Every engine has its own intricacies and unique features that contribute to its performance and longevity. Having a comprehensive understanding of these elements is essential for maintaining optimal functionality. This section delves into the various components that make up a specific engine type, providing valuable insights for enthusiasts and professionals alike.

Detailed illustrations serve as an invaluable resource, allowing users to visualize the configuration and relationship between different elements. By examining these visuals, one can gain clarity on how each part interacts within the overall system. This knowledge is crucial for anyone looking to enhance their expertise in engine mechanics.

Furthermore, knowing the specifics of each component not only aids in troubleshooting but also empowers users to undertake projects with confidence. Whether you’re conducting maintenance or seeking to enhance performance, a solid grasp of the inner workings is indispensable. Join us as we explore the various facets of this engine type, equipping you with the tools necessary for success.

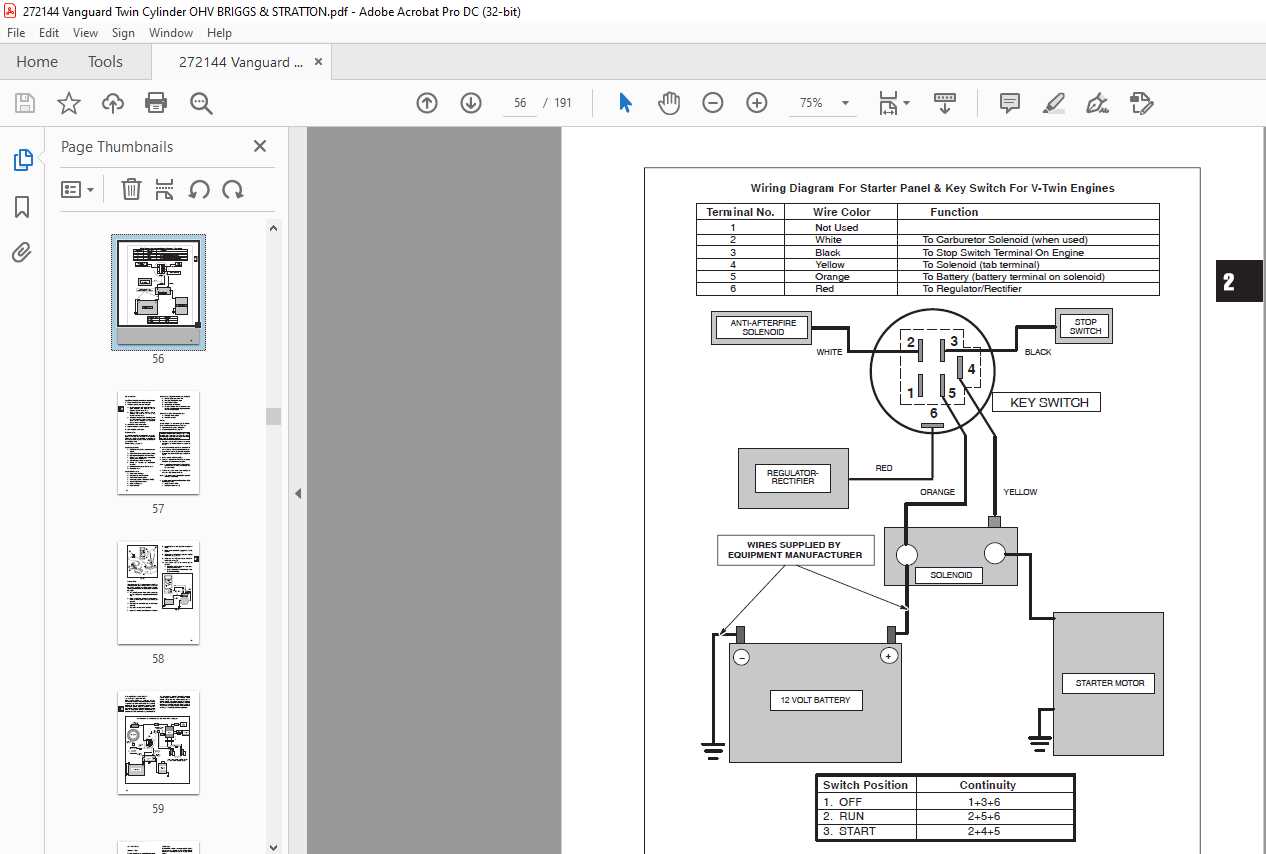

Understanding V-Twin Engines

V-engines are a popular choice in various applications due to their unique design and performance characteristics. These power units feature two sets of cylinders arranged in a ‘V’ configuration, allowing for a more compact and efficient engine layout. This design not only enhances power output but also contributes to smoother operation and reduced vibration.

