In this section, we explore the essential steps for the safe and efficient operation of a reliable winch system. Understanding how to handle each feature can greatly improve the experience of both setup and usage. Here, you’ll find insightful guidance on how to make the most of every function and keep your equipment in peak condition.

Detailed instructions will take you through each aspect of the setup, usage, and upkeep process, ensuring that you have all the necessary information to optimize performance. From initial connection to troubleshooting, these steps help guarantee that you are well-prepared to handle any situation that might arise.

Additionally, practical tips on regular maintenance and safety protocols are included to enhance the longevity and reliability of your equipment. Dive into each section to gain a complete understanding of how to maintain consistent, smooth operation and prevent common issues.

This guide provides a detailed overview of essential aspects for understanding and operating this robust recovery tool. It covers key components, proper handling techniques, safety measures, and maintenance tips. Each section is tailored to help users gain confidence in setup, efficient use, and basic troubleshooting practices for continued reliable performance.

Key Components and Functionality

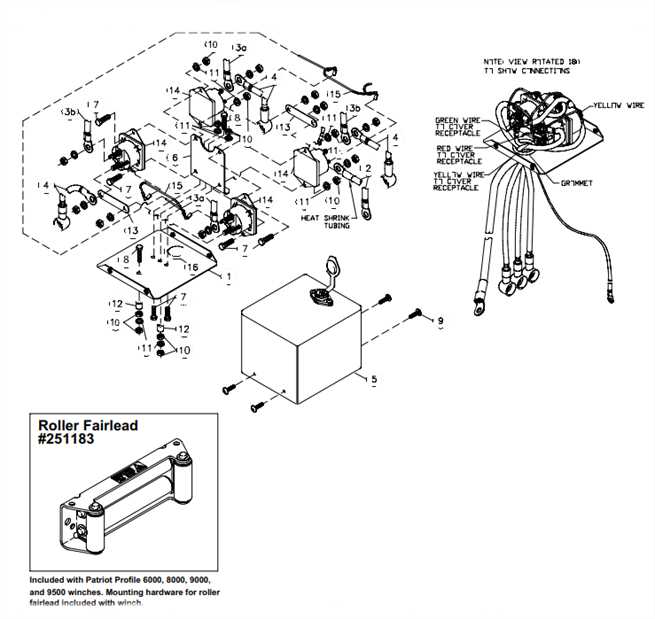

Familiarizing oneself with the fundamental parts and operational capabilities is crucial. This section provides an overview of the main components, such as the power system, cable, and control mechanisms, and how they interact to deliver strong and reliable pulling power.

Setup and Installation

- Proper attachment techniques for secure and effective installation

- Step-by-step mounting instructions for various vehicle types

- Essential checks before initial use to ensure safe operation

- Safety Features: An overview of essential s

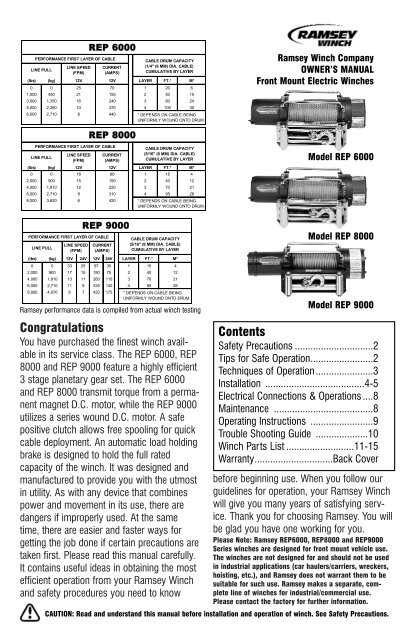

Key Specifications and Capabilities

Understanding the main features and operational strengths of this equipment provides a solid foundation for effective and safe use. It offers a range of capabilities designed to enhance performance in demanding tasks, ensuring both reliability and durability in challenging environments.

Built with a focus on efficiency, this model combines powerful mechanics with user-friendly controls, allowing for streamlined operation even in high-stress situations. Its design emphasizes resilience, making it suitable for various applications where strength and precision are essential.

Among its core specifications, the equipment includes a robust motor, optimized for consistent power output, and a durable build, meant to withstand intensive use. Enhanced by efficient torque management, this model supports controlled operation, adapting seamlessly to the user’s requirements.

Additional capabilities include advanced safety mechanisms to protect both the operator and the device, along with adaptable mounting options for diverse setups. Overall, these specifications make it an invaluable tool, offering both stability and flexibility for a wide range of applications.

