In the world of transportation, the effective upkeep of heavy-duty vehicles plays a vital role in ensuring their longevity and performance. This comprehensive resource aims to equip enthusiasts and professionals alike with essential knowledge and practices for maintaining these powerful machines. By delving into various aspects of vehicle servicing, readers can gain insights into proper procedures, troubleshooting techniques, and preventative measures that contribute to overall functionality.

Understanding the intricacies of heavy machinery involves more than just mechanical knowledge; it requires an appreciation for the various components that work harmoniously to deliver optimal performance. This compilation emphasizes the importance of systematic approaches to maintenance, providing readers with the tools needed to tackle common challenges. With a focus on clarity and practicality, this guide serves as an invaluable asset for anyone dedicated to mastering the art of vehicle care.

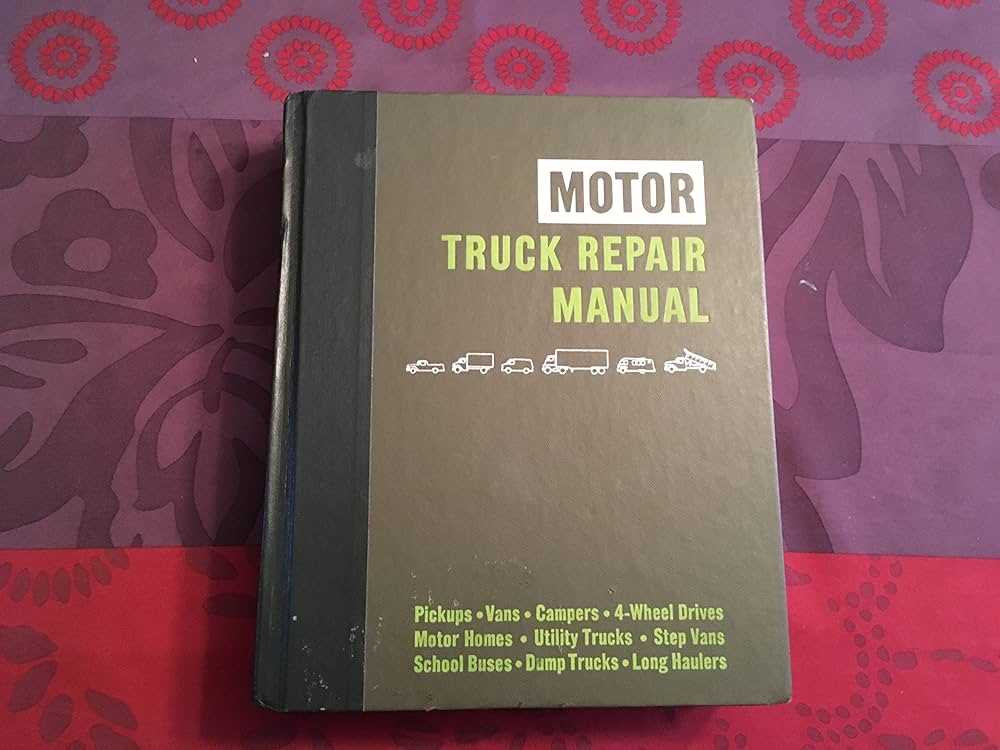

Overview of the 34th Edition

This latest volume offers comprehensive insights and practical guidance for professionals in the field. It emphasizes modern techniques and industry standards, ensuring that users are well-equipped with the necessary knowledge to handle a wide range of tasks effectively.

In this release, significant updates and revisions have been implemented, reflecting the evolving practices and technologies in the industry. Illustrations and detailed explanations accompany each section, enhancing the learning experience and facilitating better understanding.

Moreover, this version incorporates feedback from practitioners, making it a valuable resource that addresses real-world challenges faced in day-to-day operations. The content is structured to cater to both newcomers and seasoned experts, promoting a deeper grasp of intricate concepts.

Overall, this publication stands as a vital tool, ensuring that users remain at the forefront of best practices and are capable of applying advanced methodologies in their work environments.

