For those seeking to bring longevity and resilience to their essential machinery, understanding effective restoration and consistent upkeep practices is invaluable. This guide offers a thorough approach to maintaining your equipment’s performance and ensuring that all components function reliably. Rather than focusing on specific issues, this section provides a holistic view of care techniques that benefit mechanical units over time.

Maintenance is not merely about fixing issues; it’s a proactive effort to prevent wear and optimize each part’s functionality. Proper inspection methods and preventative care routines can extend the lifespan of any machine, making it more efficient and durable. By following these well-researched practices, operators can avoid many common problems and keep equipment in peak condition.

Explore essential steps, from assessing basic mechanisms to addressing more complex parts that often need special attention. This guide is designed to equip users with both

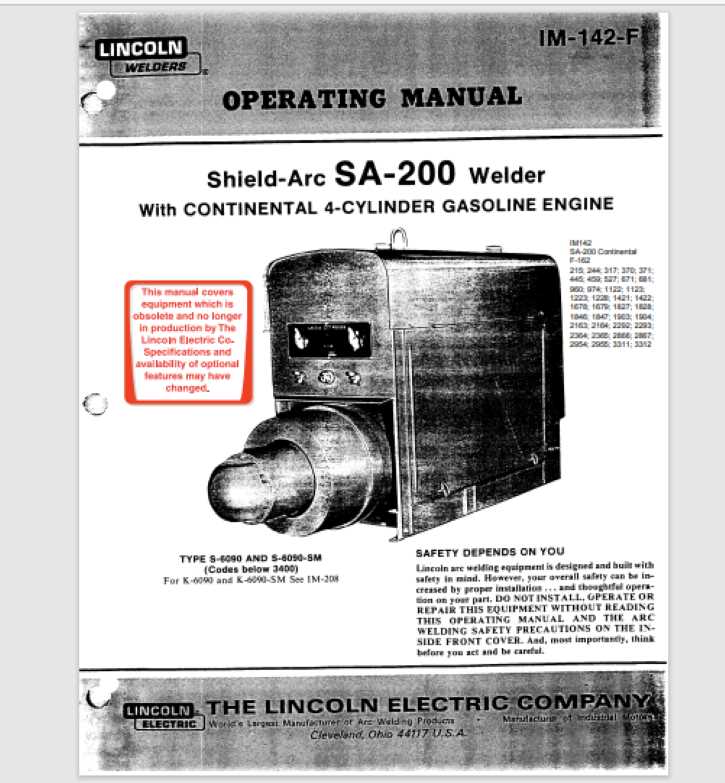

Lincoln SA 200 Repair Manual

One of the most reliable and time-tested arc power sources, this model is known for its durability and longevity in demanding conditions. Maintaining this equipment optimally extends its lifespan and keeps it operating at peak performance, ensuring reliable functionality in diverse work environments. This section provides essential insights on maintaining its functionality and diagnosing any issues that may arise.

Maintenance and Upkeep Guidelines

To ensure consistent performance, it’s crucial to follow a structured approach to equipment care. Routine checks should include assessing components for wear, ensuring connectors are clean, and replacing worn parts. This regular care can help prevent more complex issues and reduce downtime.

| Component | Inspection Frequency | Maintenance Action | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel System | Monthly | Check for leaks, clean fuel filters, replace if needed | ||||||||||||

| Maintenance Activity | Frequency | Benefits |

|---|---|---|

| Inspect belts and hoses | Monthly | Prevents failures and ensures safety |

| Change oil and filters | Every 500 hours | Reduces friction and enhances efficiency |

| Check battery connections | Monthly | Ensures reliable starting and operation |

| Test electrical systems | Quarterly | Identifies issues that can lead to breakdowns |

Guide to Welding Output Adjustments

Adjusting the welding output is crucial for achieving optimal results in various welding tasks. This process involves fine-tuning the settings of your welding equipment to ensure that the output matches the specific requirements of the materials being joined. Proper adjustments not only enhance the quality of the weld but also improve efficiency and reduce the risk of defects.

Understanding Output Settings

The output settings on a welding machine dictate the amount of power delivered during the welding process. Familiarizing yourself with these settings is essential for effective operation. Here are the key factors to consider:

- Voltage: This controls the arc length and heat input.

- Amperage: Determines the overall heat generated and penetration into the base material.

- Travel Speed: Affects the cooling rate and bead profile.

Steps to Adjust Output

- Identify the material type and thickness to determine the appropriate settings.

- Set the voltage based on the welding process and material specifications.

- Adjust the amperage to achieve the desired penetration and bead appearance.

- Test the adjustments on a scrap piece to verify the quality of the weld.

- Make any necessary modifications based on the test results.

Battery and Charging System Basics

The battery and charging system are essential components that ensure the smooth operation of electrical systems in vehicles. Understanding their functionality is crucial for maintaining performance and reliability. The battery provides the initial electrical power needed to start the engine, while the charging system replenishes the battery during operation, preventing depletion.

Function of the Battery

The primary role of the battery is to store energy for starting the engine and powering electrical components when the engine is off. It also stabilizes voltage levels, ensuring that all electrical systems receive a consistent supply of power. Regular checks on the battery’s condition can help avoid unexpected failures.

