Maintaining a vehicle is essential for ensuring its longevity and optimal performance. This section aims to provide comprehensive insights into various aspects of upkeep, covering everything from routine checks to complex interventions. Understanding the intricate systems within the automobile is vital for anyone looking to keep their vehicle running smoothly.

The importance of proper care cannot be overstated. Regular assessments not only enhance the vehicle’s functionality but also contribute to safety on the road. By familiarizing oneself with key procedures, drivers can proactively address potential issues before they escalate into significant problems.

This guide will serve as a valuable resource for enthusiasts and everyday drivers alike. With detailed instructions and practical advice, readers will gain the confidence to tackle maintenance tasks and make informed decisions regarding their vehicle’s health. Embracing a hands-on approach can lead to a deeper appreciation of the machinery that powers our journeys.

Addressing issues with your vehicle’s transmission can be challenging but understanding common symptoms and solutions can significantly ease the process. Identifying specific problems early can help avoid more serious complications down the road. Below are essential tips to assist in diagnosing and resolving typical transmission-related issues.

Common Symptoms of Transmission Issues

- Slipping Gears: If the transmission unexpectedly changes gears or fails to engage, it may indicate a problem.

- Unusual Noises: Grinding or whining sounds can suggest internal damage or low fluid levels.

- Fluid Leaks: Puddles of reddish fluid under the vehicle can signal a leak in the transmission system.

- Delayed Engagement: A noticeable delay when shifting from park to drive or reverse can be a sign of trouble.

- Warning Lights: Dashboard alerts related to the transmission should not be ignored, as they often indicate a serious issue.

Troubleshooting Steps

- Check Fluid Levels: Ensure the transmission fluid is at the recommended level, as low fluid can lead to several performance issues.

- Inspect for Leaks: Examine the area around the transmission for signs of leakage. If found, address the source promptly.

- Listen for Sounds: Pay attention to any abnormal noises while driving. Document these occurrences to discuss with a professional.

- Scan for Codes: Use a diagnostic scanner to check for error codes that may provide insights into the problem.

- Seek Professional Help: If issues persist despite initial troubleshooting, consulting a qualified technician is advisable to prevent further damage.

Suspension System Inspection

The suspension system plays a crucial role in ensuring vehicle stability and comfort while driving. Regular inspection of this system is essential to identify potential issues that may affect handling and ride quality. Proper assessment can help in maintaining optimal performance and prolonging the lifespan of various components.

Key Components to Check

During the inspection process, focus on several key elements. Examine the shock absorbers and struts for signs of leakage or wear, as these components significantly influence ride comfort. Inspect the control arms and bushings for any signs of cracking or excessive play, which could lead to misalignment and poor handling.

Signs of Wear and Damage

Be alert for any unusual noises, such as clunking or squeaking sounds when driving over bumps. These noises may indicate that certain parts have deteriorated. Additionally, observe the vehicle’s stance; if it appears uneven or sagging, this could be a clear sign that the suspension system requires immediate attention.

Electrical System Diagnostics

The effective functioning of an automotive electrical system is crucial for overall vehicle performance. This section delves into the processes involved in assessing and troubleshooting electrical components. By following systematic approaches, one can identify malfunctions, ensuring that every electrical unit operates optimally and contributes to the vehicle’s reliability.

Common Issues and Symptoms

Electrical problems can manifest in various ways, such as flickering lights, failure to start, or malfunctioning accessories. Recognizing these symptoms is the first step in diagnosing underlying issues. Common culprits include battery depletion, poor connections, and faulty fuses. Understanding these indicators can lead to a more efficient troubleshooting process.

Testing Procedures

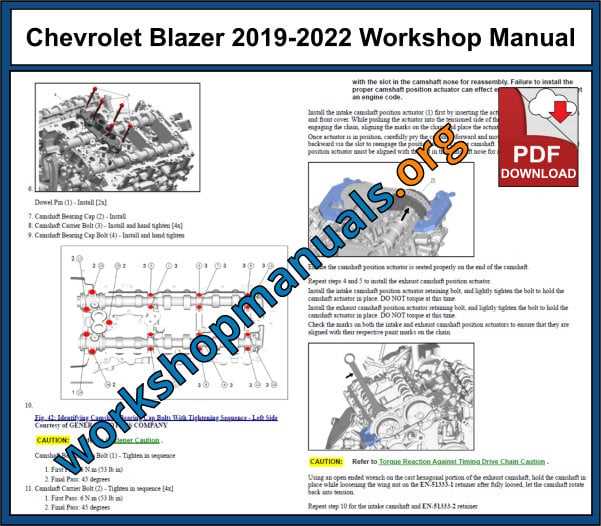

Conducting tests is essential for verifying the condition of electrical components. Utilizing tools like multimeters and circuit testers enables precise measurements of voltage, current, and resistance. These assessments help pinpoint faulty elements within the system, guiding necessary interventions and repairs. Ensuring that testing procedures are thorough and methodical enhances the likelihood of successful resolutions.

Brake System Maintenance

Proper upkeep of the braking system is crucial for ensuring optimal performance and safety while driving. Regular checks and maintenance can prevent wear and tear, ultimately prolonging the lifespan of various components. This section provides insights into the essential practices for maintaining the braking system effectively.

Regular Inspections

Routine inspections should be performed to identify any potential issues. Here are key areas to focus on:

- Brake pads and shoes: Check for wear and replace them when they are worn down.

- Brake fluid: Ensure the fluid is at the recommended level and replace it if it appears contaminated.

- Rotors and drums: Inspect for any signs of damage or warping.

- Lines and hoses: Look for leaks, cracks, or signs of deterioration.

