For anyone relying on a reliable and powerful marine engine, understanding its upkeep is essential to ensure consistent performance on the water. This section provides insight into effective ways to maintain and service a 50 HP marine motor, offering knowledge to tackle common issues and routine checks with ease. Whether you’re a seasoned boat owner or new to the mechanics of marine engines, these guidelines will help you approach the process confidently and safely.

Routine maintenance is key to keeping your motor in optimal shape. Regular care helps prevent costly malfunctions, prolonging the engine’s life while keeping it efficient. Here, we’ll explore essential upkeep tasks and highlight potential issues that may arise with frequent use, offering clear steps to address them.

By following these practices and tips, you can navigate the essentials of motor care, ensuring that each component functions smoothly. This guide is designed to support you in getting the most out of your engine, helping maintain its power and reliability for countless adventures ahead.

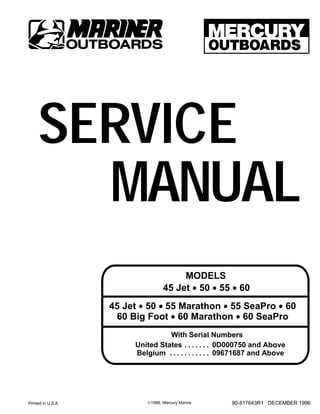

Mercury 50 hp Outboard Repair Guide

This section provides essential insights into maintaining and troubleshooting a specific type of marine propulsion system. It aims to assist users in enhancing performance and longevity by addressing common issues and offering guidance for effective upkeep.

Common Issues and Solutions

Understanding typical problems can significantly streamline the maintenance process. Issues such as starting difficulties, fuel inefficiency, and unusual noises are often reported. Identifying the root cause is crucial; for example, a faulty ignition system may lead to starting troubles, while clogged fuel lines can result in performance drops.

Maintenance Tips

Regular maintenance is key to ensuring optimal functionality. It is advisable to check the oil levels frequently and replace filters as needed. Inspecting the propeller for damage and ensuring proper alignment can prevent unnecessary wear and improve efficiency. Additionally, cleaning the cooling system can prevent overheating and extend the lifespan of the unit.

Understanding the Mercury 50 hp Engine

This section provides an overview of a specific type of propulsion system commonly used in various watercraft. The design of this engine emphasizes efficiency and reliability, making it a preferred choice for both recreational and commercial applications. By delving into its key components and operational principles, users can gain insights into its performance characteristics and maintenance requirements.

Key Features

The engine is characterized by several notable attributes that contribute to its effectiveness:

| Feature | Description |

|---|---|

| Power Output | Delivers a robust performance suitable for various boating needs. |

| Fuel Efficiency | Designed to maximize fuel usage, offering economical operation. |

| Durability | Constructed with high-quality materials to withstand harsh marine conditions. |

Operational Principles

Understanding how this engine operates involves recognizing its key systems, including fuel delivery, ignition, and cooling mechanisms. Each system plays a vital role in ensuring smooth operation and optimal performance during use. Proper knowledge of these principles is essential for effective troubleshooting and maintenance.

Essential Tools for Outboard Repair

Maintaining and fixing marine engines requires a variety of essential equipment to ensure effective and safe operation. Having the right tools at hand not only streamlines the process but also enhances the quality of the work performed. Below is a compilation of necessary instruments that can greatly assist in tasks related to engine maintenance.

Basic Tools

- Socket set

- Wrenches

- Phillips and flathead screwdrivers

- Pliers

- Torque wrench

Specialized Instruments

- Compression tester

- Multimeter

- Fuel line removal tool

- Propeller puller

- Engine hoist

Equipping yourself with these tools will facilitate a more efficient workflow and contribute to the longevity of the engine. Regular maintenance is key to ensuring optimal performance on the water.

Common Issues and Troubleshooting Tips

This section provides an overview of frequent problems encountered with marine propulsion systems and offers practical advice for resolving these issues. Understanding the underlying causes can help in maintaining optimal performance and prolonging the lifespan of the equipment.

Starting Difficulties: One of the most common challenges is trouble starting the engine. This may be due to a drained battery, faulty connections, or issues with the fuel system. Ensuring that the battery is fully charged and connections are clean can often remedy this situation.

Overheating: Engines may overheat due to a blocked cooling system or insufficient coolant levels. Regularly inspecting the cooling passages and ensuring adequate fluid levels can prevent overheating and potential damage.

