When faced with the challenge of malfunctioning entryway mechanisms, homeowners often find themselves searching for solutions that are both effective and budget-friendly. Understanding the inner workings of these systems can empower individuals to tackle common issues with confidence. This section aims to guide you through essential techniques for getting your access point back in optimal condition.

Many times, simple adjustments or maintenance can alleviate problems without the need for professional assistance. By exploring various methods, you will gain insights into the tools required and the steps involved in restoring functionality. This approach not only saves money but also enhances your knowledge of how these mechanisms operate.

Embracing a hands-on approach can transform the daunting task of addressing issues into an achievable project. With the right information and a little patience, you can overcome obstacles and ensure your entryway remains secure and accessible.

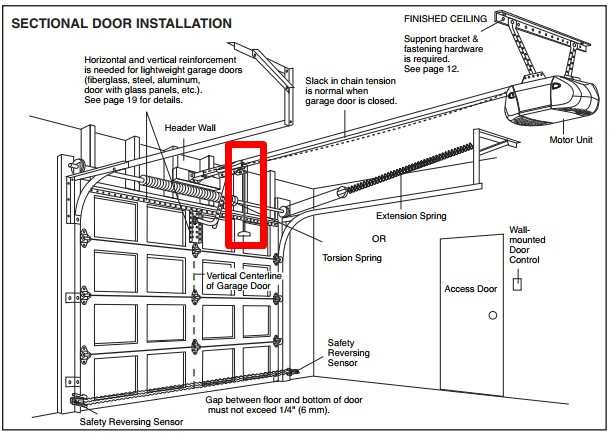

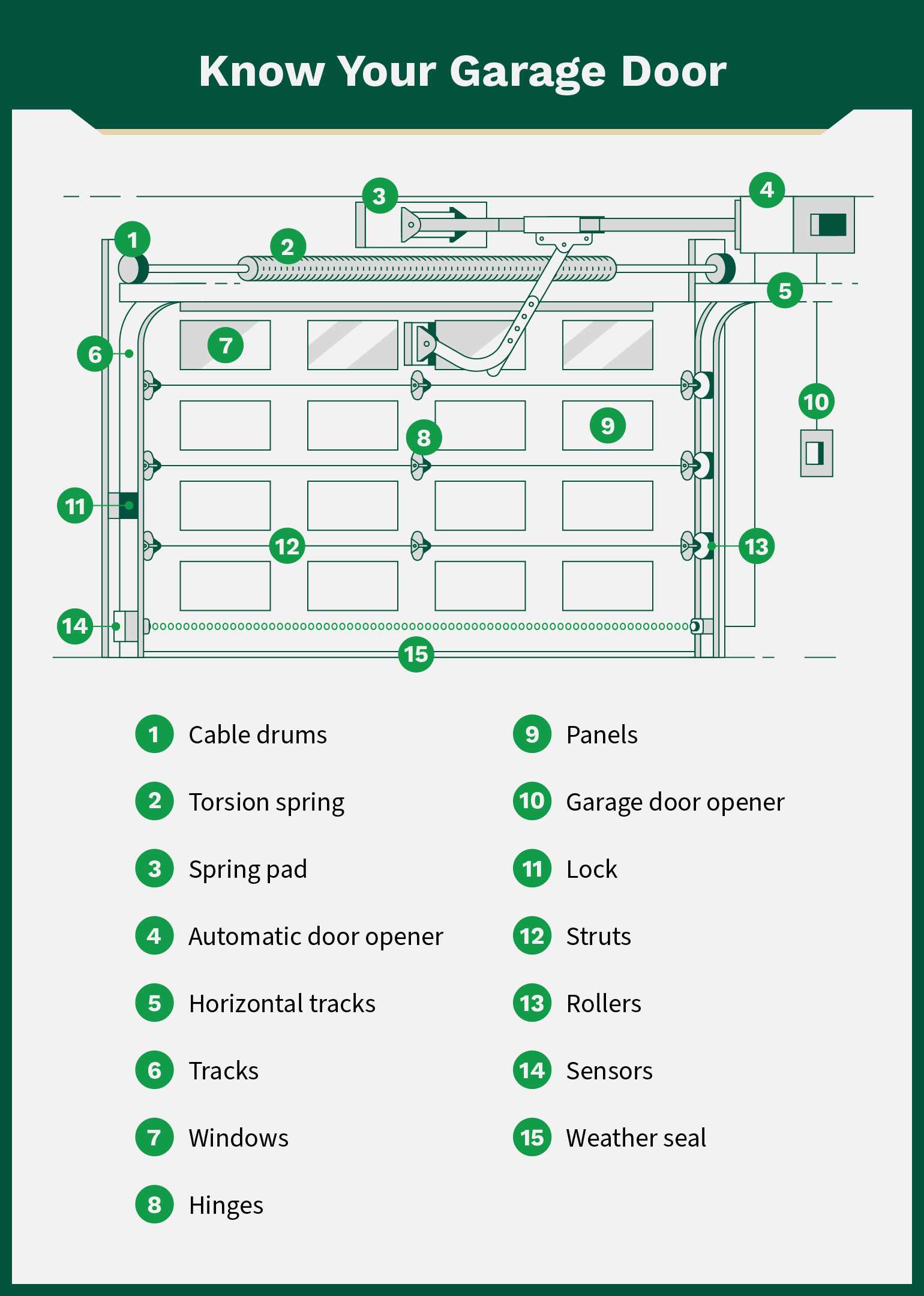

This section delves into the fundamental principles behind the functioning of these systems, highlighting their essential components and how they interact to facilitate operation.

The typical setup includes several key elements:

- Frame: The sturdy structure that supports the entire assembly.

- Panel: The main piece that provides the barrier, often constructed from durable materials.

- Track: A guiding pathway that ensures smooth movement during opening and closing.

- Rollers: Wheels that enable seamless travel along the track.

- Handle: The component that allows for manual operation, providing grip and leverage.

Each of these parts plays a critical role in ensuring efficient and reliable functionality. Understanding their interactions can aid in troubleshooting and enhancing performance.

Tools Needed for Repairs

To effectively address issues related to the opening mechanism, it’s essential to gather the right equipment. Having the appropriate instruments not only streamlines the process but also ensures safety and efficiency during maintenance tasks.

- Wrenches and Sockets: Vital for loosening and tightening bolts.

- Screwdrivers: Essential for removing or adjusting screws on various components.

