Ensuring the longevity and optimal performance of an automobile requires a thorough understanding of its various components and systems. This section aims to provide essential information and insights that will empower owners to confidently address common challenges encountered during vehicle operation. From understanding mechanical intricacies to diagnosing issues, knowledge is key to effective maintenance.

In this guide, readers will discover practical tips and procedures tailored to enhance the ownership experience. Each segment focuses on crucial aspects of vehicle care, offering step-by-step instructions and valuable recommendations. Whether you are dealing with routine checks or specific malfunctions, the information presented here is designed to support informed decision-making.

By following the outlined practices, owners can not only troubleshoot effectively but also foster a deeper connection with their vehicle. This comprehensive resource serves as a foundation for anyone looking to enhance their understanding and skills in maintaining automotive excellence.

Understanding the 1997 Mirage Model

This section explores the key features and characteristics of a compact vehicle that gained popularity in the late ’90s. Its efficient design and practical layout made it a favored choice for those seeking a reliable means of transportation.

Notable aspects include:

- Compact size for urban maneuverability

- Fuel efficiency that appeals to budget-conscious drivers

- Variety of trims offering different features and specifications

Additionally, the model is recognized for its:

- Durable engine performance

- Comfortable interior layout

- Safety features relevant to its era

Understanding these elements provides insight into the vehicle’s appeal and enduring legacy in the automotive market.

Essential Tools for Vehicle Repairs

Having the right equipment is crucial for any automotive maintenance task. A well-equipped workspace ensures efficiency and safety while allowing individuals to tackle various challenges that may arise during servicing. The following tools form the foundation for effective vehicle upkeep, enabling both amateur enthusiasts and seasoned professionals to achieve successful outcomes.

One of the primary necessities is a comprehensive set of hand tools, including wrenches, sockets, and screwdrivers. These instruments are essential for loosening and tightening various components. Additionally, a reliable jack and jack stands are vital for safely elevating the vehicle, providing access to its undercarriage for inspection and repair.

Moreover, diagnostic tools such as scanners and multimeters are invaluable for troubleshooting electrical systems. They help identify faults, ensuring that issues can be addressed promptly. Further, specialized tools like torque wrenches and oil filter wrenches can enhance precision during specific tasks, promoting longevity and optimal performance.

Lastly, maintaining a clean workspace with organizational tools, such as toolboxes and storage solutions, contributes to a more productive environment. This approach not only streamlines the repair process but also fosters a greater understanding of the vehicle’s components and systems, leading to more informed maintenance decisions.

Common Issues and Solutions

This section addresses frequent challenges encountered by vehicle owners and provides effective solutions to enhance performance and reliability. Understanding these common problems can save time and resources while ensuring a smoother driving experience.

-

Engine Performance Issues:

Many drivers report reduced engine efficiency. Regular maintenance, including changing air filters and checking spark plugs, can significantly improve performance.

-

Electrical System Malfunctions:

Problems with the electrical system, such as battery failures or faulty wiring, are not uncommon. Conducting routine inspections and replacing worn-out components can prevent unexpected breakdowns.

-

Suspension and Steering Problems:

Noises or instability in the steering can indicate suspension wear. Regular checks of shock absorbers and bushings can enhance handling and safety.

-

Brake System Concerns:

Unresponsive brakes or unusual noises may signify wear on brake pads or rotors. Timely replacement of these parts is crucial for maintaining safety.

By being aware of these potential issues and implementing the recommended solutions, owners can ensure their vehicles remain in optimal condition.

Step-by-Step Maintenance Procedures

This section outlines a series of essential procedures aimed at ensuring the longevity and optimal performance of your vehicle. Regular upkeep is crucial for maintaining reliability and efficiency, encompassing various tasks that can be performed with basic tools and knowledge.

Follow these systematic steps to keep your vehicle in peak condition:

| Task | Description | Frequency |

|---|---|---|

| Oil Change | Replace engine oil and filter to ensure smooth operation. | Every 5,000 miles |

| Tire Rotation | Switch tire positions to promote even wear. | Every 6,000 miles |

| Brake Inspection | Check brake pads and rotors for wear and performance. | Every 10,000 miles |

| Fluid Levels Check | Inspect and top up essential fluids such as coolant and brake fluid. | Monthly |

| Battery Maintenance | Clean terminals and check the battery charge. | Every 3 months |

By adhering to these guidelines, vehicle owners can enhance their driving experience while reducing the risk of unexpected issues.

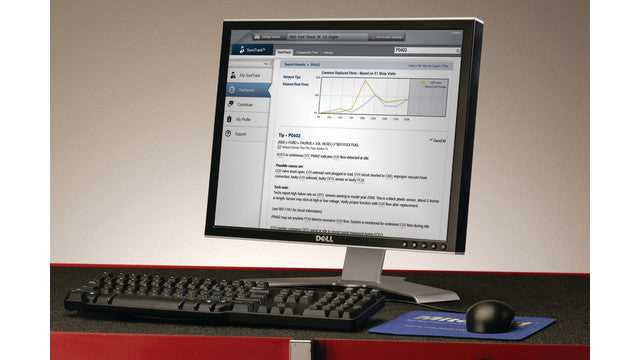

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of a vehicle is essential for ensuring optimal performance. This process involves systematically identifying faults that can lead to malfunctions in various components, including lighting, starting systems, and onboard electronics.

Begin by inspecting fuses and relays, as these are common points of failure. A blown fuse can interrupt power to critical systems, while a faulty relay may prevent components from receiving the necessary signals. Use a multimeter to check for continuity and ensure that connections are secure.

Next, examine the battery and charging system. Low voltage or corroded terminals can result in starting difficulties. Verify the integrity of cables and connectors, as poor connections can lead to voltage drops that affect overall functionality.