Loss of Power: A noticeable decrease in power could indicate fuel delivery issues or problems with the ignition system. Checking fuel lines for blockages and inspecting spark plugs for wear can help restore performance.

Unusual Noises: Strange sounds during operation can signal mechanical issues. Regular maintenance checks, including lubrication and inspection of moving parts, are essential to identify and address these concerns early.

By staying attentive to these common problems and applying the suggested solutions, users can effectively manage their marine propulsion systems and enhance their reliability on the water.

Step-by-Step Maintenance Procedures

This section outlines essential practices for ensuring the longevity and optimal performance of your marine engine. Regular attention to various components will help prevent issues and maintain efficiency, making your boating experience more enjoyable.

Inspection and Cleaning

Begin by thoroughly inspecting the engine for any signs of wear or damage. Remove debris from air intakes and ensure that cooling systems are unobstructed. Cleaning the exterior surfaces helps prevent corrosion and promotes heat dissipation.

Fluid Checks and Replacements

Regularly check the levels of fuel, oil, and cooling liquids. Replace these fluids as needed to ensure the engine operates smoothly. Using the correct type of fluids is crucial for maintaining efficiency and protecting components from wear.

Replacing the Water Pump Impeller

The water pump impeller is a crucial component that ensures the cooling system operates effectively. Over time, this part may wear out or become damaged, leading to decreased performance and potential overheating. Regular maintenance and timely replacement are essential to keep the engine running smoothly.

Before beginning the replacement process, gather the necessary tools and materials:

- New impeller

- Socket set

- Screwdrivers

- Gasket sealant

- Clean cloth

Follow these steps to successfully replace the impeller:

- Disconnect the power supply to the engine to ensure safety.

- Remove the housing cover to access the water pump.

- Carefully take out the old impeller, noting its orientation for proper installation of the new one.

- Inspect the housing and other components for any signs of wear or damage.

- Apply gasket sealant if required, then position the new impeller into the housing.

- Reassemble the housing cover, ensuring all screws are tightened securely.

- Reconnect the power supply and run the engine to check for proper operation.

By following these steps, you can ensure that the cooling system remains efficient, helping to prolong the life of the engine.

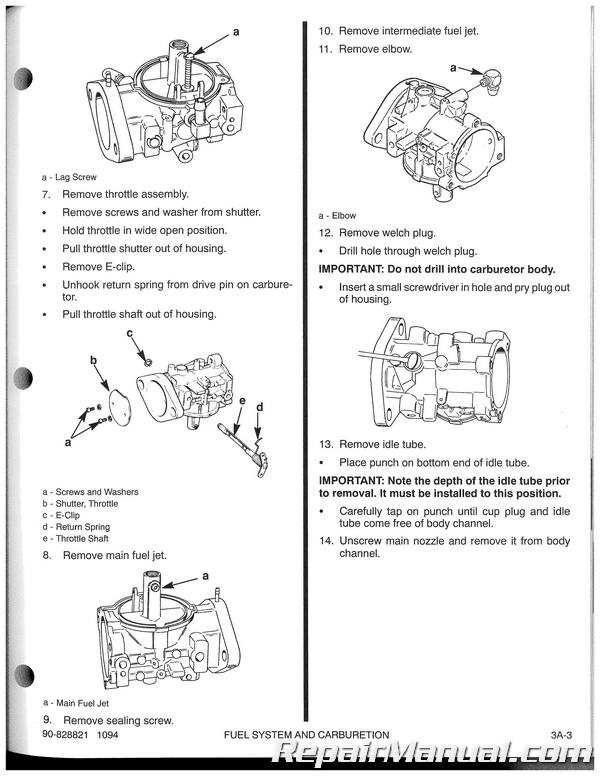

Carburetor Cleaning and Adjustment Tips

Maintaining optimal performance in marine engines often requires attention to the fuel delivery system. Proper upkeep of the fuel mixing component is essential for ensuring efficient operation and longevity. Regular cleaning and precise adjustments can significantly enhance engine performance.

To begin the cleaning process, carefully disassemble the component, noting the arrangement of parts for reassembly. Use a suitable solvent to remove any deposits or residues. Pay special attention to small passages, as clogs can impede fuel flow. After thorough cleaning, allow all parts to dry completely.

Once clean, inspect the various components for wear and damage. If any parts are found to be compromised, consider replacing them to prevent future issues. During reassembly, ensure that all connections are secure and that gaskets are in good condition to avoid leaks.

