Proper care and troubleshooting of aquatic propulsion systems are essential for optimal performance and longevity. Understanding the intricacies of these devices allows users to enhance their efficiency while minimizing the risk of unexpected breakdowns. This section aims to provide insights into key aspects of upkeep and common issues faced during usage.

Users will discover various techniques to keep their equipment in top condition, ensuring smooth operation and reliability. Furthermore, addressing typical challenges and implementing corrective measures can significantly extend the lifespan of these essential tools. By following these guidelines, one can achieve a seamless experience on the water.

Outboard Motors Maintenance Overview

Ensuring the longevity and performance of marine engines involves regular care and attention. By following systematic procedures, boat owners can enhance the reliability of their vessels while reducing the likelihood of unexpected breakdowns.

Importance of Routine Checks

Conducting frequent inspections plays a crucial role in identifying potential issues before they escalate. Regularly examining vital components not only safeguards the engine’s functionality but also contributes to a safer boating experience.

Key Practices for Engine Longevity

Implementing essential practices, such as changing fluids, checking filters, and cleaning components, is vital for optimal operation. These simple yet effective tasks ensure that the equipment runs smoothly and efficiently, prolonging its lifespan.

Essential Tools for Maintenance

Proper upkeep of aquatic propulsion devices requires a selection of fundamental instruments that enhance performance and longevity. Understanding which tools to have on hand can make routine servicing tasks more efficient and effective, ensuring that everything operates smoothly.

Here are some vital instruments to consider for optimal care:

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening and loosening fasteners. |

| Screwdriver Set | Used for assembling and disassembling components. |

| Socket Set | Ideal for removing bolts in tight spaces. |

| Oil Pump | Facilitates the efficient transfer of lubricants. |

| Multimeter | Essential for electrical diagnostics. |

| Cleaners and Degreasers | Helps maintain the exterior and internal parts. |

Routine Inspection Procedures

Regular evaluation of equipment is essential to ensure optimal performance and longevity. By systematically checking various components, potential issues can be identified before they escalate, allowing for timely interventions.

Begin by examining the exterior for any signs of wear or damage. Pay attention to the casing and joints, ensuring they are secure and free from cracks. Next, inspect the fuel system, looking for leaks or obstructions that could hinder operation. The electrical connections should also be assessed; ensure all wires are intact and that terminals are free from corrosion.

Check the cooling system, ensuring the intake is unobstructed and the coolant levels are adequate. It’s also important to verify that the propeller is in good condition, free from dents or deformities. Lastly, listen for unusual noises during a brief run test, which can indicate underlying problems.

Changing Oil and Filters

Regularly replacing lubricants and filtration components is essential for ensuring optimal performance and longevity of your watercraft’s engine. This process not only enhances efficiency but also prevents potential damage caused by contaminants and degraded fluids.

Essential Tools and Materials

Before starting the procedure, gather necessary equipment such as an oil extractor, new oil, a suitable filter, a wrench set, and a clean container for waste fluid. Having all items at hand will streamline the process and minimize the risk of overlooking crucial steps.

Step-by-Step Procedure

Begin by warming the engine slightly to thin the oil, making it easier to drain. Next, locate the drain plug and carefully remove it to allow the used lubricant to flow into the collection container. After the old fluid is fully drained, replace the drain plug securely. Proceed to unscrew the filter, ensuring that any residual oil is captured. Install the new filter and refill the system with fresh oil, checking the level to ensure it meets the manufacturer’s specifications. Finally, dispose of the used oil and filter responsibly to protect the environment.

