Maintaining your power equipment is essential for ensuring optimal performance and longevity. Proper upkeep not only enhances functionality but also contributes to safety during use. This section provides valuable insights into troubleshooting and servicing your tools effectively.

By understanding the mechanisms and components involved, users can address common issues with ease. This knowledge empowers individuals to conduct routine inspections and make necessary adjustments, ensuring their equipment remains in peak condition. Whether you are a seasoned user or a novice, these guidelines will assist you in navigating the complexities of maintenance.

With a proactive approach, users can avoid potential breakdowns and enhance the overall efficiency of their machines. Following these practices will help extend the lifespan of your tools, allowing you to enjoy seamless operation for years to come.

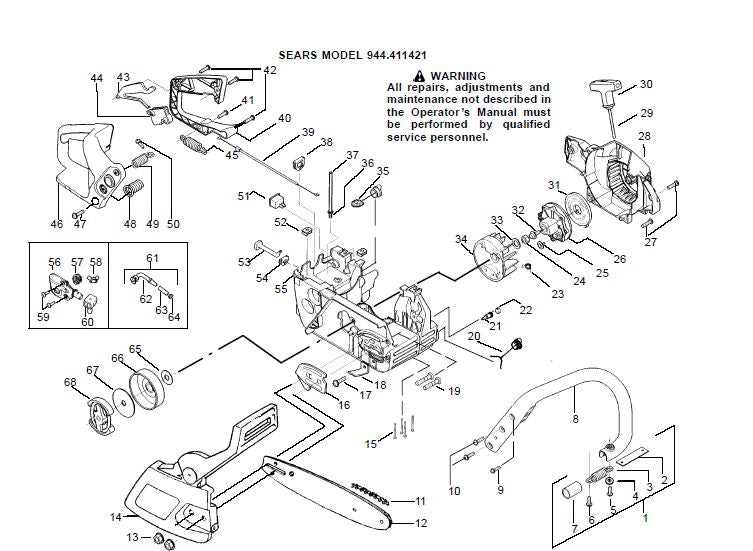

Exploring the intricate parts of a power cutting tool is essential for effective maintenance and optimal performance. Each component plays a significant role in the overall functionality, contributing to its efficiency and safety. Familiarity with these elements can empower users to troubleshoot issues and enhance longevity.

Main Parts of the Tool

- Engine: The powerhouse that drives the entire mechanism.

- Guide Bar: The long, flat piece that supports the cutting chain.

- Cutting Chain: The loop of sharp links that performs the actual cutting action.

- Handle: The part that provides control and stability during operation.

- Fuel Tank: Stores the energy source needed for operation.

