Maintaining complex machinery requires a deep understanding of its components and their interrelationships. This section delves into the intricacies of a specific engine type, emphasizing the importance of proper care and timely intervention to ensure optimal performance. Knowledge of each system’s functionality enables users to address issues efficiently, minimizing downtime.

Systematic approaches to diagnosing and resolving mechanical problems are essential for any operator or technician. This guide will explore various procedures, offering insights into both common challenges and advanced techniques. Through careful examination of technical details, users will gain a clearer perspective on effective solutions.

Incorporating practical advice and troubleshooting steps, this resource aims to enhance proficiency in managing engine issues. Whether dealing with routine checks or unexpected complications, understanding the underlying principles will empower individuals to make informed decisions and achieve successful outcomes.

When operating complex machinery, various challenges may arise that can hinder performance and efficiency. Understanding these prevalent problems and their solutions is essential for maintaining optimal functionality and longevity of the equipment.

Frequent Challenges

- Overheating: This can lead to engine shutdowns and reduced performance.

- Fuel delivery issues: Inconsistent fuel flow can result in poor acceleration and engine misfires.

- Electrical failures: Problems with wiring and connections may cause components to malfunction.

- Fluid leaks: These can impact the overall system and lead to severe damage if not addressed promptly.

- Excessive smoke: This may indicate improper combustion or oil contamination.

Troubleshooting Methods

- Inspect the Cooling System: Check coolant levels and ensure there are no obstructions in the radiator.

- Examine Fuel Lines: Ensure that all fuel lines are free from blockages and leaks.

- Test Electrical Components: Use a multimeter to verify voltage levels at various points in the system.

- Look for Fluid Leaks: Regularly inspect under the machinery for any signs of leaking fluids.

- Monitor Exhaust Emissions: Identify the color and smell of exhaust to pinpoint combustion issues.

Addressing these common issues with the appropriate steps can help ensure the reliable operation of the machinery and prevent more significant problems in the future.

Essential Tools for Repair Work

When engaging in maintenance tasks, having the right set of instruments can significantly enhance efficiency and effectiveness. A well-equipped toolkit allows individuals to tackle a variety of challenges with confidence, ensuring that each task is performed accurately.

Basic Hand Tools: A fundamental assortment of hand tools, including wrenches, screwdrivers, and pliers, is indispensable for any maintenance activity. These tools provide the necessary leverage and precision required to assemble or disassemble components easily.

Power Tools: Electric drills, impact wrenches, and saws can expedite labor-intensive tasks. Utilizing power tools not only saves time but also improves the quality of work by allowing for more precise cuts and fastenings.

Diagnostic Equipment: To troubleshoot issues effectively, diagnostic devices such as multimeters and pressure gauges are essential. These instruments help identify malfunctions, enabling swift resolution of problems and minimizing downtime.

Safety Gear: Personal protective equipment, including gloves, goggles, and helmets, is crucial for ensuring safety during maintenance activities. Adhering to safety protocols reduces the risk of accidents and promotes a secure working environment.

In conclusion, a comprehensive selection of instruments is vital for successful maintenance tasks. Prioritizing quality and variety in tools not only enhances performance but also ensures a smoother workflow.

Step-by-Step Maintenance Procedures

Maintaining equipment is essential for optimal performance and longevity. This section outlines systematic approaches to ensure all components are functioning efficiently. Following these guidelines will help in identifying potential issues before they escalate, thereby enhancing reliability and reducing downtime.

1. Inspection and Cleaning: Regularly examine all parts for wear and tear. Clean surfaces and components to prevent dirt accumulation, which can lead to malfunction. Utilize appropriate cleaning agents and tools for effective results.

2. Lubrication: Apply suitable lubricants to moving parts as per the specifications. This step minimizes friction and prevents overheating, ensuring smooth operation. Check lubricant levels frequently and replenish as necessary.

3. Component Testing: Test electrical systems and connections to verify functionality. Use diagnostic tools to measure performance metrics, ensuring all systems are operating within acceptable parameters.

4. Filter Replacement: Regularly replace air, fuel, and oil filters according to the recommended schedule. Clean filters can significantly improve efficiency and prolong the lifespan of the machinery.

5. Calibration: Perform calibration on various systems to ensure accuracy. This includes adjusting settings and fine-tuning components to align with manufacturer specifications.

By adhering to these structured procedures, operators can maintain the equipment effectively, ensuring its performance remains at peak levels.

