Understanding the intricacies of maintaining equipment is essential for ensuring longevity and optimal performance. Proper attention to detail in the upkeep process can prevent significant issues down the line. This section delves into the essential practices and techniques that facilitate effective management of mechanical devices.

Comprehensive knowledge about components and their functions empowers users to address potential challenges proactively. By familiarizing oneself with operational protocols, individuals can enhance their proficiency in handling various situations that may arise during usage. The subsequent information provides valuable insights into troubleshooting and enhancing functionality.

Regular examination and timely interventions not only improve efficiency but also contribute to safety. By implementing recommended procedures, users can significantly mitigate risks associated with operational failures. This guidance aims to equip users with the necessary tools and understanding to navigate common concerns effectively.

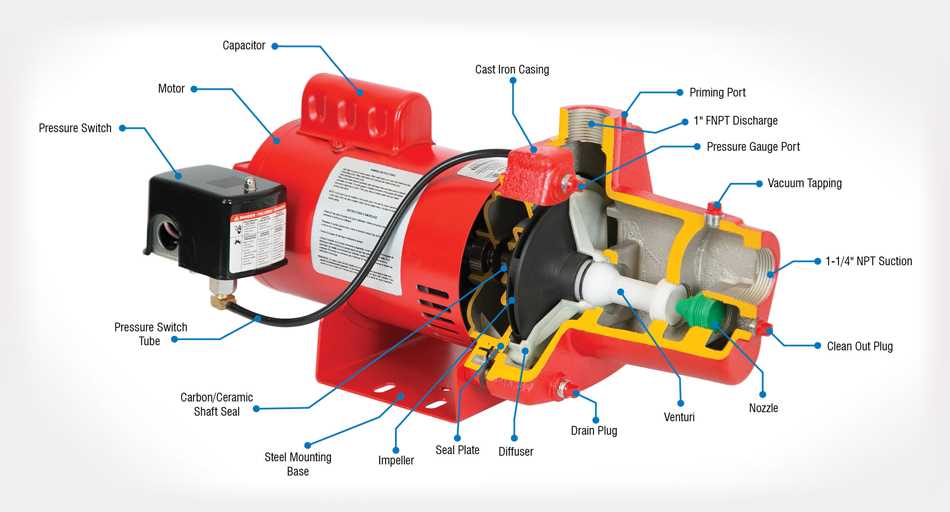

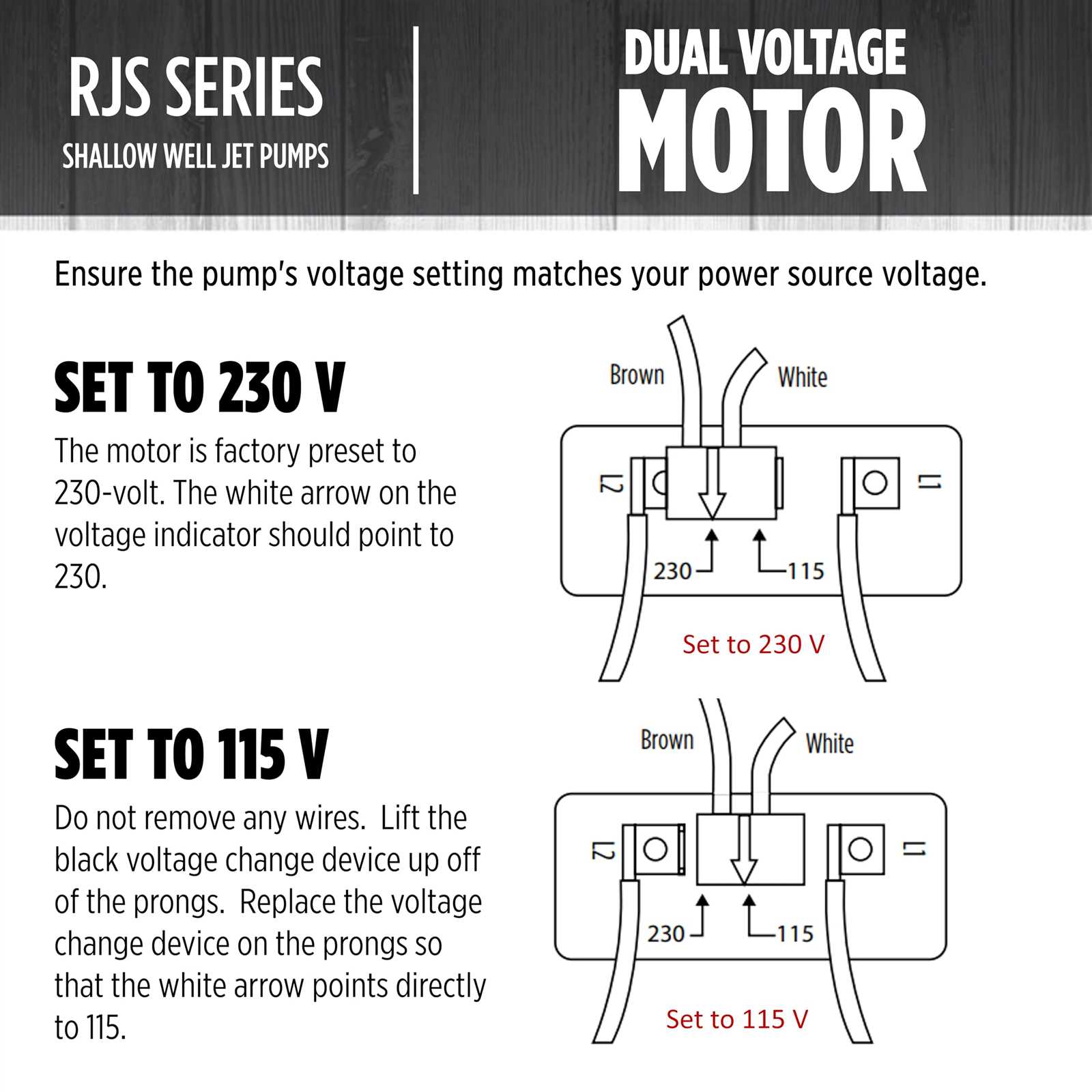

This section will delve into the essential elements that make up a typical fluid transfer device. By exploring each component, readers will gain a comprehensive understanding of how these parts function together to ensure efficiency and reliability. Familiarity with these elements is crucial for troubleshooting and maintaining the unit effectively.

Key Elements of the Mechanism

The primary parts of the device include the motor, housing, and various seals and valves. Each element plays a pivotal role in the overall operation, contributing to the smooth movement of fluids. Understanding their functions will aid users in identifying potential issues and implementing appropriate solutions.

Importance of Regular Maintenance

Common Issues in Pump Operation

Understanding the frequent complications that can arise during the functioning of fluid transfer devices is crucial for maintaining efficiency and performance. By recognizing these challenges, operators can implement effective solutions to enhance longevity and reliability.

Frequent Complications

- Inconsistent flow rates

- Unusual noises during operation

- Vibrations that may indicate imbalance

- Overheating of components

Possible Causes

