When it comes to maintaining powerful vehicles designed for rigorous tasks, having access to detailed information is essential. A well-structured resource can provide insights into troubleshooting, routine servicing, and intricate repairs, ensuring optimal performance and longevity. This guide serves as a valuable asset for owners and mechanics alike, focusing on the nuances that come with managing these robust machines.

Understanding the intricacies of large vehicle systems can seem daunting, but with the right framework, the process becomes manageable. From engine diagnostics to electrical systems, this comprehensive approach highlights the importance of each component and how they interconnect. By equipping oneself with the necessary knowledge, one can address issues with confidence and precision.

Moreover, the significance of regular maintenance cannot be overstated. It not only enhances performance but also safeguards against unforeseen breakdowns. This resource emphasizes proactive care, providing practical tips and step-by-step instructions that empower users to take charge of their vehicle’s health. Embracing this knowledge ultimately leads to a more efficient and reliable operation.

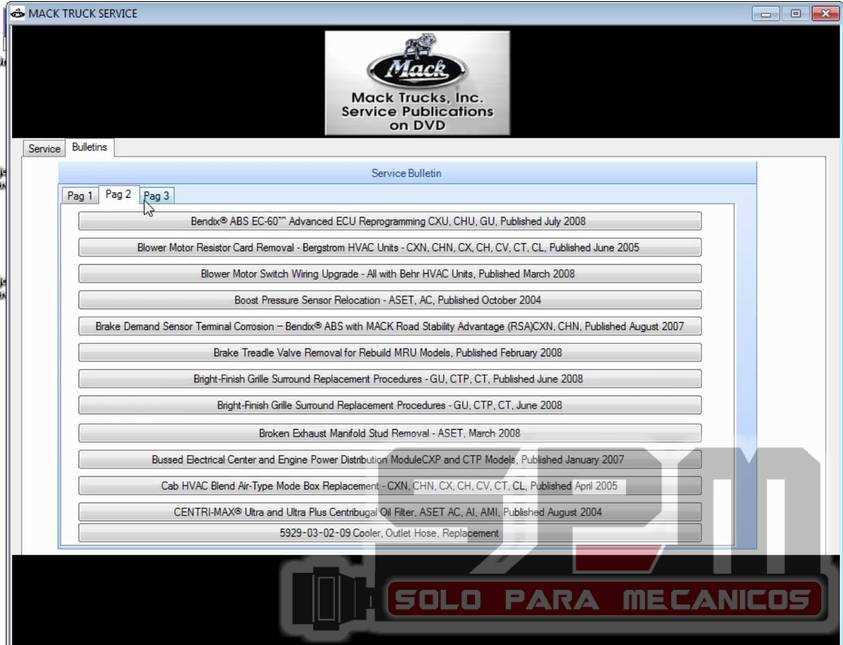

Mack Truck Repair Manual Overview

This section provides a comprehensive introduction to the essential guidelines and resources designed for maintaining and troubleshooting heavy-duty vehicles. Understanding these resources is vital for ensuring optimal performance and longevity of the machinery.

Users will find valuable information covering various aspects, including maintenance schedules, diagnostic procedures, and specific component details. Each resource is structured to facilitate efficient reference, ensuring that operators and technicians can swiftly access the information they need.

| Feature | Description |

|---|---|

| Maintenance Schedules | Detailed timelines for routine checks and servicing tasks to enhance reliability. |

| Troubleshooting Guides | Step-by-step processes for identifying and resolving common issues. |

| Component Diagrams | Illustrations depicting parts and assemblies for better understanding of structure. |

| Specifications | Technical data for various models, ensuring compatibility with replacement parts. |

| Safety Protocols | Guidelines aimed at ensuring safe practices during maintenance and operation. |

By familiarizing oneself with these resources, individuals can enhance their technical knowledge and skill set, ultimately contributing to the effective operation of these robust vehicles.

Essential Tools for Truck Maintenance

Proper upkeep of heavy vehicles requires a well-equipped toolkit to ensure optimal performance and longevity. A combination of basic hand tools, specialized equipment, and diagnostic instruments is vital for addressing various mechanical and electrical issues. Understanding which tools are indispensable can significantly enhance the efficiency of maintenance tasks.