After cleaning, adjustment is crucial for optimal operation. Start by setting the air-fuel mixture according to the manufacturer’s specifications. Fine-tuning may be necessary based on engine performance. Listen for any irregularities while the engine is running; slight adjustments can often lead to noticeable improvements.

In summary, regular maintenance of the fuel mixing unit is vital for reliable engine function. By following these cleaning and adjustment guidelines, you can help ensure that your engine runs smoothly and efficiently.

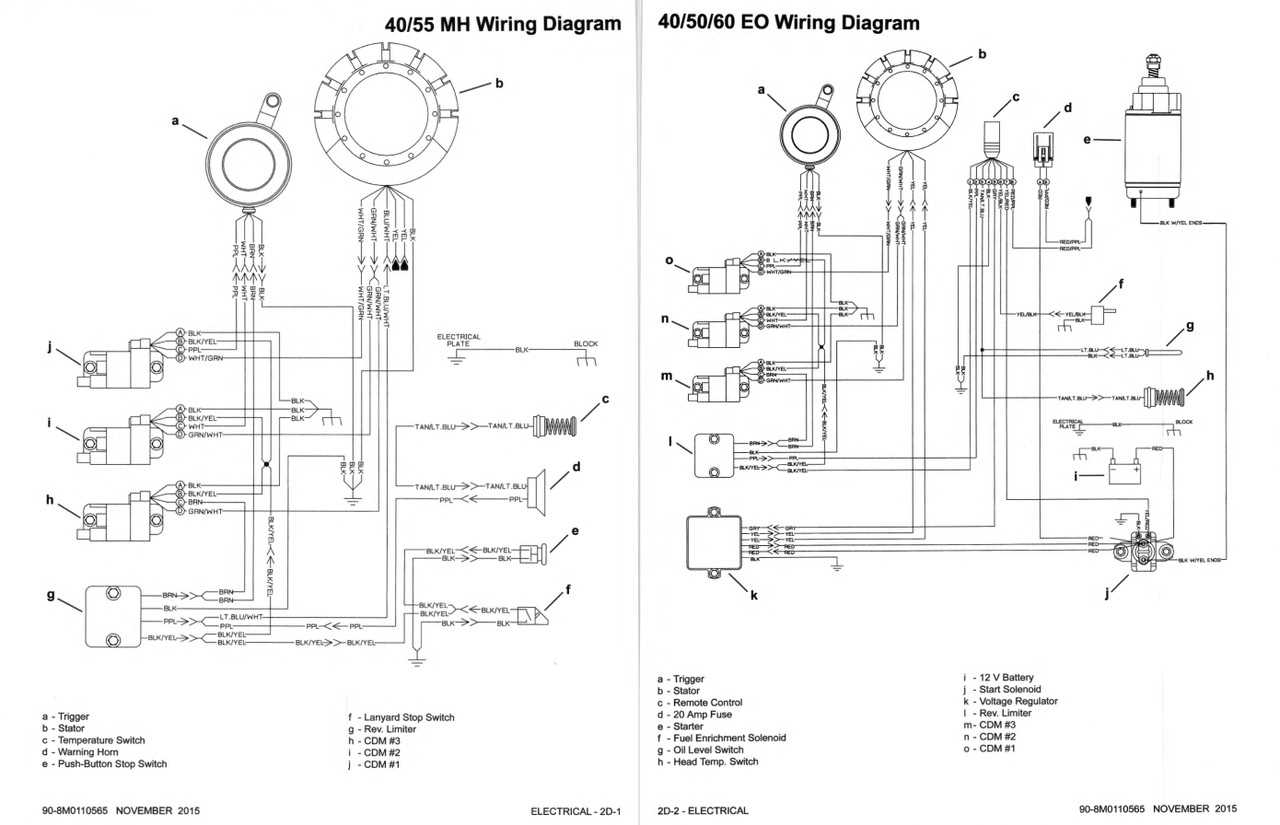

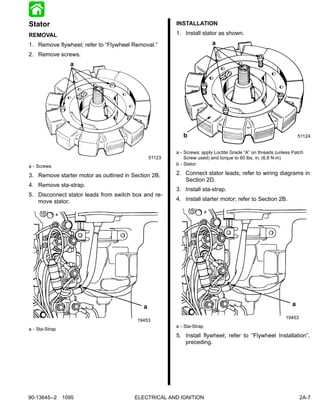

Electrical System Inspection and Repair

This section focuses on assessing and maintaining the electrical components of marine engines. A thorough examination is essential to ensure optimal performance and prevent potential failures. Proper functionality of the electrical system is crucial for starting the engine, powering essential devices, and maintaining safe operation on the water.