- Pliers: Useful for gripping and bending wires or small parts.

- Level: Ensures that all mechanisms are properly aligned.

- Measuring Tape: Helps in measuring distances and ensuring correct fittings.

- Lubricant: Important for maintaining smooth operation of moving parts.

- Safety Gear: Includes gloves and goggles to protect yourself while working.

Gathering these essential tools will prepare you to tackle a variety of issues, making the process smoother and more manageable.

Steps to Lubricate Garage Door Parts

Maintaining smooth operation of your access system is essential for its longevity and efficiency. Regular lubrication minimizes friction and wear, ensuring all components function harmoniously. Follow these steps to achieve optimal performance.

Gather Necessary Materials

Before starting, collect the required items: a quality lubricant designed for mechanical systems, a clean cloth, and a ladder for hard-to-reach areas. Ensure the workspace is clear to facilitate the process.

Apply Lubricant Strategically

Begin by inspecting all moving components, including rollers, hinges, and tracks. Use the cloth to wipe away any dirt or debris. Then, apply the lubricant sparingly to each part, focusing on joints and contact points. Allow the substance to penetrate for improved effectiveness.

Adjusting Door Tracks for Smooth Operation

Ensuring effortless movement of the entrance requires precise alignment of its guiding elements. Proper adjustments can significantly enhance functionality and longevity, allowing for seamless usage.

Start by inspecting the tracks for any visible signs of misalignment or debris. Clear away any obstacles that may hinder movement. Following this, assess the level of the tracks to confirm they are straight and parallel to each other. If adjustments are necessary, loosen the mounting hardware slightly to reposition the tracks.

| Step | Description |

|---|---|

| 1 | Inspect tracks for obstructions and level. |

| 2 | Loosen hardware to adjust tracks as needed. |

| 3 | Tighten the hardware securely after adjustment. |

| 4 | Test movement to ensure smooth operation. |

Regular maintenance and adjustments not only prevent issues but also extend the lifespan of the system. Always prioritize safety by ensuring that the elements are securely fastened before concluding your adjustments.