Charging System Overview

The charging system comprises several key parts, including the alternator, voltage regulator, and associated wiring. The alternator converts mechanical energy from the engine into electrical energy, which recharges the battery and powers electrical accessories. A properly functioning charging system is vital for keeping the battery charged and the vehicle’s electrical systems operational.

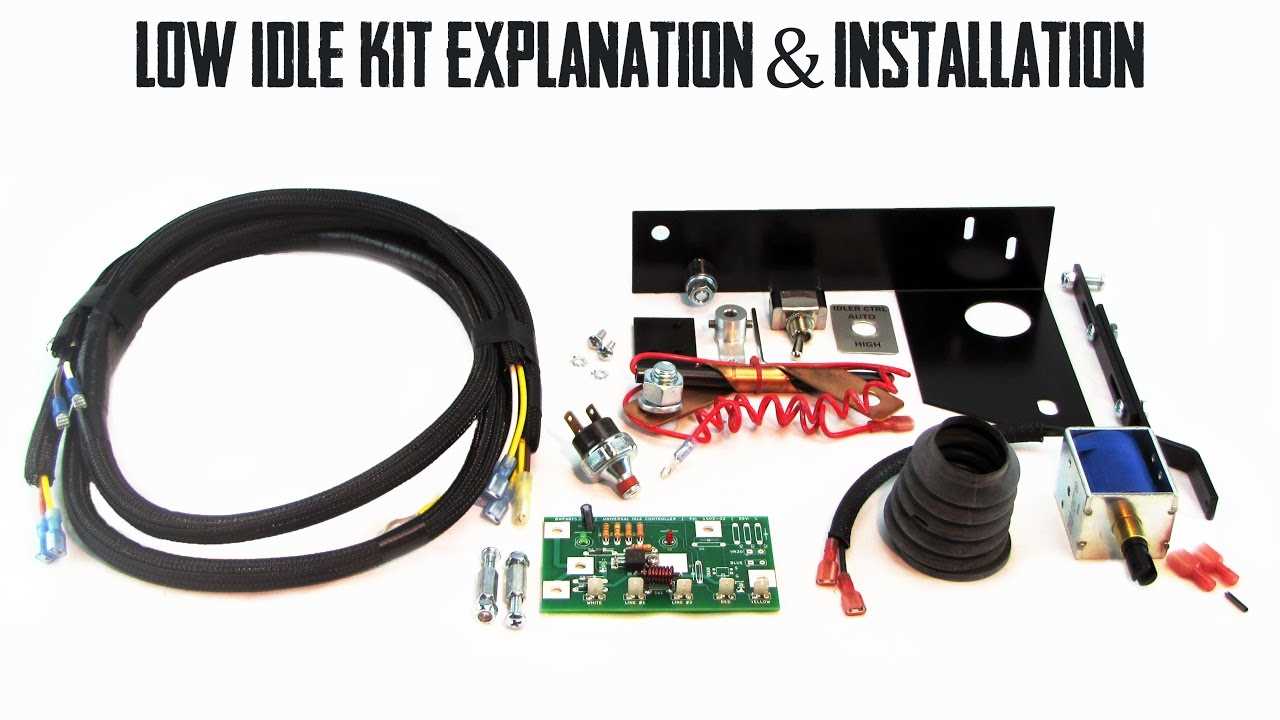

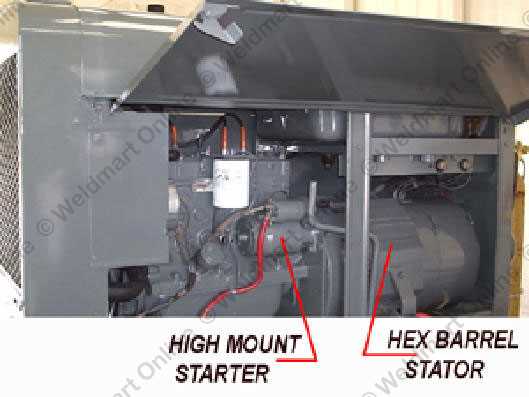

Restoring Your Lincoln SA 200

Revitalizing your welding apparatus can breathe new life into its functionality and enhance your work quality. This process not only restores its aesthetic appeal but also ensures optimal performance for various tasks. Following a systematic approach will simplify the restoration and improve your equipment’s reliability.

Essential Steps for Restoration

- Assessment: Begin by thoroughly examining the unit for any visible damage or wear. Check the engine, controls, and electrical components.

- Cleaning: Remove dirt and grime using appropriate cleaning agents. A clean surface will facilitate repairs and paint adhesion.

- Parts Replacement: Identify worn or damaged components and replace them with quality parts. This may include gaskets, seals, or electrical components.

- Paint and Finish: Apply a fresh coat of paint to protect the exterior and improve appearance. Choose a durable finish suitable for outdoor conditions.

Maintenance Tips Post-Restoration

- Regularly inspect all moving parts to prevent future issues.

- Keep the equipment clean to avoid buildup of dust and debris.

- Perform routine maintenance as recommended to extend the lifespan of your apparatus.