Engine Specifications and Features

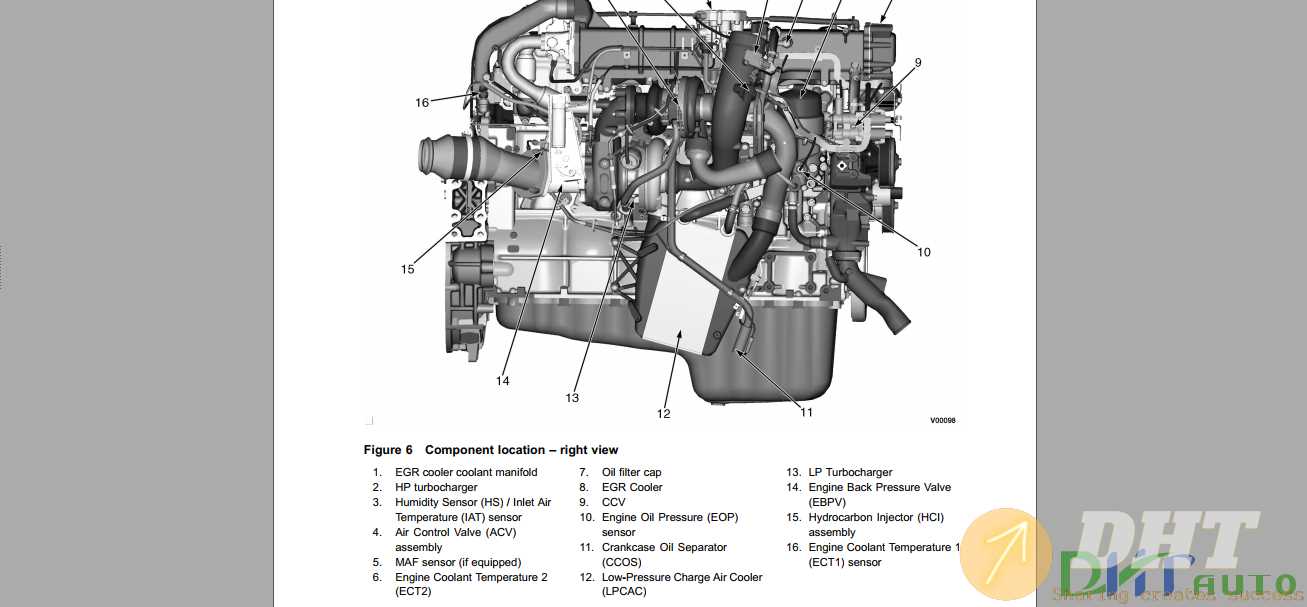

This section provides a comprehensive overview of the fundamental characteristics and specifications of the power unit, highlighting its design, performance, and technological advancements. Understanding these aspects is crucial for evaluating the engine’s capabilities and ensuring optimal functionality in various applications.

Performance Metrics

The engine is engineered to deliver robust performance, characterized by its displacement and output ratings. With a focus on efficiency, it incorporates advanced fuel management systems that enhance combustion, resulting in improved torque and horsepower. This power unit is designed to meet demanding operational requirements while maintaining compliance with emission standards.

Construction and Materials

Durability and reliability are key components of this engine’s design. Constructed with high-quality materials, it features a robust block and reinforced components that withstand extreme conditions. The integration of innovative engineering techniques ensures longevity and reduces the likelihood of mechanical failure, making it suitable for a variety of heavy-duty tasks.

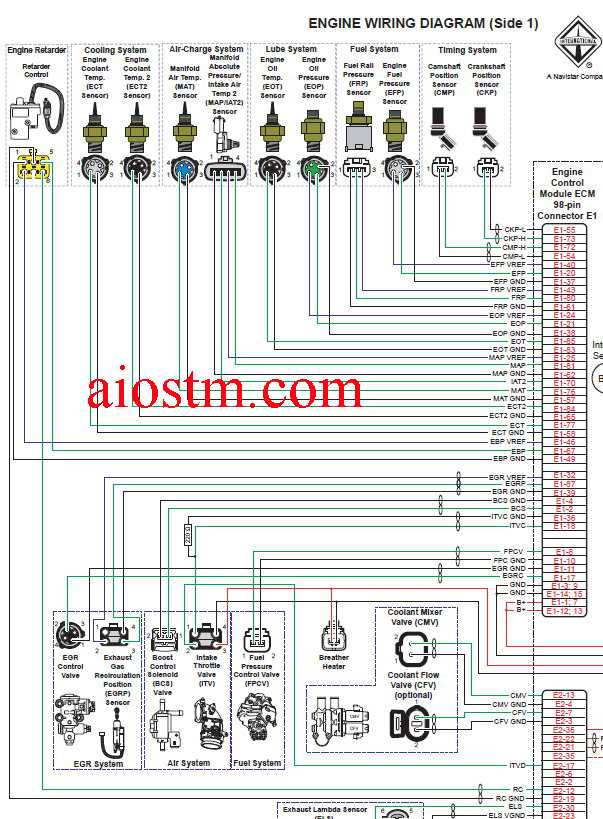

Electrical System Diagnostics Guide

This section provides a comprehensive overview of troubleshooting procedures for electrical systems. Understanding the intricacies of these systems is crucial for effective maintenance and performance enhancement. This guide will assist you in identifying common issues, utilizing diagnostic tools, and ensuring optimal functionality.