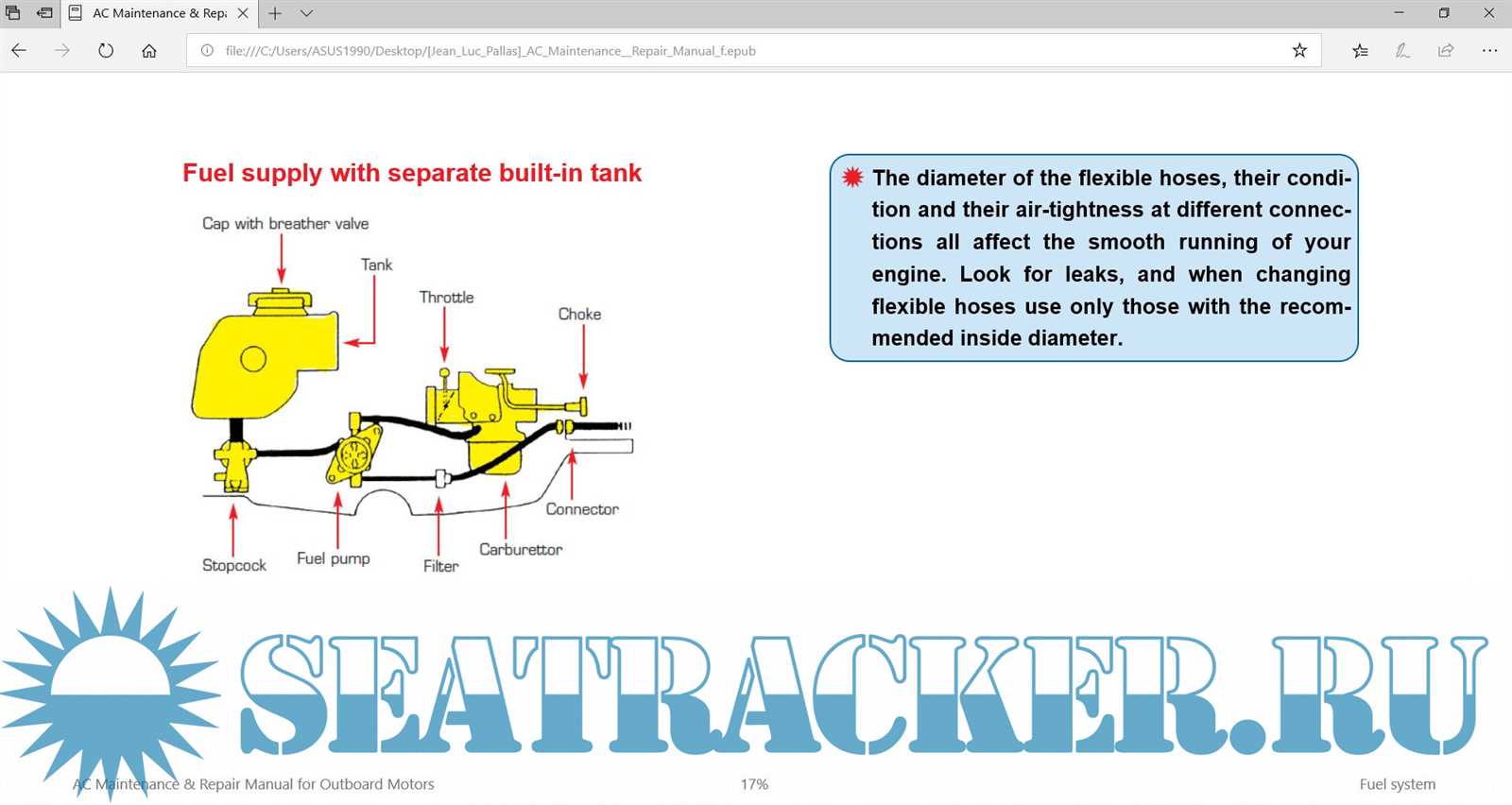

Fuel System Care and Upkeep

The efficiency and reliability of any marine engine largely depend on the condition of its fuel delivery system. Proper attention to this system ensures optimal performance and prolongs the life of the engine. Regular checks and procedures are essential to keep the fuel system in top shape.

To maintain the fuel delivery system effectively, consider the following key practices:

- Inspect Fuel Lines: Regularly check for cracks, leaks, or signs of wear. Replace any damaged lines promptly.

- Replace Fuel Filters: Change filters according to the manufacturer’s recommendations to prevent contaminants from reaching the engine.

- Check Fuel Quality: Ensure that the fuel used is clean and free from water or debris. Stale fuel can lead to performance issues.

- Clean Fuel Tank: Periodically remove sediments and contaminants from the fuel tank to maintain a clear flow of fuel.

- Monitor Fuel Pump: Listen for unusual noises from the pump and check its pressure to ensure it operates efficiently.

By adhering to these guidelines, you can enhance the functionality of the fuel system, ensuring that the engine runs smoothly and efficiently. Regular attention to these components will significantly reduce the likelihood of problems in the future.

Cooling System Maintenance Techniques

Ensuring the proper functionality of the cooling system is essential for the longevity and performance of marine propulsion units. This section covers various strategies to keep the cooling components in optimal condition, preventing overheating and enhancing efficiency during operation.

Regular Inspection

Routine checks of the cooling components are crucial. Inspect hoses for wear and tear, ensuring there are no cracks or leaks that could impede fluid flow. Examine the water intake screen to prevent debris buildup, which can restrict water passage and lead to overheating.

Cleaning and Flushing

Periodically flushing the cooling system helps remove any accumulated deposits or salt buildup. Use fresh water to clean the system thoroughly, ensuring that all passages are clear. This process not only enhances performance but also extends the life of the components involved.

Electrical System Troubleshooting Guide

This section provides guidance for diagnosing issues within electrical systems. Understanding the common problems can help users effectively identify faults and implement solutions to ensure optimal performance.

Common symptoms of electrical system failures include:

- Inconsistent power supply

- Failure to start

- Flickering lights

- Unusual noises from electrical components

Follow these troubleshooting steps to isolate and resolve issues:

- Check the battery:

- Ensure connections are tight and free of corrosion.