Fixing Broken Springs Safely

Dealing with malfunctioning components in a lifting system can be a daunting task. Ensuring safety during the process is paramount, as these elements are under significant tension and can cause serious injury if handled improperly. This section provides essential guidance on how to approach the situation with care and precision.

Before beginning any work, it is crucial to gather the right tools and equipment. Protective gear such as gloves and safety goggles should be worn to shield against potential hazards. Additionally, having a sturdy ladder and appropriate wrenches at hand will facilitate the process.

When you are ready to proceed, first ensure that the system is completely disconnected from any power source. Carefully release the tension from the springs using a winding tool, taking extra precautions to maintain control. Once the tension is alleviated, you can safely remove the broken components and replace them with new ones, following manufacturer specifications. Re-tensioning should be done slowly and methodically to avoid sudden movements.

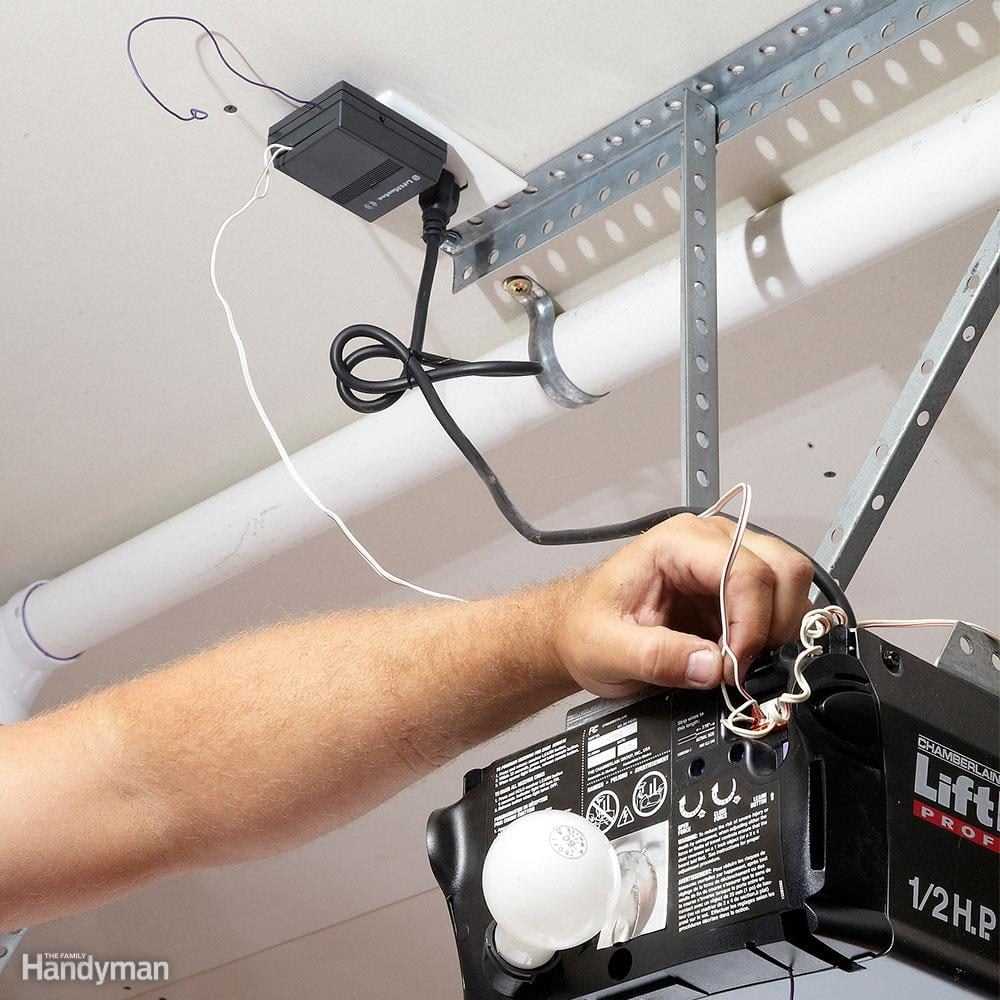

Replacing Damaged Cables Effectively

When dealing with malfunctioning mechanisms, addressing frayed or broken wires is crucial for restoring functionality. These components play a vital role in ensuring smooth operation and safety. A careful approach can prevent further complications and enhance the longevity of the system.