Installation Guidelines for Optimal Use

Proper installation ensures reliable performance and enhances the longevity of equipment. Following these setup guidelines will help maximize functionality and reduce wear over time, contributing to a smoother operation in demanding environments.

Preparation and Placement

Before starting the setup, choose a stable and suitable surface for installation. Ensure the area is free from obstacles and provides enough space to accommodate the equipment securely. Verify that all mounting points and attachments are clean and robust, minimizing any potential shifts during operation.

Securing the Components

Once the placement is ready, align the mounting brackets and fasten them tightly using the recommended tools and hardware. Secure each connection carefully, especially in high-tension areas. Regularly check these connections to ensure the equipment remains stable during frequent use.

Step Description 1 Position the equipment in a clear, stable location. 2 Align mounting brackets and secure firmly. 3 Double-check all fastenings for stability. Electrical Setup and Connection Tips

Setting up the electrical connections requires careful attention to ensure reliable performance and safe operation. This section provides practical guidance on connecting power cables and securing stable connections.

To start, make sure all power sources are disconnected before handling any wiring. This step prevents any accidental short circuits or potential risks while working on the setup. Inspect cables and connectors for any signs of wear or damage, as even minor faults can impact functionality.

When connecting the main cables, double-check the polarity to align positive and negative terminals correctly. Use quality connectors and, where possible, secure with additional insulation or protective covers to reduce exposure to moisture and dust. Regularly inspect and tighten all connections to maintain optimal performance over time.

Finally, always follow any specific guidelines related to grounding or earthing to enhance safety. A well-grounded connection can prevent voltage spikes and contribute to the stability of the entire electrical system.

Safe Operation Techniques and Precautions

Ensuring safety during equipment operation is essential to prevent accidents and maintain both the user’s wellbeing and the machinery’s performance. This section outlines critical guidelines and precautions for a secure handling experience, aimed at reducing risks and enhancing overall safety.

Prioritize Inspection: Before initiating any operation, conduct a thorough inspection of the equipment. Check for signs of wear, loose connections, and ensure all components are functioning as expected. An early inspection helps detect issues that could lead to unexpected failures.

Maintain a Safe Distance: Keep a safe distance from the equipment while in use, and ensure any bystanders are also at a secure distance. Maintaining this buffer zone reduces the chance of injuries from sudden movements or unexpected loads.

Use Protective Gear: Always wear appropriate protective gear, including gloves, eye protection, and sturdy footwear. Proper attire significantly minimizes personal injury risks during operation.

Avoid Overloading: Exceeding the equipment’s weight capacity can lead to dangerous malfunctions. Ensure load limits are followed to avoid straining the machinery and creating hazardous conditions.

Regular Maintenance: Routine maintenance is crucial for ensuring safe, long-term operation. Follow the recommended servicing schedules and replace any worn or damaged parts promptly to keep the equipment in optimal working order.

Adhering to these techniques and precautions fosters a safer operational environment, promoting durability and reliability in equipment performance while safeguarding users and surrounding personnel.

Maintenance Routine for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of equipment. A consistent maintenance routine not only enhances functionality but also extends the lifespan of your device, ultimately leading to greater efficiency and reliability. By following a few key practices, users can prevent unexpected breakdowns and costly repairs.

To achieve the best results, consider implementing the following maintenance tasks:

- Regular Cleaning: Keep the device free from dust and debris to prevent buildup that may affect performance.

- Lubrication: Apply appropriate lubricants to moving parts periodically to ensure smooth operation.

- Inspection: Conduct frequent inspections for signs of wear and tear or damage that could lead to malfunctions.

- Calibration: Regularly calibrate the equipment to maintain accuracy and efficiency.

- Component Replacement: Replace worn or damaged components as necessary to avoid further issues.

Following this routine will not only enhance performance but also provide peace of mind knowing that the equipment is well cared for. Regular maintenance plays a crucial role in preventing breakdowns and ensuring longevity.

Effective Troubleshooting Strategies

When encountering issues with equipment, employing systematic troubleshooting methods is essential for identifying and resolving problems efficiently. These approaches not only streamline the process but also enhance the understanding of the device’s functionality, leading to better maintenance and operation.

Step-by-Step Diagnostic Approach

Implementing a structured diagnostic procedure can significantly aid in pinpointing the source of malfunctions. Start by defining the symptoms and gathering relevant information about the device’s performance. Next, develop a hypothesis regarding the possible causes, followed by testing each assumption methodically to confirm or eliminate potential issues.