- Test the battery voltage with a multimeter; it should be within the recommended range.

- Inspect fuses:

- Locate the fuse panel and check for blown fuses.

- Replace any faulty fuses with ones of the correct amperage.

- Examine wiring:

- Look for damaged or frayed wires.

- Ensure all connectors are secure and free from corrosion.

- Test electrical components:

- Use a multimeter to test the functionality of switches and relays.

- Replace any components that fail the test.

By following these steps, users can effectively troubleshoot and address electrical system issues, ensuring reliable operation.

Propeller Inspection and Repair

Ensuring the optimal performance of your marine vessel requires regular examination and enhancement of its propulsion components. These essential elements are crucial for achieving efficient movement through the water and must be carefully assessed for any signs of wear or damage.

Begin the inspection by thoroughly examining the blades for nicks, dents, or any signs of corrosion. Pay special attention to the edges, as even minor imperfections can lead to reduced efficiency and increased fuel consumption. If you discover significant damage, consider replacing the affected blades or the entire unit.

Additionally, check the hub for any looseness or play. A secure connection between the hub and the blades is vital for the effective transfer of power. If you notice any instability, it may require realignment or tightening to ensure proper function.

Lastly, cleaning is a vital part of the process. Remove any debris, marine growth, or barnacles that may have accumulated, as these can hinder performance. Regular upkeep not only extends the lifespan of the components but also enhances the overall efficiency of the vessel.

Common Issues and Solutions

Understanding typical challenges that may arise during the operation of marine engines is crucial for ensuring their longevity and optimal performance. This section highlights frequent problems encountered by users and provides effective remedies to address them.

Performance Degradation

Engines may experience reduced efficiency over time, leading to sluggish acceleration and poor fuel economy. Several factors can contribute to this issue:

| Issue | Solution |

|---|---|

| Clogged fuel filter | Replace the fuel filter regularly to ensure a clean fuel supply. |

| Worn spark plugs | Inspect and replace spark plugs as needed to maintain ignition efficiency. |

| Incorrect propeller size | Choose a propeller that matches the specifications for optimal thrust. |

Starting Difficulties

Issues with starting the engine can be frustrating. Identifying the cause is essential for timely solutions:

| Issue | Solution |

|---|---|

| Dead battery | Charge or replace the battery to ensure sufficient power for starting. |

| Faulty ignition switch | Test and replace the ignition switch if it fails to engage the engine. |

| Blocked fuel lines | Inspect and clean fuel lines to ensure proper fuel flow. |

Winterization Steps for Storage

Preparing equipment for the cold months is essential to ensure its longevity and optimal performance. Proper procedures can help prevent damage from freezing temperatures and moisture. This section outlines key actions to take before storing your equipment for winter.

1. Cleaning the Equipment: Thoroughly clean all surfaces to remove dirt, salt, and debris. Use fresh water and mild soap to ensure all areas are free from contaminants that could cause corrosion.

2. Draining Fluids: Empty all fluids, including fuel and oil, to prevent any residue from causing issues during the storage period. Ensure that the fuel system is purged, and consider adding a stabilizer to protect against varnish buildup.

3. Lubrication: Apply appropriate lubricants to moving parts to protect against rust and maintain functionality. Check all seals and gaskets for wear and replace them if necessary.

4. Covering and Protection: Use a suitable cover to shield the equipment from dust and moisture. Ensure it is breathable to prevent condensation buildup that could lead to damage.

5. Storage Location: Store in a dry, temperature-controlled environment to minimize exposure to extreme cold and humidity. Ensure the area is secure and accessible for any necessary checks throughout the storage period.

Best Practices for Long-Term Reliability

Ensuring enduring performance of your watercraft propulsion system requires adherence to certain principles. Implementing these guidelines can significantly enhance the longevity and dependability of your equipment.

Regular Inspection: Conducting routine evaluations is essential. Check for any signs of wear or damage that could compromise functionality. Promptly addressing minor issues can prevent major failures.

Proper Storage: When not in use, store your vessel in a dry, sheltered location. This protects it from environmental factors that can lead to deterioration over time.

Quality Fuels and Fluids: Use only high-grade fuels and lubricants suitable for your device. Contaminated or subpar fluids can cause significant harm, affecting performance and reliability.

Consistent Operation: Frequent usage helps maintain optimal function. Allowing the engine to sit idle for extended periods can lead to stagnation and potential damage.

Thorough Cleaning: After each outing, clean your equipment thoroughly to remove salt, dirt, and debris. This practice helps prevent corrosion and buildup that could impair performance.

Professional Servicing: Schedule periodic check-ups with qualified technicians. Their expertise can identify potential issues early and ensure your system operates smoothly.