the specified path in the user guidelines.

3. Evaluate the Needles: Dull or bent needles can cause complications. Replace them if necessary, using the appropriate type for your project.

4. Examine Tension Settings: Improper tension can lead to poor stitch quality. Adjust the tension dial according to the material being used.

5. Clean the Area: Dust and debris accumulation can hinder performance. Regularly clean the internal and external components to maintain optimal functioning.

By systematically addressing these areas, you can resolve most common challenges encountered during use, enhancing the longevity and efficiency of your crafting tool.

How to Clean Your Sewing Machine

Regular maintenance is essential for ensuring optimal performance and longevity of your crafting tool. Cleaning helps to remove dust, lint, and other debris that can affect functionality. This process not only enhances efficiency but also prevents potential issues that may arise from neglecting upkeep.

Follow these simple steps to keep your equipment in top condition:

| Step | Description |

|---|---|

| 1 | Unplug the device to ensure safety before starting any cleaning process. |

| 2 | Remove any attachments, such as feet and needle plates, to access all areas. |

| 3 | Use a soft brush or lint brush to gently sweep away dust and lint from the interior. |

| 4 | Wipe down exterior surfaces with a damp cloth to remove any accumulated grime. |

| 5 | Examine and clean the feed dogs if necessary, using a small brush or cloth. |

| 6 | Reassemble the parts and plug the device back in, ensuring everything is secured properly. |

By following these steps regularly, you can help maintain the performance and reliability of your equipment, making each crafting session smoother and more enjoyable.

Replacing Needles: A Quick Guide

Changing out the pointed tools in your fabric crafting apparatus is essential for maintaining optimal performance and achieving high-quality results. This brief guide will walk you through the steps to effortlessly replace these components, ensuring your project runs smoothly and efficiently.

Gather Your Supplies

Before starting, ensure you have the following items at hand: a new pointed tool, a small screwdriver (if needed), and a cleaning cloth. Having everything ready will make the process seamless and quick.

Step-by-Step Instructions

1. Turn Off the Device: Always disconnect from the power source to avoid accidents.

2. Remove the Current Tool: Depending on your model, this may involve loosening a screw or simply pulling it out.

3. Insert the New Tool: Position it correctly and secure it in place, ensuring it is firmly attached.

4. Check Alignment: Ensure the new component is aligned properly for optimal function.

5. Test the Setup: Power on your apparatus and run a quick test on scrap fabric to confirm everything works smoothly.

Following these straightforward steps will enhance your crafting experience and ensure excellent results every time.

Maintaining Your Riccar Sewing Machine

Proper upkeep is essential for ensuring longevity and optimal performance of your device. Regular care not only enhances its functionality but also prevents potential issues that may arise over time. By following a few simple steps, you can keep your equipment in excellent condition.

Essential Maintenance Steps

- Clean the exterior regularly to remove dust and debris.

- Oil the moving parts as recommended by the manufacturer.

- Check and replace needles when they become dull or damaged.

- Inspect the cords and foot pedal for wear or damage.

Storage Tips

- Keep the device covered when not in use to protect it from dust.

- Avoid placing it in direct sunlight or areas with extreme temperatures.

- Store in a dry environment to prevent moisture-related issues.

Following these guidelines will help ensure your apparatus remains reliable and efficient for many years to come.

Identifying and Fixing Tension Problems

Correct tension is crucial for achieving optimal results when crafting fabric items. Imbalances can lead to various issues, such as puckering, uneven stitching, or thread breakage. This section will guide you through recognizing common signs of tension discrepancies and provide practical solutions to address them effectively.

To understand whether tension is causing issues, look for these typical symptoms:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Puckered fabric | Too much tension | Reduce the tension settings gradually and test. |

| Loose stitches | Insufficient tension | Increase the tension slightly and test on scrap fabric. |

| Thread breakage | Tension too high or poor quality thread | Check tension settings and consider using a different thread. |

| Uneven stitching | Misaligned threading or tension imbalance | Re-thread according to the guidelines and adjust tension as needed. |

By systematically analyzing these signs and applying the corresponding adjustments, you can ensure smoother operations and enhance the quality of your projects. Regular maintenance and periodic checks will also help prevent tension-related issues in the future.

Electrical Issues: Diagnosis and Repair

Understanding electrical problems is crucial for maintaining optimal functionality of your device. These issues can range from minor faults to significant failures, affecting performance and reliability. Proper diagnosis is essential to identify the root cause and implement effective solutions, ensuring that the equipment operates smoothly.

Begin by checking the power source. Ensure that the outlet is functional and that all connections are secure. A multimeter can be a valuable tool to measure voltage and continuity, helping you pinpoint any interruptions in the electrical flow. If the power supply checks out, investigate the internal components, such as the wiring and circuit boards, for signs of damage or wear.