Basic Hand Tools

Having a solid selection of hand tools is fundamental for any maintenance enthusiast. Tools such as wrenches, sockets, and screwdrivers are crucial for performing routine tasks. Torque wrenches are especially important, as they ensure that bolts are tightened to the correct specifications, preventing potential failures. Additionally, pliers and hammers are essential for handling various components during service.

Specialized Diagnostic Equipment

Beyond basic tools, specialized diagnostic equipment is crucial for identifying underlying issues. Multimeters are invaluable for checking electrical systems, while code readers help interpret error codes from onboard systems. Investing in a quality compression tester can also provide insights into engine performance, allowing for timely interventions and effective troubleshooting.

Understanding Mack Truck Models

This section delves into the diverse range of vehicles produced by the renowned manufacturer, highlighting the unique characteristics and applications of various models. Recognizing these distinctions can enhance comprehension and facilitate informed decisions for owners and operators alike.

Categories of Vehicles

- Heavy-Duty: Designed for challenging tasks, these units are equipped to handle substantial loads and demanding terrains.

- Medium-Duty: Offering a balance between performance and maneuverability, these models are ideal for urban operations and lighter hauls.

- Light-Duty: These vehicles provide versatility and efficiency, catering to smaller tasks and local deliveries.

Key Features

- Engine Options: Different models come with a variety of engine sizes and power ratings to suit specific requirements.

- Cab Configurations: Choices range from basic to luxurious interiors, catering to driver comfort and convenience.

- Payload Capacity: Each model has a specified limit, essential for ensuring compliance with regulations and safe operation.

Common Issues and Troubleshooting Tips

Understanding the frequent challenges faced by heavy-duty vehicles can significantly enhance maintenance efforts and prolong lifespan. This section outlines typical problems and provides practical advice for effective resolution.

Frequent Problems

- Engine Performance Issues

- Transmission Difficulties

- Electrical Failures

- Overheating

- Brake Malfunctions

Troubleshooting Strategies

- Engine Performance:

- Check fuel levels and quality.

- Inspect air filters for blockages.

- Examine ignition components for wear.

- Transmission:

- Ensure fluid levels are adequate.

- Listen for unusual noises when shifting.

- Inspect linkage for proper alignment.

- Electrical System:

- Test battery charge and connections.

- Look for blown fuses and damaged wires.

- Check alternator function.

- Overheating:

- Inspect coolant levels and hoses.

- Check the thermostat operation.

- Examine the radiator for blockages.

- Braking System:

- Check brake fluid levels.

- Inspect brake pads and discs for wear.

- Test for proper pedal response.

By systematically addressing these common challenges, operators can ensure their vehicles remain in optimal condition, enhancing safety and efficiency on the road.

Routine Maintenance Procedures Explained

Regular upkeep is essential for ensuring optimal performance and longevity of heavy-duty vehicles. A structured approach to maintenance not only enhances safety but also minimizes unexpected breakdowns and costly repairs.

Effective maintenance encompasses several key tasks that should be performed consistently. These procedures can be categorized into daily, weekly, and monthly actions:

- Daily Inspections:

- Check fluid levels (oil, coolant, brake fluid).

- Inspect tires for pressure and wear.

- Ensure all lights and signals are functioning properly.

- Weekly Tasks:

- Clean air filters and replace if necessary.

- Examine battery terminals for corrosion.

- Check for any fluid leaks underneath the vehicle.

- Monthly Maintenance:

- Rotate tires to promote even wear.

- Inspect brake pads and discs for wear.

- Perform a thorough cleaning of the exterior and undercarriage.

Adhering to these routine procedures helps maintain peak efficiency and reliability. Keeping a detailed log of completed tasks can also assist in tracking performance trends and identifying potential issues before they escalate.

Electrical System Diagnostics Techniques

Effective troubleshooting of electrical systems requires a systematic approach to identify faults and ensure proper functionality. This section outlines various methodologies and tools that can be employed to diagnose issues, enhancing reliability and performance.