Key Features and Updates

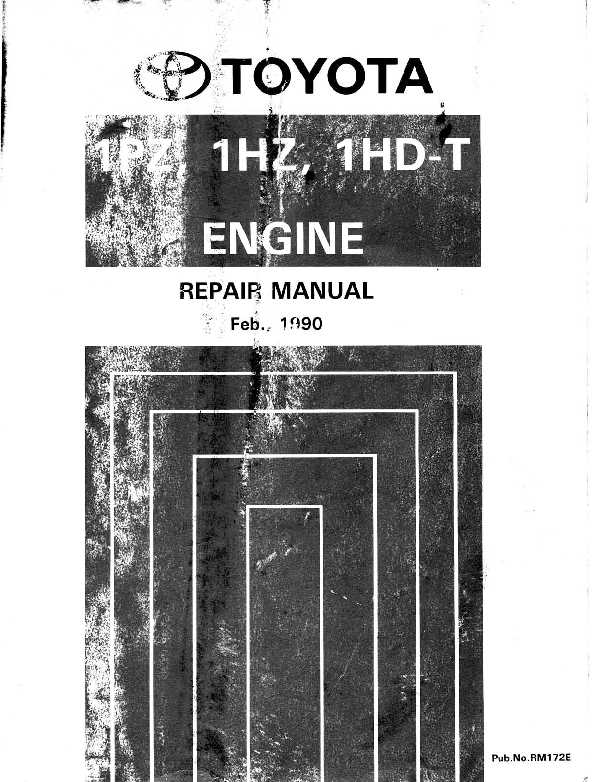

This section highlights the essential elements and enhancements found in the latest version of the guide. The document is designed to provide comprehensive support for individuals engaged in the maintenance and servicing of heavy-duty vehicles, ensuring they have access to the most relevant and practical information.