- Clogs in the intake or discharge lines

- Wear and tear on seals or bearings

- Improper alignment during installation

- Inadequate lubrication of moving parts

Identifying these issues early allows for timely interventions, which can prevent extensive damage and costly repairs. Regular maintenance and inspections are recommended to address these potential problems before they escalate.

Troubleshooting Techniques for Repairs

Identifying issues in equipment often requires systematic approaches to ensure effective resolution. By employing various methods, one can diagnose problems accurately and apply the necessary solutions efficiently.

Here are some common techniques to consider during the troubleshooting process:

| Technique | Description |

|---|---|

| Visual Inspection | Examine the unit for obvious signs of damage, wear, or misalignment. |

| Functional Testing | Operate the device under normal conditions to observe performance and identify irregularities. |

| Listening for Sounds | Pay attention to unusual noises during operation, which may indicate underlying issues. |

| Pressure Checks | Monitor pressure levels to detect discrepancies that could suggest malfunctions. |

| Component Testing | Test individual parts for functionality to isolate the source of the problem. |

Essential Tools for Pump Maintenance

Regular upkeep of fluid handling equipment is crucial for optimal performance and longevity. To ensure efficiency, having the right instruments on hand can make a significant difference. Below is a list of fundamental tools necessary for effective servicing and maintenance tasks.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening or tightening fittings and connections. |

| Screwdriver Set | Essential for removing and securing screws in various components. |

| Multimeter | Helps in checking electrical connections and diagnosing issues. |

| Pressure Gauge | Monitors system pressure to ensure it operates within specified limits. |

| Leak Detection Kit | Identifies any leaks in the system that may compromise functionality. |

Step-by-Step Repair Process

This section outlines a systematic approach to restoring functionality to a malfunctioning device. Following these steps will help ensure a thorough evaluation and effective resolution of issues encountered during operation.

