In recent years, the need for effective and minimally invasive methods to maintain vehicle aesthetics has grown significantly. Car owners and professionals alike are seeking ways to address minor imperfections without resorting to conventional, often costly, procedures. This approach, relying on careful methods and tools, allows for the preservation of the original factory finish and structural integrity, making it a preferred option for many.

What makes this technique particularly appealing is its precision. By using specialized instruments and expertise, surface flaws can be minimized without the need for fillers or repainting. This method not only keeps the vehicle looking pristine but also offers a sustainable, efficient solution by eliminating the use of additional materials and reducing overall processing time.

In this guide, we’ll explore the essential practices, tools, and skills required to master this form of surface correction. Whether you’re a professional looking to expand your skill set or a car owner wanting to understand the basics, this comprehensive outline will provide valuable insights into achieving remarkable, seamless results.

Paintless Dent Repair Manual

Guidebooks for techniques in vehicle surface restoration offer practical insights into methods that preserve the car’s original finish without invasive procedures. These guides focus on approaches that gently restore exterior panels, achieving impressive results with minimal disruption to the vehicle’s existing paintwork.

Fundamentals of Surface Restoration

One of the primary aspects involves assessing the affected area to determine the most efficient way to smooth out imperfections. This process requires a precise combination of hand tools and an understanding of metal flexibility, enabling the technician to subtly reshape surfaces from behind the panel.