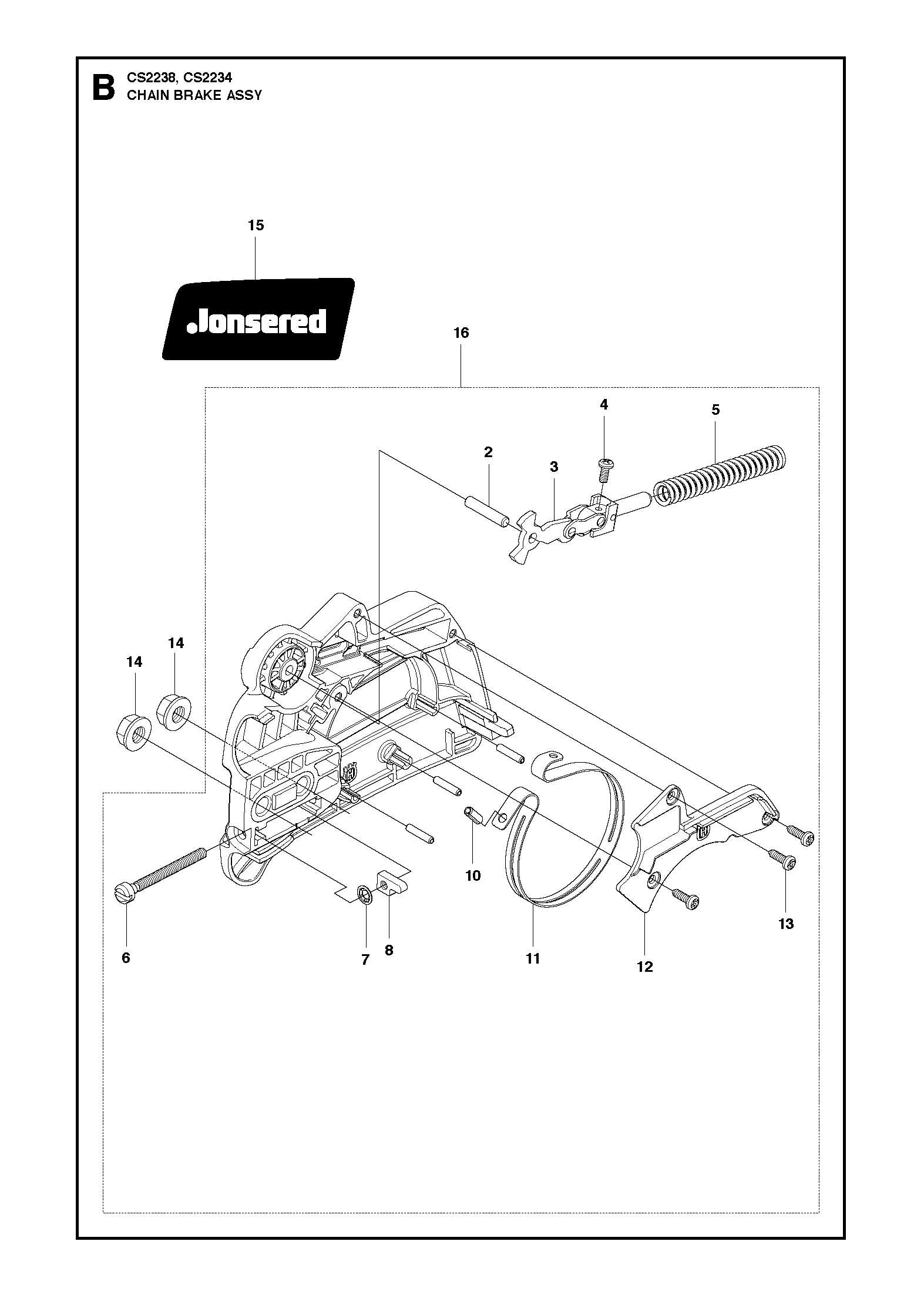

Supportive Components

- Starter Mechanism: Engages the engine to initiate operation.

- Chain Brake: A safety feature that stops the chain’s motion in emergencies.

- Clutch: Connects and disconnects the engine from the cutting chain.

- Air Filter: Keeps dirt and debris from entering the engine.

Common Chainsaw Problems

When working with cutting tools, users often encounter various issues that can hinder performance. Recognizing these challenges is crucial for ensuring optimal functionality and longevity of the equipment. Addressing these concerns promptly can prevent more severe complications down the line.

Starting Difficulties

One of the most frequent issues is trouble starting the device. This may stem from several factors, such as fuel problems, spark plug issues, or a clogged air filter. Ensuring that the fuel mixture is correct and that all components are clean can often resolve this problem.

Inconsistent Cutting Performance

Another common concern is irregular cutting performance. This can manifest as difficulty in making clean cuts or the tool stalling during operation. Factors contributing to this issue include dull blades, improper tension, or debris caught in the cutting mechanism. Regular maintenance, including sharpening and adjusting the chain, is essential for maintaining effective operation.

Basic Maintenance Tips

Proper upkeep of your cutting equipment is essential for ensuring its longevity and optimal performance. Regular attention to specific components can help prevent breakdowns and enhance efficiency during operation.

Start by checking the sharpness of the cutting element; a dull blade can lead to increased wear and tear on the device. Ensure that it is sharpened regularly to maintain cutting precision. Additionally, keeping the air filter clean is crucial, as it allows for better airflow and reduces the risk of overheating.