- Initial Assessment:

- Examine the equipment for visible signs of damage.

- Identify any unusual sounds or performance issues.

- Check for leaks or fluid irregularities.

- Disassembly:

- Gather necessary tools for disassembly.

- Carefully remove outer casing and components.

- Document the arrangement of parts for reassembly.

- Component Inspection:

- Inspect internal parts for wear or damage.

- Clean any debris or buildup affecting performance.

- Test electrical connections and components.

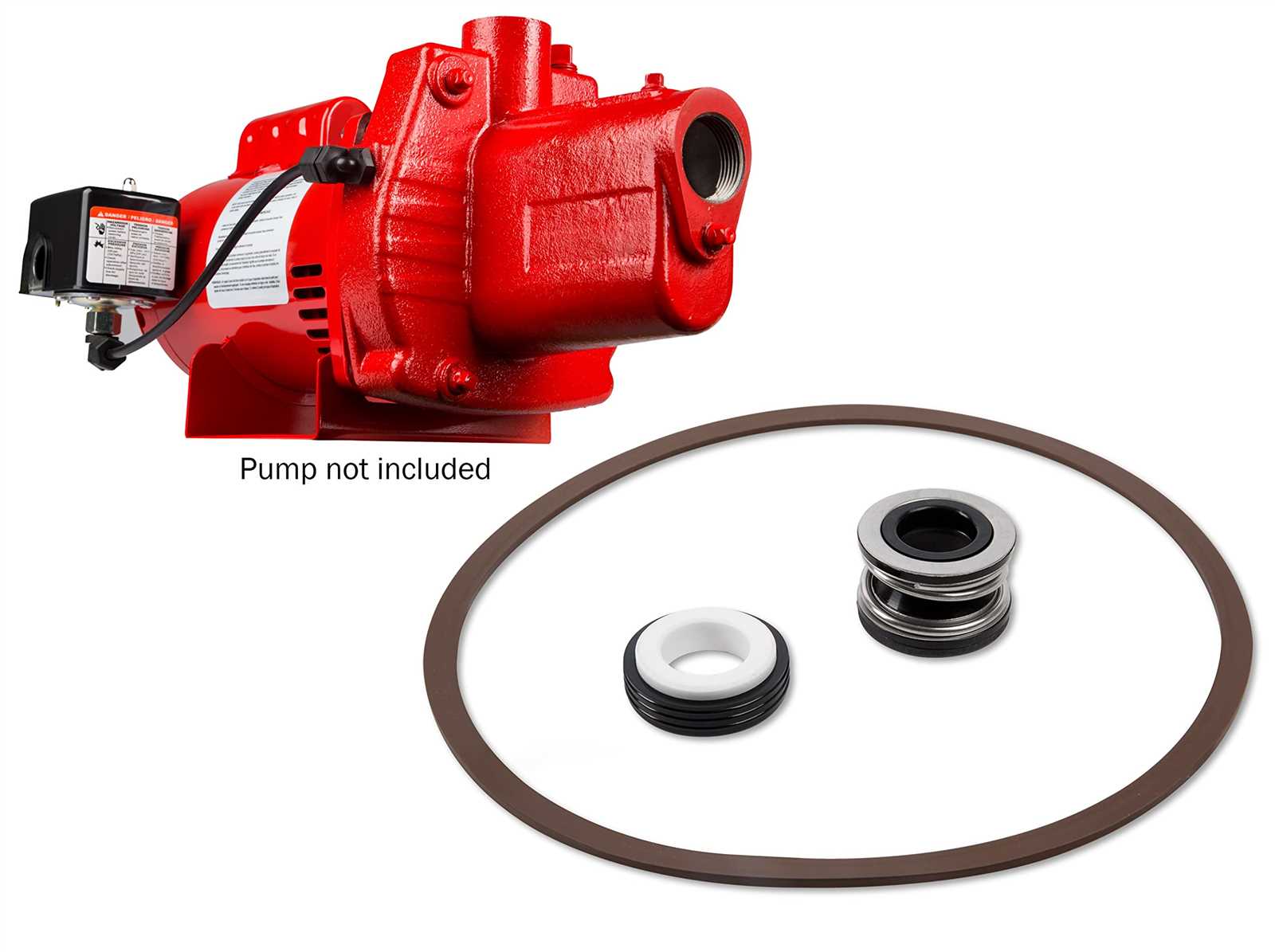

- Replacement and Repair:

- Replace any worn or broken parts with suitable alternatives.