Essential Techniques and Tools

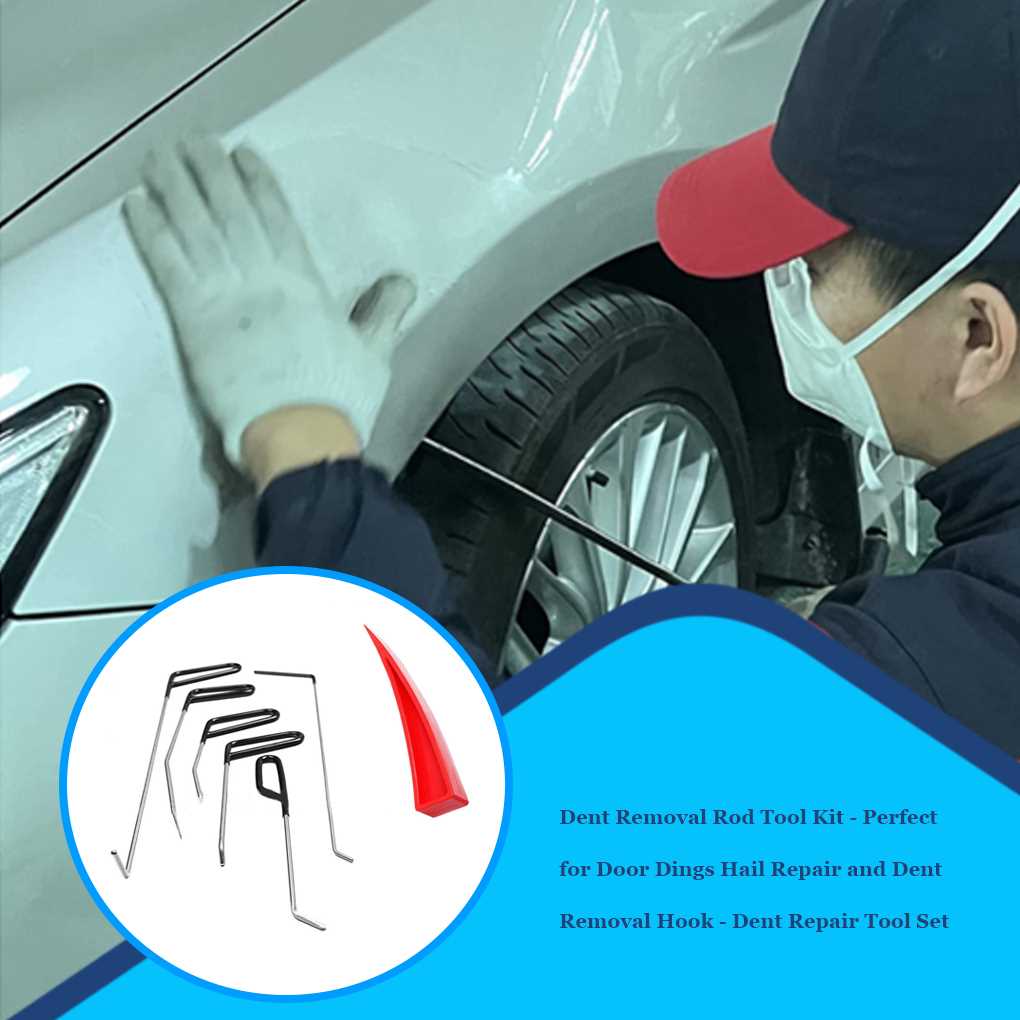

Professionals employ a set of specialized tools to access and manipulate inner surfaces without damaging the outer layer. Key instruments, such as rods and levers, are carefully used to apply measured pressure from

Essential Tools for Dent Repair

Properly addressing minor surface imperfections requires a set of specialized equipment that enhances precision and control. Each tool plays a specific role, allowing technicians to work efficiently and minimize damage to the vehicle’s finish. This section highlights the core instruments necessary for effective, meticulous restoration.

Core Instruments for Surface Restoration

- Leverage Rods: These tools provide the necessary force to adjust the surface from within, reaching spots inaccessible from the outside.

- Tap Down Tools: Designed for fine-tuning, these are used to smooth out any protruding areas, offering a more polished result.

- Light Boards: These boards assist by illuminating imperfections, allowing a technician to accurately detect and adjust surface contours.

Additional Equipment for Enhanced Accuracy

Understanding the Paintless Technique

This innovative approach offers a way to restore vehicle surfaces without traditional tools or materials, focusing instead on a more precise and subtle method. It emphasizes skill and technique to maintain the car’s original appearance while minimizing disruption to the existing finish.

- Preserves the original paint and finish, preventing the need for costly repainting.

- Utilizes specialized tools designed for gentle surface correction, allowing access to hard-to-reach areas.

- Minimizes the use of fillers or abrasives, keeping the car’s exterior as close to its original state as possible.

- Requires specific knowledge of surface elasticity and metal memory, essential for effective restoration.

By emphasizing a non-intrusive approach, this technique aims to bring back the car’s original form in a cost-effective and efficient

Identifying Suitable Surfaces for PDR

Evaluating surfaces for compatibility with non-invasive reshaping techniques is essential to achieving optimal outcomes. Selecting appropriate materials and finishes helps ensure effective results while preserving the integrity of the surface.

Factors Affecting Surface Compatibility

Several factors influence whether a surface can withstand reshaping methods, including material composition, thickness, and flexibility. Surfaces with excessive rigidity or brittleness are more challenging, as they may not respond well to subtle adjustments.

Commonly Suitable Materials

Material Characteristics Aluminum Lightweight, flexible, commonly found in automotive applications Steel Durable and moderately pliable, suitable for most reshaping techniques Key Steps in Dent Removal

Effective surface reshaping relies on precise techniques to restore materials to their original form. This process involves gradually working out imperfections, requiring a keen understanding of the pressure and tools necessary to avoid further impact on the surface.

The first step involves a careful assessment of the area to determine the best approach, as different types of deformations require unique methods. Following this, gentle pressure is applied from behind or on the edges of the affected section, slowly easing the material back into place. A systematic approach ensures minimal disruption to the surrounding area, preserving the surface’s original look and structure.

Finally, a meticulous inspection helps confirm that the area is fully smoothed out, with no visible signs of the original irregularities. This stage is essential to achieving a flawless result, restoring both function and appearance to the affected area without additional refinishing work.

Avoiding Common PDR Mistakes

Understanding the pitfalls in the process of restoring surfaces can significantly enhance the overall outcome. Many individuals face challenges that stem from a lack of knowledge or improper techniques. By being aware of these common errors, one can achieve better results and maintain the integrity of the surface being worked on.

Here are some frequent mistakes to avoid:

- Not assessing the damage properly before beginning the work.

- Using inappropriate tools that may cause further harm.

- Applying excessive force, which can lead to irreversible issues.

- Neglecting to practice on scrap materials before attempting on actual surfaces.

- Overlooking environmental factors such as temperature and humidity.

- Failing to clean the area thoroughly, which can interfere with the process.