Common Diagnostic Methods

There are several widely used techniques for diagnosing electrical system problems. Each method offers unique advantages, allowing technicians to pinpoint issues more efficiently.

| Technique | Description | Advantages |

|---|---|---|

| Visual Inspection | Examine wiring and components for obvious signs of damage or wear. | Quick and cost-effective; often reveals immediate issues. |

| Multimeter Testing | Use a multimeter to measure voltage, current, and resistance in the circuit. | Provides accurate readings; essential for detailed diagnostics. |

| Scan Tool Analysis | Utilize diagnostic software to read fault codes and system data. | Streamlines the identification of electronic faults; saves time. |

| Load Testing | Apply a load to components to assess their performance under stress. | Identifies weak points that may not appear during standard testing. |

Advanced Techniques

In addition to standard methods, advanced techniques can be employed for more complex electrical issues. These approaches leverage technology and analytical tools to enhance diagnostic accuracy.

Implementing these techniques not only aids in identifying problems but also contributes to better maintenance practices, ultimately extending the lifespan of electrical components.

Engine Repair Steps and Guidelines

This section outlines the essential procedures and recommendations for addressing issues related to engine performance. A systematic approach ensures that problems are diagnosed accurately and resolved effectively, enhancing the longevity and efficiency of the machinery.

Initial Diagnosis

Before proceeding with any intervention, it is crucial to perform a thorough assessment. This helps in identifying the root cause of any malfunction. Follow these steps:

- Gather information on symptoms.

- Conduct visual inspections for leaks or damages.

- Use diagnostic tools to retrieve error codes.

- Analyze fluid levels and conditions.

Repair Process

Once the diagnosis is complete, follow these general guidelines for the repair process:

- Ensure safety by disconnecting the power source.

- Remove necessary components for access, such as covers or brackets.

- Replace or repair faulty parts as identified during the diagnosis.

- Reassemble components carefully, ensuring all connections are secure.

- Perform a final inspection to check for any missed issues.

- Reconnect the power source and conduct a test run to verify functionality.

Document all steps taken and any parts replaced to maintain a comprehensive service record. Regular maintenance following repairs can prevent future complications and enhance performance.

Transmission Service and Repair Insights

This section delves into the essential aspects of servicing and maintaining gear systems, emphasizing the importance of regular attention to ensure optimal performance and longevity. Proper upkeep can prevent costly breakdowns and enhance overall efficiency.

Key considerations for effective transmission maintenance include:

- Regular fluid checks and changes

- Inspection of components for wear and tear

- Timely identification of leaks

Understanding the symptoms of potential issues is crucial. Common signs that may indicate a need for intervention are:

- Unusual noises during operation

- Difficulty in shifting gears

- Unresponsive or delayed engagement

When addressing problems, follow a systematic approach:

- Conduct a thorough diagnostic to identify the root cause

- Consult reliable resources for specifications and procedures

- Utilize quality replacement parts when necessary

Ultimately, maintaining these systems not only extends their lifespan but also enhances the overall functionality of the vehicle, leading to a safer and more reliable driving experience.

Brake System Maintenance Essentials

Ensuring the reliability and efficiency of a vehicle’s stopping mechanism is crucial for safe operation. Regular upkeep not only extends the lifespan of components but also enhances overall performance. This section outlines key practices to maintain optimal functionality.

Regular Inspections: Conduct thorough assessments of the braking apparatus to identify wear and tear. Inspect pads, rotors, and hydraulic systems for any signs of deterioration. Early detection can prevent more extensive damage and costly repairs.

Fluid Checks: Brake fluid is essential for effective operation. Monitor the fluid level regularly and check for contamination. Replace the fluid according to the manufacturer’s recommendations to ensure proper hydraulic performance.

Component Replacement: Be vigilant about replacing worn parts. Brake pads should be swapped out when they reach their wear limit. Similarly, rotors may need resurfacing or replacement to maintain smooth operation and prevent noise or vibration.

System Bleeding: Air trapped within the hydraulic system can lead to decreased responsiveness. Periodically bleed the brakes to remove any air pockets, ensuring a firm pedal feel and reliable stopping power.

Routine Testing: Test the braking system regularly under various conditions. Listen for unusual sounds and pay attention to any changes in performance. Addressing issues promptly can prevent dangerous situations.

Implementing these essential maintenance practices will contribute significantly to the longevity and reliability of the braking system, ensuring safe travels for all occupants.