- Make necessary adjustments to ensure proper alignment.

- Use appropriate lubricants or sealants as needed.

- Reassembly:

- Carefully put all components back in their original places.

- Ensure all screws and fasteners are securely tightened.

- Double-check that all connections are intact.

- Final Testing:

- Power on the device and monitor its operation.

- Listen for any irregular noises during functionality checks.

- Verify that performance meets expected standards.

Following these outlined steps will facilitate an effective resolution to the encountered issues and restore the device to its optimal performance.

Safety Precautions During Repairs

When performing maintenance tasks, it is essential to prioritize safety to prevent accidents and ensure a smooth process. Proper precautions not only protect the individual conducting the work but also safeguard the equipment and surrounding environment.

First and foremost, always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. This gear acts as a barrier against potential hazards, including sharp objects and harmful substances.

Additionally, ensure that the workspace is well-ventilated and free from clutter. A tidy area reduces the risk of slips, trips, and falls, allowing for a more efficient workflow. Keep all necessary tools and materials organized and within reach to minimize distractions.

Furthermore, familiarize yourself with the specific guidelines and protocols related to the equipment you are handling. Understanding the operational and safety features will help mitigate risks during the procedure.

Lastly, if any uncertainty arises regarding the task, do not hesitate to seek assistance or consult with a knowledgeable individual. Safety should always be the primary focus, and taking the time to ensure correct practices can prevent mishaps and promote a successful outcome.

Preventive Measures for Longevity

Ensuring the extended lifespan of equipment involves a series of proactive strategies. These measures are designed to minimize wear and tear, thereby enhancing operational efficiency and reliability over time.

Regular Maintenance Practices

Consistent upkeep is crucial for preventing unexpected breakdowns. Implementing a routine schedule can significantly contribute to longevity. Key practices include:

- Conducting routine inspections to identify wear and tear.

- Cleaning components to prevent buildup of debris.

- Lubricating moving parts as recommended.

Optimal Operating Conditions

Maintaining suitable operating environments plays a vital role in enhancing durability. Consider the following factors:

- Ensure proper ventilation to prevent overheating.

- Avoid exposure to extreme temperatures or humidity.

- Monitor load levels to prevent overexertion.

When to Seek Professional Help

There are times when addressing issues with equipment requires expertise beyond basic troubleshooting. Recognizing these moments can prevent further complications and ensure proper functionality.

If you encounter persistent problems despite following standard guidelines, it may be wise to consult a specialist. Additionally, if you notice unusual sounds, leaks, or performance drops, these can indicate underlying issues that need professional assessment.

Attempting to fix complex problems without adequate knowledge can lead to more significant damage. Therefore, when in doubt, reaching out to a qualified technician is often the best course of action.

Frequently Asked Repair Questions

This section addresses common inquiries regarding the maintenance and troubleshooting of various fluid-moving devices. Understanding these issues can greatly enhance efficiency and prolong the lifespan of the equipment.

What are the signs that indicate a malfunction? Identifying symptoms such as unusual noises, decreased output, or leaks can help pinpoint potential problems before they escalate.

How often should maintenance be performed? Regular upkeep is essential; it’s advisable to follow a scheduled routine based on the manufacturer’s recommendations to ensure optimal performance.

Can I fix the issues myself, or should I call a professional? Many issues can be addressed with basic troubleshooting; however, complex problems may require the expertise of a certified technician.

What tools are necessary for basic upkeep? A standard toolkit including wrenches, screwdrivers, and gauges is typically sufficient for routine maintenance tasks.

Where can I find replacement parts? Replacement components are often available through authorized distributors or online retailers specializing in equipment supplies.