Assessment of the situation is the first step. Identify the extent of the damage and determine whether a complete replacement is necessary or if a simple fix will suffice. It’s essential to ensure that all power sources are disconnected to avoid any hazards during the process.

Once the damaged wires are located, gather the necessary tools, such as wire cutters, crimpers, and suitable replacement materials. Measure the length of the cables accurately to ensure a proper fit. Carefully detach the damaged wires, making sure not to disturb surrounding components.

Next, install the new cables by securing them in place with appropriate connectors. Ensure that each connection is tight and insulated to prevent future wear and tear. After installation, conduct a thorough check to confirm that everything is functioning correctly before re-energizing the system.

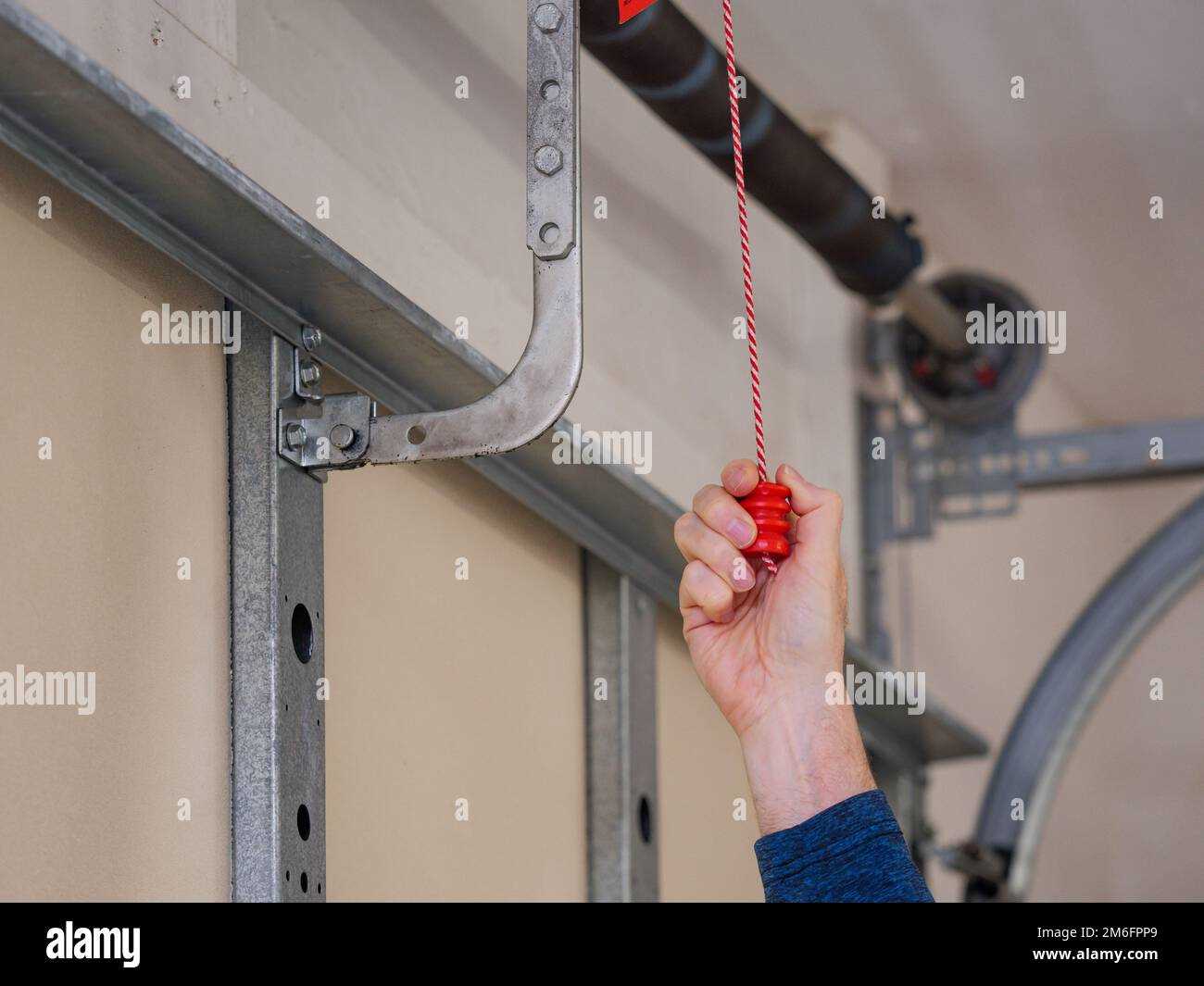

How to Realign Garage Door Sensors

Ensuring proper alignment of safety devices is essential for the smooth operation of your overhead entry system. Misalignment can lead to malfunctioning or, worse, accidents. This guide will help you adjust these devices effectively, enhancing both functionality and safety.