Common symptoms of electrical failures include unusual noises, inconsistent operation, or complete shutdowns. If any of these occur, proceed to isolate the issue by testing each component methodically. This can involve inspecting fuses, relays, and other electronic parts for signs of malfunction. Replace any defective elements with compatible replacements to restore functionality.

After addressing any identified issues, reassemble the device carefully and conduct a thorough test. Monitoring its performance over time can help detect any recurring problems, allowing for proactive maintenance. By taking these steps, you can ensure longevity and reliability in your equipment.

Understanding Bobbin and Threading Issues

Proper function of your crafting device relies heavily on the accuracy of the bobbin and threading processes. Misalignment or improper setup can lead to a variety of problems that affect performance and the quality of your projects. Identifying these common concerns is crucial for achieving optimal results.

Bobbin Problems: One of the primary issues arises from incorrect bobbin placement. If the bobbin is not seated properly, it can cause uneven tension and result in thread bunching. Additionally, using a damaged or incompatible bobbin can lead to similar complications. Regularly checking the condition of your bobbin and ensuring it fits correctly is essential.

Threading Complications: Incorrect threading is another common challenge. If the upper thread is not threaded through all necessary guides and tension discs, it can cause skips in stitches or breakage. It is important to follow the threading path meticulously, ensuring each step is followed. Pay attention to the tension settings, as too loose or too tight can also impact the outcome.

In summary, understanding the intricacies of bobbin placement and threading is vital. Addressing these issues proactively can enhance the performance of your crafting apparatus and lead to more satisfying results in your projects.

When to Seek Professional Help

Understanding when to turn to an expert can be crucial for maintaining your equipment in optimal condition. Certain issues may appear minor but could lead to more significant complications if not addressed properly. Recognizing the signs that indicate the need for professional intervention can save both time and resources in the long run.

Signs You Need Assistance

There are specific indicators that suggest it might be time to consult a specialist. These signs often point to underlying problems that require advanced knowledge and experience to resolve effectively.

| Issue | Description |

|---|---|

| Persistent Malfunctions | If issues continue despite attempts at troubleshooting, professional help is advisable. |

| Unusual Noises | Strange sounds can signal serious mechanical problems that need expert assessment. |

| Frequent Breakdowns | Regular interruptions in performance may indicate deeper issues requiring specialized knowledge. |

| Complex Problems | Challenges involving intricate systems are best handled by those with the right expertise. |

Benefits of Professional Support

Engaging a qualified technician not only ensures that problems are diagnosed accurately but also provides peace of mind. Experts can often identify potential issues before they escalate, leading to longer-lasting performance and efficiency. Investing in professional help can ultimately enhance the lifespan of your equipment and improve your overall experience.

Parts Replacement: A How-To Guide

Replacing components in your device can significantly enhance its performance and longevity. This guide provides a step-by-step approach to help you identify, source, and install various parts effectively, ensuring your equipment remains in optimal condition.

Identifying Necessary Components

The first step in any replacement process is to pinpoint which parts need to be changed. Common signs of wear include unusual noises, irregular functioning, or visible damage. Refer to the following table to identify typical components that may require replacement:

| Component | Symptoms of Wear | Replacement Frequency |

|---|---|---|

| Needle | Skipped stitches, breakage | Every 6-8 hours of use |

| Feed Dogs | Poor fabric movement | As needed |

| Presser Foot | Inconsistent pressure | When damaged |

| Belts | Slipping or fraying | Annually |

Installation Process

Once you have identified the parts that need replacement, follow these steps for successful installation. Always ensure you have the appropriate tools and a clean workspace before you begin:

1. Gather Tools: Ensure you have the necessary tools such as screwdrivers, pliers, and any specific tools recommended for your parts.

2. Remove Old Parts: Carefully detach the worn components by following the manufacturer’s guidelines to avoid causing additional damage.

3. Install New Parts: Position the new components accurately and secure them in place, ensuring they are fitted as per the specifications.

4. Test the Equipment: After installation, conduct a test run to confirm that everything functions correctly. Address any issues immediately.

By following these guidelines, you can effectively replace essential parts and maintain the efficiency of your device.

Resources for Further Assistance

For those seeking additional guidance on maintaining or troubleshooting their devices, a variety of resources are available. These can provide invaluable support, whether through online forums, instructional videos, or printed literature.

- Online Forums: Engage with communities of enthusiasts and experts who can share insights and experiences.

- Video Tutorials: Platforms like YouTube host a wealth of visual guides that demonstrate techniques and solutions step-by-step.

- User Guides: Access official documentation from manufacturers, often available in PDF format, to gain detailed information on your device.

- Local Workshops: Consider attending classes or workshops in your area where experienced individuals can provide hands-on assistance.

- Support Hotlines: Reach out to customer service representatives who can offer expert advice tailored to specific issues.

By utilizing these resources, individuals can enhance their understanding and effectively address any challenges they encounter.