Inspect the fuel system periodically, ensuring that fuel lines are free of blockages and that the fuel is fresh. Stale fuel can affect performance significantly. Regularly examine the spark plug for wear and replace it if necessary to ensure reliable ignition.

Lastly, don’t overlook the importance of lubricating moving parts. Using the appropriate lubricant helps reduce friction and prevents premature wear, contributing to smoother operation and extended equipment life.

Fuel System Troubleshooting

Ensuring the optimal performance of the fuel system is crucial for the effective operation of your equipment. This section addresses common issues related to fuel delivery and offers insights on identifying and resolving them. Proper maintenance and understanding of the components involved can prevent frequent breakdowns and enhance longevity.

Common Issues and Solutions

Below are frequent problems encountered with the fuel system along with their potential solutions:

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | No fuel reaching the engine | Check fuel lines for clogs and ensure the fuel tank is filled. |

| Rough idling | Contaminated fuel | Replace the fuel filter and refill with fresh fuel. |

| Excessive smoke | Rich fuel mixture | Adjust the carburetor settings to achieve the correct air-fuel ratio. |

Maintenance Tips

Regular inspections and proper upkeep of the fuel components can mitigate issues. Clean filters, inspect hoses, and ensure the correct type of fuel is used to maintain peak performance.

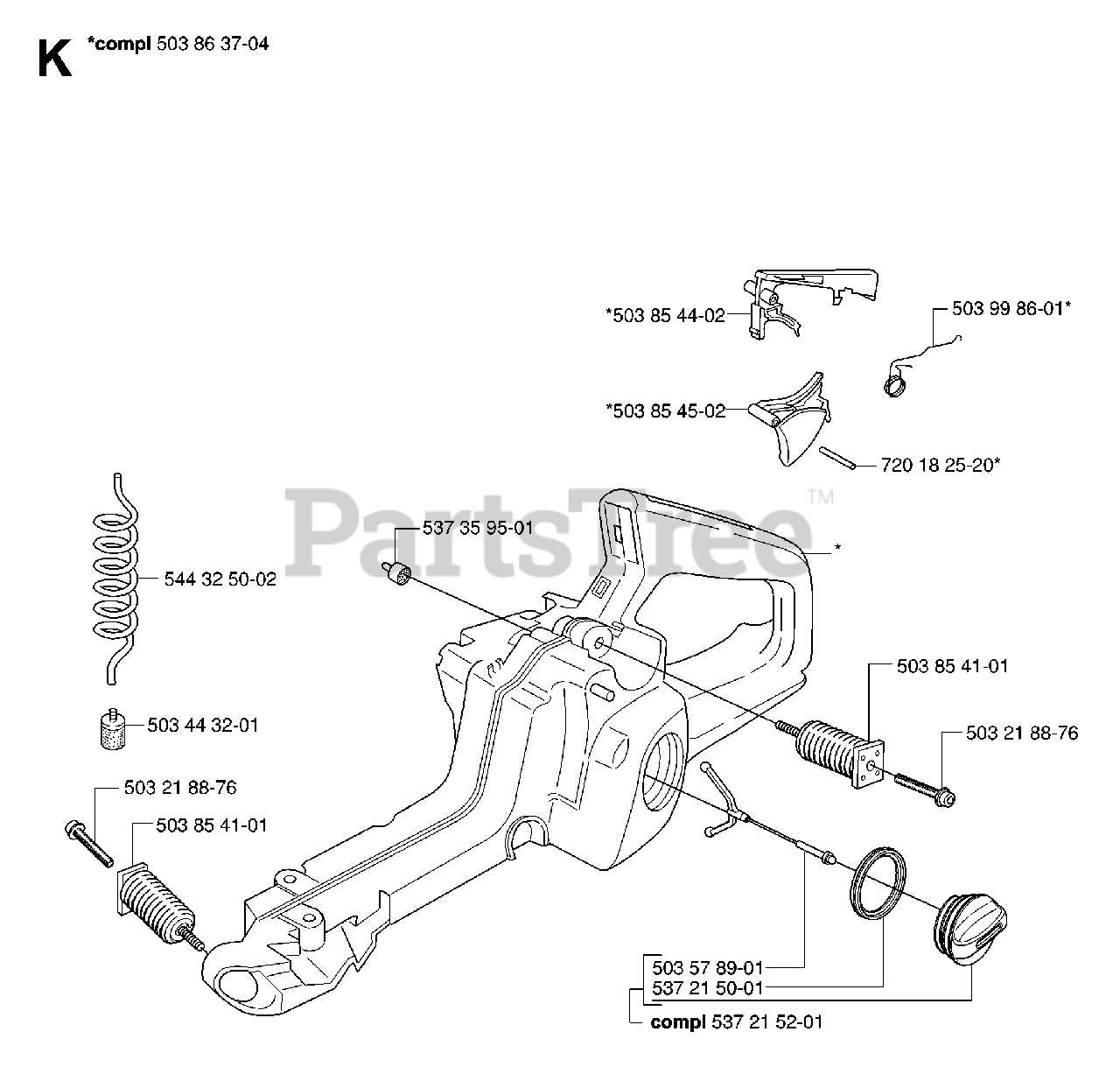

Chain Tension Adjustments

Proper tensioning of the cutting component is crucial for optimal performance and safety during operation. Ensuring the correct tightness helps maintain effective cutting and reduces the risk of accidents or equipment damage. This section outlines the necessary steps to achieve the appropriate level of tension.

Follow these guidelines for adjusting the tension:

- Ensure the equipment is turned off and cool to the touch.

- Locate the tensioning mechanism, usually found near the guide bar.

- Using the appropriate tool, loosen the nuts securing the guide bar.

- Adjust the tension by turning the screw clockwise to tighten or counterclockwise to loosen.

- Check the tension by pulling on the cutting component; it should move slightly but not excessively.

- Once the desired tension is achieved, securely tighten the nuts to hold the guide bar in place.