Utilizing Resources and Documentation

Accessing available resources, including user guides and online forums, can provide valuable insights. Many users share their experiences and solutions to common problems, making these platforms a useful reference. Additionally, maintaining a log of past issues and resolutions can serve as a helpful tool for future troubleshooting efforts.

Common Issues Possible Causes Recommended Solutions Device not powering on Power supply failure Check power connections and replace power supply if needed Unresponsive controls Faulty buttons or software glitch Inspect buttons for damage and perform a reset Inconsistent performance Overheating or outdated firmware Ensure proper ventilation and update firmware Understanding the Gear System

The gear system is a crucial component in various mechanical devices, playing a significant role in transmitting power and facilitating motion. This system comprises different gear types, each designed to serve specific functions and optimize performance in various applications.

Gears operate through a set of interlocking teeth, allowing for the transfer of rotational force between shafts. The arrangement and size of these gears influence the overall efficiency and torque output of the mechanism. Different gear configurations, such as spur, bevel, and planetary gears, each offer unique advantages that can enhance functionality based on the intended use.

Understanding how these gears interact can help in achieving optimal performance, ensuring that the system runs smoothly and efficiently. Proper maintenance and knowledge of gear ratios can further improve the longevity and reliability of the entire apparatus.

Proper Cable Handling and Spooling

Effective management of cables is crucial for maintaining equipment functionality and ensuring safety during operations. Proper techniques in handling and spooling not only prolong the lifespan of the cable but also prevent operational hazards. This section provides essential guidelines to optimize cable management practices.

Key Guidelines for Cable Handling

- Always inspect cables for any signs of wear or damage before use.

- Avoid sharp bends and kinks when handling to prevent internal damage.

- Keep cables clean and free from debris to ensure optimal performance.

- Utilize appropriate storage methods to avoid tangling and knots.

Effective Spooling Techniques

- When spooling, ensure that the cable is wound evenly around the spool to prevent tangling.

- Leave sufficient slack when spooling to accommodate movement and flexibility.

- Label spools clearly to identify the type and length of cable for easy retrieval.

- Store spools in a dry, cool environment to prevent deterioration.

Remote Control Features and Uses

The ability to control devices from a distance has revolutionized how users interact with various equipment. Remote controls offer convenience and efficiency, allowing users to manage functions without being physically present. This section explores the various features and practical applications of these handy devices.

Convenient Operation

One of the primary advantages of remote controls is the ease of operation they provide. With just the push of a button, users can adjust settings, switch modes, or power devices on and off. This feature enhances the user experience by eliminating the need for manual adjustments, making it particularly useful in larger spaces where reaching the device may be cumbersome.

Versatile Functionality

Remote controls often come equipped with a range of functions that extend beyond basic on/off capabilities. Users can customize settings, access different modes, and even program specific commands tailored to their preferences. This versatility makes remote controls indispensable tools in various environments, from home theaters to professional setups.

Mounting Instructions for Vehicle Compatibility

This section provides essential guidelines for ensuring proper installation of winching equipment on various vehicle types. Correct mounting is crucial for optimal performance and safety during operations. Follow the outlined steps to achieve a secure and compatible setup.

Preparation Steps

- Identify the vehicle model and its specifications.

- Gather necessary tools and mounting hardware.

- Ensure the work area is clean and well-lit.

Installation Process

- Locate the designated mounting points on the vehicle’s frame.

- Align the winch assembly with the mounting points.

- Securely fasten the winch using bolts, ensuring all connections are tight.

- Check for any obstructions that may interfere with the winching operation.

- Conduct a final inspection to verify that everything is properly installed.

Common Issues and Their Solutions

This section addresses frequent challenges encountered with the device and provides effective solutions to enhance its performance. Understanding these common problems can help users troubleshoot effectively and ensure a smooth experience.

Power Supply Problems

One of the typical issues involves difficulties related to the power supply. Users may notice that the device fails to turn on or operates intermittently. This can often be traced back to a faulty power source or loose connections. To resolve this, ensure that all connections are secure and consider testing the power outlet with another device to confirm its functionality.

Operational Inconsistencies

Another common concern is irregular operation, where the equipment may not perform as expected. This issue might arise from improper settings or software glitches. To address this, check the configuration settings and reset the device if necessary. Regular updates can also improve functionality, so make sure the latest software is installed.