Additionally, review the wiring harness for any signs of wear or damage. Frayed wires or loose connections can cause intermittent issues that are challenging to diagnose. A thorough visual inspection paired with functional testing can reveal underlying problems that require attention.

Engine Components and Functions

The internal combustion engine is a complex assembly of parts that work together to convert fuel into motion. Each component plays a vital role in ensuring optimal performance, efficiency, and reliability. Understanding these elements is essential for diagnosing issues and maintaining the overall health of the engine.

1. Cylinder Block: The foundation of the engine, this heavy-duty metal casing houses the cylinders where fuel and air mixture is compressed and ignited. Its robust structure supports various components and withstands high pressures during operation.

2. Pistons: These cylindrical pieces move up and down within the cylinders, creating the necessary pressure to initiate combustion. As they travel, they convert the energy generated from explosions into mechanical energy that drives the crankshaft.

3. Crankshaft: This critical part transforms the linear motion of the pistons into rotational motion. It is connected to the drivetrain, allowing the vehicle to move. The crankshaft must be balanced to minimize vibrations and ensure smooth operation.

4. Camshaft: Operating in tandem with the crankshaft, the camshaft controls the timing of the intake and exhaust valves. By regulating airflow in and out of the cylinders, it plays a crucial role in the engine’s efficiency and power output.

5. Valves: These components open and close at precise intervals to allow the air-fuel mixture into the combustion chamber and exhaust gases to exit. Their operation is critical for maintaining the engine’s performance and preventing backflow.

6. Timing Belt/Chain: This component synchronizes the movement of the crankshaft and camshaft. A properly functioning timing mechanism is essential for the precise timing of valve openings and closings, ensuring optimal combustion cycles.

Each of these elements is integral to the operation of the engine. Regular maintenance and a clear understanding of their functions can lead to improved performance and longevity of the vehicle.

Transmission and Drivetrain Insights

This section delves into the intricate components responsible for transferring power from the engine to the wheels. Understanding these elements is crucial for effective maintenance and optimization of vehicle performance. Proper insight into the operation and configuration of these systems can lead to improved handling and efficiency.

The transmission system plays a pivotal role in adjusting the engine’s output to the wheels, ensuring that the vehicle responds accurately to the driver’s input. Various types of transmissions, including manual and automatic, offer distinct characteristics that can enhance the driving experience. Each type requires specific maintenance practices to ensure longevity and reliability.

The drivetrain encompasses all components involved in delivering power, including the driveshaft, differential, and axles. Attention to these parts can prevent wear and tear, which is essential for maintaining overall vehicle performance. Regular inspections and understanding the signs of potential issues can save time and resources in the long run.

| Component | Function |

|---|---|

| Transmission | Modulates engine output to wheels |

| Driveshaft | Transfers torque from transmission to differential |

| Differential | Allows wheels to rotate at different speeds during turns |

| Axles | Connects differential to wheels, supporting vehicle weight |

Suspension and Steering Adjustments

Proper calibration of the suspension and steering systems is crucial for maintaining optimal vehicle performance and safety. Ensuring that these components are in harmony contributes to improved handling, comfort, and overall driving experience. This section outlines essential adjustments to consider for achieving the desired ride quality and steering response.

Alignment and Leveling

Correct alignment is fundamental for the longevity of tires and the stability of the vehicle. Regular checks should be performed to ensure that the angles of the wheels are set according to manufacturer specifications. Additionally, leveling the suspension helps maintain even weight distribution, which is vital for balanced handling.

Damping and Spring Rate Adjustments

Adjusting the damping settings and spring rates can significantly influence ride characteristics. Softer springs provide more comfort on uneven surfaces, while stiffer settings enhance responsiveness during aggressive maneuvers. It is essential to find a suitable compromise that aligns with the driver’s preferences and intended usage of the vehicle.

Safety Features and Guidelines

This section provides an overview of essential safety mechanisms and recommendations designed to enhance vehicle protection and ensure the well-being of all occupants. Understanding these elements is crucial for both maintaining the integrity of the automobile and promoting responsible usage.

Key Safety Features

Modern vehicles are equipped with various safety components aimed at minimizing risks during operation. These include advanced restraint systems, impact-absorbing structures, and technology that aids in collision avoidance. Familiarity with these features can significantly improve overall safety while driving.

Recommended Safety Practices

Adhering to established safety protocols can further enhance protection. Regular inspections, proper use of seat belts, and avoiding distractions are vital practices that every driver should incorporate into their routine.

| Feature | Description |

|---|---|

| Airbags | Deploy to cushion occupants during a collision. |

| Anti-lock Braking System (ABS) | Prevents wheel lock-up during hard braking for better control. |

| Electronic Stability Control (ESC) | Helps maintain vehicle stability by detecting and reducing loss of traction. |

| Traction Control System | Minimizes wheel spin during acceleration, enhancing grip. |

Recommended Fluids and Specifications

When maintaining a vehicle, it is crucial to use the appropriate fluids and adhere to specified parameters to ensure optimal performance and longevity. This section outlines the essential liquids required for various systems, including engine, transmission, and cooling, along with their recommended standards.

Engine Oil

For optimal engine function, utilize high-quality motor oil that meets the manufacturer’s viscosity and certification requirements. A viscosity rating of 5W-30 is typically advisable, providing excellent lubrication across a range of temperatures. Additionally, look for oils that comply with API SN or higher classifications for enhanced protection and efficiency.

Transmission Fluid

Choosing the right transmission fluid is vital for smooth gear shifting and overall drivability. It is recommended to use fluids that meet the Dexron III or equivalent specifications. Regular checks and changes will help maintain transmission health, reducing the risk of premature wear and costly repairs.