Regular inspections of the cutting component’s tightness can enhance safety and extend the lifespan of the equipment. Always consult the specifications for your specific model to ensure proper adjustment procedures are followed.

Bar and Chain Care

Maintaining the cutting components of your tool is essential for optimal performance and longevity. Proper care not only enhances efficiency but also ensures safety during operation.

Regular inspection and maintenance routines are crucial. Here are some key practices to consider:

- Cleaning: Remove sawdust, resin, and debris after each use. This prevents buildup that can hinder performance.

- Lubrication: Apply appropriate lubricant to keep the moving parts functioning smoothly. Insufficient lubrication can lead to wear and overheating.

- Inspection: Check for any signs of wear or damage, including cracks or bent links. Addressing these issues promptly can prevent further complications.

- Tension Adjustment: Ensure that the cutting chain is correctly tensioned. A loose chain can derail, while one that is too tight can cause unnecessary strain on the components.

By following these guidelines, you can significantly enhance the performance and lifespan of your tool’s cutting elements.

Engine Issues and Solutions

Engines can experience a variety of complications that affect their performance and efficiency. Understanding these common problems and their respective solutions is crucial for maintaining optimal functionality. Addressing issues promptly can prevent further damage and extend the lifespan of the equipment.

Common Engine Problems

One frequent concern is the engine not starting, often due to fuel-related issues or electrical failures. Clogged fuel lines, old fuel, or a faulty ignition system can all contribute to this problem. Regular maintenance and checks can help identify these issues before they escalate.

Troubleshooting and Solutions

If starting difficulties arise, begin by inspecting the fuel supply and ensuring it is clean and fresh. If the ignition system is suspect, check the spark plug for wear or damage. Replacing the spark plug or cleaning the fuel filter can often resolve the issue. For persistent problems, consulting a professional may be necessary to conduct more in-depth diagnostics.

Electrical System Check

Assessing the electrical components is essential for ensuring optimal functionality of the equipment. This process involves evaluating various elements that contribute to the power supply and ignition system. Proper diagnostics can help identify issues that may affect performance and safety.