By keeping these points in mind, practitioners can minimize errors and ensure a more successful restoration process.

Improving Accuracy in Dent Repairs

Achieving precision in the restoration process is crucial for ensuring a flawless finish and maintaining the vehicle’s value. Various techniques and tools can enhance the accuracy of the intervention, allowing for better outcomes and minimized risk of damage during the procedure.

Utilizing specialized instruments designed for this purpose can significantly contribute to improved results. These tools provide the necessary control and finesse required to address imperfections effectively. Furthermore, honing the skills of the technician through training and practice is essential for mastering the subtleties involved in the process.

In addition, adopting a systematic approach to each task, including thorough inspections and careful planning, can lead to greater effectiveness. By prioritizing attention to detail and developing a keen eye for nuances, professionals can elevate their performance and deliver superior results.

Evaluating Dent Types and Repair Options

Understanding the various forms of surface imperfections is essential for selecting the appropriate methods for their correction. Each type of imperfection requires a tailored approach based on its characteristics, location, and the extent of the damage. This section provides insights into different categories of surface flaws and the corresponding techniques that can be utilized to restore the original appearance.

Types of Surface Imperfections

Type Description Recommended Approach Shallow Indentations Minor surface flaws with minimal depth. Gentle pushing techniques using specialized tools. Medium Dents Moderate imperfections that require more effort to restore. Combination of pushing and tapping methods to evenly distribute pressure. Severe Damage Deep and extensive flaws that may affect the paint. Considerable care with heat application and advanced pulling techniques. Choosing the Right Method

Selecting the correct technique involves assessing the severity and location of the flaws. Factors such as the vehicle’s material, existing finishes, and the access to the area of concern play a significant role in the decision-making process. Proper evaluation ensures that the restoration process is effective and preserves the vehicle’s integrity.

Mastering the Art of Metal Shaping

Creating flawless surfaces from metal requires a blend of skill and technique. This process involves understanding the properties of different materials and applying the right methods to achieve a smooth finish. Mastery in this craft allows for the restoration of the original shape without compromising the integrity of the material.

Techniques such as tapping, stretching, and shrinking are essential in achieving desired contours. Each method serves a specific purpose, whether it’s to eliminate imperfections or refine the overall form. Practicing these techniques helps in developing an intuitive feel for the material, leading to better outcomes.

In addition to technique, having the right tools is crucial. Tools must be selected based on their compatibility with the material being shaped. A deep understanding of tool application can greatly enhance efficiency and precision, enabling craftsmen to work with confidence and creativity.

Safety Precautions for PDR Technicians

Ensuring a secure working environment is crucial for specialists in automotive restoration. Proper safety measures not only protect the technician but also enhance the quality of service provided. Understanding the potential hazards and implementing appropriate strategies can significantly reduce risks associated with this field.

Technicians should always wear personal protective equipment (PPE), including gloves, safety glasses, and appropriate footwear, to shield against accidental injuries. Additionally, it is essential to maintain a clean and organized workspace to prevent slips, trips, and falls. Regularly inspecting tools and equipment for any signs of wear or damage can further enhance safety.

Moreover, awareness of chemical handling is vital, especially when using adhesives or solvents. Following manufacturer guidelines and ensuring proper ventilation can help minimize exposure to harmful substances. Continuous education and training on safety protocols will equip technicians with the knowledge needed to navigate potential hazards effectively.

Maintaining Tools for Long-Term Use

Proper care and upkeep of your instruments are essential for ensuring their longevity and effectiveness. Regular maintenance not only enhances performance but also minimizes the risk of premature wear and tear. By implementing a few simple practices, you can extend the lifespan of your equipment and maintain optimal functionality.

Routine Cleaning and Inspection

Consistent cleaning is vital to remove any residues or debris that may accumulate during use. After each session, wipe down your tools with a soft cloth and suitable cleaning solution to prevent corrosion or damage. Inspecting your equipment regularly for any signs of wear or defects can help identify potential issues before they escalate, ensuring that everything remains in good working order.

Proper Storage Techniques

Storing your instruments correctly is equally important. Utilize designated storage solutions to keep them organized and protected from environmental factors. Climate-controlled areas are ideal, as extreme temperatures and humidity can negatively impact their integrity. Additionally, using protective cases or covers can safeguard against accidental damage.