One of the key advantages of this engine type is its ability to deliver a balance of torque and horsepower. With two cylinders working in unison, these engines can achieve impressive performance across a range of speeds. This makes them particularly suitable for demanding tasks, such as in heavy machinery and recreational vehicles.

Additionally, the construction of these engines often leads to improved cooling and airflow. The angled arrangement of the cylinders facilitates better heat dissipation, which is crucial for maintaining optimal operating temperatures. This feature can significantly enhance the longevity and reliability of the engine, making it a preferred choice for many users.

In summary, the design and functionality of V-engines provide numerous benefits, from power delivery to thermal efficiency. Understanding these aspects can aid in making informed decisions regarding their application and maintenance.

Briggs and Stratton Overview

This section provides insight into a renowned manufacturer of small engines, known for their durability and performance. Their products are widely used across various applications, ensuring reliability and efficiency in operation.

The company’s legacy spans over a century, highlighting their commitment to innovation and quality. They offer a diverse range of engine types, each tailored for specific uses. Key features include:

- Robust construction for long-lasting performance

- Wide applicability in residential and commercial settings

- Continuous advancements in technology for improved efficiency

In addition to engines, they also provide a variety of accessories and support options, catering to customer needs. Their reputation is built on:

- Dependability in demanding environments

- Comprehensive service networks for assistance

- Commitment to sustainable practices and eco-friendly solutions

Overall, this manufacturer remains a pivotal player in the small engine industry, reflecting a dedication to quality and customer satisfaction.

Importance of Repair Manuals

Having comprehensive guides is essential for anyone working with machinery. These resources provide valuable insights, ensuring users understand how to effectively troubleshoot, maintain, and restore equipment to optimal condition.

Key benefits include:

- Enhanced Understanding: Detailed instructions clarify complex processes, enabling users to grasp the intricacies of their machinery.

- Time Efficiency: Quick access to information reduces downtime, allowing for faster resolution of issues.

- Cost Savings: By empowering individuals to perform their own maintenance, these guides help avoid unnecessary service fees.

- Safety: Knowledge of proper procedures minimizes the risk of accidents, ensuring safe operation.

- Longevity: Regular upkeep guided by accurate resources extends the life of equipment.

In summary, these documents serve as indispensable tools, promoting a deeper connection between users and their machines while fostering responsible ownership and effective stewardship.