Key components to focus on include:

- Batteries

- Wiring harnesses

- Fuses and relays

- Connectors

- Control modules

Follow these steps for effective diagnostics:

- Visual Inspection: Examine all components for signs of wear, damage, or corrosion. Ensure that connections are secure and free from debris.

- Use of Diagnostic Tools: Employ multimeters and scan tools to check voltage levels and diagnose fault codes. This step is essential for pinpointing electrical issues.

- Functional Tests: Conduct tests on various components to verify their operational status. This includes checking the functionality of switches, sensors, and actuators.

- Analyze Data: Review data from diagnostic tools to identify patterns or recurrent issues that may indicate a larger problem.

- Documentation: Record findings and actions taken during the diagnostic process. Maintaining accurate records can aid future troubleshooting efforts.

By following this guide, you will enhance your ability to diagnose and resolve electrical system challenges effectively, ensuring improved reliability and performance.

Fluid Types and Capacities

Understanding the various types of liquids and their respective volumes is crucial for the optimal performance and longevity of any engine system. This section provides insights into the specific fluid requirements necessary for maintaining efficiency and ensuring proper functionality.

Engine Oil

Engine oil is vital for lubricating moving components and minimizing wear. It is essential to use oil that meets the specified viscosity and quality standards. Typically, a capacity of 10 to 12 quarts is required, depending on the engine configuration. Regular checks and changes help maintain peak performance.

Coolant

Maintaining the appropriate coolant level is equally important for preventing overheating and ensuring efficient temperature regulation. The system usually holds around 15 to 20 quarts of coolant. Using the correct type, which is often a mix of antifreeze and water, is necessary to protect against corrosion and freezing.

Replacing Key Components Effectively

When addressing the replacement of crucial parts in complex machinery, it’s essential to approach the task with precision and attention to detail. Proper execution can significantly enhance the functionality and lifespan of the equipment, ensuring optimal performance over time.

Preparation and Planning

Before commencing the replacement process, thorough preparation is key. Consider the following steps:

- Review component specifications to ensure compatibility.

- Gather necessary tools and materials to facilitate a smooth operation.

- Consult technical documents or guidelines for reference on procedures.

Steps for Effective Replacement

To replace components effectively, adhere to the following process:

- Power down the system and disconnect any electrical sources to ensure safety.

- Carefully remove the faulty component, taking note of any attached wiring or connections.

- Install the new component, ensuring it is secured correctly and all connections are reestablished.

- Conduct a thorough inspection of the installation to confirm everything is in place.

- Restore power and run tests to verify that the new part operates as intended.

By following these guidelines, individuals can achieve effective results when replacing essential components, leading to improved reliability and performance of the machinery.

Understanding Warranty and Service Plans

This section delves into the significance of coverage and maintenance agreements for your vehicle. These plans not only provide peace of mind but also help ensure the longevity and optimal performance of your equipment. By understanding the various options available, you can make informed decisions that align with your needs and expectations.

Typically, these agreements cover specific repairs and routine servicing, protecting you from unexpected expenses. It’s essential to comprehend the terms and conditions associated with these plans to fully leverage their benefits.

| Aspect | Description |

|---|---|

| Types of Coverage | Various plans are available, ranging from basic coverage to comprehensive options that include major components. |

| Duration | Coverage periods can vary; understanding the timeline helps you choose the right plan for your usage. |

| Costs | Consideration of upfront and ongoing fees is crucial to assess the financial impact of the chosen plan. |

| Claim Process | Familiarizing yourself with the claims procedure ensures smooth service when repairs are needed. |

| Exclusions | Being aware of what is not covered can prevent misunderstandings and unexpected out-of-pocket expenses. |

In conclusion, having a thorough understanding of warranty and service agreements empowers you to make choices that enhance your ownership experience and safeguard your investment.

Resources for Further Assistance

When facing challenges with your machinery, having access to a variety of resources can significantly enhance your troubleshooting experience. This section highlights various avenues where you can obtain valuable insights, guidance, and community support, ensuring you are well-equipped to address any issues that may arise.

Online Forums and Communities

Engaging with online platforms dedicated to enthusiasts and professionals alike can be immensely beneficial. These forums often feature discussions on common concerns, sharing of personal experiences, and expert advice. Participating in such communities not only provides immediate solutions but also connects you with others who share similar interests.

Manufacturer and Dealer Support

Reaching out to the original equipment provider or authorized dealerships can yield precise information and assistance tailored to your specific needs. They often have dedicated support teams ready to offer technical help, parts availability, and warranty guidance, ensuring you have reliable support throughout your ownership experience.

Utilizing these resources will empower you to tackle any difficulties with confidence, ensuring optimal performance and longevity of your equipment.