Enhanced Technical Details

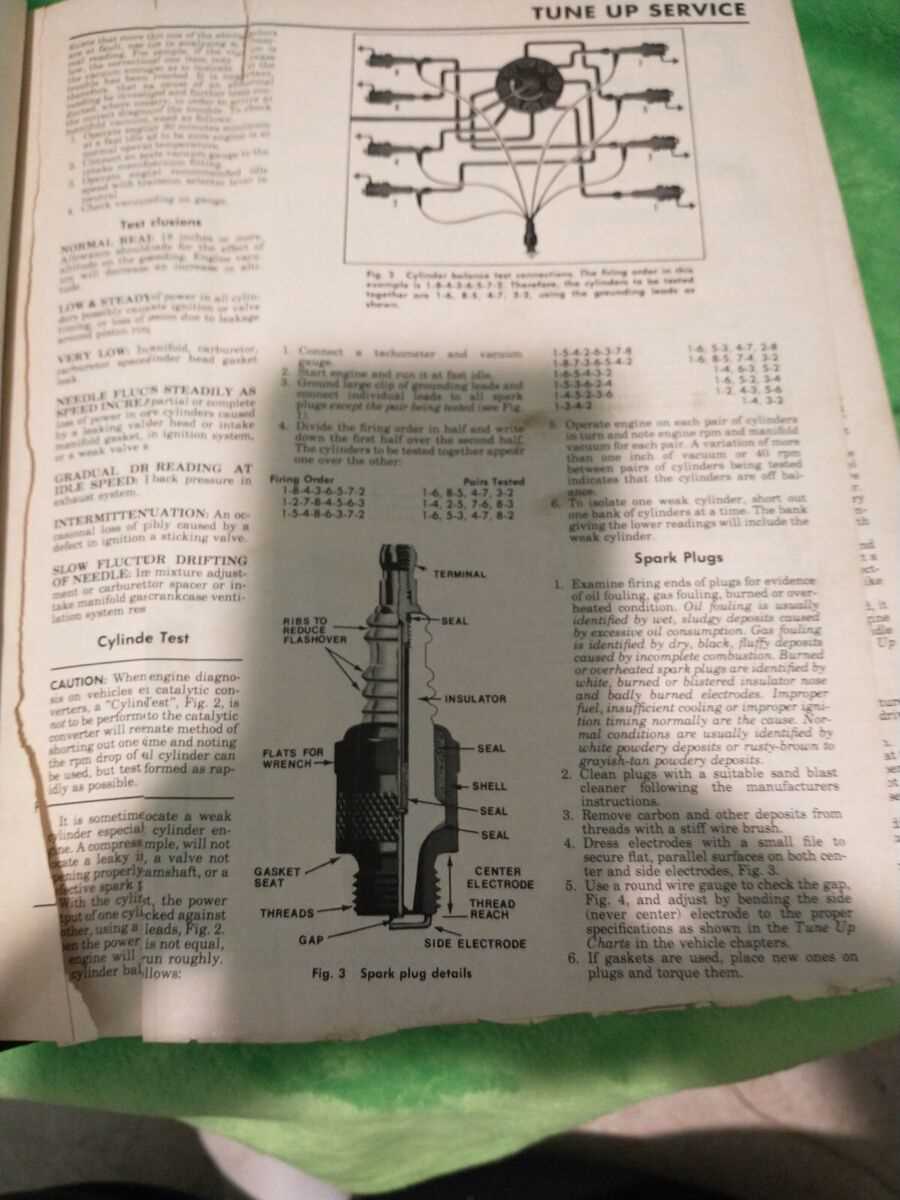

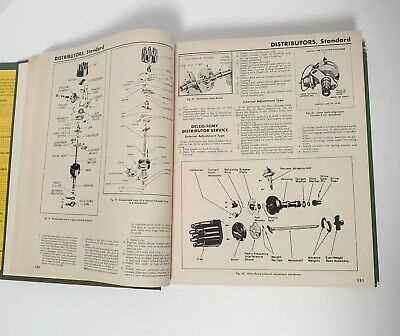

One of the significant improvements includes a more detailed technical specification section, offering in-depth insights into engine performance metrics, component layouts, and diagnostic procedures. This update facilitates better understanding and troubleshooting, allowing users to effectively address issues that may arise during vehicle servicing.

User-Friendly Layout

The latest version introduces a user-friendly format that enhances navigation through various topics. Color-coded sections, clear headings, and streamlined indexing allow users to quickly locate specific information, significantly improving the overall experience when seeking guidance on complex tasks.

Essential Tools for Truck Repairs

Maintaining and restoring vehicles requires a well-equipped toolkit to ensure efficiency and effectiveness in every task. Whether addressing minor adjustments or tackling major issues, having the right instruments on hand can make all the difference in achieving optimal performance and longevity.

Wrenches are fundamental, as they allow for the secure fastening and loosening of various components. A set of both standard and metric sizes is crucial to accommodate different fasteners. In addition, ratchet sets enhance accessibility in tight spaces, making them indispensable for comprehensive work.

Equally important are screwdrivers, which come in various types, including flathead and Phillips. These tools are essential for tasks that involve electrical components and panel adjustments. Furthermore, pliers, particularly needle-nose varieties, provide the grip and precision necessary for intricate tasks.

Another vital category includes diagnostic tools. These devices help in identifying issues quickly and accurately, streamlining the troubleshooting process. By integrating technology, such as code readers and multimeters, one can diagnose electrical systems and performance metrics effectively.

Finally, safety gear cannot be overlooked. Items such as gloves, goggles, and ear protection ensure that individuals remain safe while working in potentially hazardous environments. Combining these essential instruments creates a robust arsenal that facilitates efficient vehicle maintenance and enhances overall work quality.

Maintenance Guidelines and Best Practices

Ensuring the longevity and optimal performance of heavy vehicles requires a comprehensive approach to upkeep. Regular assessments and timely interventions are crucial for preventing issues and enhancing operational efficiency. By adhering to established procedures, operators can safeguard their assets and reduce the likelihood of unexpected breakdowns.

Routine Inspections

Consistent evaluations are essential for identifying potential concerns before they escalate. Key areas to focus on include fluid levels, brake functionality, and tire condition. A proactive stance in monitoring these components fosters early detection of wear and tear, which can be addressed promptly to maintain peak performance.

Scheduled Maintenance

Implementing a structured maintenance schedule is vital for systematic care. This plan should encompass tasks such as oil changes, filter replacements, and alignment checks. Utilizing high-quality parts and adhering to manufacturer recommendations can significantly enhance reliability and extend the operational life of the vehicle. Regular documentation of maintenance activities also provides valuable insights for future reference.

Understanding Truck Systems and Components

The complexity of heavy-duty vehicles lies in the intricate interplay of their various systems and parts. Each component serves a distinct function, contributing to the overall performance and reliability of the vehicle. A comprehensive grasp of these systems is essential for effective maintenance and troubleshooting, ensuring optimal operation over time.