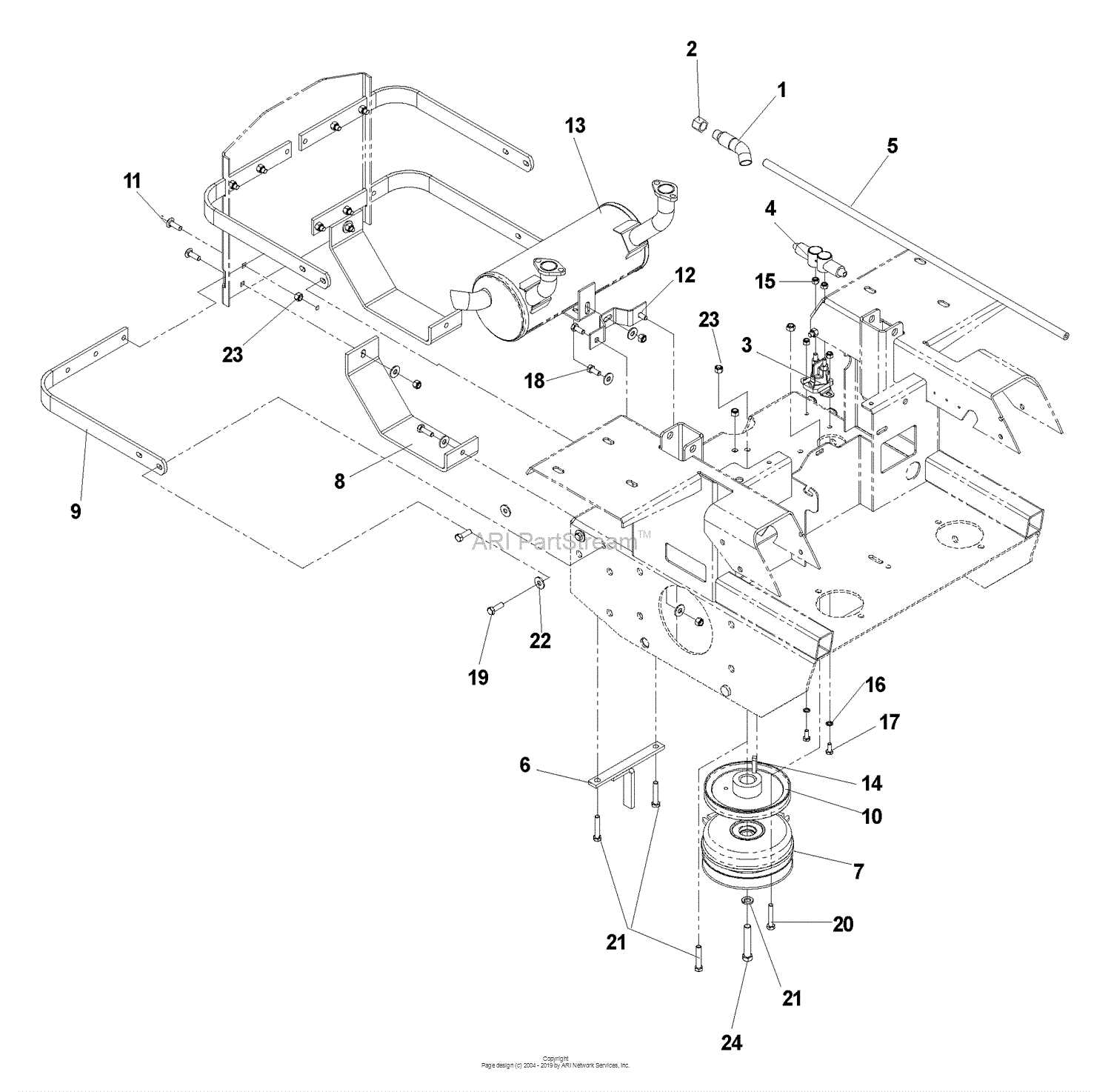

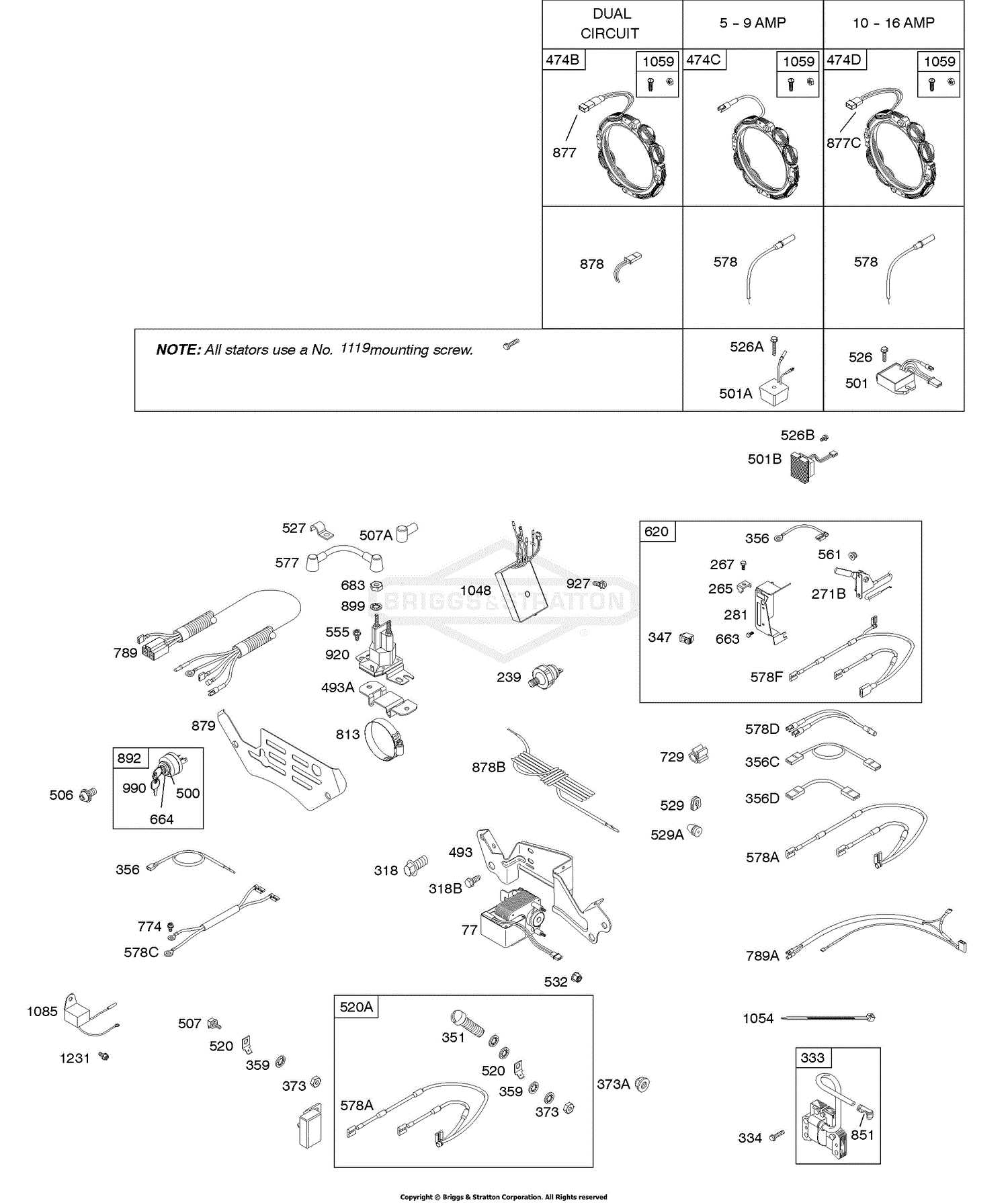

Parts Identification for Vanguard Engines

Understanding the various components of an engine is crucial for maintaining its performance and longevity. Identifying each element accurately can significantly enhance the efficiency of troubleshooting and replacements. This section delves into essential identifiers that aid in recognizing the specific elements within these powerful machines.

Key Components Overview

Engines consist of numerous critical elements, each playing a vital role in overall functionality. From the fuel system to the ignition assembly, recognizing each part’s location and purpose can streamline the maintenance process. Familiarity with these components not only facilitates repairs but also supports informed decision-making regarding upgrades and replacements.

Visual Identification Techniques

Utilizing visual aids can greatly enhance the identification process. Diagrams and illustrations serve as invaluable resources for both novices and experienced technicians alike. By comparing physical components to labeled images, one can easily pinpoint necessary replacements or adjustments. Additionally, consulting specific reference materials can provide deeper insights into each component’s function and importance.

Common Issues in V-Twin Models

Understanding the typical problems encountered in these powerful engine designs is essential for optimal performance and longevity. Various factors can contribute to operational difficulties, ranging from mechanical wear to fuel system complications. Identifying these common issues allows for timely intervention and maintenance, ensuring smooth operation.

Mechanical Failures

One prevalent concern involves the breakdown of internal components. Over time, parts such as pistons, crankshafts, and valves may wear down, leading to decreased efficiency and power loss. Regular inspection can help in identifying wear patterns early, minimizing extensive damage.