Fuel System Cleaning Methods

Maintaining the cleanliness of a fuel delivery system is essential for optimal performance and longevity of the engine. Over time, contaminants can accumulate, leading to inefficiencies and potential damage. Various techniques can be employed to ensure the system remains in top condition, enhancing fuel flow and combustion efficiency.

Common Cleaning Techniques

- Chemical Cleaning: This method involves using specialized cleaning solutions to dissolve deposits within the fuel system. Chemicals can be introduced directly into the fuel tank or through dedicated service ports.

- Ultrasonic Cleaning: Utilizing high-frequency sound waves, this technique can effectively remove contaminants from small components, such as injectors and filters, providing a thorough cleanse without physical abrasion.

- Manual Cleaning: For more severe cases, disassembling components for manual scrubbing may be necessary. This allows for detailed inspection and removal of stubborn buildup.

Preventive Measures

- Regular fuel filter replacement to prevent clogs.

- Using high-quality fuel to minimize contaminants.

- Incorporating fuel system additives designed to clean and protect components.

By employing these methods and preventive strategies, operators can significantly extend the lifespan of the fuel delivery system, ensuring reliable performance and efficiency in various operating conditions.

Wheel and Tire Care Recommendations

Maintaining the condition of your vehicle’s wheels and tires is crucial for optimal performance and safety. Proper care not only extends the lifespan of these components but also enhances overall driving experience. Regular inspection and maintenance can prevent costly issues and ensure reliable operation on various terrains.

Regular Inspections

Perform routine checks to identify any signs of wear or damage. Look for uneven tread wear, cracks, or bulges in the sidewalls. Regularly monitoring air pressure is equally important; maintaining the correct pressure improves fuel efficiency and handling. Use a reliable gauge to check pressure at least once a month.

Cleaning and Protection

Keep wheels and tires clean to prevent the buildup of grime and brake dust. Use mild soap and water for cleaning, avoiding harsh chemicals that may damage surfaces. Additionally, consider applying a protective dressing to tires to prevent cracking and fading from UV exposure. This practice helps in maintaining the aesthetic appeal and functionality of your vehicle.

In conclusion, adhering to these care recommendations will significantly enhance the performance and longevity of your vehicle’s wheels and tires. Prioritizing regular inspections and cleaning routines fosters a safer driving environment.

Safety Protocols During Repairs

Ensuring a secure working environment is crucial when conducting maintenance tasks on heavy machinery. Adhering to established safety guidelines not only protects individuals involved but also prolongs the lifespan of the equipment. Proper precautions help prevent accidents, injuries, and costly damages, allowing for efficient and effective work.

Personal Protective Equipment (PPE)

One of the primary measures to enhance safety is the use of personal protective equipment. Essential gear includes helmets, gloves, goggles, and steel-toed boots. Each item serves a specific purpose, shielding the worker from potential hazards such as falling objects, sharp edges, and hazardous materials. Always ensure that the equipment fits properly and is in good condition before commencing any task.

Workspace Organization

Maintaining a tidy and organized workspace is another key aspect of safety. A cluttered area increases the risk of trips and falls. Tools and materials should be stored correctly and within easy reach. Additionally, ensuring adequate lighting can significantly reduce the likelihood of accidents, allowing for better visibility of both the equipment and the working environment. Regularly assessing the workspace for potential hazards is essential for ongoing safety.

Finding Replacement Parts Effectively

Locating the right components for heavy vehicles can be a challenging task. Whether you’re dealing with a breakdown or conducting routine maintenance, having a reliable strategy for sourcing parts is essential. This guide will help you navigate the process efficiently, ensuring that you find what you need without unnecessary delays or complications.

Utilizing Online Resources

The internet offers a wealth of information and tools for finding suitable components. Websites dedicated to automotive parts provide search functionalities that allow you to input specific details, such as model numbers and compatibility criteria. Engaging with online forums and communities can also yield valuable recommendations from experienced users who have faced similar challenges.

Local Suppliers and Salvage Yards

In addition to digital avenues, local suppliers and salvage yards can be invaluable resources. Establishing relationships with nearby vendors can lead to quicker access to necessary items and potential cost savings. Salvage yards often carry a wide variety of used components that are still in excellent condition, providing an economical option for many enthusiasts and professionals alike.