Key Systems in Heavy-Duty Vehicles

Heavy-duty vehicles are equipped with numerous key systems, each designed to manage specific functions. Among these, the propulsion system plays a crucial role, converting fuel into mechanical energy to move the vehicle. In addition, the braking system is vital for safety, providing the necessary stopping power and control. Furthermore, the electrical system supports various functions, from starting the engine to powering auxiliary components.

Essential Components and Their Functions

Understanding the essential components is critical for effective vehicle management. The engine, often considered the heart of the vehicle, is responsible for generating power. The transmission system transfers this power to the wheels, allowing for movement. Other important parts include the suspension system, which enhances ride comfort and stability, and the cooling system, which prevents the engine from overheating. Each component is interdependent, highlighting the importance of a holistic approach to vehicle understanding.

Diagnostic Techniques for Common Issues

Identifying and addressing typical problems in heavy vehicles requires a systematic approach. By utilizing various techniques and tools, one can effectively pinpoint the underlying causes of malfunctions, ensuring timely and accurate resolutions. This section delves into effective diagnostic methods that can be employed to tackle frequent challenges encountered in these machines.

Visual Inspection

Conducting a thorough visual examination is often the first step in troubleshooting. Look for the following:

- Fluid leaks beneath the vehicle.

- Corroded or damaged wires and connectors.

- Unusual wear on belts and hoses.

- Signs of overheating or discoloration in engine components.

Utilizing Diagnostic Tools

Employing advanced diagnostic instruments can significantly enhance the troubleshooting process. Consider these tools:

- OBD-II Scanner: Accesses onboard diagnostic systems to retrieve trouble codes.

- Multimeter: Measures voltage, current, and resistance to verify electrical system integrity.

- Pressure Gauge: Evaluates fluid pressure levels in systems like the fuel or hydraulic lines.

By integrating these techniques, one can develop a comprehensive understanding of the issues at hand, leading to effective solutions and improved performance of the vehicle.

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing various maintenance and restoration tasks effectively. By following a structured sequence of actions, individuals can enhance their understanding of the intricate processes involved, ensuring that each phase of the job is completed with precision and care.

Preparation and Assessment

Begin by thoroughly examining the equipment to identify any issues. Conduct a visual inspection to look for signs of wear, damage, or irregularities. Gather the necessary tools and materials required for the job. This preparation phase is crucial for ensuring that all resources are available, minimizing delays during the process.

Execution of Procedures

Follow the defined sequence of steps to perform the necessary tasks. Start with the disassembly of components as needed, taking care to document each step for future reference. Maintain a clean workspace to prevent contamination or loss of parts. After completing the adjustments or replacements, meticulously reassemble the parts and conduct a thorough check to verify that everything is functioning correctly.

Safety Protocols in Truck Maintenance

Ensuring safety during the upkeep of heavy vehicles is crucial to prevent accidents and injuries. A systematic approach to maintenance not only extends the lifespan of the equipment but also guarantees the well-being of the personnel involved in the process. Adopting effective safety measures is essential for creating a secure working environment.

Personal Protective Equipment (PPE)

The use of appropriate personal protective gear is fundamental in safeguarding individuals while performing maintenance tasks. Workers should always wear helmets, gloves, and protective eyewear to shield against potential hazards. Additionally, employing steel-toed boots can protect feet from heavy falling objects, ensuring comprehensive safety during operations.

Proper Tools and Equipment Handling

Utilizing the correct tools and equipment is vital to avoid mishaps. Regular inspections of tools should be conducted to confirm their functionality. Furthermore, following proper lifting techniques and ensuring all devices are in good working order significantly reduces the risk of injury. Keeping the workspace organized and free from clutter also contributes to a safer environment.

Parts Identification and Replacement

Understanding the various components and their proper handling is crucial for effective maintenance and longevity of any vehicle. Proper identification of these elements ensures that replacements are conducted accurately, minimizing the risk of malfunctions and enhancing overall performance.

When dealing with component substitution, it’s essential to follow a structured approach:

- Identification: Begin by locating the specific part number or description in the vehicle’s documentation.