Fuel System Challenges

Another frequent issue arises from the fuel delivery system. Clogs, leaks, or improper fuel mixtures can hinder engine performance. Ensuring that the fuel lines are clean and that the correct type of fuel is used can prevent these complications.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Piston Wear | Power loss, excessive noise | Inspect and replace worn pistons |

| Valve Problems | Rough idling, backfiring | Adjust or replace valves as needed |

| Fuel Leaks | Difficulty starting, fuel odor | Check and seal any leaks in fuel lines |

| Clogged Filters | Reduced power, engine stalling | Replace fuel and air filters regularly |

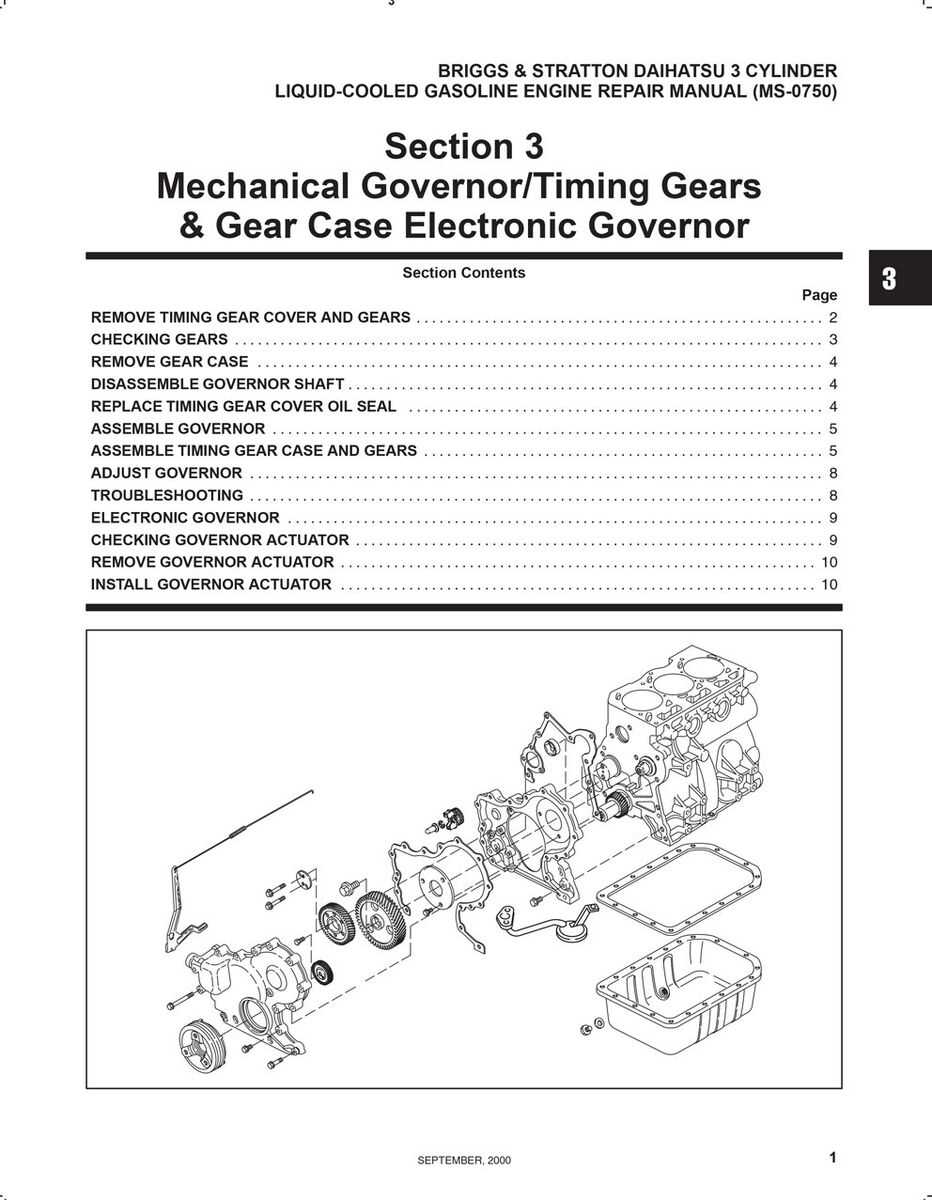

Step-by-Step Repair Procedures

This section outlines a systematic approach to address common issues with small engines. Following a structured method not only ensures thorough diagnostics but also enhances the likelihood of restoring functionality effectively.