Fluid Replacement

Maintaining the proper fluid levels is vital for effective braking. Follow these guidelines:

- Check the brake fluid level monthly, ensuring it meets manufacturer specifications.

- Flush and replace the brake fluid every two years to remove moisture and contaminants.

- Use the recommended type of fluid to prevent compatibility issues.

Bodywork Repair Techniques

This section focuses on essential methods for addressing damage to vehicle exteriors, emphasizing the importance of precision and technique. Proper approaches can significantly enhance the longevity and appearance of the automobile, ensuring it remains in optimal condition. Understanding various methods and tools is crucial for achieving high-quality outcomes in restoring the vehicle’s body.

Methods for Dent Removal

Dent removal is a critical aspect of exterior restoration. Techniques such as paintless dent repair allow for effective correction without damaging the original finish. Specialized tools are employed to gently massage the metal back into its original shape. Alternatively, traditional methods involving fillers and repainting can be utilized for more severe damages, ensuring a seamless blend with the surrounding surfaces.

Surface Preparation and Finishing

Preparing the surface before applying new paint or protective coatings is vital for a successful finish. This includes thorough cleaning, sanding, and priming to ensure adhesion and durability. Following preparation, the application of high-quality paints and clear coats provides both aesthetic appeal and protection against environmental factors, enhancing the overall resilience of the vehicle’s exterior.

Upgrading Components for Performance

Enhancing the efficiency and capabilities of a vehicle can significantly improve the driving experience. By focusing on specific elements, such as the engine, suspension, and exhaust systems, enthusiasts can achieve better acceleration, handling, and overall power output. This section explores the various upgrades that can be implemented to elevate performance levels and provide a more exhilarating driving experience.

Engine Enhancements

One of the most impactful areas to consider for improvement is the engine. Upgrading components like the intake system, fuel injectors, and ignition systems can lead to increased horsepower and torque. Additionally, performance tuning software can optimize engine parameters, ensuring that the vehicle runs efficiently under varying conditions.

Suspension and Handling Modifications

Improving the suspension system is essential for enhancing handling and stability. Replacing factory shock absorbers with high-performance alternatives can reduce body roll and improve cornering capability. Furthermore, upgrading sway bars and adding strut braces can enhance the overall rigidity of the chassis, resulting in a more responsive and enjoyable ride.

Routine Maintenance Schedule

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. Adhering to a structured timetable can prevent issues and enhance the overall driving experience. Below is a recommended maintenance schedule that covers various aspects of vehicle care.

Daily Checks

- Inspect tire pressure and condition.

- Check fluid levels, including oil, coolant, and brake fluid.

- Examine lights and indicators for proper functionality.

Weekly Tasks

- Clean the windshield and check wiper blades.

- Assess the condition of the battery terminals.

- Review the interior for cleanliness and remove any debris.

Monthly Inspections

- Rotate tires to promote even wear.

- Inspect the air filter and replace if necessary.

- Check the alignment and suspension components.

Quarterly Services

- Change the engine oil and oil filter.

- Inspect belts and hoses for wear and tear.

- Flush and replace the coolant if required.

Annual Maintenance

- Replace brake pads and inspect rotors.

- Examine and replace spark plugs as needed.

- Conduct a comprehensive inspection of all systems.

Following this maintenance schedule will help in maintaining your vehicle’s reliability and safety. Always refer to your specific guidelines for any unique requirements based on the model and usage.

Parts Replacement Guide

This section provides essential information regarding the process of substituting various components within your vehicle. Understanding when and how to replace parts can significantly enhance performance and prolong the lifespan of your automobile.

Identifying Components: Begin by recognizing which elements require replacement. Regular inspection can help detect wear and tear, ensuring timely intervention before further damage occurs.

Replacement Procedures: Follow specific guidelines for removing old components and installing new ones. It’s crucial to consult detailed instructions or diagrams tailored to your vehicle model to avoid complications during the process.

Quality of Parts: When sourcing replacements, prioritize high-quality products that meet or exceed manufacturer specifications. Utilizing substandard components may result in suboptimal performance and increased risk of failure.

Tools Required: Gather the necessary tools beforehand. Commonly needed items include wrenches, screwdrivers, and specialty tools specific to certain parts. Having everything prepared will streamline the replacement process.

Safety Precautions: Always take safety measures into account. Ensure the vehicle is properly secured and utilize protective gear as needed to avoid injuries during the replacement task.

Safety Precautions During Repairs

Ensuring a secure working environment is essential when performing maintenance tasks. Adhering to safety guidelines not only protects the individual conducting the work but also safeguards the vehicle and surrounding area. Proper preparation and awareness of potential hazards play a crucial role in preventing accidents and injuries.

Before commencing any work, it is important to gather the necessary tools and materials, as well as to understand the specific requirements of the task at hand. Utilizing personal protective equipment (PPE) and maintaining a tidy workspace can greatly reduce risks. Below are some key precautions to consider:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety glasses, gloves, and appropriate footwear to shield yourself from potential injuries. |

| Ensure Adequate Ventilation | Work in a well-ventilated area to prevent inhalation of harmful fumes or dust particles. |

| Disconnect Power Sources | Before starting, disconnect the battery or any electrical components to avoid shocks or short circuits. |

| Use Tools Properly | Handle all tools with care and follow the manufacturer’s instructions for safe operation. |

| Keep Area Clean | Maintain a clutter-free workspace to reduce the risk of trips and falls. |

By following these precautions, individuals can create a safer environment while performing essential maintenance tasks. Awareness and diligence are key factors in ensuring successful and safe completion of any project.