- Assessment: Evaluate the condition of the existing part to determine whether it requires replacement or can be repaired.

- Selection: Choose a compatible replacement part, considering factors such as quality, manufacturer, and warranty.

- Installation: Follow the appropriate guidelines for fitting the new component, ensuring all connections are secure.

- Testing: After installation, perform necessary checks to confirm proper functionality of the new part.

Here are some common categories of components that may require identification and replacement:

- Engine Components: Includes filters, belts, and gaskets.

- Electrical Systems: Covers batteries, fuses, and wiring harnesses.

- Transmission Parts: Encompasses clutches, gears, and fluids.

- Suspension Elements: Involves shock absorbers, struts, and bushings.

- Braking System: Features pads, rotors, and calipers.

By systematically identifying and replacing parts, owners can significantly extend the life of their vehicles while ensuring optimal performance and safety on the road.

Service Intervals and Scheduling

Establishing appropriate maintenance timelines is crucial for ensuring optimal performance and longevity of any heavy vehicle. Adhering to specified intervals for service tasks minimizes the risk of breakdowns and costly repairs, while also enhancing safety. Proper scheduling allows operators to plan effectively, ensuring that essential checks and services do not interfere with operational efficiency.

Recommended Maintenance Schedule

The following table outlines the suggested intervals for various maintenance tasks. This serves as a guideline for owners and operators to monitor the health of their vehicles.

| Service Task | Interval |

|---|---|

| Oil Change | Every 5,000 miles or 6 months |

| Air Filter Replacement | Every 15,000 miles |

| Tire Rotation | Every 10,000 miles |

| Brake Inspection | Every 20,000 miles |

| Fluid Checks (Coolant, Brake, Transmission) | Every 30,000 miles |

Flexibility in Scheduling

While the above intervals serve as a general framework, it is important to consider individual operating conditions. Factors such as load capacity, terrain, and climate can influence maintenance frequency. Operators should remain vigilant and adjust their service schedules based on vehicle performance and any indicators of wear and tear.

Cost Management for Truck Repairs

Effective financial oversight is crucial for maintaining the efficiency of any heavy vehicle fleet. Strategic planning and diligent monitoring can significantly reduce expenditures while ensuring optimal performance. Understanding the various components that contribute to overall costs enables operators to make informed decisions, ultimately enhancing profitability and operational effectiveness.

One key aspect of financial management is budgeting. Establishing a comprehensive budget involves considering several factors:

- Parts and Materials: Assess the quality and cost of components needed for maintenance.

- Labor Costs: Evaluate the expenses associated with skilled technicians and service personnel.

- Time Management: Minimize downtime by scheduling maintenance effectively to reduce lost productivity.

In addition to budgeting, regular performance analysis can aid in identifying trends and potential areas for savings. Implementing a systematic approach includes:

- Tracking Expenses: Keep detailed records of all costs related to maintenance activities.

- Evaluating Service Providers: Compare quotes and service levels from various suppliers and mechanics.

- Setting Performance Metrics: Establish clear standards to measure the efficiency and effectiveness of maintenance work.

By embracing these strategies, organizations can enhance their financial health, ensuring their fleet remains reliable while keeping expenditures under control.

Resources for Further Learning

Expanding your knowledge in the field of vehicle maintenance can significantly enhance your skills and understanding of various systems and techniques. Numerous resources are available for enthusiasts and professionals alike, providing valuable information and insights into best practices, troubleshooting, and innovative technologies. These materials can serve as a solid foundation for mastering the intricacies of automotive service.

| Resource Type | Description | Where to Find |

|---|---|---|

| Books | Comprehensive texts covering a wide range of topics from basic maintenance to advanced diagnostics. | Local libraries, bookstores, online retailers |

| Online Courses | Interactive learning platforms offering courses on various subjects, including electrical systems, engines, and suspension. | Websites like Coursera, Udemy, and edX |

| Forums | Communities where individuals share experiences, ask questions, and provide solutions to common issues. | Reddit, specialized automotive forums |

| YouTube Channels | Video tutorials and demonstrations covering everything from simple fixes to complex repairs. | Search for automotive channels on YouTube |

| Workshops | Hands-on sessions led by experts to enhance practical skills and techniques in a collaborative environment. | Local community colleges, automotive schools |