Initial Assessment

Begin by conducting a visual inspection of the engine. Look for any signs of wear, damage, or leaks. Checking fluid levels and connections is essential at this stage. Identifying obvious problems early can save time during the subsequent steps.

Disassembly and Inspection

Once the initial assessment is complete, proceed with disassembling the necessary components. Keep track of all parts and their arrangement for easier reassembly. Carefully examine each component for wear or damage, making note of any parts that may require replacement. This thorough inspection is crucial for effective troubleshooting.

Using the Parts Diagram Effectively

Understanding the layout and components of your equipment can greatly enhance your maintenance and troubleshooting processes. By familiarizing yourself with a visual representation of the individual elements, you can streamline your approach to servicing and ensure that you have a clear roadmap for your tasks. This knowledge empowers you to tackle issues with confidence and precision.

Identifying Components

One of the primary benefits of a visual guide is the ability to quickly identify specific components. Each element is labeled and organized, making it easier to locate the necessary pieces for replacement or inspection. This can save time and prevent frustration, especially when dealing with complex machinery. Make sure to familiarize yourself with the layout, as understanding where each component is situated is crucial for efficient work.

Enhancing Troubleshooting Skills

When faced with operational challenges, a visual reference can be invaluable. By cross-referencing the symptoms with the elements shown in the illustration, you can narrow down potential issues more effectively. Highlighting key parts that are commonly associated with problems can lead to quicker resolutions. Emphasizing the importance of thorough examination will help in avoiding unnecessary replacements and ensure that the underlying cause is addressed.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your engine requires regular upkeep and attention. Following a consistent maintenance routine can significantly extend its lifespan and efficiency, reducing the likelihood of unexpected issues.

- Regular Inspections: Periodically check for any signs of wear or damage. Look for leaks, cracks, or unusual noises.

- Clean Air Filters: Replace or clean air filters regularly to ensure proper airflow and prevent dust and debris from entering the engine.

- Change Oil: Follow the recommended intervals for oil changes. Fresh oil keeps components lubricated and reduces friction.

- Check Spark Plugs: Inspect spark plugs for signs of wear and replace them as needed. Proper ignition is crucial for optimal performance.

Incorporating these practices into your routine can lead to better functionality and longevity. Always refer to your specific guidelines for any additional recommendations or requirements.

Tools Required for Repairs

When undertaking maintenance tasks on small engines, having the right instruments is essential for achieving effective outcomes. The appropriate equipment not only simplifies the process but also ensures safety and precision during the work.

Essential Tools

- Socket Set

- Wrenches

- Screwdrivers

- Torque Wrench

- Air Compressor

Additional Equipment

- Safety Goggles

- Gloves

- Cleaning Brushes

- Fuel Stabilizer

- Multimeter

Having these tools readily available will facilitate a smoother process and enhance the overall efficiency of your tasks. Make sure to maintain your equipment in good condition for optimal performance.

Safety Precautions During Repair

When engaging in maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Proper preparation and awareness of potential hazards can make the process more efficient and secure. By following established guidelines, individuals can protect themselves and ensure a smooth workflow.

Essential Safety Measures

Implementing fundamental safety practices is crucial. Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. Additionally, ensuring a clean workspace can minimize risks associated with clutter and unexpected hazards.

Tools and Equipment Safety

Using the correct tools for specific tasks can significantly reduce the likelihood of accidents. Regularly inspect tools for wear and tear, and replace any damaged items immediately. Always follow the manufacturer’s instructions when utilizing equipment to ensure proper handling and usage.

| Safety Tip | Description |

|---|---|

| Wear PPE | Always use gloves, goggles, and protective clothing. |

| Keep Workspace Clean | A tidy area reduces the risk of tripping and accidents. |

| Inspect Tools | Check tools for damage before use to ensure safety. |

| Follow Instructions | Adhere to guidelines provided by manufacturers for safe operation. |