Begin by inspecting the battery connections for corrosion and secure fit. Ensure that the terminals are clean and tightly fastened to prevent interruptions in power delivery. Next, examine the wiring harness for signs of wear or damage, such as frayed wires or exposed insulation, which can lead to short circuits.

Additionally, check the spark plug for proper gap and condition. A faulty spark plug can hinder ignition, resulting in poor operation. If necessary, replace it with a suitable component to restore efficient performance. Finally, test the ignition coil to confirm it is generating the appropriate voltage. This can be done using a multimeter, which provides readings to assess functionality.

By following these steps, you can effectively diagnose and resolve electrical issues, enhancing the overall performance and longevity of the equipment.

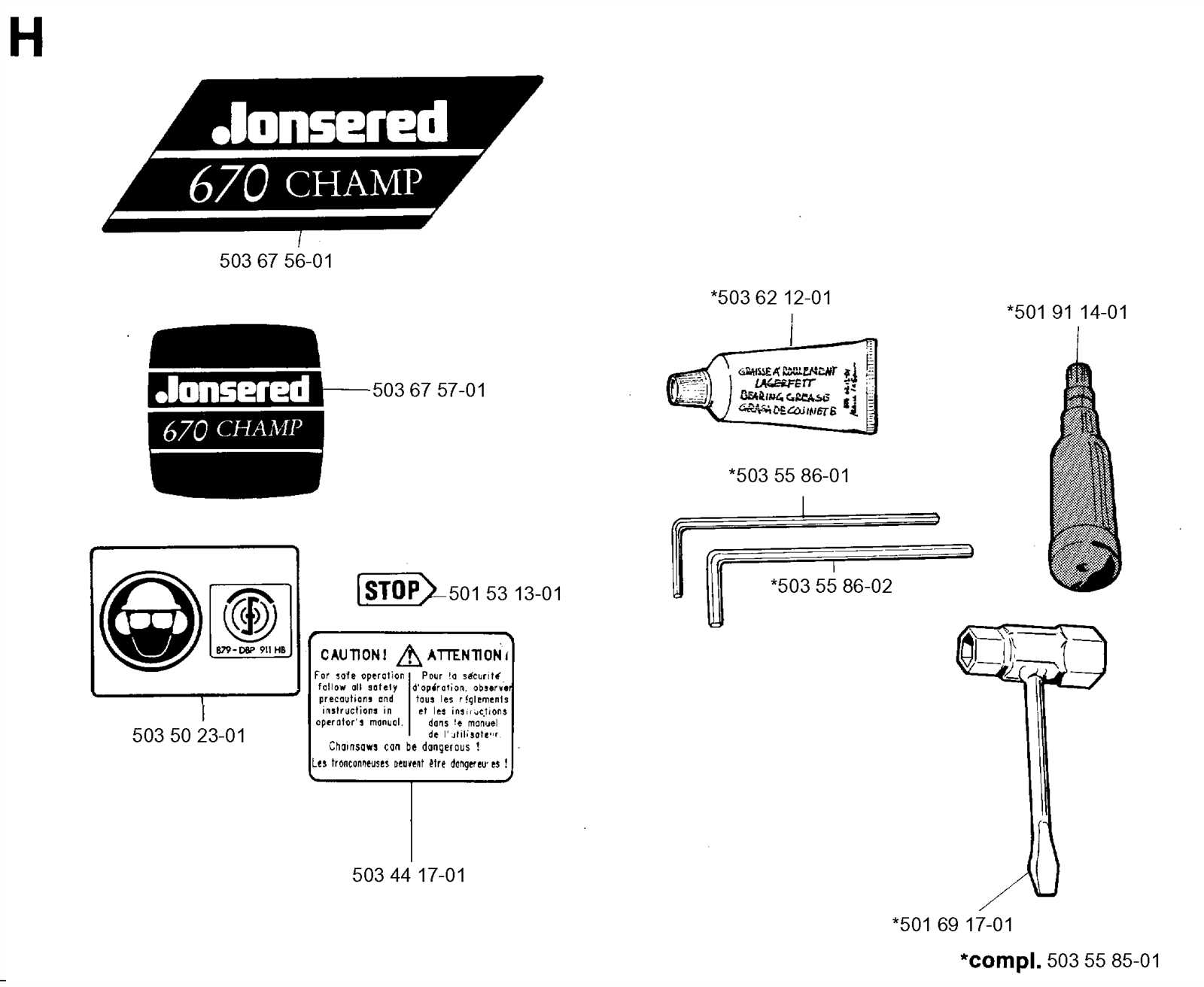

Tools Required for Repairs

When it comes to maintaining and fixing outdoor power equipment, having the right instruments at your disposal is essential. Proper tools not only streamline the process but also enhance safety and efficiency during tasks. Understanding what is necessary for upkeep ensures that you can tackle any issue with confidence.

Essential Hand Tools

The foundation of any repair task lies in a good set of hand tools. Items such as wrenches, screwdrivers, and pliers are indispensable for disassembling components and making adjustments. A reliable set of sockets can also aid in reaching various bolts and fasteners, making the work much more manageable.

Specialized Equipment

In addition to standard hand tools, certain specialized equipment may be required for specific tasks. This could include items like torque wrenches for precise fastening, or a feeler gauge for measuring gaps. Having a good cleaning solution and brushes on hand can help maintain parts in optimal condition, ensuring longevity and reliability.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment to optimal functionality. By following a series of methodical steps, you can address common issues and enhance performance effectively. Whether you’re dealing with mechanical failures or routine maintenance, this guide will facilitate a systematic process for troubleshooting.

Preparation and Tools

Before starting the restoration process, gather the necessary tools and materials. Proper preparation is crucial for a successful outcome.

- Safety gear (gloves, goggles)

- Wrenches and screwdrivers

- Replacement parts

- Lubricants and cleaning agents

- Workbench or stable surface

Step-by-Step Instructions

- Safety First: Ensure that your workspace is clear and free from hazards. Wear appropriate protective equipment.