Identify the Issue

The first step is to determine if misalignment is indeed the problem. Observe whether the mechanism operates correctly or if it halts unexpectedly. Check for any blinking indicators on the sensors, which often signal alignment issues.

Adjusting the Sensors

Begin by locating the sensors, usually mounted on each side of the opening. If they appear off, gently loosen the mounting screws. Position them so they face each other directly. Once aligned, tighten the screws securely. To test, attempt to operate the system; it should function smoothly without interruptions. If issues persist, repeat the alignment process, ensuring that the sensors are clean and unobstructed.

Weatherproofing Your Garage Door

Ensuring that your entryway remains shielded from the elements is crucial for maintaining a comfortable environment within your space. Effective sealing and insulation techniques can significantly reduce energy loss and enhance the durability of your structure. By implementing a few strategic measures, you can keep moisture and drafts at bay, contributing to a more stable indoor climate.

Sealing Gaps and Cracks

Identifying and sealing any openings is the first step toward enhanced protection. Utilize weatherstripping materials to cover gaps along the edges. Caulking can also be applied to cracks to prevent water infiltration, which could lead to mold growth and structural damage. Regularly inspect these areas for wear and replace them as necessary to maintain optimal performance.

Insulating for Efficiency

Adding insulation not only improves energy efficiency but also minimizes sound transmission. Consider using insulated panels or foam board to enhance the thermal barrier. This will help regulate temperatures inside and lower heating or cooling costs. A well-insulated structure is less susceptible to external temperature fluctuations, ensuring a more pleasant atmosphere year-round.

Maintaining the Door’s Exterior Finish

Preserving the outer appearance of your structure is essential for both aesthetic appeal and longevity. Regular upkeep not only enhances the visual charm but also protects the materials from environmental wear. Below are some key practices to ensure your surface remains in top condition.

Regular Cleaning

Keeping the exterior clean is vital to prevent dirt and grime buildup. Follow these steps:

- Use a soft cloth or sponge to gently wipe the surface.

- Opt for a mild detergent mixed with water for effective cleaning.

- Rinse thoroughly with clean water to remove any soap residue.

Protective Coatings

Applying protective layers can greatly enhance durability. Consider the following options:

- Paint: Choose a high-quality exterior paint to shield against UV rays and moisture.

- Sealants: Regularly apply sealants to protect wood from rot and metal from rust.

- Wax: For a glossy finish, a coat of automotive wax can provide an extra layer of protection.

Recognizing When to Call a Professional

Understanding when to seek expert assistance can save time and prevent further complications. Certain issues may require specialized knowledge and tools that are beyond typical DIY capabilities.

Consider the following indicators:

- Persistent problems despite attempts at self-resolution.

- Unusual sounds or behaviors that arise unexpectedly.

- Difficulty in accessing crucial components.

- Presence of rust, damage, or wear that seems extensive.

- Inability to operate the mechanism safely.

If any of these signs are present, it’s wise to consult a qualified technician who can ensure everything is functioning correctly and safely.

Preventive Measures for Future Issues

Taking proactive steps can significantly reduce the likelihood of encountering difficulties with your entry mechanism. By implementing a routine maintenance schedule and being aware of potential risks, you can ensure smooth operation and extend the lifespan of the system.

Regular Maintenance Checks

Routine inspections are crucial for identifying and addressing minor problems before they escalate. Consider the following key aspects during your assessments:

| Component | Check Frequency | Action |

|---|---|---|

| Tracks | Monthly | Clean and lubricate |

| Springs | Quarterly | Inspect for wear |

| Hardware | Monthly | Tighten loose bolts |

Awareness of Environmental Factors

External elements can impact the functionality of your system. Being mindful of these factors can help mitigate potential issues:

- Keep the surrounding area clear of debris and obstructions.

- Avoid exposing the components to harsh weather conditions.

- Monitor for signs of rust or corrosion and address them promptly.