Common Issues to Check

Regular inspection can help identify problems before they escalate. Here are some typical concerns to look for:

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Weak Battery | Difficulty starting, dim lights | Charge or replace the battery |

| Corroded Connections | Intermittent power loss | Clean and secure connections |

| Faulty Alternator | Battery not charging | Test and replace if necessary |

Inspection Procedures

Follow these steps for a thorough evaluation of the electrical components:

- Start by checking the battery voltage with a multimeter.

- Inspect all wiring for signs of wear or damage.

- Examine fuses and circuit breakers for functionality.

- Test the alternator output while the engine is running.

Fuel System Cleaning and Maintenance

Ensuring the optimal performance of your engine’s fuel delivery system is essential for efficiency and longevity. Regular cleaning and maintenance can prevent issues such as clogging and poor fuel flow, which can lead to decreased performance and increased wear.

Regular Inspections: Frequent checks of fuel lines, filters, and injectors are crucial. Look for any signs of wear or leaks that could compromise functionality.

Cleaning Procedures: Use a suitable cleaning solution to remove any deposits that may accumulate over time. Flushing the system periodically can help maintain clear pathways for fuel.

Filter Replacement: Change fuel filters as recommended to ensure contaminants do not enter the system. A clean filter is vital for maintaining optimal pressure and flow.

Professional Servicing: If unsure about the cleaning process, consider consulting a professional. Expert servicing can provide thorough maintenance and identification of potential issues.

Propeller Damage and Replacement Guide

This section provides essential insights into the identification, assessment, and resolution of issues related to propeller impairments. Understanding the signs of damage and knowing when to consider a replacement can significantly enhance performance and safety on the water.

Common indicators of propeller damage include:

- Visible cracks or bends in the blades

- Unusual vibrations during operation

- Decreased performance or acceleration

- Unexplained noise or grinding sounds

When assessing the extent of damage, consider the following steps:

- Inspect the propeller closely for any physical deformities.

- Check the hub for signs of wear or misalignment.

- Perform a test run to evaluate performance and handling.

If damage is confirmed, replacing the propeller may be necessary. Follow these guidelines for replacement:

- Ensure the new propeller matches the specifications required for optimal performance.

- Use appropriate tools for removal and installation to prevent further damage.

- Tighten all connections securely to avoid issues during operation.

Regular inspections and timely replacements can greatly extend the lifespan of the propulsion system, ensuring reliable and efficient navigation.

Battery Care and Charging Instructions

Proper maintenance and charging of batteries are crucial for ensuring optimal performance and longevity. Understanding the essential practices for keeping batteries in good condition can prevent unexpected failures and enhance reliability.

General Maintenance Tips

- Regularly inspect the battery terminals for corrosion and clean them as needed.

- Ensure that the battery is securely mounted to prevent vibrations that can damage internal components.

- Check the electrolyte levels (if applicable) and top up with distilled water to maintain proper operation.

Charging Procedures

- Choose an appropriate charger compatible with your battery type.

- Connect the charger to the battery, ensuring the positive and negative terminals are correctly aligned.

- Set the charger to the correct voltage and amperage settings for your battery.

- Monitor the charging process and disconnect once the battery is fully charged.

Testing and Adjusting Engine Compression

Assessing and modifying the compression of a marine engine is crucial for ensuring optimal performance and efficiency. This process helps identify potential issues that may affect power output and fuel consumption, allowing for necessary adjustments to maintain engine health.

To conduct a compression test, follow these steps:

- Gather the required tools, including a compression gauge and a socket set.

- Ensure the engine is at operating temperature and has been turned off for a few minutes.

- Remove the spark plugs to allow for easier access and to prevent misfires during testing.

- Insert the compression gauge into the spark plug opening of the first cylinder.

- Crank the engine several times to obtain a reading on the gauge.

- Record the reading and repeat the process for each cylinder.

After obtaining the compression readings, compare them to the manufacturer’s specifications. If the measurements fall below the recommended range, adjustments may be necessary.

Consider the following methods for improving compression:

- Inspect and replace worn or damaged piston rings.

- Check the cylinder head for cracks or leaks.

- Ensure the valves are sealing properly and adjust the valve clearance if needed.

Regular testing and adjustment of engine compression are essential for maintaining performance and extending the lifespan of the engine.