- Disassembly: Carefully disassemble the equipment, taking note of each component’s location. Use a diagram if necessary.

- Inspection: Examine all parts for wear or damage. Replace any components that show signs of deterioration.

- Cleaning: Clean the components using suitable agents to remove dirt and debris. Ensure that all moving parts are free from obstruction.

- Reassembly: Reassemble the equipment, following your notes or diagram to ensure accuracy.

- Testing: Once reassembled, conduct a thorough test to confirm that the device operates smoothly. Monitor for any unusual sounds or performance issues.

Safety Precautions During Repairs

Ensuring safety is paramount when conducting maintenance or servicing on any power tool. Adopting the right safety measures protects the user from potential hazards and contributes to a smooth working environment. Awareness of the tools and techniques involved in the process is essential for preventing accidents and injuries.

First and foremost, always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. This gear shields against flying debris and sharp components. Additionally, keep the workspace clean and organized to minimize the risk of slips, trips, and falls.

Moreover, before beginning any work, disconnect the power source to eliminate the risk of accidental activation. Familiarize yourself with the specific device to understand its components and the correct procedures for handling them. Ensure that all tools are in good condition, as using damaged equipment can lead to mishaps.

Finally, never rush through the process. Take the time to follow guidelines carefully and double-check your work. If you encounter any unfamiliar situations or issues, consult reliable resources or seek assistance from a qualified professional to avoid unnecessary risks.

When to Seek Professional Help

Knowing when to enlist the expertise of a professional can make a significant difference in the longevity and performance of your equipment. While many issues can be addressed through DIY approaches, certain situations require specialized knowledge and tools to ensure safety and efficiency.

Signs of Serious Malfunctions

If you notice unusual sounds, persistent vibrations, or failure to start, it may be time to consult an expert. Ignoring these signs can lead to more severe damage, potentially resulting in costly repairs.

Safety Concerns

When handling tools poses a risk to your safety, professional intervention is crucial. If you feel uncertain or uncomfortable performing maintenance tasks, seek assistance from a qualified technician. Safety should always be the top priority.